Abstract

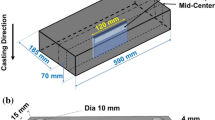

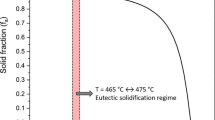

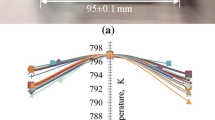

A comprehensive investigation, encompassing microstructural analysis of the subsurface and bulk regions, along with tensile testing near the solidus temperature in the range of 520–580 °C and with two strain rates (10–4 and 10–3 s−1), was conducted on two AA5182 alloy ingots (A and B) cast at casting speeds of 60 and 75 mm \(\bullet\) min−1, respectively. Microstructural analysis revealed an equiaxed grain structure throughout Ingot A, whereas Ingot B transitioned from an equiaxed structure in the subsurface to a columnar grain structure in the bulk region. Regarding intermetallic phases, Ingot A showed predominant Al6(Fe,Mn), whereas Ingot B exhibited a high amount of needle-like Al3Fe. Consequently, Ingot A exhibited superior semisolid tensile properties compared to Ingot B at the given test temperatures. The difference between the two ingots became pronounced at the low strain rate of 10–4 s−1, with the brittle temperature range (BTR) values of Ingot B higher than those of Ingot A. An assessment of the hot-tearing susceptibility (HTS) using the BTR criterion revealed that the HTS of Ingot B was higher than that of Ingot A, confirmed by the occurrence of a large transverse macrocrack during the direct-chill casting of Ingot B.

Similar content being viewed by others

Data and code availability

The measured data are available on request.

References

Van Haaften W, Kool W, Katgerman L (2002) Tensile behaviour of semi-solid industrial aluminium alloys AA3104 and AA5182. Mater Sci Eng A 336(1–2):1–6. https://doi.org/10.1016/s0921-5093(01)01987-6

Farup I, Drezet J-M, Rappaz M (2001) In situ observation of hot tearing formation in succinonitrile-acetone. Acta Mater 49(7):1261–1269. https://doi.org/10.1016/s1359-6454(01)00013-1

Lin S, Aliravci C, Pekguleryuz M (2007) Hot-tear susceptibility of aluminum wrought alloys and the effect of grain refining. Metall Trans A 38:1056–1068. https://doi.org/10.1007/s11661-007-9132-7

Eskin DG, Suyitno, Katgerman L (2004) Mechanical properties in the semi-solid state and hot tearing of aluminium alloys. Prog Mater Sci 49(5):629–711. https://doi.org/10.1016/s0079-6425(03)00037-9

Eskin DG, Suyitno, Katgerman L (2007) A quest for a new hot tearing criterion. Metall Trans A 38:1511–1519. https://doi.org/10.1007/s11661-007-9169-7

Sengupta J, Thomas B, Wells M (2005) The use of water cooling during the continuous casting of steel and aluminum alloys. Metall Trans A 36:187–204. https://doi.org/10.1007/s11661-005-0151-y

Grandfield J, McGlade P (1996) DC casting of aluminium: process behaviour and technology. Mater Forum-Rushcutters Bay 20:29–51

Caron EJ, Baserinia AR, Ng H, Wells MA, Weckman DC (2012) Heat-transfer measurements in the primary cooling phase of the direct-chill casting process. Metall Trans B 43:1202–1213. https://doi.org/10.1007/s11663-012-9688-5

Eskin DG, Zuidema J Jr, Savran V, Katgerman L (2004) Structure formation and macrosegregation under different process conditions during DC casting. Mater Sci Eng A 384(1–2):232–244. https://doi.org/10.1016/j.msea.2004.05.066

Grandfield JF, Davidson CJ, Taylor JA (2000) The columnar to equiaxed transition in horizontal direct chill cast magnesium alloy AZ91. In: Continuous casting, pp 245–250. https://doi.org/10.1002/3527607331.ch36

Suyitno, Eskin DG, Savran V, Kargerman L (2004) Effects of alloy composition and casting speed on structure formation and hot tearing during direct-chill casting of Al-Cu alloys. Metall Trans A 35:3551–3561. https://doi.org/10.1007/s11661-004-0192-7

