Abstract

Alginate–zinc oxide (Alg–ZnO) biocomposite was synthesized and tested as a chromium ions Cr(VI) adsorbent for environmental applications. Alg–ZnO biocomposite was prepared by the interaction between sodium alginate biopolymer and zinc oxide nanoparticles (ZnO–NPs), prepared by modified wet chemical method. The solid adsorption characteristics of the synthesized Alg–ZnO biocomposite were characterized by Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), transmission electron microscopy (TEM), and UV–Vis spectroscopy. Adsorption isotherms of chromium ions on the prepared Alg–ZnO biocomposite were investigated with varying the initial concentration of Cr(VI) under different application conditions such as pH, contact time, adsorbent dosage, and temperature. Adsorption of Cr(VI) was investigated by different isotherm models such as Langmuir, Freundlich, Temkin and Dubinin–Radushkevich models. Maximum adsorption capacities (31.09 and 34.63 mg/g) were achieved by ZnO–NPs and Alg–ZnO, respectively at 25 °C. The results of isotherm models indicate the perfect applicability of Langmuir and Dubinin–Radushkevich models, revealing the dominance of monolayer and the physisorption of chromium ions onto the studied adsorbents.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

One of the most serious challenges worldwide is the environmental pollution by heavy metals and minerals. The increase in heavy metals concentrations to hazardous levels is due to extensive activities such as industrial operations, disposal of industrial waste materials, mining, and agricultural processes. The heavy metals in squander water are non-biodegradable, seriously poisonous, aggregates in nature and sullies ground/surface water presenting a genuine danger to the living creatures and the climate. One of the most toxic metals in wastewaters is chromium [1]. Chromium is poisonous because of its carcinogenic, mutagenic and teratogenic properties [2]. Strong exposure to hexavalent chromium has been correlated to malignancy in the intestinal system [3]. Also, in some exposure rate may causes vomiting, gastric pain, nausea, hemorrhage, and acute diarrhea.

Numerous treatment techniques are accessible to treat the wastewater from heavy metal fixation. Because of the high reagent prerequisite cost of the technique, and a few different drawbacks of that large number of strategies, adsorption appears as a powerful strategy to eliminate heavy metals from wastewater [4]. The ordinarily involved systems for eliminating heavy metals from water streams include coagulation, chemical precipitation, reverse osmosis, ion exchange, and so on [5]. The high costs, inefficient toxins removal and the high energy needs are of the common disadvantages of the present pollution removal techniques [6]. Adsorption is a technique in which certain adsorptives are specifically removed from the solution by adsorption on the surface of the adsorbent material [7,8,9]. The advantages of Adsorption technique over the other different techniques owes to its simple procedures with no sludge and can include low investment in case of both introductory expense and land requirement. In this study sodium alginate-zinc oxide biocomposite was prepared and used as a solid adsorbent for Cr(VI). The adsorption isotherms of chromium ions were investigated onto the prepared solid adsorbents by different isotherm models like Langmuir, Freundlich, Temkin and Dubinin–Radushkevich models [10,11,12].

This study aim at the synthesis of two adsorbents, namely, ZnO nanoparticles (ZnO–NP) prepared by modified wet chemical method, and alginate-zinc oxide (Alg–ZnO) biocomposite beads. The absorbents were characterized by FTIR, XRD, SAED, and TEM techniques. The chromium ions adsorption was studied under the effect of initial adsorbate concentration at 25 °C.

It is the first time that sodium alginate and ZnO–NPs (ALg–ZnO) biocomposite beads were synthesized by the interaction between sodium alginate biopolymer and zinc oxide nanoparticles prepared by modified wet chemical method and used for the adsorption of chromium ions. Our study provides clue that ALg–ZnO biocomposite can be considered a promising solid adsorbent for the environmental applications, especially the elimination of toxic metals [8, 13,14,15,16,17].

