Abstract

The magnetocaloric effect-(MCE) of MgB2 is simulated, considering the effect of sintering temperature on MCE. The results show that MCE of MgB2 samples is an inverse type in a temperature range of diamagnetic-paramagnetic transition. Moreover, the MCE for MgB2 is improved with high sintering temperature. The comparison between MCE of MgB2 samples and other some reported magnetic materials has been done, showing that MCE parameters of MgB2 samples are larger than some MCE parameters of La1-xCdxMnO3, La1.25Sr0.75MnCoO6, Gd1−xCaxBaCo2O5.5, Ni58Fe26Ga28, Ni2+xMn1−xGe, Ge0.95Mn0.05 film, and (001)-oriented MnAs film. It suggested that MgB2 samples could be a promising sharing candidate for MR in cryogenic temperatures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The magnetic refrigerator (MR) has become very important as an alternative to gas refrigerator because of its low consumption of electricity, more environmentally friendly device, lower noise, and larger efficiency in the process of cooling [1,2,3,4,5,6,7]. The basic idea of MR depends on using the magnetocaloric effect-(MCE) in the magnetic materials [7,8,9]. This MCE is an effect that occurs upon a sudden change in the applied magnetic field (ΔH) and is followed by a change in magnetic entropy change (∆SM) and temperature [8,9,10,11,12,13,14]. Subsequently, it is thought that the efficiency of MR can be enhanced by functioning many types of magnets, having MCE at cryogenic and room temperatures such as magnetic alloys, magnetic composites, ferrites, manganites, rare earth-based materials, and other types [15,16,17,18,19].

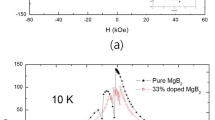

In a usual MCE, the cooling operation in magnetic material occurs as a result of adiabatic demagnetization that is done by removing the applied magnetic field [20]. Conversely, the magnetic materials can be cooled via the adiabatic magnetization that is done by increasing the external magnetic field. This effect is named inverse MCE [21]. This inverse MCE can occur in superconductors over the temperature range of the diamagnetic-paramagnetic transition. Therefore, it is recommended to use different types of superconductors over various temperature ranges of the diamagnetic-paramagnetic transition in the cryogenic system.

Since the detection of MgB2 as a metallic superconductor material with a transition temperature (Ttrans) of 39 K, there are extreme efforts to detect its performance and improve its physical properties [22,23,24].

MgB2 is used in many significant applications like magnets due to its high proficiency that allows it to trap magnetic fields more than different types of ferromagnets and Ttrans of 39 K, creating it as a practical material for exploiting in the cryogenic system and superconducting magnets for accelerators and superconducting motors in electric aircraft [25]. Furthermore, MgB2 is very important in magnetic resonance imaging-(MRI) systems without using liquid helium (LHe), because the price of LHe is increased rapidly in recent years, causing the MRI system to be very expensive [26]. Yudanto et al. prepared MgB2 superconductors by mechanical alloying at various sintering temperatures, revealing that the content percentage of MgB2 phase in the prepared sample is enhanced and more than 90% in samples sintered at temperatures of 850 °C and 900 °C [27]. Furthermore, they have revealed that the behavior of MgB2 as a superconductor was enhanced in samples sintered at temperatures of 850 °C and 900 °C. From these noteworthy results, its purpose is to investigate the MCE of MgB2 in this work. In this research, a phenomenological model (PM) was used to deduce the thermomagnetic properties of MgB2 by simulating the M(T) curves, concluding ∆SM, heat capacity change (\(\Delta \, C_{P,H}\)), and relative cooling power (RCP).