Turchin A, Eskin DG, Katgerman L (2005) Effect of melt flow on macro-and microstructure evolution during solidification of an Al–4.5% Cu alloy. Mater Sci Eng A 413:98–104. https://doi.org/10.1016/j.msea.2005.09.020

Kurz W, Bezençon C, Gäumann M (2001) Columnar to equiaxed transition in solidification processing. Sci Technol Adv Mater 2(1):185. https://doi.org/10.1016/s1468-6996(01)00047-x

Jones S, Prasada Rao A, Fan Z (2013) Melt conditioned direct chill (MC-DC) casting of Al alloys. Trans Indian Inst Met 66:117–121. https://doi.org/10.1007/s12666-012-0235-5

Dong H, Lee PD (2005) Simulation of the columnar-to-equiaxed transition in directionally solidified Al–Cu alloys. Acta Mater 53(3):659–668. https://doi.org/10.1016/j.actamat.2004.10.019

Suyitno, Katgerman L (2003) Evaluation of mechanical and non-mechanical hot tearing criteria for DC casting of an aluminum alloy. Light Met 2003:753–758

Nagaumi H, Umeda T (2002) Prediction of internal cracking in a direct-chill cast, high strength, Al–Mg–Si alloy. J Light Met 2(3):161–167. https://doi.org/10.1016/s1471-5317(02)00042-1

Suyitno, Kool W, Katgerman L (2004) Finite element method simulation of mushy zone behavior during direct-chill casting of an Al-4.5 pct Cu alloy. Metall Mater Trans A 35:2918–2926. https://doi.org/10.1007/s11661-004-0239-9

M’hamdi M, Benum S, Mortensen D, Fjaer H, Drezet J-M (2003) The importance of viscoplastic strain rate in the formation of center cracks during the start-up phase of direct-chill cast aluminum extrusion ingots. Metall Trans A 34:1941–1952. https://doi.org/10.1007/s11661-003-0159-0

Suyitno, Kool W, Katgerman L (2005) Hot tearing criteria evaluation for direct-chill casting of an Al-4.5 pct Cu alloy. Metall Trans A 36:1537–1546. https://doi.org/10.1007/s11661-005-0245-6

Das SK (2006) Modeling and optimization of direct chill casting to reduce ingot cracking, No. ORNL/TM-2006/56, Secat, Inc., https://doi.org/10.2172/862129

Katgerman L, Van Haaften W, Kool W (2004) Constitutive behaviour and hot tearing during aluminium DC casting. Mater Forum 28:312–318

Suery M, Flemings M (1982) Effect of strain rate on deformation behavior of semi-solid dendritic alloys. Metall Trans A 13:1809–1819. https://doi.org/10.1007/bf02647837

Colley L, Wells M, Maijer D (2004) Tensile properties of as-cast aluminum alloy AA5182 close to the solidus temperature. Mater Sci Eng A 386(1–2):140–148. https://doi.org/10.1016/s0921-5093(04)00928-1

Qassem M, Javidani M, Larouche D, Colbert J, Chen X-G (2022) Effect of chemical composition on the semisolid tensile properties and hot tearing susceptibility of AA6111 DC cast alloys. J. Mater. Sci. 57(46):21519–21536. https://doi.org/10.1007/s10853-022-07960-9

Rakhmonov J, Qassem M, Larouche D, Liu K, Javidani M, Colbert J, Chen X-G (2021) A new approach to determine tensile stress-strain evolution in semi-solid state at near-solidus temperature of aluminum alloys. Metals 11(3):396. https://doi.org/10.3390/met11030396

Algendy AY, Liu K, Chen X (2020) Formation of intermetallic phases during solidification in Al-Mg-Mn 5xxx alloys with various Mg levels. MATEC Web Conf 326:1–10. https://doi.org/10.1051/matecconf/202032602002

Engler O, Kuhnke K, Hasenclever J (2017) Development of intermetallic particles during solidification and homogenization of two AA 5xxx series Al-Mg alloys with different Mg contents. J Alloys Compd 728:669–681. https://doi.org/10.1016/j.jallcom.2017.09.060

Flynn JH (1993) Analysis of DSC results by integration. Thermochim Acta 217:129–149. https://doi.org/10.1016/0040-6031(93)85104-h

