Abstract

This manuscript explores the applications and advancements in three-dimensional (3D) printing with a focus on incorporating additive particles with unique properties into polymer composites. The benefits of 3D printing, such as design flexibility and rapid prototyping, are discussed along with the challenges of incorporating reinforcement materials with the polymer matrix. The review emphasizes the importance of achieving a homogeneous distribution of particles in the polymer matrix for filament fabrication in 3D printers. Thus, this review introduces the optimum method to produce a homogenous distribution of particles in the polymer matrix for fabricating filament for a FDM 3D printer. The use of filler particles enhances the properties of 3D printed parts, increasing their density, stiffness, and tribological performance, thereby expanding their applicability in industrial and biomedical fields.

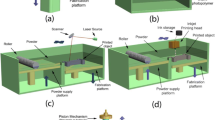

Reproduced with permission from Reference 31

Reproduced with permission from Reference 62

Reproduced with permission from Reference 62

Reproduced with permission from Reference 63

Reproduced with permission from Reference 64

Reproduced with permission from Reference 67

Reproduced with permission from Reference 71

Similar content being viewed by others

Data Availability

Not applicable.

References

M. Khedr, A. Hamada, W. Abd-Elaziem, M. Jaskari, M. Elsamanty, J. Kömi, A. Järvenpää, Effects of wall thickness variation on hydrogen embrittlement susceptibility of additively manufactured 316L stainless steel with lattice Auxetic structures. Materials 16(6), 2523 (2023)

X. Luo, H. Cheng, Wu. Xin, Nanomaterials reinforced polymer filament for fused deposition modeling: a state-of-the-art review. Polymers 15(14), 2980 (2023)

H.K. Sezer, O. Eren, FDM 3D printing of MWCNT reinforced ABS nano-composite parts with enhanced mechanical and electrical properties. J. Manuf. Process. 37, 339–347 (2019)

K. Takagishi, S. Umezu, Development of the improving process for the 3D printed structure. Sci. Rep. 7(1), 1–10 (2017)

O.T. Bafakeeh, W.M. Shewakh, A. Abu-Oqail, W. Abd-Elaziem, M. Abdel Ghafaar, M. Abu-Okail, Synthesis and Characterization of hybrid fiber-reinforced polymer by adding ceramic nanoparticles for aeronautical structural applications. Polymers 13(23), 4116 (2021)

D. Bekas, Y. Hou, Y. Liu, A. Panesar, 3D printing to enable multifunctionality in polymer-based composites: a review. Composites B 179, 107540 (2019)

T.D. Ngo, A. Kashani, G. Imbalzano, K.T. Nguyen, D. Hui, Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Composites B 143, 172–196 (2018)

B.I. Oladapo, S. Zahedi, A. Adeoye, 3D printing of bone scaffolds with hybrid biomaterials. Composites B 158, 428–436 (2019)

A. Ambrosi, M. Pumera, 3D-printing technologies for electrochemical applications. Chem. Soc. Rev. 45(10), 2740–2755 (2016)

J.-Y. Lee, J. An, C.K. Chua, Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 7, 120–133 (2017)

H. Guo, R. Lv, S. Bai, Recent advances on 3D printing graphene-based composites. Nano Mater. Sci. 1(2), 101–115 (2019)

A.D. Valino, J.R.C. Dizon, A.H. Espera Jr., Q. Chen, J. Messman, R.C. Advincula, Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog. Polym. Sci. 98, 101162 (2019)

J. Saroia, Y. Wang, Q. Wei, M. Lei, X. Li, Y. Guo, K. Zhang, A review on 3D printed matrix polymer composites: its potential and future challenges. Int. J. Adv. Manuf. Technol. 106(5), 1695–1721 (2020)

X. Wang, M. Jiang, Z. Zhou, J. Gou, D. Hui, 3D printing of polymer matrix composites: a review and prospective. Composites B 110, 442–458 (2017)

S. Park, W. Shou, L. Makatura, W. Matusik, K.K. Fu, Investigation of LCD 3D printing of carbon fiber composites by utilizing central composite design. Matter 5(1), 43–76 (2022)