2 Theoretical Aspects of MCE

According to PM [28,29,30,31,32], the magnetization (M) versus temperature (T) of MgB2 through the magnetic transition can be simulated by:

where, \(\Delta M = M_{i} - M_{f}\) (\(M_{i}\) and \(M_{f}\) are the initial and final values of the magnetization at the diamagnetic-paramagnetic transition region, respectively, as shown in Fig. 1), \(A = \frac{{2(B - S_{c} )}}{\Delta M}\), B is the average of (\(\frac{{{\text{d}}M}}{{{\text{dT}}}}\)) at diamagnetic state, Sc is the maximum value of \(\frac{{{\text{d}}M}}{{{\text{dT}}}}\) and \(C = (\frac{{M_{i} + M_{f} }}{2}) - BT_{{{\text{trans}}}}\). In this work, we can observe \(M_{f} \approx 0\). Then \(\Delta M = M_{i}\).

3 Results and Discussion

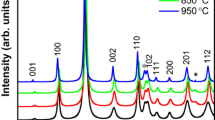

The open symbols and solid lines indicate the experimental data of M(T) curves for MgB2 in Ref. [27] and the simulated data using Eq. (1), respectively. The MgB2 samples that were sintered at temperatures of 700, 800, 850, and 900 °C are named MB600, MB700, MB800, MB850, and MB900, respectively, as depicted in Fig. 2.

There is a convincing agreement between the experimental and simulated M(T) for MgB2 under 0.01 T magnetic field, deducing that PM is a suitable model for fitting M(T) curves for MgB2. MgB2 displays a sharp transition from the diamagnetic state to the paramagnetic state. This sharp transition allows the \(\Delta S_{M}\) value of MgB2 to be maximized but it is covering low-temperature range. This \(\Delta S_{M}\) of MgB2 under an adiabatic magnetic field shift of 0.01 T can be evaluated as follows [28, 29]:

A maximum of \(\Delta S_{M}\) (∆SMax) can be determined as follows:

The rise in sintering temperature causes the particle size increase in samples due to grain growth. Also, the saturation magnetization and transition temperature increase with a particle size which improves the magnetic properties. The Ttrans increases with sintering temperature and the intensity of main diffraction peaks increase and FWHM decreases, clearly signifies that the crystallinity of MgB2 is enhanced [33].

Figure 3 shows the simulated temperature dependence of \(\Delta S_{M}\) for MgB2 under an adiabatic magnetic field shift of 0.01 T, calculated by using Eq. (2). This diamagnetic-paramagnetic transition leads to an increase in the magnetic spin disorder causing \(\Delta S_{M}\) and \(\Delta S_{M}\) to reach a peak value at Ttrans.

It is clear that the MB700 sample has the lowest value of \(\Delta S_{{{\text{Max}}}}\) due to its MgO content, which is higher than the MgO content of other samples [34]. Furthermore, the MB700 sample has remarkable defects that are detected from the values of the critical temperature gap and residual resistivity ratio [35, 36]. There is a required parameter called RCP which is a measure of the ability of a material to carry heat at a relatively high-temperature difference between the hot and cold sinks in the cycle of an ideal MR. RCP of MgB2 can be given by the ∆SMax and full-width at half-maximum (\(\delta {\text{T}}_{{{\text{FWHM}}}}\)) of the ∆SM curve as follows:

where \(\delta {\text{T}}_{{{\text{FWHM}}}}\) can be obtained as follows:

In conclusion, when using different magnetic fields, magnetism and entropy will be enhanced with different calcination temperatures, which is in agreement with [37,38,39,40].

As shown in Table 1, the values of δTFWHM and RCP change with sintering temperature, indicating the RCP of MgB2 can be tailored with sintering temperature.

The behavior of the \(\Delta \, C_{P,H}\) curve of MgB2 under ∆H of 0.01 T can be predicted using the PM model [28,29,30] as follows:

Figure 4 shows the simulated ∆CP,H versus temperature for MgB2 samples under ∆H = 0.01 T. The simulated \(\Delta \, C_{P,H}\) deviated from positive values to negative values around \(T_{{{\text{trans}}}}\).

