Abstract

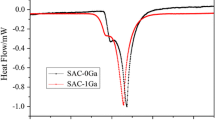

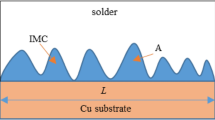

Low silver (Ag) solder alloys e.g., SAC 105 (Sn–1.0Ag–0.5Cu) have attracted a great deal of attention recently due to economic concerns and improved in impact resistance as compared to other SAC solder with higher silver content. This work studies the influence of addition of minor zinc (0.1–0.5 wt%) to SAC105 on the interfacial structure between solder and copper substrate during reflow and after aging. Zn has shown significant solubility in Cu–Sn intermetallic compound (IMC) and formed Cu6(Sn,Zn)5 which resided in the bulk microstructure and at the solder/Cu interface. Results reveal that minor Zn addition decreased the thickness of interfacial Cu6Sn5 IMC after reflow and significantly suppressed the growth of interfacial Cu3Sn after thermal aging without changing the IMC’s morphology. It is suggested that Zn exerts its influence by stabilizing Cu6(Sn,Zn)5 and hindering the flow of Sn and Cu atoms at the solder/IMC and IMC/Cu interface. Nanoindentation results showed that Cu6(Sn,Zn)5 exhibited a higher hardness in comparison to Cu6Sn5 and creep performance of SAC + Zn has improved in comparison to that of SAC105.

Similar content being viewed by others

References

Official Journal of the European Union, DIRECTIVE 2002/95/EC OF The European Parliament and of the Council (2003)

S.K. Kang, D.Y. Shih, D. Leonard, N.Y. Donald, D.W. Henderson, T. Gosselin, A. Sarkhel, N.Y.C. Goldsmith, JOM 56, 34 (2004)

C. Handwerker, U. Kattner, K.-W. Moon, Fundamental Properties of Pb-Free Solder Alloys (Springer, New York, 2007)

W. Liu, N.C. Lee, JOM 56, 26 (2007)

T. Lee, T.R. Bieler, C. Kim, H. Ma, Fundamentals of Lead-Free Solder Interconnect Technology (Springer, New York, 2015)

A.E. Ahmad, Mater. Des. 52, 663 (2013)

K.S. Kim, S.H. Huh, K. Suganuma, Microelectron. Reliab. 43, 259 (2003)

I.E. Anderson, J.W. Walleser, H.F. Laabs, A. Kracher, J. Electron. Mater. 38, 2770 (2010)

Y.W. Shi, J. Tian, H. Hao, Z. Xia, L.F. Guo, J. Alloys Compd. 453, 180 (2008)

T. Laurila, V. Vuorinen, M. Paulasto-Kröckel, Mat. Sci. Eng. R. 68, 1 (2010)

S. Lei, L. Zhang, Adv. Mater. Sci. Eng. 2, 16 (2015)

S.K. Kang, D.Y. Shih, D. Leonard, L. Gignac, D.W. Henderson, S. Cho, J. Electron. Mater. 35, 479–485 (2007)

H.R. Kotadia, O. Mokhtari, O.M. Bottrill, M.P. Clode, M.A. Green, S.H. Mannan, J. Electron. Mater. 39, 2720 (2010)

M. Cho, S. Kang, S.Y. Shih, DY. J. Electron. Mater. 36, 1501 (2007)

M. Amagai, Microelectron. Reliab. 48, 1–16 (2008)

I.E. Anderson, J.W. Walleser, J.L. Harringa, J. Electron. Mater. 38, 2770 (2009)

C.Y. Chou, S.W. Chen, Acta Mater. 54, 2393 (2006)

C.C. Yu, J.-G. Duh, Scr. Mater. 65, 783 (2011)

S. Chen, W. Zhou, P. Wu, J. Electron. Mater. 44, 3920 (2015)

A.S. Maxwell, M.A. Monclus, N.M. Jennet, G. Dean, Polym. Test 30, 366–371 (2011)

W.M. Roellig, M. Mueller, K.-J. Wolter, Microelectron. Reliab. 48, 843 (2008)