Rindler W, Kozeschnik E, Buchmayr B (2000) Computer simulation of the brittle-temperature-range (BTR) for hot cracking in steels. Steel Res 71(11):460–465. https://doi.org/10.1002/srin.200005715

Phillion A, Thompson S, Cockcroft S, Wells M (2008) Tensile properties of as-cast aluminum alloys AA3104, AA6111 and CA31218 at above solidus temperatures. Mater Sci Eng A 497(1–2):388–394. https://doi.org/10.1016/j.msea.2008.07.027

Adamiec J (2011) Assessment of high-temperature brittleness range of the casted alloy AZ91. Mater Sci Forum 690:41–44. Trans Tech Publ. https://doi.org/10.4028/www.scientific.net/MSF.690.41

Long Z, Han Q, Viswanathan S, Ningileri S, Das S, Kuwana K, Hassan M, Khraisheh M, Sabau A, Saito K (2005) Integrated 3D model to simulate solidification and predict hot cracking during DC casting of aluminum alloys. J Light Met 134:1057–1062

Kannengiesser T, Boellinghaus T (2014) Hot cracking tests—an overview of present technologies and applications. Weld World 58:397–421. https://doi.org/10.1007/s40194-014-0126-y

Prokhorov N (1962) The technological strength of metals while crystallising during welding. Weld Prod 9(4):1–8

Suyitno, Eskin DG, Katgerman L (2006) Structure observations related to hot tearing of Al-Cu billets produced by direct-chill casting. Mater Sci Eng A 420:1–7. https://doi.org/10.1016/j.msea.2005.12.037

Lalpoor M, Eskin DG, ten Brink G, Katgerman L (2010) Microstructural features of intergranular brittle fracture and cold cracking in high strength aluminum alloys. Mater Sci Eng A 527(7–8):1828–1834. https://doi.org/10.1016/j.msea.2009.11.003

Emley EF (1976) Continuous casting of aluminium. Int Met Rev 21(1):75–115. https://doi.org/10.1179/imtr.1976.21.1.75

Diepers H-J, Beckermann C, Steinbach I (1999) Simulation of convection and ripening in a binary alloy mush using the phase-field method. Acta Mater 47(13):3663–3678. https://doi.org/10.1016/s1359-6454(99)00239-6

Allen C, O’reilly K, Cantor B, Evans P (1998) Intermetallic phase selection in 1XXX Al alloys. Prog Mater Sci 43(2):89–170. https://doi.org/10.1016/s0079-6425(98)00003-6

Easton M, Wang H, Grandfield J, St John D, Sweet E (2004) An analysis of the effect of grain refinement on the hot tearing of aluminium alloys. Mater Forum 28:224–229. https://doi.org/10.4028/www.scientific.net/msf.630.213

Warrington D, McCartney D (1990) Hot-cracking in aluminium alloys 7050 and 7010—a comparative study. Int J Cast Met Res 3(4):202–208. https://doi.org/10.1080/09534962.1990.11819040

Li S, Apelian D (2011) Hot tearing of aluminum alloys: a critical literature review. Int J Metalcast 5:23–40. https://doi.org/10.1007/bf03355505

Nagaumi H, Suzuki S, Okane T, Umeda T (2008) Hot tearing of machinability improved 2xxx aluminum alloy of high tin content with manganese and chromium addition. Mater Trans 49(2):324–330. https://doi.org/10.2320/matertrans.mra2007167

Acknowledgements

The authors would like to acknowledge the financial supports given by the Fonds de recherche du Québe—Nature et technologies (FRQNT) under Grant No. 2018-LU-252831 and the Mitacs Acceleration under Grant No. IT14722.

Author information

Authors and Affiliations

Contributions

Conceptualization was performed by MQ, DL, and X-GC; methodology was done by MQ, MJ, and DL; investigation and writing—original draft preparation were performed by MQ; validation was revised by DL, MJ, and X-GC; writing—review and editing was done by DL, MJ, JC, and X-GC; supervision was performed by DL, JC, and X-GC. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

There are no conflicts of interest that could potentially affect or bias the results of this work.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qassem, M., Larouche, D., Javidani, M. et al. Semisolid tensile properties near solidus temperature of direct-chill-cast AA5182 alloy and its hot-tearing susceptibility. J Mater Sci 59, 7457–7472 (2024). https://doi.org/10.1007/s10853-024-09625-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09625-1