Abstract

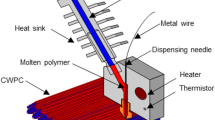

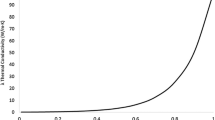

New metal/polymer composite filaments for fused deposition modeling (FDM) processes were developed in order to observe the thermo-mechanical properties of the new filaments. The acrylonitrile butadiene styrene (ABS) thermoplastic was mixed with copper and iron particles. The percent loading of the metal powder was varied to confirm the effects of metal particles on the thermo-mechanical properties of the filament, such as tensile strength and thermal conductivity. The printing parameters such as temperature and fill density were also varied to see the effects of the parameters on the tensile strength of the final product which was made with the FDM process. As a result of this study, it was confirmed that the tensile strength of the composites is decreased by increasing the loading of metal particles. Additionally, the thermal conductivity of the metal/polymer composite filament was improved by increasing the metal content. It is believed that the metal/polymer filament could be used to print metal and large-scale 3-dimensional (3D) structures without any distortion by the thermal expansion of thermoplastics. The material could also be used in 3D printed circuits and electromagnetic structures for shielding and other applications.

Similar content being viewed by others

References

B.V. Hooreweder, D. Moens, R. Boonen, J. Kruth, and P. Sas, Polym. Test. 32, 972 (2013).

E.O. Olakanmia and J. Mats, Process. Technol. 213, 1387 (2013).

K.N. Han and N.S. Kim, KONA Powder Part. J. 27, 73 (2009).

L.E. Murr, K.N. Amato, S.J. Li, Y.X. Cheng, S.M. Gaytan, E. Martinez, P.W. Shindo, F.R. Medina, and R.B. Wicker, J. Mech. Behav. Biomed. Mater. 4, 1396 (2011).

L.E. Murr, S.M. Gaytan, D.A. Ramirez, E. Martinez, J. Hernandez, K.N. Amato, P.W. Shindo, F.R. Medina, and R.B. Wicker, J. Mater. Sci. Technol. 28, 1 (2012).

N.S. Kim and K.N. Han, J. Appl. Phys. 108, 102801 (2010).

Ph Bertrand, F. Bayle, C. Combe, P. Goeuriot, and I. Smurov, Appl. Surf. Sci. 254, 989 (2007).

S.H. Ahn, M. Montero, D. Odell, S. Roundy, and P.K. Wright, Rapid Prototyp. 8, 248 (2002).

A. Bellini and S. Guceri, Rapid Prototyp. 9, 252 (2003).

A.K. Sood, R.K. Ohdar, and S.S. Mahapatra, Mater. Des. 31, 287 (2010).

S.H. Masood and W.Q. Song, Mater. Des. 25, 587 (2004).

S.H. Masood and W.Q. Song, Assem. Autom. 25, 309 (2005).

N. Saude, S.H. Masood, M. Nikzad, M. Ibrahim, and M.H.I. Ibrahim, Int. J. Eng. Res. Appl. 3, 1257 (2013).

J.D. Bronzino, The Biomedical Engineering Handbook, 2nd ed. (Boca Raton: CRC, 2000).

M. Leeuwen, N.A.A. Buijs, A.B. Canelas, J.J. Heijnen, and W.M. Gulik, Chem. Eng. Sci. 64, 1877 (2009).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hwang, S., Reyes, E.I., Moon, Ks. et al. Thermo-mechanical Characterization of Metal/Polymer Composite Filaments and Printing Parameter Study for Fused Deposition Modeling in the 3D Printing Process. J. Electron. Mater. 44, 771–777 (2015). https://doi.org/10.1007/s11664-014-3425-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-014-3425-6