Abstract

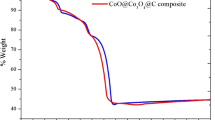

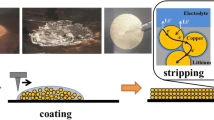

The lithium metal anode has been considered the “holy grail” of lithium batteries, but its safety and stability have been compromised by the formation of unstable dendrites. In this study, a CoO@PAN composite with a core-shell structure was prepared via a simple calcination method and used as a protective layer on the surface of lithium metal tablets. The treated lithium tablets exhibited improved electrochemical properties and cycle stability. Symmetric batteries with the CoO@PAN protective layer demonstrated better cycle stability and showed a 300-hour cycle life, compared to only 100 h for pristine lithium tablets. Ex-situ morphology characterization confirmed that the CoO@PAN protective layer could passivate the electrode surface and mediate smooth Li deposition. Galvanostatic intermittent titration technique (GITT) and activation energy (Ea) tests revealed that the CoO@PAN layer had an improved Li+/Li transformation kinetics, which reduced the formation of dead lithium and dendrites. In LiFePO4 full batteries, the capacity retention of treated lithium tablets increased by 35% after 1000 cycles of consistent operation at a 10 C ultrahigh rate. These results suggest that this effective strategy offers a new perspective on the design of novel protective layers for the next generation of lithium metal batteries.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

G. Zhou, F. Li, H.-M. Cheng, Progress in flexible lithium batteries and future prospects. Energy Environ. Sci. 7, 1307–1338 (2014). https://doi.org/10.1039/c3ee43182g

M.-S. Balogun, W. Qiu, Y. Luo, H. Meng, W. Mai, A. Onasanya, T.K. Olaniyi, Y. Tong, A review of the development of full cell lithium-ion batteries: the impact of nanostructured anode materials. Nano Res. 9, 2823–2851 (2016). https://doi.org/10.1007/s12274-016-1171-1

B. Huang, Z. Pan, X. Su, L. An, Recycling of lithium-ion batteries: recent advances and perspectives. J. Power Sources. 399, 274–286 (2018). https://doi.org/10.1016/j.jpowsour.2018.07.116

G. Zubi, R. Dufo-López, M. Carvalho, G. Pasaoglu, The lithium-ion battery: state of the art and future perspectives. Renew. Sustain. Energy Rev. 89, 292–308 (2018). https://doi.org/10.1016/j.rser.2018.03.002

G. Harper, R. Sommerville, E. Kendrick, L. Driscoll, P. Slater, R. Stolkin, A. Walton, P. Christensen, O. Heidrich, S. Lambert, A. Abbott, K. Ryder, L. Gaines, P. Anderson, Recycling lithium-ion batteries from electric vehicles. Nature. 575, 75–86 (2019). https://doi.org/10.1038/s41586-019-1682-5

X.B. Cheng, R. Zhang, C.Z. Zhao, Q. Zhang, Toward Safe Lithium Metal Anode in Rechargeable Batteries: a review. Chem. Rev. 117, 10403–10473 (2017). https://doi.org/10.1021/acs.chemrev.7b00115

D. Lin, Y. Liu, Y. Cui, Reviving the lithium metal anode for high-energy batteries. Nat. Nanotechnol. 12, 194–206 (2017). https://doi.org/10.1038/nnano.2017.16

P. Albertus, S. Babinec, S. Litzelman, A. Newman, Status and challenges in enabling the lithium metal electrode for high-energy and low-cost rechargeable batteries. Nat. Energy. 3, 16–21 (2017). https://doi.org/10.1038/s41560-017-0047-2

B. Liu, J.-G. Zhang, W. Xu, Joule 2, 833–845 (2018). https://doi.org/10.1016/j.joule.2018.03.008

X. Zhang, A. Wang, X. Liu, J. Luo, Dendrites in lithium metal anodes: suppression, regulation, and elimination. Acc. Chem. Res 52, 3223–3232 (2019). https://doi.org/10.1021/acs.accounts.9b00437

