Abstract

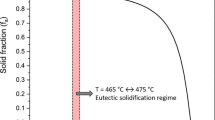

The semisolid tensile properties of two AA6111 direct-chill cast alloys (A and B) have been studied. The Cu, Mn, and Si contents of alloy A are higher than those of alloy B. The microstructures of the alloys were analyzed before tensile testing and after tensile fracture. Isothermal holding was performed in the temperatures of 510, 520, 535, 552, 564 and 580 °C for 1 h to study porosity/void formation in both alloys. Tensile tests were conducted near the solidus temperature in the temperature range of 450–580 °C at a strain rate of 10–4 s−1. The strain during tensile testing was measured using the digital image correlation method to obtain reliable stress–strain curves. The results revealed that the tensile strengths of the alloys gradually decreased to zero with increasing temperature to arrive at the zero-stress temperature, whereas the strains at the failure decreased sharply with increasing temperature until zero-ductility temperature (ZDT) was reached. Moreover, the failure strain of alloy B at any given testing temperature was higher than that of alloy A. Non-mechanical and mechanical hot-tearing criteria were used to study the hot-tearing susceptibilities (HTSs) of the alloys. Considering the mechanical criterion, the ZDT and brittle temperature range of alloy A were lower and larger than those of alloy B, respectively, indicating that the HTS index of alloy A was higher than that of alloy B.

Similar content being viewed by others

References

Li S, Apelian D (2011) Hot tearing of aluminum alloys. Int J Met 5:23–40. https://doi.org/10.1007/bf03355505

Eskin DG, Suyitno L (2004) Katgerman, mechanical properties in the semi-solid state and hot tearing of aluminium alloys. Prog Mater Sci 49:629–711. https://doi.org/10.1016/S0079-6425(03)00037-9

Eskin DG (2008) Direct chill casting: development of the technology. In: Eskin DG (ed) Physical metallurgy of direct chill casting of aluminum alloys. CRC Press, Boca Raton, pp 1–18. https://doi.org/10.1201/9781420062823.ch1

Han Q, Hassan MI, Viswanathan S, Saito K, Das SK (2005) The reheating-cooling method: a technique for measuring mechanical properties in the nonequilibrium mushy zones of alloys. Metall Mater Trans A Phys Metall Mater Sci 36:2073–2080. https://doi.org/10.1007/s11661-005-0328-4

Bolouri A, Liu K, Chen XG (2016) Effects of iron-rich intermetallics and grain structure on semisolid tensile properties of Al-Cu 206 cast alloys near solidus temperature. Metall Mater Trans A Phys Metall Mater Sci. 47:6466–6480. https://doi.org/10.1007/s11661-016-3744-8

Phillion AB, Cockcroft SL, Lee PD (2008) A new methodology for measurement of semi-solid constitutive behavior and its application to examination of as-cast porosity and hot tearing in aluminum alloys. Mater Sci Eng A 491:237–247. https://doi.org/10.1016/j.msea.2008.01.078

Colley LJ, Wells MA, Maijer DM (2004) Tensile properties of as-cast aluminum alloy AA5182 close to the solidus temperature. Mater Sci Eng A 386:140–148. https://doi.org/10.1016/j.msea.2004.07.019

Van Haaften WM, Kool WH, Katgerman L (2002) Hot tearing studies in AA5182. J Mater Eng Perform 11:537–543. https://doi.org/10.1361/105994902770343791

Van Haaften WM, Magnin B, Kool WH, Katgerman L (2002) Constitutive behavior of as-cast AA1050, AA3104, and AA5182. Metall Mater Trans A Phys Metall Mater Sci 33:1971–1980. https://doi.org/10.1007/s11661-002-0030-8

Phillion AB, Thompson S, Cockcroft SL, Wells MA (2008) Tensile properties of as-cast aluminum alloys AA3104, AA6111 and CA31218 at above solidus temperatures. Mater Sci Eng A 497:388–394. https://doi.org/10.1016/j.msea.2008.07.027

Giraud E, Suery M, Coret M (2010) Mechanical behavior of AA6061 aluminum in the semisolid state obtained by partial melting and partial solidification. Metall Mater Trans A Phys Metall Mater Sci 41:2257–2268. https://doi.org/10.1007/s11661-010-0268-5

Lahaie DJ, Bouchard M (2001) Physical modeling of the deformation mechanisms of semisolid bodies and a mechanical criterion for hot tearing. Metall Mater Trans B Process Metall Mater Process Sci 32:697–705. https://doi.org/10.1007/s11663-001-0124-5

Ludwig O, Drezet JM, Ménésès P, Martin CL, Suéry M (2005) Rheological behavior of a commercial AA5182 aluminum alloy during solidification. Mater Sci Eng A 413–414:174–179. https://doi.org/10.1016/j.msea.2005.09.087

Javidani M, Larouche D (2014) Application of cast Al–Si alloys in internal combustion engine components. Int Mater Rev 59:132–158. https://doi.org/10.1179/1743280413Y.0000000027

