Abstract

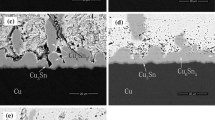

The formation and growth of intermetallic compound (IMC) layer at the interface between Sn3.0Ag0.5Cu (SAC305) solder and Cu–xNi (x = 0, 0.5, 1.5, 5, 10 wt%) substrate during reflowing and aging were investigated. The soldering was conducted at 270 °C using reflowing method, following by aging treatment at 150 °C for up to 360 h. The experimental results indicated that the total thickness of IMC increased with increasing aging time. The scallop-like Cu6Sn5 and planar-like Cu3Sn IMC layer were observed between SAC305 solder and purely Cu substrate. As the content of Ni element in Cu substrate was 0.5% or 1.5%, the scallop-like Cu6Sn5 and planar-like Cu3Sn IMC layer were still found between solder and Cu–Ni substrate and the total thickness of IMC layer decreased with the increasing Ni content. Besides, when the Ni content was up to 5%, the long prismatic (Cu,Ni)6Sn5 phase was the only product between solder and substrate and the total thickness of IMC layer increased significantly. Interestingly, the total thickness of IMC decreased slightly as the Ni addition was up to 10%. In the end, the grains of interfacial IMC layer became coarser with aging time increasing while the addition of Ni in Cu substrate could refine IMC grains.

Similar content being viewed by others

References

A. Wierzbicka-Miernik, K. Miernik, J. Wojewoda-Budka et al., Microstructure and chemical characterization of the intermetallic phases in Cu/(Sn,Ni) diffusion couples with various Ni additions. Intermetallics 59, 23–31 (2015)

H. Ma, A. Kunwar, R. Huang et al., Size effect on IMC growth induced by Cu concentration gradient and pinning of Ag3Sn particles during multiple reflows. Intermetallics. 90, 90–96 (2017)

Y.M. A.S.M.A. Haseeb, M.M. Leong, Arafat In-situ alloying of Sn–3.5Ag solder during reflow through Zn nanoparticle addition and its effects on interfacial intermetallic layers. Intermetallics 54, 86–94 (2014)

L. Liu, Z. Chen, C. Liu, Y. Wu, B. An, Micro-mechanical and fracture characteristics of Cu6Sn5 and Cu3Sn intermetallic compounds under micro-cantilever bending. Intermetallics 76, 10–17 (2016)

C.H. Wang, H.T. Shen, Effects of Ni addition on the interfacial reactions between Sn–Cu solders and Ni substrate. Intermetallics 18, 616–622 (2010)

T.C. Chiu, K. Zeng, R. Stierman et al., in Effect of thermal aging on board level drop reliability for Pb-free BGA packages. Proceedings of the electronic components and technology conference, 2004, vol. 2. (IEEE, 2004), pp. 1256–1262

S.K. Seo, M.G. Cho, S.K. Kang, S.-K. Seo, M.G. Cho, S.K. Kang, J.W. Jang, H.M. Lee et al., in Minor Alloying Effects of Ni or Zn on Microstructure and Microhardness of Pb-free Solders. Proceeding 2011 (ECTC, Orlando, FL, 2011) pp. 84–89

Y.W. Wang, Y.W. Lin, C.T. Tu et al., Effects of minor Fe, Co, and Ni additions on the reaction between Sn–Ag–Cu solder and Cu. J. Alloys Compd. 478, 121–127 (2009)

H.K. Cheng, C.W. Huang, H. Lee et al., Interfacial reactions between Cu and SnAgCu solder doped with minor Ni. J. Alloys Compd. 622, 529–534 (2015)

F. Gao, T. Takemoto, H. Nishikawa, Effects of Co and Ni addition on reactive diffusion between Sn–3.5Ag solder and Cu during soldering and annealing. Mater. Sci. Eng., A 420, 39–46 (2006)

J.Y. Tsai, Y.C. Hu, C.M. Tsai et al., A study on the reaction between Cu and Sn3.5Ag solder doped with small amounts of Ni. J. Electron. Mater. 32, 1203–1208 (2003)

Q.B. Tao, L. Benabou, L. Vivet et al., Effect of Ni and Sb additions and testing conditions on the mechanical properties and microstructures of lead-free solder joints. Mater. Sci. Eng., A 669, 403–416 (2016)

H. Nishikawa, Y.P. Jin, T. Takemoto, Interfacial reaction between Sn–0.7Cu (–Ni) solder and Cu substrate. J. Electron. Mater. 35, 1127–1132 (2006)

X. Yu, X. Hu, Y. Li et al., Effect of alloying Cu substrate on microstructure and coarsening behavior of Cu6Sn5, grains of soldered joints. J. Mater. Sci. Mater. Electron. 26, 2782–2794 (2015)