2 Materials and Methods

2.1 Materials

Sodium alginate ((C5H7O4COONa)n) with an intrinsic viscosity of 1.132 dL/g and average molecular weight of 36.000 g/mol, Zinc acetate dihydrate (Zn(O2CCH3)2(H2O)2), Sodium hydroxide (NaOH), Potassium dichromate (K2Cr2O7), and Calcium chloride (CaCl2).

2.2 Synthesis of Adsorbent Solid

2.2.1 Preparation of ZnO Nanoparticles (ZnO–NP)

ZnO–NP were synthesized by modified wet chemical method according to Cao et al. [18]. The method is built on chemical reaction between zinc acetate dihydrate, and sodium hydroxide. The chemicals and regents were purchased from Sigma-Aldrich, USA at at least 99% purity to be used without any modifications. Two solutions were prepared to obtain the reaction, Sol. (A) and Sol. (B). Sol. (A) was prepared by preparing 10 mmol of zinc acetate dihydrate in 250 ml DDH2O. Sol. (B) was prepared by preparation of sodium hydroxide solution in concentration 7.5 mmol in 100 mL DDH2O. Solution A was pre-warmed by stirring at 60 °C for 30 min, then sol. (B) was added drop-wise to sol. (A) under continuous stirring for 6 h. The developed white solution then left for cooling at room temperature. The white precipitate then separated by centrifugation at 6000 rpm for 15 min. Zn nanoparticles precipitate was washed thoroughly with DDH2O and left to dry over night at 60 °C. The synthesis of Zn nanoparticles was investigated by UV-Visible spectrum measurements at wavelength range 200 to 600 nm at ambient temperature using JASCO V-730 spectrophotometer (JAPAN).

The synthesis of Zn nanoparticles was illustrated by the following equations [19]:

2.2.2 Preparation of Sodium Alginate and ZnO–NPs (ALg–ZnO) Bioomposite Beads

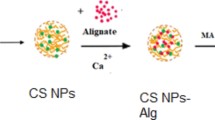

For preparation of Alginate–ZnO beads: Solution of calcium chloride (3%) and sodium alginate (1%) were prepared in DDH2O separately. The prepared ZnO–NPs (1 g) were added to sodium alginate solution with vigorous mixing using probe sonicator device until completely dispersion. The Alg–ZnO solution then added drop by drop to CaCl2 solution. As a result of crosslinking of calcium chloride to sodium alginate, the solution of soluble sodium alginate formed water insoluble beads of calcium alginate. The excess of unbound calcium chloride in the beads surface was removed from the obtained beads by washing with deionized water several times. All washed beads were collected for draying at 80 °C for one day and kept in a dry and clean glass bottle [20].

2.3 Characterization Techniques of Solid Adsorbents

The structural properties of the solid adsorbent were detected using Fourier transforms infrared spectrometer (FT-IR, Jasco FT-IR 6100) and ultraviolet-visible (UV–Vis) spectra. X-ray diffractometer (XRD) (Schimadzu 6000DX device) is used to study the crystalline structure of the prepared solid samples with Cu Kα radiation source (λ = 1.5405 Å) and operating voltage of 40 kV. The Bragg’s angle (2θ) at range of 5–80° with scanning speed 0.02°/min. Transmission electron microscope (TEM, JEOL-JEM-1011) and selected area electron diffraction (SAED) were used to studied the size and distribution of the pure ZnO–NPs.

2.4 Adsorption Experiment of Chromium Ion

The adsorption procedures are prepared as follows; first, a stock solution from K2Cr2O7 was prepared with Cr concentration of 500 mg/L in distilled water. A series of initial different concentrations (50–500 mg/L) from the prepared solution were separated in pyrex bottles with 50 mL constant volume and 0.1 g of adsorbent beads. All sample bottles were kept under shaken for 10 h at 25 °C.

The supernatant was filtered and the equilibrium concentration of the chromium ion adsorbed solutions was measured using Flame Atomic Absorption Spectroscopy (Agilent Technologies 200 series FAAS). The amount of adsorbed material qe (mg/g) at equilibrium was calculated by Eq. 5:

where Ce and Co (mg/L) are the equilibrium and initial concentrations of chromium solution, respectively. V is the working solution volume (L) and W is the adsorbent weight (g).