Rappaz M, Drezet JM, Gremaud M (1999) A new hot-tearing criterion. Metall Mater Trans A Phys Metall Mater Sci 30:449–455. https://doi.org/10.1007/s11661-999-0334-z

Li Y, Li H, Katgerman L, Du Q, Zhang J, Zhuang L (2020) Recent advances in hot tearing during casting of aluminium alloys. Prog Mater Sci. https://doi.org/10.1016/j.pmatsci.2020.100741

Singer A, Jennings PH (1947) Hot-shortness of some aluminum-iron-silicon alloys of high purity. J Inst Met 73:273–284

Shabestari SG, Moemeni H (2004) Effect of copper and solidification conditions on the microstructure and mechanical properties of Al–Si–Mg alloys. J Mater Process Technol 153–154:193–198. https://doi.org/10.1016/j.jmatprotec.2004.04.302

Stanić D, Brodarac ZZ, Li L (2020) Influence of copper addition in AlSi7MgCu alloy on microstructure development and tensile strength improvement. Metals (Basel) 10:1–16. https://doi.org/10.3390/met10121623

Guven Y, Hunt J (1988) Hot tearing in aluminium–copper alloys. Cast Met. https://doi.org/10.1080/09534962.1988.11818955

Eskin DG, Katgerman L (2007) A quest for a new hot tearing criterion. Metall Mater Trans A Phys Metall Mater Sci A 38:1511–1519. https://doi.org/10.1007/s11661-007-9169-7

Kamguo Kamga H, Larouche D, Bournane M, Rahem A (2010) Hot tearing of aluminum–copper B206 alloys with iron and silicon additions. Mater Sci Eng A 1:7413–7423. https://doi.org/10.1016/j.msea.2010.08.025

Nagaumi H, Suzuki S, Okane T, Umeda T (2006) Effect of iron content on hot tearing of high-strength Al-Mg-Si alloy. Mater Trans 47:2821–2827. https://doi.org/10.2320/matertrans.47.2821

Kool WH, Katgerman L (2005) Hot tearing criteria evaluation for direct-chill casting of an Al-4.5 pct Cu alloy. Metall Mater Trans A Phys Metall Mater Sci 36:1537–1546. https://doi.org/10.1007/s11661-005-0245-6

Kou S (2015) A criterion for cracking during solidification. Acta Mater 88:366–374. https://doi.org/10.1016/j.actamat.2015.01.034

Song J, Pan F, Jiang B, Atrens A, Zhang MX, Lu Y (2016) A review on hot tearing of magnesium alloys. J Magnes Alloy 4:151–172. https://doi.org/10.1016/j.jma.2016.08.003

Won YM, Yeo TJ, Seol DJ, Kyu Hwan O (2000) A new criterion for internal crack formation in continuously cast steels. Metall Mater Trans B Process Metall Mater Process Sci 31:779–794. https://doi.org/10.1007/s11663-000-0115-y

Krbetschek C, Trân R, Wemme H, Ullmann M, Prahl U, Rafaja D (2021) Hot crack susceptibility of cast Mg97Y2Zn1. Eng Rep. https://doi.org/10.1002/eng2.12380

Sweet L, Zhu SM, Gao SX, Taylor JA, Easton MA (2011) The effect of iron content on the iron-containing intermetallic phases in a cast 6060 aluminum alloy. Metall Mater Trans A Phys Metall Mater Sci 42:1737–1749. https://doi.org/10.1007/s11661-010-0595-6

Clyne TW, Kurz W (1981) Solute redistribution during solidification with rapid solid state diffusion. Metall Trans A Phys Metall Mater Sci A 12:965–971. https://doi.org/10.1007/BF02643477

Liu J, Kou S (2017) Susceptibility of ternary aluminum alloys to cracking during solidification. Acta Mater 125:513–523. https://doi.org/10.1016/j.actamat.2016.12.028

Rindler W, Kozeschnik E, Buchmayr B (2000) Computer simulation of the brittle-temperature-range (BTR) for hot cracking in steels. Steel Res 71:460–465. https://doi.org/10.1002/srin.200005715

Drezet JM, Allehaux D (2008) Application of the rappaz-drezet-gremaud hot tearing criterion to welding of aluminium alloys. Hot Crack Phenom Welds I I:19–37. https://doi.org/10.1007/978-3-540-78628-3_2

Sweet L, Easton MA, Taylor JA, Grandfield JF, Davidson CJ, Lu L, Couper MJ, Stjohn DH (2013) Hot tear susceptibility of Al-Mg-Si-Fe alloys with varying iron contents. Metall Mater Trans A 44A:5396–5407. https://doi.org/10.1007/s11661-012-1562-1

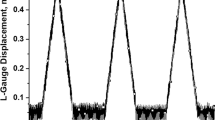

Rakhmonov J, Qassem M, Larouche D, Liu K, Javidani M, Chen X-G, Colbert J (2021) A new approach to determine tensile stress–strain evolution in semi-solid state at near-solidus temperature of aluminum alloys. Metals (Basel) 11:1–13