For further details, the refrigerant capacity (RC) is an important parameter to evaluate the efficiency for MgB2 samples as effective materials in MR. RC was calculated as follows [29, 30]:

It is clear that from Table 1, ∆CP,H(max), and RC show an increase with increasing sintering temperature. This is due to MgB2 content going on to grow while MgO content decreases with increasing sintering temperature [27].

Table 1 shows also comparisons between MCE parameters of MgB2 samples and corresponding ones of other compositions in previous works under low values of magnetic field variation. The MCE parameters of MgB2 samples are significantly larger, and comparable with some MCE parameters of La1-xCdxMnO3, La1.25Sr0.75MnCoO6, Gd1−xCaxBaCo2O5.5, Ni58Fe26Ga28, Ni2+xMn1−xGe, Ge0.95Mn0.05 Films, and (001)-oriented MnAs films as shown in Table 1 [41,42,43,44,45,46,47]. Finally, the combination of MCE and the electrocaloric effect creates opportunities for real-world uses of contemporary refrigeration technology [48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80].

4 Conclusion

A detailed investigation of MCE for MgB2 samples has been done via PM, considering the effect of the sintering temperature on MCE. The results of simulation show that this PM is a valuable model for the calculation of thermomagnetic properties for MgB2 samples in the temperature range of the diamagnetic-paramagnetic transition, confirming MCE of MgB2 samples is of inverse type. Moreover, the MCE for MgB2 samples is compared with those of some other reported magnetic materials, concluding that MgB2 samples could be a promising sharing candidate for MR at cryogenic temperatures. This research will be extended in the future to optimize the magnetic properties of MgB2 samples using a variety of external effects.

References

G. Kotnana, D.P. Sahu, S.N. Jammalamadaka, J. Alloys Compd. 709, 410–414 (2017)

Y. Zhang, X. Xu, AIP Adv. 10, 035220 (2020)

Y. Zhang, X. Xu, Appl. Phys. A 126, 1–12 (2020)

S. Narayana Jammalamadaka, S.S. Rao, S.V. Bhat, J. Vanacken, V.V. Moshchalkov, J. Appl. Phys. 112(8), 083917 (2012)

M.A. Hamad, O.M. Hemeda, H.R. Alamri et al., Phys. Solid State 63, 709–713 (2021)

E.M. Ahmed, H.R. Alamri, S.M. Elghnam et al., Solid State 63, 1601–1604 (2021)

M.A. Hamad, H.R. Alamri, J. Mater. Res. Technol. 17, 2670–2674 (2022)

A.M. Ewas, M.A. Hamad, Ceram. Int. 43, 7660–7662 (2017)

E.M. Ahmed, O.M. Hemeda, H.R. Alamri et al., Phase Trans. 94, 835 (2021)

Y.H. Abdelalim, A.M. Mohamed, O.M. Hemeda, M.E. Harb, S.M. Elghnam, J. Magn. Magn. Mater. 560, 169661 (2022)

M.A. Hamad, H.R. Alamri, J. Electron. Mater. 51, 3359–3363 (2022)

Y. Zhang, X. Xu, J. Supercond. Novel Magn. 34, 63–73 (2021)

Y. Zhang, X. Xu, Phys. C 592, 1353998 (2022)

Y. Zhang, X. Xu, RSC Adv. 10, 20646–20653 (2020)

M.A. Hamad, O.M. Hemeda, H.R. Alamri, A.M. Mohamed, Phys. Lett. A 394, 127204 (2021)

M.A. Hamad, H.R. Alamri, Front. Mater. 9, 832703 (2022)

A.H. El-Sayed, M.A. Hamad, Phase Trans. 92, 517 (2019)

E.M. Ahmed, O.M. Hemeda, H.R. Alamri, S.M. Elghnam, M.A. Hamad, Russ. J. Phys. Chem. 96, S101–S104 (2022)

M.A. Hamad, H.R. Alamri, J. Low Temp. Phys. 207, 181–189 (2022)