A. Nikhil, 3D Printing Processes - Vat Photo polymerisation (Part 3/8), Engineers Garage, January 10, 2017.

A. Bagheri, J. Jin, Photopolymerization in 3D printing. ACS Appl. Polym. Mater. 1(4), 593–611 (2019)

M. Layani, X. Wang, S. Magdassi, Novel materials for 3D printing by photopolymerization. Adv. Mater. 30(41), 1706344 (2018)

A. Medellin, W. Du, G. Miao, J. Zou, Z. Pei, C. Ma, Vat photopolymerization 3D printing of nanocomposites: a literature review. J. Micro- Nano-Manuf. 7(3), 031006 (2019)

Y. Bao, N. Paunović, J.C. Leroux, Challenges and opportunities in 3D printing of biodegradable medical devices by emerging photopolymerization techniques. Adv. Funct. Mater. 32(15), 2109864 (2022)

A. Gallastegui, A. Dominguez-Alfaro, L. Lezama, N. Alegret, M. Prato, M.L. Gómez, D. Mecerreyes, Fast visible-light photopolymerization in the presence of multiwalled carbon nanotubes: toward 3D printing conducting nanocomposites. ACS Macro Lett. 11(3), 303–309 (2022)

E. Geisler, M. Lecompère, O. Soppera, 3D printing of optical materials by processes based on photopolymerization: materials, technologies, and recent advances. Photonics Res. 10(6), 1344–1360 (2022)

M.G.M. Benal, P.K. GS, V. Tambrallimath, G. HR, T.Y. Khan, A.A. Rajhi, M.A.A. Baig, Influence of short glass fibre reinforcement on mechanical properties of 3D printed ABS-based polymer composites. Polymers 14(6), 1182 (2022)

F.N. Chaudhry, S.I. Butt, A. Mubashar, A.B. Naveed, S.H. Imran, Z. Faping, Effect of carbon fibre on reinforcement of thermoplastics using FDM and RSM. J. Thermoplast. Compos. Mater. 35(3), 352–374 (2022)

F. Safari, A. Kami, V. Abedini, 3D printing of continuous fiber reinforced composites: a review of the processing, pre- and post-processing effects on mechanical properties. Polym. Polym. Compos. 30, 09673911221098734 (2022)

I. Blanco, G. Cicala, G. Recca, C. Tosto, Specific heat capacity and thermal conductivity measurements of PLA-based 3D-printed parts with milled carbon fiber reinforcement. Entropy 24(5), 654 (2022)

M.S. Saharudin, J. Hajnys, T. Kozior, D. Gogolewski, P. Zmarzły, Quality of surface texture and mechanical properties of PLA and PA-based material reinforced with carbon fibers manufactured by FDM and CFF 3D printing technologies. Polymers 13(11), 1671 (2021)

M. Heidari-Rarani, M. Rafiee-Afarani, A. Zahedi, Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites. Composites B 175, 107147 (2019)

M.N. Ahmad, M.K. Wahid, N.A. Maidin, M.H. AbRahman, M.H. Osman, Mechanical characteristics of oil palm fiber reinforced thermoplastics as filament for fused deposition modeling (FDM). Adv. Manuf. 8(1), 72–81 (2020)

N. Su, R. Pierce, C. Rudd, X. Liu, Comprehensive investigation of reclaimed carbon fibre reinforced polyamide (rCF/PA) filaments and FDM printed composites. Composites B 233, 109646 (2022)

Q. Wang, J. Sun, Q. Yao, C. Ji, J. Liu, Q. Zhu, 3D printing with cellulose materials. Cellulose 25, 4275–4301 (2018)

G. Griffini, M. Invernizzi, M. Levi, G. Natale, G. Postiglione, S. Turri, 3D-printable CFR polymer composites with dual-cure sequential IPNs. Polymer 91, 174–179 (2016)

A. Shahzad, I. Lazoglu, Direct ink writing (DIW) of structural and functional ceramics: recent achievements and future challenges. Composites B 225, 109249 (2021)