V.M.F. Marques, C. Johnston, P.S. Grant, Act. Mater. 61, 2460 (2013)

V.M.F. Marques, B. Wunderle, C. Johnston, P.S. Grant, Acta Mater. 61, 2471 (2013)

D. Mu, H. Huang, K. Nogita, Mater. Lett. 86, 46 (2012)

D. Mu, H. Huang, S.D. Macdonald, K. Nogita, J. Electron. Mater. 42, 304 (2012)

D. Mu, H. Huang, S.D. McDonald, J. Read, K. Nogita, Mater. Sci. Eng. A 566, 126 (2013)

P.Y. Chia, A.S.M.A. Haseeb, S.H. Mannan, Materials 9, 430 (2016)

F. Gao, T. Takemoto, H. Nishikawa, J. Electron. Mater. 35, 905 (2006)

Y.M. Leong, A.S.M.A. Haseeb, Materials 9, 522 (2016)

W.C. Oliver, G.M.J. Pharr, Mater. Res. 19, 3 (2004)

M.A. Meyers, K. Chawla, Mechanical Behavior of materials (Cambridge University Press, Cambridge, 2008)

A. LaLonde, D. Emelander, J. Jeannette, C. Larson, W. Rietz, D. Swenson, D.W. Henderson, J. Electron. Mater. 33, 1545 (2004)

H. Shang, Z.L. Ma, S.A. Belyakov, C.M. Gourlay, J. Alloys Compd. 715, 471 (2017)

J. Mao, B. Reeves, B. Lenz, D. Ruscitto, D. Lewis, J. Electron. Mater. 46, 6319 (2017)

K. Subramaniam, Lead-Free Solders: Materials Reliability for Electronics (Wiley, New York, 2012)

D. Swenson, J. Mater. Sci.: Mater. Electron. 18, 39 (2007)

T. Gancarz, Mater. Lett. 171, 187–190 (2016)

J.M. Song, J. Mater. Res. 22, 4332–4433 (2007)

C.S. Lee, F.S. Shieu, J. Electron. Mater. 35, 1660–1664 (2006)

G. Bruggeman, E.B. Kula, Segregation at Interphase Boundaries.Surfaces and Interfaces II (Springer, Boston, 1968)

S.-J.L. Sintering, Sintering (Elsevier, Amsterdam, 2005)

S. Zhou, O. Mokhtari, M.G. Rafique, V.C. Shunmugasamy, B. Mansoor, H. Nishikawa, J. Alloys Compd. 765, 1243 (2018)

S.L. Tay, A.S.M.A. Haseeb, M.R. Johan, P.R. Munroe, M.Z. Quadir, Intermetallics 33, 8 (2013)

G. Zeng, D. Stuart, D. McDonald, D. Mu, Y. Terada, H. Yasuda, O. Gu, K. Nogita, Intermetallics 54, 20–27 (2014)

M.S. Park, R. Arroyave, Acta Mater 60, 923 (2012)

H. Zhang, X.Y. Wang, L.L. Zheng, S. Sampath, Int. J. Heat Mass Transfer. 47, 2191 (2004)

M.S. Park, R. Arróyave, Acta Mater. 58, 4900 (2010)

A.C. Fischer-Cripps, Mater. Sci. Eng., A 385, 74 (2004)

H.J. Frost, M.F. Ashby, Deformation Mechanism Maps (Pergamon Press, Oxford, 1982)

H. Ohtani, M. Miyashita, K. Ishida, J. Jpn Inst. Metals 63, 685 (1999)

Acknowledgments

The authors would like to acknowledge the financial support from Postgraduate Research Grant (PPP), University of Malaya (Project No. PG176-2016A).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Leong, Y.M., Haseeb, A.S.M.A., Nishikawa, H. et al. Microstructure and mechanical properties of Sn–1.0Ag–0.5Cu solder with minor Zn additions. J Mater Sci: Mater Electron 30, 11914–11922 (2019). https://doi.org/10.1007/s10854-019-01532-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01532-5