Y. Liu, X. Zhang, D. Xing, H. Shen, D. Chen, J. Liu, J. Sun, J. Alloys Compd. 616, 184 (2014)

X. Moya, L. Mañosa, A. Planes, S. Aksoy, M. Acet, E.F. Wassermann, T. Krenke, Phys. Rev. B 75, 184412 (2007)

J. Nagamatsu, N. Nakagawa, T. Muranaka, Y. Zenitani, J. Akimitsu, Nature 410, 63–64 (2001)

M. Tomsic, M. Rindfleisch, J. Yue, K. McFadden, J. Phillips, M.D. Sumption, M. Bhatia, S. Bohnenstiehl, E.W. Collings, Int. J. Appl. Ceram. Technol. 4, 250–259 (2007)

Y. Zhang, X. Xu, Phys. C 573, 1353633 (2020)

D.Y. Wang, X.F. Pan, D. Xi, Q.Y. Wang, J.Q. Feng, G. Yan, Y. Zhao, J. Supercond. Nov. Magn. 33, 2657–2662 (2020)

Z. Wang, J.M. van Oort, M.X. Zou, Phys. C Supercond. Appl. 482, 80–86 (2012)

S.D. Yudanto, Y.P. Dewi, A. Imaduddin, Y. Nakanishi, M. Yoshizawa, B. Kurniawan, A. Manaf, J. Supercond. Nov. Magn. 32, 2829 (2019)

M.A. Hamad, Process. Appl. Ceram. 9, 11 (2015)

M.A. Hamad, H.R. Alamri, J. Taibah Univ. Sci. 16, 670–675 (2022)

M.A. Hamad, J. Adv. Ceram. 4, 206–210 (2015)

M.A. Hamad, H.R. Alamri, J. Supercond. Nov. Magn. 35, 515–518 (2022)

M.A. Hamad, J. Supercond. Nov. Magn. 28, 173 (2015)

S.S. Kekade, P.A. Yadav, B.R. Thombare, P.R. Dusane, D.M. Phase, R.J. Choudhary, S.I. Patil, Mater. Res. Express 6, 096108 (2019)

D.K. Singh, B. Tiwari, R. Jha, H. Kishan, V.P.S. Awana, Phys. C 505, 104–108 (2014)

K.S.B. De Silva, X. Xu, S. Gambir, D.C.K. Wong, W.X. Li, Q.Y. Hu, IEEE Trans. Appl. Supercond. 23, 1–4 (2013)

S. Rajput, S. Chaudhary, IEEE Trans. Appl. Supercond. 20, 26–32 (2010)

G. Rivero, M. Multigner, J. Valdés, P. Crespo, A. Martínez, A. Hernando, J. Magn. Magn. Mater. 290–291, 618–620 (2005)

J.R. Thompson, M. Paranthaman, D.K. Christen, K.D. Sorge, H.J. Kim, J.G. Ossandon, Supercond. Sci. Technol. 14(5), L17–L20 (2001)

G. Fuchs, K.-H. Müller, A. Handstein, K. Nenkov, V. Narozhnyi, D. Eckert, L. Schultz, Solid State Commun. 118(10), 497–501 (2001)

P.C. Canfield, S.L. Budko, D.K. Finnemore, Phys. Supercond. 385(1–2), 1–7 (2003)

M.A. Hamad, J. Supercond. Nov. Magn. 26, 3459 (2013)

M.A. Hamad, J. Therm. Anal. Calorim. 115, 523 (2014)

M.A. Hamad, Mater. Lett. 82, 181 (2012)

A.H. El-Sayed, M.A. Hamad, J. Supercond. Nov. Magn. 31, 1895 (2018)

A.H. El-Sayed, M.A. Hamad, J. Supercond. Nov. Magn. 32, 1447 (2018)

M.A. Hamad, J. Supercond. Nov. Magn. 26, 449 (2013)