K. Osouli-Bostanabad, K. Adibkia, Made-on-demand, complex and personalized 3D-printed drug products. BioImpacts 8(2), 77 (2018)

J.C. Capricho, B. Fox, N. Hameed, Multifunctionality in epoxy resins. Polym. Rev. 60(1), 1–41 (2020)

C.C. Spackman, C.R. Frank, K.C. Picha, J. Samuel, 3D printing of fiber-reinforced soft composites: process study and material characterization. J. Manuf. Process. 23, 296–305 (2016)

K. Chen, X. Kuang, V. Li, G. Kang, H.J. Qi, Fabrication of tough epoxy with shape memory effects by UV-assisted direct-ink write printing. Soft Matter 14(10), 1879–1886 (2018)

D.A. Rau, M. Forgiarini, C.B. Williams, Hybridizing Direct Ink Write and mask-projection Vat Photopolymerization to enable additive manufacturing of high viscosity photopolymer resins. Addit. Manuf. 42, 101996 (2021)

B.G. Compton, J.A. Lewis, 3D-printing of lightweight cellular composites. Adv. Mater. 26(34), 5930–5935 (2014)

https://en.wikipedia.org/wiki/Selective_laser_sintering#cite_note-8. Accessed 5 June 2023.

S. Lekurwale, T. Karanwad, S. Banerjee, Selective laser sintering (SLS) of 3D printlets using a 3D printer comprised of IR/red-diode laser. Ann. 3D Print. Med. 6, 100054 (2022)

X. Chen, J. Yin, X. Liu, B. Pei, J. Huang, X. Peng, A. Xia, L. Huang, Z. Huang, Effect of laser power on mechanical properties of SiC composites rapidly fabricated by selective laser sintering and direct liquid silicon infiltration. Ceram. Int. 48(13), 19123–19131 (2022)

F. Fina, A. Goyanes, S. Gaisford, A.W. Basit, Selective laser sintering (SLS) 3D printing of medicines. Int. J. Pharm. 529(1–2), 285–293 (2017)

C.Y. Yap, C.K. Chua, Z.L. Dong, Z.H. Liu, D.Q. Zhang, L.E. Loh, S.L. Sing, Review of selective laser melting: materials and applications. Appl. Phys. Rev. 2(4), 041101 (2015)

J. Zhang, B. Song, Q. Wei, D. Bourell, Y. Shi, A review of selective laser melting of aluminum alloys: processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 35(2), 270–284 (2019)

H. Jia, H. Sun, H. Wang, Y. Wu, H. Wang, Scanning strategy in selective laser melting (SLM): a review. Int. J. Adv. Manuf. Technol. 113(9), 2413–2435 (2021)

W. Abdel-Aziem, S. Elkatatny, A.-E. Abd-Elaziem, M. Khedr, M.A. Abd El-baky, M.A. Hassan, M. Abu-Okail, M. Mohammed, A. Järvenpää, T. Allam, on the current research progress of metallic materials fabricated by laser powder bed fusion process: a review. J. Mater. Res. Technol. 20, 681–707 (2022)

M. Ziaee, N.B. Crane, Binder jetting: a review of process materials, and methods. Addit. Manuf. 28, 781–801 (2019)

A. Lores, N. Azurmendi, I. Agote, E. Zuza, A review on recent developments in binder jetting metal additive manufacturing: materials and process characteristics. Powder Metall. 62(5), 267–296 (2019)

J. Park, M.J. Tari, H.T. Hahn, Characterization of the laminated object manufacturing (LOM) process. Rapid Prototyp. J. 6, 36–50 (2000)

D.D. Chung, Materials for thermal conduction. Appl. Therm. Eng. 21(16), 1593–1605 (2001)

S.I. Asiya et al., Sustainable preparation of gold nanoparticles via green chemistry approach for biogenic applications. Mater. Today Chem. 17, 100327 (2020)

K. Pal et al., Cutting edge development on graphene derivatives modified by liquid crystal and CdS/TiO2 hybrid matrix: optoelectronics and biotechnological aspects. Crit. Rev. Solid State Mater. Sci. 46(5), 385–449 (2021)