C. Brissot, M. Rosso, J.-N. Chazalviel, S. Lascaud, Dendritic growth mechanisms in lithiumrpolymer cells. J Power Sources 81, 925–929 (1999)

S.-T. Jun-ichi Yamaki, K. Hayashi, K. Saito, Y. Nemoto, M. Arakawa, A consideration of the morphology of electrochemically deposited lithium in an organic electrolyte. J. Power Sources. 74, 219–227 (1998)

C. Ling, D. Banerjee, M. Matsui, Study of the electrochemical deposition of mg in the atomic level: why it prefers the non-dendritic morphology. Electrochim. Acta. 76, 270–274 (2012). https://doi.org/10.1016/j.electacta.2012.05.001

F. Ding, W. Xu, G.L. Graff, J. Zhang, M.L. Sushko, X. Chen, Y. Shao, M.H. Engelhard, Z. Nie, J. Xiao, X. Liu, P.V. Sushko, J. Liu, J.G. Zhang, Dendrite-free lithium deposition via self-healing electrostatic shield mechanism. J. Am. Chem. Soc. 135, 4450–4456 (2013). https://doi.org/10.1021/ja312241y

E. Doron Aurbach, H.T. Zinigrad, Yaron Cohen, A short review of failure mechanisms of lithium metal and lithiated graphite anodes in liquid electrolyte solutions. Solid State Ionics. 148, 405–416 (2002)

Y. Sawada, A. Dougherty, J.P. Gollub, Dendritic and fractal patterns in electrolytic metal deposits. Phys. Rev. Lett. 56, 1260–1263 (1986). https://doi.org/10.1103/PhysRevLett.56.1260

M.D. Tikekar, S. Choudhury, Z. Tu, L.A. Archer, Design principles for electrolytes and interfaces for stable lithium-metal batteries. Nat Energy (2016). https://doi.org/10.1038/nenergy.2016.114

A. Aryanfar, D.J. Brooks, A.J. Colussi, M.R. Hoffmann, Quantifying the dependence of dead lithium losses on the cycling period in lithium metal batteries. Phys. Chem. Chem. Phys. 16, 24965–24970 (2014). https://doi.org/10.1039/c4cp03590a

A.B. Gunnarsdottir, C.V. Amanchukwu, S. Menkin, C.P. Grey, Noninvasive in situ NMR study of “dead lithium” formation and lithium corrosion in full-cell lithium metal batteries. J. Am. Chem. Soc 142, 20814–20827 (2020). https://doi.org/10.1021/jacs.0c10258

X.-R. Chen, C. Yan, J.-F. Ding, H.-J. Peng, Q. Zhang, New insights into “dead lithium” during stripping in lithium metal batteries. J. Energy Chem. 62, 289–294 (2021). https://doi.org/10.1016/j.jechem.2021.03.048

G.C.L. Chen, W. Tang, F. Chen, X. Liu, A robust and lithiophilic three-dimension framework of CoO nanorod arrays on carbon cloth for cycling-stable lithium metal anodes. Mater Today Energy (2020). https://doi.org/10.1016/j.mtener.2020.100520

T. Li, P. Shi, R. Zhang, H. Liu, X.-B. Cheng, Q. Zhang, Dendrite-free sandwiched ultrathin lithium metal anode with even lithium plating and stripping behavior. Nano Res. 12, 2224–2229 (2019). https://doi.org/10.1007/s12274-019-2368-x

X. Sun, X. Zhang, Q. Ma, X. Guan, W. Wang, J. Luo, Revisiting the electroplating process for Lithium-metal anodes for Lithium-metal batteries. Angew Chem. Int. Ed. Engl. 59, 6665–6674 (2020). https://doi.org/10.1002/anie.201912217