2.5 Adsorption Isotherm Models

With a finite and identical number of comparable localized adsorption sites, the Langmuir isotherm holds true for monolayer adsorption onto the surface of the solid adsorbent [21].

Langmuir model are derived with:

where qe (mg/g) is the amount adsorbed at equilibrium, qm (mg/g) is the maximum adsorption capacity, and b (L/mg) is the Langmuir constant. The nature of chromium ion adsorption can be determined by the calculation of the dimensionless separation factor (RL).

The value of RL is unfavorable if (RL > 1), favorable if (0 < RL < 1) and irreversible if (RL = 0). Where \({C}_{o}\) (mg/L) is the chromium ion initial concentration.

Freundlich model illustrates the distribution of active centers on a heterogeneous surface for the multilayer adsorption and explained by the subsequent equation [22]:

where 1/n represents the adsorption intensity and KF is Freundlich constant expressing the adsorption capacity.

Temkin model (Eq. 9) describes the interaction between the adsorbent and adsorbate particles quite clearly, the adsorption heat reduced linearly with the adsorbent dose, and is represented as [23]:

In both equations T represented the absolute temperature in Kelvin, A represented the adsorption heat and R (8.314 J/mol.K) is the gas adsorption constant. bT (J/mol) and KT (L/g) are Temkin constants.

Dubinin-Radushkevich model (Eq. 12) discussed the isotherm analyzing method with a great degree of regularity. Compared to the Langmuir type, this isotherm has a more generic nature. The linear form is derived as [24]:

where \({q}_{DR}\) and KDR are maximum adsorption capacity (mg/g) and Dubinin–Radushkevich constant (mol2/kJ2). T, R and ε are denotes Kelvin temperature, the gas constant and the Polanyi potential, respectively.

The mean free energy of adsorption (EDR, kJ /mol) is described as:

3 Results and Discussion

3.1 Characterization of the Solid Adsorbents

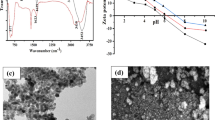

Figure 1 shows the absorption spectra of ZnO in ultraviolet–visible spectral region. The resulted particles solution absorbs UV light at 370, which is indicative to the synthesis of ZnO nanoparticles as the developed turbidity of the final solution was clearly visualized indicating the suspended nanoparticles presence, which absorb UV beams at distinct wavelength. Furthermore, UV–Vis spectroscopy data were confirmed by TEM and XRD analyses. The amount of purified ZnO nanoparticles obtained from the reaction was 100 mg for one reaction.

Figure 2a represents the TEM images of ZnO nanoparticles and (SAED) to describe the shape, size and crystallinity of the nanoparticles. The images indicated a spherical morphology shape of the nanoparticles and the size of the nanoparticles was revealed to be 5–18 nm. Figure 2b shows the SAED pattern of the prepared samples. The spotty circular ring pattern confirms the high degree of crystallinity of the sample.

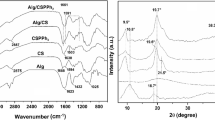

Considered as one of the most effective non-destructive techniques for examining multi-component systems [25,26,27,28,29]. Fourier transformer infrared spectroscopy (FTIR) was used to further investigate the prepared Alg–ZnO beads. The FTIR spectra of the prepared samples were measured in the frequency range 4000 to 400 cm−1. Figure 3 represents the FTIR spectra for pure sodium alginate (Alg) and alginate-zinc oxide beads (Alg–ZnO). For pure sodium alginate, the infrared spectrum shows two different vibrations related to the presence of carboxylate group, a symmetric stretch at 1417 cm−1, and an asymmetric stretch at 1616 cm−1 [30, 31]. The vibrational peak at 2936 cm−1 can be characterized as C–H bond peak, and at 3419 cm−1 can be characterized as O–H stretching vibration [30, 32]. The main adsorption peaks of ZnO are observed at 460 cm−1 and 417 cm−1 in Alg–ZnO composite spectra (Fig. 3) and correspond to the stretching vibrations of the Zn–O bond [33, 34].