H. Dommati et al., A comprehensive review of recent developments in 3D printing technique for ceramic membrane fabrication for water purification. RSC Adv. 9, 16869 (2019)

N. Nath et al., Carbon nanostructure embedded novel sensor implementation for detection of aromatic volatile organic compounds: an organized review. ACS Omega 8, 4436–4452 (2023)

K. Pal et al., A critical review on multifunctional smart materials ‘nanographene’ emerging avenue: nano-imaging and biosensor applications. Crit. Rev. Solid State Mater. Sci. 47(5), 691–707 (2022)

H. Chung, S. Das, Processing and properties of glass bead particulate-filled functionally graded Nylon-11 composites produced by selective laser sintering. Mater. Sci. Eng. A 437(2), 226–234 (2006)

A.R. Torrado Perez, D.A. Roberson, R.B. Wicker, Failure analysis and anisotropy evaluation of 3D-printed tensile test specimens of different geometries and print raster patterns. J. Fail. Anal. Prev. 14(3), 343–353 (2014)

R. Singh, P. Bedi, F. Fraternali, I. Ahuja, Effect of single particle size, double particle size and triple particle size Al2O3 in Nylon-6 matrix on mechanical properties of feed stock filament for FDM. Composites B 106, 20–27 (2016)

Y. Zhang, L. Hao, M. Savalani, R.A. Harris, K. Tanner, Dynamics of in vitro polymer degradation of polycaprolactone-based scaffolds: accelerated versus simulated physiological conditions. J. Biomed. Mater. Res. A 86(3), 607–616 (2008)

N. Sa’ude, M. Ibrahim, M.H.I. Ibrahim, Mechanical properties of highly filled iron-ABS composites in injection molding for FDM wire filament. Mater. Sci. Forum 733–774, 448–453 (2014)

N. Vidakis et al., Fused filament fabrication 3D printed polypropylene/alumina nanocomposites: effect of filler loading on the mechanical reinforcement. Polym. Test. 109, 107545 (2022)

P. Wang et al., Effect of carbon nanotubes on the interface evolution and dielectric properties of polylactic acid/ethylene–vinyl acetate copolymer nanocomposites. Adv. Compos. Hybrid Mater. 5, 1100–1110 (2022)

K. Boparai, R. Singh, H. Singh, Comparison of tribological behavior for Nylon6-Al Al2O3 and ABS parts fabricated by fused deposition modelling. Virtual and Phys. Prototyp. 10(2), 59–66 (2015)

N. Vidakis, M. Petousis, E. Velidakis, L. Tzounis, N. Mountakis, J. Kechagias, S. Grammatikos, Optimization of the filler concentration on fused filament fabrication 3D printed polypropylene with titanium dioxide nanocomposites. Materials 14(11), 3076 (2021)

N. Vidakis, M. Petousis, E. Velidakis, N. Mountakis, L. Tzounis, M. Liebscher, S.A. Grammatikos, Enhanced mechanical, thermal and antimicrobial properties of additively manufactured polylactic acid with optimized nano silica content. Nanomaterials 11(4), 1012 (2021)

Y. Jia, H. He, Y. Geng, B. Huang, X. Peng, High through-plane thermal conductivity of polymer based product with vertical alignment of graphite flakes achieved via 3D printing. Compos. Sci. Technol. 145, 55–61 (2017)

U. Kalsoom, A. Peristyy, P. Nesterenko, B. Paull, A 3D printable diamond polymer composite: a novel material for fabrication of low cost thermally conducting devices. RSC Adv. 6(44), 38140–38147 (2016)

F. Castles, D. Isakov, A. Lui, Q. Lei, C. Dancer, Y. Wang, J. Janurudin, S. Speller, C. Grovenor, P.S. Grant, High-field high-repetition-rate sources for the coherent THz control of matter. Sci. Rep. 6(1), 1–8 (2016)

S.W. Kwok, K.H.H. Goh, Z.D. Tan, S.T.M. Tan, W.W. Tjiu, J.Y. Soh, Z.J.G. Ng, Y.Z. Chan, H.K. Hui, K.E.J. Goh, Electrically conductive filament for 3D-printed circuits and sensors. Appl. Mater. Today 9, 167–175 (2017)