K.N. Wood, E. Kazyak, A.F. Chadwick, K.H. Chen, J.G. Zhang, K. Thornton, N.P. Dasgupta, Dendrites and pits: untangling the complex behavior of lithium metal anodes through operando video microscopy. ACS Cent. Sci 2, 790–801 (2016). https://doi.org/10.1021/acscentsci.6b00260

P. Hundekar, S. Basu, X. Fan, L. Li, A. Yoshimura, T. Gupta, V. Sarbada, A. Lakhnot, R. Jain, S. Narayanan, Y. Shi, C. Wang, N. Koratkar, In situ healing of dendrites in a potassium metal battery. Proc. Natl. Acad. Sci. U S A 117, 5588–5594 (2020). https://doi.org/10.1073/pnas.1915470117

W. Guo, W. Zhang, Y. Si, D. Wang, Y. Fu, A. Manthiram, Artificial dual solid-electrolyte interfaces based on in situ organothiol transformation in lithium sulfur battery. Nat. Commun. 12, 3031 (2021). https://doi.org/10.1038/s41467-021-23155-3

L. Wang, L. Zhang, Q. Wang, W. Li, B. Wu, W. Jia, Y. Wang, J. Li, H. Li, Long lifespan lithium metal anodes enabled by Al2O3 sputter coating. Energy Storage Mater. 10, 16–23 (2018). https://doi.org/10.1016/j.ensm.2017.08.001

Y. Ma, L. Wei, Y. Gu, L. Zhao, Y. Jing, Q. Mu, Y. Su, X. Yuan, Y. Peng, Z. Deng, Insulative ion-conducting lithium selenide as the artificial solid-electrolyte interface enabling heavy-duty lithium metal operations. Nano Lett (2021). https://doi.org/10.1021/acs.nanolett.1c02658

C. Wang, X. Fu, S. Lin, J. Liu, W.-H. Zhong, A protein-enabled protective film with functions of self-adapting and anion-anchoring for stabilizing lithium-metal batteries. J. Energy Chem. 64, 485–495 (2022). https://doi.org/10.1016/j.jechem.2021.05.014

H. Lee, T. Han, K.Y. Cho, M.H. Ryou, Y.M. Lee, Dopamine as a Novel Electrolyte Additive for High-Voltage Lithium-Ion Batteries. ACS Appl. Mater. Interfaces. 8, 21366–21372 (2016). https://doi.org/10.1021/acsami.6b06074

J.J. Walton, T. Hiasa, H. Kumita, K. Takeshi, G. Sandford, Fluorocyanoesters as additives for Lithium-Ion Battery Electrolytes. ACS Appl. Mater. Interfaces. 12, 15893–15902 (2020). https://doi.org/10.1021/acsami.9b23028

F. Meng, S. Zhu, J. Gao, F. Zhang, D. Li, Effect of electrolyte additives on the performance of lithium-ion batteries. Ionics. 27, 3821–3827 (2021). https://doi.org/10.1007/s11581-021-04163-1

H. Kang, M. Song, M. Yang, J.- Lee, Lithium metal anode with lithium borate layer for enhanced cycling stability of lithium metal batteries. J Power Sources (2021). https://doi.org/10.1016/j.jpowsour.2020.229286

T. Li, X.Q. Zhang, N. Yao, Y.X. Yao, L.P. Hou, X. Chen, M.Y. Zhou, J.Q. Huang, Q. Zhang, Stable anion-derived solid electrolyte interphase in lithium metal batteries. Angew Chem. Int. Ed. Engl 60, 22683–22687 (2021). https://doi.org/10.1002/anie.202107732

R. Andersson, G. Hernández, J. See, T.D. Flaim, D. Brandell, J. Mindemark, Designing polyurethane solid polymer electrolytes for high-temperature lithium metal batteries. ACS Appl. Energy Mater 5, 407–418 (2022). https://doi.org/10.1021/acsaem.1c02942