The crystalline phase and the purity of the prepared samples were determined using X-ray diffraction (XRD) pattern. Figure 4 shows the XRD spectra of the pure synthesized ZnO nanoparticles and ALg–ZnO biocomposite. Figure 4 shows the characteristic reflection peaks at 2θ values 31.35°, 34.1°, 35.83°, 47.15°, 56.24°, 62.48°, 67.70° and 76.60° that related to the crystalline plans (100), (002), (101), (102), (110), (103), (112) and (202) of ZnO hexagonal structure, respectively [35]. These ZnO–NPs peaks may correspond to the hexagonal structure of ZnO (JCPDS card no. 36-1451). While the lack of any impurity peaks indicates a good purity of prepared ZnO nanoparticles. The XRD pattern for Alg–ZnO biocomposite in Fig. 4. X-ray diffraction (XRD) data indicate that sodium alginate shows a semi-crystalline nature. The 2θ diffraction peaks at 13.6° and 21° observed in XRD pattern of ALg–ZnO composite is due to the reflection at (110) and (200) diffraction planes of sodium alginate structure [36].

3.2 Investigation of the Adsorption Isotherms of Chromium Ions on the Prepared ZnO–NPs and ALg–ZnO Biocomposite

The chromium ions adsorption isotherms on ZnO–NPs and ALg–ZnO at 25 °C were investigated. As shown in Fig. 5, the adsorption capacity (qe, mg/g) increased significantly at the beginning of the initial rise in Cr(VI) concentration and started to stabilize at higher initial concentrations of adsorbate as a result of the active sites saturation [37]. To determine the chromium ions adsorption mechanism, the experimental data were estimated with models of adsorption isotherm. Langmuir, Freundlich, Temkin, and Dubinin–Radushkevich isotherm models were used to estimate the equilibrium data (Eqs. 6, 8, 9, and 12, respectively) as listed in Table 1. The aqueous solution of chromium with initial concentrations of 50–500 mg/L were utilized to establish the experimental equilibrium data. Adsorption experiments were conducted by using 2 g/L at 25 °C.

For Langmuir isotherm (Fig. 6a), the correlation coefficients (R2) (0.9905–0.9985) showed the best-fitting model for chromium ions adsorption using ZnO–NPs and ALg–ZnO as given in Table 1. Adsorption capacities of ZnO–NPs and ALg–ZnO (31.09 and 34.63 mg/g, respectively) assume that the adsorption of Cr ions on the surface of ZnO–NPs and its composite occurs at a homogeneous adsorption sites, and also there is no mutual interaction between the adsorbed molecules [38]. The values of Langmuir constant (b, L/mg) follow the sequence ALg–ZnO > ZnO–NPs, revealing the higher binding strength between ALg–ZnO and Cr(VI). RL values (0.1221–0.2122) calculated from Eq. 7 are numbers between 0 and 1, and reveal that the Cr(VI) adsorption results onto the prepared adsorbents in the Langmuir isotherm are in the favorable range. The R2 values (0.6144–0.6872) for Freundlich isotherm model (Fig. 6b) are lower than the values obtained from Langmuir Isotherm, displaying the current equilibrium adsorption data are not better explained by Freundlich isotherm model [39]. It further indicated the dominance of monolayer chromium ions adsorption phase over ZnO–NPs and ALg–ZnO surface due to their uniform shape [40].

Linear plots of Temkin and Dubinin–Radushkevich models for the Cr(VI) adsorption onto the prepared adsorbents are observed in Fig. 7a and b while their parameters are presented in Table 1. Temkin isotherm analysis showed the poor fitting of this model according to the lower correlation coefficient values (0.6044–0.7698). But, the higher R2 > 0.9386 for Dubinin–Radushkevich isotherm indicated its good application for the Cr(VI) adsorption in addition to the small difference (2.1–3.4%) between the adsorption capacities (\({q}_{DR}\)) and (qm) calculated by Dubinin–Radushkevich and Langmuir models, respectively.