A. Kania, K. Berent, T. Mazur, M. Sikora, 3D printed composites with uniform distribution of Fe3O4 nanoparticles and magnetic shape anisotropy. Addit. Manuf. 46, 102149 (2021)

S. Kumar, R. Singh, M. Singh, Multi-material 3D printed PLA/PA6-TiO2 composite matrix: rheological, thermal, tensile, morphological and 4D capabilities. Adv. Mater. Process. Technol. 8(2), 2329–2348 (2022)

S. Tsai, D. Botts, J. Plouff, Effects of particle properties on the rheology of concentrated noncolloidal suspensions. J. Rheol. 36(7), 1291–1305 (1992)

M. Nikzad, S.H. Masood, I. Sbarski, Thermo-mechanical properties of a highly filled polymeric composites for fused deposition modeling. Mater. Des. 32(6), 3448–3456 (2011)

S. Masood, W. Song, Thermal characteristics of a new metal/polymer material for FDM rapid prototyping process. Assem. Autom. 25, 309 (2005)

M.A. Ryder, D.A. Lados, G.S. Iannacchione, A.M. Peterson, Fabrication and properties of novel polymer-metal composites using fused deposition modeling. Compos. Sci. Technol. 158, 43–50 (2018)

J. Liu, Z. Li, Y. Yu, P. Wang, 3D-printed polymer composites based upon low melting point alloys filled into polylactic acid. J. Phys. 2002, 012008 (2021)

S. Singh, S. Ramakrishna, R. Singh, Material issues in additive manufacturing: a review. J. Manuf. Process. 25, 185–200 (2017)

K. Vishal, K. Rajkumar, P. Sabarinathan, V. Dhinakaran, Mechanical and wear characteristics investigation on 3D printed silicon filled poly (lactic acid) biopolymer composite fabricated by fused deposition modeling. SILICON 14, 9379 (2022)

B. Nagarajan, M. Arshad, A. Ullah, P. Mertiny, A.J. Qureshi, dditive manufacturing ferromagnetic polymers using stereolithography – Materials and process development. Manuf. Lett. 21, 12–16 (2019)

V.S. Vakharia, L. Kuentz, A. Salem, M.C. Halbig, J.A. Salem, M. Singh, Additive manufacturing and characterization of metal particulate reinforced polylactic acid (PLA) polymer composites. Polymers 13(20), 3545 (2021)

S. Masood, W. Song, Development of new metal/polymer materials for rapid tooling using fused deposition modelling. Mater. Des. 25(7), 587–594 (2004)

S.J. Kalita, S. Bose, H.L. Hosick, A. Bandyopadhyay, Development of controlled porosity polymer-ceramic composite scaffolds via fused deposition modeling. Mater. Sci. Eng. C 23(5), 611–620 (2003)

F.S. Senatov, K.V. Niaza, M.Y. Zadorozhnyy, A. Maksimkin, S. Kaloshkin, Y. Estrin, Mechanical properties and shape memory effect of 3D-printed PLA-based porous scaffolds. J. Mech. Behav. Biomed. Mater. 57, 139–148 (2016)

S. Hwang, E.I. Reyes, K.-S. Moon, R.C. Rumpf, N.S. Kim, Thermo-mechanical characterization of metal/polymer composite filaments and printing parameter study for fused deposition modeling in the 3D printing process. J. Electron. Mater. 44(3), 771–777 (2015)

C.M. Shemelya, A. Rivera, A.T. Perez, C. Rocha, M. Liang, X. Yu, C. Kief, D. Alexander, J. Stegeman, H. Xin, Mechanical, electromagnetic, and X-ray shielding characterization of a 3D printable Tungsten-polycarbonate polymer matrix composite for space-based applications. J. Electron. Mater. 44(8), 2598–2607 (2015)

N. Ayrilmis, M. Kariz, J.H. Kwon, M. Kitek Kuzman, Effect of printing layer thickness on water absorption and mechanical properties of 3D-printed wood/PLA composite materials. Int. J. Adv. Manuf. Technol. 102(5), 2195–2200 (2019)