M.A. Hamad, J. Supercond. Nov. Magn. 27, 263 (2014)

M.A. Hamad, J. Adv. Dielect. 3, 1350029 (2013)

A.H. El-Sayed, M.A. Hamad, J. Supercond. Nov. Magn. 31, 3357 (2018)

A.H. El-Sayed, O.M. Hemeda, M.A. Hamad, A.M. Mohamed, Eur. Phys. J. Plus 134, 227 (2019)

A.H. El-Sayed, O.M. Hemeda, M.A. Hamad, A.M. Mohamed, J. Supercond. Nov. Magn. 33, 769–773 (2020)

M.A. Hamad, J. Supercond. Nov. Magn. 29, 1539 (2016)

M.A. Hamad, J. Supercond. Nov. Magn. 27, 223 (2014)

M.A. Hamad, O.M. Hemeda, A.M. Mohamed, J. Supercond. Nov. Magn. 33, 2521–2525 (2020)

M.A. Hamad, O.M. Hemeda, H.R. Alamri, A.M. Mohamed, J. Mater. Res. Technol. 11, 1356–1361 (2021)

M.A. Hamad, O.M. Hemeda, H.R. Alamri, A.M. Mohamed, J. Low Temp. Phys. 202, 121–127 (2021)

M.A. Hamad, J. Supercond. Nov. Magn. 28, 3111 (2015)

M.A. Hamad, J. Supercond. Nov. Magn. 27, 1777 (2014)

A.H. El-Sayed, M.A. Hamad, J. Supercond. Nov. Magn. 32, 1447 (2019)

H.R. Alamri, S.M. Elghnam, O.M. Hemeda, M.A. Hamad, Phys. Solid State 63, 1332–1336 (2021)

M.A. Hamad, J. Supercond. Nov. Magn. 31, 337 (2018)

M.A. Hamad, Process. Appl. Ceram. 11, 225–229 (2017)

M.A. Hamad, Int. J. Thermophys. 34, 1158–1165 (2013)

M.A. Hamad, Int. J. Thermophys. 36, 2748 (2015)

M.A. Hamad, Int. J. Thermophys. 34, 214 (2013)

M.A. Hamad, J. Adv. Ceram. 2, 308–312 (2013)

A.H. El-Sayed, M.A. Hamad, J. Supercond. Nov. Magn. 31, 4167–4171 (2018)

M. A. Hamad, O. M. Hemeda, H. M. Alamri, A. M. Mohamed, 33, 3853–3856 (2020)

M.A. Hamad, J. Supercond. Nov. Magn. 28, 2525–2528 (2015)

M.A. Hamad, J. Supercond. Nov. Magn. 28, 3365 (2015)

M.A. Hamad, J. Supercond. Nov. Magn. 29, 2867–2871 (2016)

M.A. Hamad, J. Supercond. Nov. Magn. 27, 2569 (2014)

M.A. Hamad, J. Supercond. Nov. Magn. 28, 3329–3333 (2015)

M.A. Hamad, J. Adv. Dielect. 3, 1350008 (2013)

M.A. Hamad, J. Supercond. Nov. Magn. 28, 2223 (2015)

A.H. El-Sayed, M.A. Hamad, J. Supercond. Nov. Magn. 31, 4091–4094 (2018)

M.A. Hamad, H.R. Alamri, M.E. Harb, J. Low Temp. Phys. 204, 57–63 (2021)

M.A. Hamad, J. Supercond. Nov. Magn. 27, 269–272 (2014)

M.A. Hamad, J. Adv. Dielect. 4, 1450026 (2014)

M.A. Hamad, Process. Appl. Ceram. 10, 33 (2016)

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abdelalim, Y.H., M.Mohamed, A., Hamad, M.A. et al. The Inverse Magnetocaloric Effect of MgB2 Superconductor. J Low Temp Phys 210, 325–333 (2023). https://doi.org/10.1007/s10909-022-02863-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10909-022-02863-0