The type of adsorption, chemical or physical can be identified using the mean adsorption energy values (EDR, kJ/mol). When EDR values are between 8 and 16 kJ/mol, the chemical adsorption force is indicated. If EDR is less than 8 kJ/mol, the adsorption is a physical process [41]. In the current study, EDR values varies fom 0.0383 to 0.0497 kJ/mol, indicating the physical adsorption of chromium ions onto ZnO–NPs and ALg–ZnO. The above mentioned discussions illuminated the perfect applicability of Dubinin-Radushkevich and Langmuir models for Cr(VI) uptake onto the studied adsorbents. The adsorption mechanism can be attributed to the electrostatic attraction between carboxylic or hydroxyl group of ALg–ZnO composite or basic oxygen group of ZnO–NPs and the positively charged chromium ions [42].

3.3 ALg–ZnO Biocomposite in Comparison to Other Adsorbents

Table 2 introduces a comparison between the maximum absorption capacity of ALg–ZnO biocomposite for chromium ions and various adsorbents values reported in the literature. Accordingly, the ALg–ZnO biocomposite show a superior chromium ions adsorption performance than different previously reported adsorbents.

4 Conclusion

The present work show the zinc oxide nanoparticles (ZnO–NPs) characterized by its high purity and high crystallinity of particles with spherical shape and size of 5–18 nm. Characterization of alginate-zinc oxide (Alg–ZnO) biocomposite with FTIR and XRD proved its crystalline structure and the presence of various functional groups. ZnO–NPs and Alg–ZnO exhibited maximum Langmuir adsorption capacities (31.09 and 34.63 mg/g), respectively for chromium ions at 25 °C and the favorable Cr(VI) adsorption. Adsorption results proved that Alg–ZnO biocomposite is an excellent solid adsorbent of chromium ion from aqueous solutions.

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

C. Liu, R.-N. Jin, X. Ouyang, Y.-G. Wang, Adsorption behavior of carboxylated cellulose nanocrystal—polyethyleneimine composite for removal of cr (VI) ions. Appl. Surf. Sci. 408, 77–87 (2017)

A. Omer, R. Khalifa, Z. Hu, H. Zhang, C. Liu, X.K. Ouyang, Fabrication of tetraethylenepentamine functionalized alginate beads for adsorptive removal of cr (VI) from aqueous solutions. Int. J. Biol. Macromol. 125, 1221–1231 (2019)

B. Hu, L. Wu, M. Ou, X. Wang, Y. Tang, Sorption studies of chromium (VI) onto cerium/ferroferric oxide composites. J. Inorg. Organomet. Polym. Mater. Lett. 31, 2627–2637 (2021)

V. Yogeshwaran, A. Priya, Removal of hexavalent chromium by adsorption using natural wastes-a review. Adv. Recycl. Waste Manage. 2(3), 1000141 (2017)

M.E. Argun, S. Dursun, C. Ozdemir, M. Karatas, Heavy metal adsorption by modified oak sawdust: thermodynamics and kinetics. J. Hazard. Mater. 141(1), 77–85 (2007)

A. Buasri, N. Chaiyut, K. Tapang, S. Jaroensin, S. Panphrom, Removal of Cu2+ from aqueous solution by biosorption on rice straw-an agricultural waste biomass. Int. J. Environ. Sci. Dev. 3(1), 10 (2012)

A. Verma, S. Chakraborty, J. Basu, Adsorption study of hexavalent chromium using tamarind hull-based adsorbents. Sep. Purif. Technol. 50(3), 336–341 (2006)

H. Zhang, A. Omer, Z. Hu, L.-Y. Yang, C. Ji, X.K. Ouyang, Fabrication of magnetic bentonite/carboxymethyl chitosan/sodium alginate hydrogel beads for Cu (II) adsorption. Int. J. Biol. Macromol. 135, 490–500 (2019)

X.X. Liang, A. Omer, Z. Hu, W. Yg, D. Yu, X.K. Ouyang, Efficient adsorption of diclofenac sodium from aqueous solutions using magnetic amine-functionalized chitosan. Chemosphere 217, 270–278 (2019)