W. Arnold, V. Shreyas, Y. Li, M.K. Koralalage, J.B. Jasinski, A. Thapa, G. Sumanasekera, A.T. Ngo, B. Narayanan, H. Wang, Synthesis of fluorine-doped lithium argyrodite solid electrolytes for solid-state lithium metal batteries. ACS Appl. Mater. Interfaces 14, 11483–11492 (2022). https://doi.org/10.1021/acsami.1c24468

J. Zhang, A. Yu, Nanostructured transition metal oxides as advanced anodes for lithium-ion batteries. Sci. Bull. 60, 823–838 (2015). https://doi.org/10.1007/s11434-015-0771-6

Z. Tian, H. Yu, Z. Zhang, X. Xu, Performance improvements of cobalt oxide cathodes for rechargeable lithium batteries. ChemBioEng. Rev. 5, 111–118 (2018). https://doi.org/10.1002/cben.201700008

G.X. Dong, H.J. Li, Y. Wang, W.J. Jiang, Z.S. Ma, Electrospun PAN/cellulose composite separator for high performance lithium-ion battery. Ionics. 27, 2955–2965 (2021). https://doi.org/10.1007/s11581-021-04073-2

X.-Y. Yue, W.-W. Wang, Q.-C. Wang, J.-K. Meng, Z.-Q. Zhang, X.-J. Wu, X.-Q. Yang, Y.-N. Zhou, CoO nanofiber decorated nickel foams as lithium dendrite suppressing host skeletons for high energy lithium metal batteries. Energy Storage Mater. 14, 335–344 (2018). https://doi.org/10.1016/j.ensm.2018.05.017

S. Fang, D. Bresser, S. Passerini, Transition metal oxide anodes for electrochemical energy storage in lithium- and sodium-ion batteries. Adv Energy Mater (2019). https://doi.org/10.1002/aenm.201902485

T. Kim, L.K. Ono, Y. Qi, Elucidating the mechanism involved in the performance improvement of lithium-ion transition metal oxide battery by conducting polymer. Adv Mater. Interfaces (2019). https://doi.org/10.1002/admi.201801785

W. Wu, M. Wang, J. Wang, Z. Wei, T. Zhang, S.-S. Chi, C. Wang, Y. Deng, Transition metal oxides as lithium-free cathodes for solid-state lithium metal batteries. Nano Energy (2020). https://doi.org/10.1016/j.nanoen.2020.104867

Y. Zheng, R. Zhou, H. Zhao, F. Ye, X. Zhang, Y. Ge, Oriented PAN/PVDF/PAN laminated nanofiber separator for lithium-ion batteries. Text. Res. J. 92, 2635–2642 (2021). https://doi.org/10.1177/00405175211005027

L. Cong, H. Zhu, S. Zhang, Y. Xing, J. Xia, X. Meng, P. Yang, Co3O4 anchored on ionic liquid modified PAN as anode materials for flexible lithium-ion batteries. J. Electroanal. Chem. 908, 116105 (2022). https://doi.org/10.1016/j.jelechem.2022.116105

J. Lang, J. Song, L. Qi, Y. Luo, X. Luo, H. Wu, Uniform lithium deposition induced by polyacrylonitrile submicron fiber array for stable lithium metal anode. ACS Appl. Mater. Interfaces 9, 10360–10365 (2017). https://doi.org/10.1021/acsami.7b00181

P. Chen, X. Yuan, Y. Xia, Y. Zhang, L. Fu, L. Liu, N. Yu, Q. Huang, B. Wang, X. Hu, Y. van Wu, Ree, an artificial polyacrylonitrile coating layer confining zinc dendrite growth for highly reversible aqueous zinc-based batteries. Adv. Sci. (Weinh) 8, e2100309 (2021). https://doi.org/10.1002/advs.202100309