A.H. Espera Jr., A.D. Valino, J.O. Palaganas, L. Souza, Q. Chen, R.C. Advincula, Studies on 3D printability of novel impact modified nylon 6: experimental investigations and performance evaluation. Macromol. Mater. Eng. 304(4), 1800718 (2019)

D. Podstawczyk, D. Skrzypczak, X. Połomska, A. Stargała, A. Witek-Krowiak, A. Guiseppi-Elie, Z. Galewski, Preparation of antimicrobial 3D printing filament: in situ thermal formation of silver nanoparticles during the material extrusion. Polym. Compos. 41(11), 4692–4705 (2020)

S.K. Jain, Y. Tadesse, Fabrication of polylactide/carbon nanopowder filament using melt extrusion and filament characterization for 3D printing. Int. J. Nanosci. 18(05), 1850026 (2019)

Q. Chen, J.D. Mangadlao, J. Wallat, A. De Leon, J.K. Pokorski, R.C. Advincula, 3D printing biocompatible polyurethane/poly(lactic acid)/graphene oxide nanocomposites: anisotropic properties. ACS Appl. Mater. Interfaces 9(4), 4015–4023 (2017)

C.T. Seng, S.Y. Eh Noum, S.K. Sivanesan, L.-J. Yu, Reduction of hygroscopicity of PLA filament for 3D printing by introducing nano silica as filler, in AIP Conference Proceedings (AIP Publishing LLC, 2020), p. 020024

J. Liu, J. Ye, F. Momin, X. Zhang, A. Li, Nonparametric bayesian framework for material and process optimization with nanocomposite fused filament fabrication. Addit. Manuf. 54, 102765 (2022)

N. Vidakis, M. Petousis, E. Velidakis, N. Mountakis, P.E. Fischer-Griffiths, S. Grammatikos, L. Tzounis, Fused filament fabrication three-dimensional printing multi-functional of polylactic acid/carbon black nanocomposites. C 7(3), 52 (2021)

S. Dul, L.G. Ecco, A. Pegoretti, L. Fambri, Graphene/carbon nanotube hybrid nanocomposites: effect of compression molding and fused filament fabrication on properties. Polymers 12(1), 101 (2020)

A.C. de Leon, Q. Chen, N.B. Palaganas, J.O. Palaganas, J. Manapat, R.C. Advincula, High performance polymer nanocomposites for additive manufacturing applications. React. Funct. Polym. 103, 141–155 (2016)

W. Xu, S. Jambhulkar, Y. Zhu, D. Ravichandran, M. Kakarla, B. Vernon, D.G. Lott, J.L. Cornella, O. Shefi, G. Miquelard-Garnier, 3D printing for polymer/particle-based processing: a review. Composites B 223, 109102 (2021)

Acknowledgements

Dr. Walaa Abdelaziem would like to acknowledge the Technology Innovation Commercialization Office (TICO) at Zagazig University in Egypt for supporting this project. Also, Dr. Mahmoud Khedr would like to express his sincere thanks for the financial assistance from the Finnish Foundation for Technology Promotion in Finland.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

WA-E: Idea, Original draft preparation, Investigation, Reviewing and Editing, Supervision. MK: Original draft preparation, Reviewing and Editing. A-EA-E: Original draft preparation, Reviewing and Editing. MMAA: Original draft preparation, Reviewing and Editing. AAM: Original draft preparation, Reviewing and Editing. HMY: Original draft preparation, Reviewing and Editing of final version. WMD: Reviewing and Editing of final version, resources and funding. MAAE: Idea, Original draft preparation, Investigation, Reviewing and Editing, Supervision. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical Approval

Not applicable.

Informed Consent

Informed consent was obtained from all subjects involved in the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abd-Elaziem, W., Khedr, M., Abd-Elaziem, AE. et al. Particle-Reinforced Polymer Matrix Composites (PMC) Fabricated by 3D Printing. J Inorg Organomet Polym 33, 3732–3749 (2023). https://doi.org/10.1007/s10904-023-02819-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-023-02819-1