I. Toumi, H. Djelad, F. Chouli, A. Benyoucef, Synthesis of PANI@ ZnO hybrid material and evaluations in adsorption of congo red and methylene blue dyes: structural characterization and adsorption performance. J. Inorg. Organomet. Polym. Mater. 32(1), 112–121 (2022)

M. Najafi, R. Rahimi, Synthesis of novel Zr-MOF/cloisite-30B nanocomposite for anionic and cationic dye adsorption: optimization by design-expert, kinetic, thermodynamic, and adsorption study. J. Inorg. Organomet. Polym. Mater., 1–13 (2022)

M.R. Abukhadra, M.H. Shemy, J.S. Khim, J.S. Ajarem, A.M. Rabie, A.A. Abdelrahman et al., Insight into the adsorption properties of β-cyclodextrin/zeolite-a structure for effective removal of Cd2+, PO43–, and methyl parathion; kinetics and advanced equilibrium studies. J. Inorg. Organomet. Polym. Mater. 2022, 1–15 (2022)

Y. Lu, Z. Wang, X. Ouyang, C. Ji, Y. Liu, F. Huang et al., Fabrication of cross-linked chitosan beads grafted by polyethylenimine for efficient adsorption of diclofenac sodium from water. Int. J. Biol. Macromol. 145, 1180–1188 (2020)

S. Wang, Y. Lu, X. Ouyang, X.X. Liang, D. Yu, L.-Y. Yang et al., Fabrication of chitosan-based MCS/ZnO@ Alg gel microspheres for efficient adsorption of as (V). Int. J. Biol. Macromol. 139, 886–895 (2019)

Y. Song, L.-Y. Yang, Y. Wang, D. Yu, J. Shen, Ouyang X-k. Highly efficient adsorption of pb (II) from aqueous solution using amino-functionalized SBA-15/calcium alginate microspheres as adsorbent. Int. J. Biol. Macromol. 125, 808–819 (2019)

H. Zhao, X.-K. Ouyang, L.-Y. Yang, Adsorption of lead ions from aqueous solutions by porous cellulose nanofiber–sodium alginate hydrogel beads. J. Mol. Liq. 324, 115122 (2021)

J. Shen, X. Xu, X. Ouyang, M. Jin, Adsorption of pb (II) from aqueous solutions using nanocrystalline cellulose/sodium alginate/K-carrageenan composite hydrogel beads. J. Polym. Environ. 2022, 1–12 (2022)

D. Cao, S. Gong, X. Shu, D. Zhu, S. Liang, Preparation of ZnO nanoparticles with high dispersibility based on oriented attachment (OA) process. Nanoscale Res. Lett. 14(1), 1–11 (2019)

X. Zou, H. Fan, Y. Tian, S. Yan, Facile hydrothermal synthesis of large scale ZnO nanorod arrays and their growth mechanism. Mater. Lett. 107, 269–272 (2013)

A. Hassan, A. Abdel-Mohsen, M.M. Fouda, Comparative study of calcium alginate, activated carbon, and their composite beads on methylene blue adsorption. Carbohydr. Polym. 102, 192–198 (2014)

I. Langmuir, The constitution and fundamental properties of solids and liquids. Part I. solids. J. Am. Chem. Soc. 38(11), 2221–2295 (1916)

S. Ehsanpour, M. Riahi, D. Toghraie, Removal of chromium (VI) from aqueous solution using eggshell/poly pyrrole composite. Alexandria Eng. J. 64, 581–589 (2022)

S. Sivaraman, N.M. Anbuselvan, P. Venkatachalam, S.R. Shanmugam, R. Selvasembian, Waste tire particles as efficient materials towards hexavalent chromium removal: characterisation, adsorption behaviour, equilibrium, and kinetic modelling. Chemosphere 295, 133797 (2022)