Sutton M, Orteu J, Schreier H (2009) Image correlation for shape, motion and deformation measurements

Dong YL, Pan B (2017) A review of speckle pattern fabrication and assessment for digital image correlation. Exp Mech 57:1161–1181. https://doi.org/10.1007/s11340-017-0283-1

Stinville JC, Echlin MP, Texier D, Bridier F, Bocher P, Pollock TM (2016) Sub-Grain scale digital image correlation by electron microscopy for polycrystalline materials during elastic and plastic deformation. Exp Mech 56:197–216. https://doi.org/10.1007/s11340-015-0083-4

Weidmann E, Guesnier A (2008) Metallographic preparation of aluminium and aluminum alloys. Struers, Ballerup

Chen XG, Langlais J (2000) Solidification behavior of AA6111 automotive alloy. Mater Sci Forum 331:215–222. https://doi.org/10.4028/www.scientific.net/msf.331-337.215

Larouche D (2007) Computation of solidification paths in multiphase alloys with back-diffusion. Calphad Comput Coupling Phase Diagr Thermochem 31:490–504. https://doi.org/10.1016/j.calphad.2007.04.002

Liu YL, Kang SB (1997) The solidification process of Al–Mg–Si alloys. J Mater Sci 2:1443–1447

Brito C, Costa TA, Vida TA, Bertelli F, Cheung N, Spinelli JE, Garcia A (2015) Characterization of dendritic microstructure, intermetallic phases, and hardness of directionally solidified Al-Mg and Al-Mg-Si alloys. Metall Mater Trans A Phys Metall Mater Sci 46:3342–3355. https://doi.org/10.1007/s11661-015-2967-4

Kumar S, Grant PS, O’Reilly KAQ (2012) Fe bearing intermetallic phase formation in a wrought Al-Mg-Si alloy. Trans Indian Inst Met 65:553–557. https://doi.org/10.1007/s12666-012-0221-y

Wang ER, Hui XD, Chen GL (2011) Eutectic Al–Si–Cu–Fe–Mn alloys with enhanced mechanical properties at room and elevated temperature. Mater Des 32:4333–4340. https://doi.org/10.1016/j.matdes.2011.04.005

Hosford WF (2010) Mechanical behavior of materials. Cambridge University Press, New York

Sih GC, Madenci E (1983) Crack growth resistance characterized by the strain energy density function. Eng Fract Mech 18:1159–1171. https://doi.org/10.1016/0013-7944(83)90008-5

Gdoutos EE (2012) Crack growth instability studied by the strain energy density theory. Arch Appl Mech 82:1361–1376. https://doi.org/10.1007/s00419-012-0690-9

Mitchell JB, Cockcroft SL, Viano D, Davidson C, Stjohn D (2007) Determination of strain during hot tearing by image correlation. Metall Mater Trans A Phys Metall Mater Sci 38:2503–2512. https://doi.org/10.1007/s11661-007-9221-7

Hu B, Li Z, Li D, Ying T, Zeng X, Ding W (2021) A hot tearing criterion based on solidification microstructure in cast alloys. J Mater Sci Technol 105:68–80. https://doi.org/10.1016/j.jmst.2021.06.071

Cao G, Kou S (2006) Hot tearing of ternary Mg–Al–Ca alloy castings. Metall Mater Trans A Phys Metall Mater Sci 37:3647–3663. https://doi.org/10.1007/s11661-006-1059-x

Vero J (1936) The hot shortness of aluminum alloys. Met Ind 48:431–442

Easton M, Sweet L, Wang H, Grandfield J, Davidson CJ, Stjohn DH, Couper MJ (2012) Observation and prediction of the hot tear susceptibility of ternary Al-Si-Mg alloys. Metall Mater Trans A Phys Metall Mater Sci 43:3227–3238. https://doi.org/10.1007/s11661-012-1132-6

Fabrègue D, Deschamps A, Suéry M, Poole WJ (2006) Rheological behavior of Al-Mg-Si-Cu alloys in the mushy state obtained by partial remelting and partial solidification at high cooling rate. Metall Mater Trans A Phys Metall Mater Sci 37:1459–1467. https://doi.org/10.1007/s11661-006-0090-2

Adamiec J (2011) Assessment of high-temperature brittleness range of the casted alloy AZ91. Mater Sci Forum 690:41–44. https://doi.org/10.4028/www.scientific.net/MSF.690.41

Acknowledgements

The authors would like to acknowledge the financial support given by the Fonds de recherche du Québec—Nature et technologies (FRQNT) under Grant No. 2018-LU-252831 and the Mitacs Acceleration under Grant No. IT14722.

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qassem, M., Javidani, M., Larouche, D. et al. Effect of chemical composition on the semisolid tensile properties and hot tearing susceptibility of AA6111 DC cast alloys. J Mater Sci 57, 21519–21536 (2022). https://doi.org/10.1007/s10853-022-07960-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07960-9