Y.M. Kim, T.J. Kim, M.Y. Choi, Interfacial reactions between Sn–3.0Ag–0.5Cu solder and Cu–xZn (x = 0–35 wt%) or Cu–xZn–yNi (x = 20 and 25 wt%, y = 15 and 10 wt%) substrates. J. Alloy. Compd. 575, 350–358 (2013)

C.Y. Yu, K.J. Wang, J.G. Duh, Interfacial reaction of Sn and Cu–xZn substrates after reflow and thermal aging. J. Electron. Mater. 39, 230–237 (2010)

T. Takemoto, T. Yamamoto, Effect of additional elements on growth rate of intermetallic compounds at copper/solder interface. J. Jpn. Copper Brass Res. Assoc. 40, 309–316 (2001)

T. Maeshima, H. Ikehata, K. Terui, Y. Sakamoto, Effect of Ni to the Cu substrate on the interfacial reaction with Sn–Cu solder. Mater. Des. 103, 106–113 (2016)

H.K. Kim, K.N. Tu, Kinetic analysis of the soldering reaction between eutectic SnPb alloy and Cu accompanied by ripening. Phys. Rev. B Condens. Matter 53, 16027 (1996)

V. Vuorinen, T. Laurila, T. Mattila, E. Heikinheimo, J.K. Kivilahti, Solid-state reactions between Cu(Ni) alloys and Sn. J. Electron. Mater. 36, 1135–1362 (2007)

J.S. Ha, T.S. Oh, K.N. Tu, Effect of super-saturation of Cu on reaction and intermetallic compound formation between Sn–Cu solder and thin film metallization. J. Mater. Res. 18, 2109–2114 (2003)

J. Shen, M. Zhao, P. He et al., Growth behaviors of intermetallic compounds at Sn–3Ag–0.5Cu/Cu interface during isothermal and non-isothermal aging. J. Alloy. Compd. 574, 451–458 (2013)

D.G. Kim, S.B. Jung, Interfacial reactions and growth kinetics for intermetallic compound layer between In–48Sn solder and bare Cu substrate. J. Alloy. Compd. 386, 151–156 (2005)

X. Hu, S. Xu, Y. Yang et al., Effect of TiO2, nanoparticle addition on electroless Ni-P under bump metallization for lead-free solder interconnection. Mater. Sci. Eng., A 600, 67–75 (2014)

A.A. El-Daly, A.M. El-Taher, T.R. Dalloul, Enhanced ductility and mechanical strength of Ni-doped Sn–3.0Ag–0.5Cu lead-free solders. Mater. Des. 55, 309–318 (2014)

F. Cheng, H. Nishikawa, T. Takemoto, Microstructural and mechanical properties of Sn–Ag–Cu lead-free solders with minor addition of Ni and/or Co. J. Mater. Sci. 43, 3643–3648 (2008)

C.M. Chuang, K.L. Lin, Effect of microelements addition on the interfacial reaction between Sn–Ag–Cu solders and the Cu substrate. J. Electron. Mater. 32, 1426–1431 (2003)

X. Yu, X. Hu, Y. Li et al., Tensile properties of Cu/Sn–58Bi/Cu soldered joints subjected to isothermal aging. J. Mater. Sci. Mater. Electron. 25, 2416–2425 (2014)

C.Y. Yu, W.Y. Chen, J.G. Duh, Improving the impact toughness of Sn–Ag–Cu/Cu–Zn Pb-free solder joints under high speed shear testing. J. Alloy. Compd. 586, 633–638 (2014)

M. Yang, Y. Cao, S. Joo, H. Chen, X. Ma, M. Li, Cu6Sn5 precipitation during Sn-based solder/Cu joint solidification and its effects on the growth of interfacial intermetallic compounds. Alloys Compd. 582, 688–695 (2014)

M. Li, M. Yang, J. Kim, Textured growth of Cu6Sn5, grains formed at a Sn3.5Ag/Cu interface. Mater. Lett. 66, 135–137 (2012)

Acknowledgements

This work was supported by the Nature Science Foundation of China (Nos. 51465039, 51665038, 51765040), Nature Science Foundation of Jiangxi Province (20161BAB206122), Key project of the natural science foundation of Jiangxi province (20171ACB21011) and Postgraduate Innovation special founds of jiangxi province (YC2016-S045).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Hu, X., Jiang, X. et al. Effect of Ni addition to the Cu substrate on the interfacial reaction and IMC growth with Sn3.0Ag0.5Cu solder. Appl. Phys. A 124, 315 (2018). https://doi.org/10.1007/s00339-018-1736-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-1736-9