W.A. Shaltout, G.A. El-Naggar, G. Esmail, A.F. Hassan, Synthesis and characterization of ferric@ nanocellulose/nanohydroxyapatite bio-composite based on sea scallop shells and cotton stalks: adsorption of Safranin-O dye. Biomass Convers. Bioref. 2022, 1–18 (2022)

A. Ricci, K.J. Olejar, G.P. Parpinello, P.A. Kilmartin, A. Versari, Application of Fourier transform infrared (FTIR) spectroscopy in the characterization of tannins. Appl. Spectrosc. Rev. 50(5), 407–442 (2015)

A.B. Abdelrazzak, A.M. Hezma, G.S. El-Bahy, ATR-FTIR spectroscopy probing of structural alterations in the cellular membrane of abscopal liver cells. Biochim. Et Biophys. Acta 1863(11), 183726 (2021)

A. Abouelsayed, A.M. Hezma, G.S. El-Bahy, A.B. Abdelrazzak, Modification of protein secondary structure as an indicator of radiation-induced abscopal effect: a spectroscopic investigation. Spectrochim. Acta Part A 287, 122093 (2023)

A.B. Abdelrazzak, G.S. El-Bahy, FT-IR spectroscopic investigation of ionizing radiation-induced damage in the small intestine of whole-body irradiated rats. Vib. Spectrosc. 99, 146–150 (2018)

A.B. Abdelrazzak, A.M. Labeeb, G.S. El-Bahy, Changes in the dielectric properties of rat lung tissue following x-irradiation. Egypt. J. Basic Appl. Sci. 5(4), 298–302 (2018)

B.V.K. Naidu, S. Bhat, M. Sairam, A. Wali, D. Sawant, S. Halligudi et al., Comparison of the pervaporation separation of a water–acetonitrile mixture with zeolite-filled sodium alginate and poly (vinyl alcohol)–polyaniline semi‐interpenetrating polymer network membranes. J. Appl. Polym. Sci. 96(5), 1968–1978 (2005)

G. Zhang, H. Chen, G. Yang, H.J.J.I. Fu, Polymers, materials, preparation of in situ ZIF-9 grown on sodium alginate/polyvinyl alcohol hydrogels for enhancing Cu (II) adsorption from aqueous solutions. J. Inorg. Organomet. Polym. Mater. 2022, 1–13 (2022)

T. Caykara, S. Demirci, Preparation and characterization of blend films of poly (vinyl alcohol) and sodium alginate. J. Macromol. Sci. Part A 43(7), 1113–1121 (2006)

K. Sowri Babu, A. Ramachandra Reddy, C. Sujatha, K. Venugopal Reddy, A. Mallika, Synthesis and optical characterization of porous ZnO. J. Adv. Ceram. 2(3), 260–265 (2013)

B. Divya, C. Karthikeyan, M. Rajasimman, Chemical synthesis of zinc oxide nanoparticles and its application of dye decolourization. Int. J. Nanosci. Nanatechnol. 14(4), 267–275 (2018)

A.M. Hezma, A. Rajeh, M. Mannaa, An insight into the effect of zinc oxide nanoparticles on the structural, thermal, mechanical properties and antimicrobial activity of Cs/PVA composite. Colloids Surf. A 581, 123821 (2019)

P. Sundarrajan, P. Eswaran, A. Marimuthu, L.B. Subhadra, P. Kannaiyan, One pot synthesis and characterization of alginate stabilized semiconductor nanoparticles. Bull. Korean Chem. Soc. 33(10), 3218–3224 (2012)

A.F. Hassan, F. Alafid, R. Hrdina, Preparation of melamine formaldehyde/nanozeolite Y composite based on nanosilica extracted from rice husks by sol–gel method: adsorption of lead (II) ion. J. Sol-Gel Sci. Technol. 95(1), 211–222 (2020)

R. Sinha, R. Kumar, K. Abhishek, J. Shang, S. Bhattacharya, S. Sengupta et al., Single-step synthesis of activated magnetic biochar derived from rice husk for hexavalent chromium adsorption: equilibrium mechanism, kinetics, and thermodynamics analysis. Groundwater Sustain. Dev. 18, 100796 (2022)