Z. Wang, Z. Yu, B. Wang, Z. Guo, N. Wang, Y. Wang, Y. Xia, Nano-Cu-embedded carbon for dendrite-free lithium metal anodes. J. Mater. Chem. A 7, 22930–22938 (2019). https://doi.org/10.1039/c9ta09232c

G. Hou, C. Ci, H. Guo, X. Zhang, Q. Sun, J. Cheng, D. Salpekar, Q. Ai, L. Chen, A.B. Puthirath, K. Kato, S.C. Pardo, R. Vajtai, G. Babu, L. Ci, P.M. Ajayan, Facile construction of a hybrid artificial protective layer for stable lithium metal anode. Chem Eng J (2020). https://doi.org/10.1016/j.cej.2019.123542

Y. Zhang, G. Wang, L. Tang, J. Wu, B. Guo, M. Zhu, C. Wu, S.X. Dou, M. Wu, Stable lithium metal anodes enabled by inorganic/organic double-layered alloy and polymer coating. J. Mater. Chem. A 7, 25369–25376 (2019). https://doi.org/10.1039/c9ta09523c

K.-H. Chen, K.N. Wood, E. Kazyak, W.S. LePage, A.L. Davis, A.J. Sanchez, N.P. Dasgupta, Dead lithium: mass transport effects on voltage, capacity, and failure of lithium metal anodes. J. Mater. Chem. A 5, 11671–11681 (2017). https://doi.org/10.1039/c7ta00371d

J.B. Park, C. Choi, S. Yu, K.Y. Chung, D.W. Kim, Porous lithiophilic Li–Si alloy-type interfacial framework via self-discharge mechanism for stable lithium metal anode with superior rate. Adv Energy Mater (2021). https://doi.org/10.1002/aenm.202101544

Z. Li, J. Fu, S. Zheng, D. Li, X. Guo, Self-healing polymer electrolyte for dendrite-free Li metal batteries with ultra-high-voltage Ni-rich layered cathodes. Small (2022). https://doi.org/10.1002/smll.202200891

C. Zhu, C. Sun, R. Li, S. Weng, L. Fan, X. Wang, L. Chen, M. Noked, X. Fan, Anion–diluent pairing for stable high-energy Li metal batteries. ACS Energy Lett. 7, 1338–1347 (2022). https://doi.org/10.1021/acsenergylett.2c00232

D. Brian, J. Adams, X. Zheng, W. Ren, J.-G. Xu, Zhang, Accurate determination of coulombic efficiency for lithium metal anodes and lithium metal batteries. Adv. Energy Mater 8, 1702097–1702108 (2018). https://doi.org/10.1002/aenm.201702097

J. Xiao, Q. Li, Y. Bi, M. Cai, B. Dunn, T. Glossmann, J. Liu, T. Osaka, R. Sugiura, B. Wu, J. Yang, J.-G. Zhang, M.S. Whittingham, Understanding and applying coulombic efficiency in lithium metal batteries. Nat. Energy. 5, 561–568 (2020). https://doi.org/10.1038/s41560-020-0648-z

D. Wang, Y. Liu, G. Li, C. Qin, L. Huang, Y. Wu, Liquid metal welding to suppress Li dendrite by equalized heat distribution. Adv. Funct. Mater (2021). https://doi.org/10.1002/adfm.202106740

Acknowledgments

This work was supported by the National Natural Science Foundation of China (22075251) and Zhejiang Province Key R&D Plan Project (2021C01176).

Funding

The authors have not disclosed any funding

Author information

Authors and Affiliations

Contributions

To the literature review, material preparation, characterization, and interpretation, all authors participated. XX wrote the manuscript’s first draft, while the other authors offered feedback on earlier drafts. The final manuscript was reviewed and approved by all authors.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xiao, X., Chen, H., Tang, J. et al. CoO@PAN core-sell structure composite as protective layer for stabilizing lithium metal batteries. J Mater Sci: Mater Electron 34, 1468 (2023). https://doi.org/10.1007/s10854-023-10722-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10722-1