A.F. Hassan, Synthesis of carbon nano-onion embedded metal–organic frameworks as an efficient adsorbent for cadmium ions: kinetic and thermodynamic studies. Environ. Sci. Pollut. Res. 26(23), 24099–24111 (2019)

A. Hsini, Y. Naciri, M. Benafqir, Z. Ajmal, N. Aarab, M. Laabd et al., Facile synthesis and characterization of a novel 1, 2, 4, 5-benzene tetracarboxylic acid doped polyaniline@ zinc phosphate nanocomposite for highly efficient removal of hazardous hexavalent chromium ions from water. J. Colloid Interface Sci. 585, 560–573 (2021)

A.F. Hassan, R. Hrdina, Enhanced removal of arsenic from aqueous medium by modified silica nanospheres: kinetic and thermodynamic studies. Arab. J. Sci. Eng. 47(1), 281–293 (2022)

R.G. Pearson, Hard and soft acids and bases. J. Am. Chem. Soc. 85(22), 3533–3539 (1963)

N. Guo, X. Lv, Q. Yang, X. Xu, H. Song, Effective removal of hexavalent chromium from aqueous solution by ZnCl2 modified biochar: effects and response sequence of the functional groups. J. Mol. Liq. 334, 116149 (2021)

Y.A. Neolaka, Y. Lawa, J.N. Naat, A.A. Riwu, M. Iqbal, H. Darmokoesoemo et al., The adsorption of cr (VI) from water samples using graphene oxide-magnetic (GO-Fe3O4) synthesized from natural cellulose-based graphite (kusambi wood or Schleichera oleosa): study of kinetics, isotherms and thermodynamics. J. Mater. Res. Technol. 9(3), 6544–6556 (2020)

X. Wang, J. Xu, J. Liu, J. Liu, F. Xia, C. Wang et al., Mechanism of cr (VI) removal by magnetic greigite/biochar composites. Sci. Total Environ. 700, 134414 (2020)

C. Su, S. Wang, Z. Zhou, H. Wang, X. Xie, Y. Yang et al., Chemical processes of cr (VI) removal by Fe-modified biochar under aerobic and anaerobic conditions and mechanism characterization under aerobic conditions using synchrotron-related techniques. Sci. Total Environ. 768, 144604 (2021)

X. Zhang, L. Lv, Y. Qin, M. Xu, X. Jia, Z. Chen, Removal of aqueous cr (VI) by a magnetic biochar derived from Melia azedarach wood. Bioresour. Technol. 256, 1–10 (2018)

H.T. Van, L.H. Nguyen, D.-H. Mac, T.T. Vu, L. Ha, X. Nguyen, Removal of Cr (vi) from aqueous solution using magnetic modified biochar derived from raw corncob. New J. Chem. 43(47), 18663–18672 (2019)

K.V. Thomas, L. Bijlsma, S. Castiglioni, A. Covaci, E. Emke, R. Grabic et al., Comparing illicit drug use in 19 european cities through sewage analysis. Sci. Total Environ. 432, 432–439 (2012)

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). No funds, grants, or other support was received.

Author information

Authors and Affiliations

Contributions

AMH: Conceptualization, Investigation, Supervision, Writing - Reviewing and Editing. WAS: Methodology, Formal analysis, Visualization. HAK: Investigation, Formal analysis, Writing- Original draft preparation. GaSEl-B: Conceptualization, Writing - Reviewing and Editing, Supervision. ABA: Investigation, Formal analysis, Writing - Original draft preparation.

Corresponding author

Ethics declarations

Conflict of interest

The authors maintain that they have no conflict of interest to be described in this communication.

Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that would influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hezma, A.M., Shaltout, W.A., Kabary, H.A. et al. Fabrication, Characterization and Adsorption Investigation of Nano Zinc Oxide–Sodium Alginate Beads for Effective Removal of Chromium (VI) from Aqueous Solution. J Inorg Organomet Polym 33, 1400–1408 (2023). https://doi.org/10.1007/s10904-023-02573-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-023-02573-4