Abstract

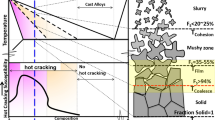

The effects of iron-rich intermetallics and grain size on the semisolid tensile properties of Al-Cu 206 cast alloys near the solidus were evaluated in relation to the mush microstructure. Analyses of the stress–displacement curves showed that the damage expanded faster in the mush structure dominated by plate-like β-Fe compared to the mush structure dominated by Chinese script-like α-Fe. While there was no evidence of void formation on the β-Fe intermetallics, they blocked the interdendritic liquid channels and thus hindered liquid flow and feeding during semisolid deformation. In contrast, the interdendritic liquid flows more freely within the mush structure containing α-Fe. The tensile properties of the alloy containing α-Fe are generally higher than those containing β-Fe over the crucial liquid fraction range of ~0.6 to 2.8 pct, indicating that the latter alloy may be more susceptible to stress-related casting defects such as hot tearing. A comparison of the semisolid tensile properties of the alloy containing α-Fe with different grain sizes showed that the maximum stress and elongation of the alloy with finer grains were moderately higher for the liquid fractions of ~2.2 to 3.6 pct. The application of semisolid tensile properties for the evaluation of the hot tearing susceptibility of experimental alloys is discussed.

Similar content being viewed by others

References

K.M. Kareh, P.D. Lee, R.C. Atwood, T. Connolley, and C.M. Gourlay: Nat. Commun., 2014, vol. 5, p. 3782.

L.J. Colley, M.A. Wells, and D.M. Maijer: Mater. Sci. Eng. A, 2004, vol. 386, pp. 140–48.

A.B. Phillion, S. Thompson, S.L. Cockcroft, and M.A. Wells: Mater. Sci. Eng. A, 2008, vol. 497, pp. 388–94.

W.M. Van Haaften, W.H. Kool, and L. Katgerman: Mater. Sci. Eng. A, 2002, vol. 336, pp. 1–6.

G. Chen, J. Jiang, Z. Du, F. Han, and H.V. Atkinson: Mater. Des., 2014, vol. 54, pp. 1–5.

I. Farup, J.M. Drezet, and M. Rappaz: Acta Mater., 2011, vol. 49, pp. 1261–69.

D.G. Eskin, Suyitno, and L. Katgerman: Prog. Mater. Sci., 2004, vol. 49, pp. 629–711.

D.G. Eskin and L. Katgerman: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1511–19.

E. Giraud, M. Suery, and M. Coret: Metall. Mater. Trans. A, 2011 vol. 42A, pp. 3370–77.

O. Ludwig, J.M. Drezet, P. Ménésès, C.L. Martin, and M. Suéry: Mater. Sci. Eng. A, 2005, vol. 413–14, pp. 174–79.

D. Fabrègue, A. Deschamps, M. Suery, and J.M. Drezet: Acta Mater., 2006, vol. 54, pp. 5209–20.

A.K. Dahle, T. Sumitomo, and S. Instone: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 105–13.

A.K. Dahle and L. Arnberg: Acta Mater., 1997, vol. 45, pp. 547–59.

A. Alankar and M.A. Wells: Mater. Sci. Eng. A, 2010, vol. 527, pp. 7812–20.

S.M. Mohseni, A.B. Phillion, and D.M. Maijer: Mater. Sci. Eng. A, 2016, vol. 649, pp. 382–89.

V. Mathier, P.-D. Grasso, and M. Rappaz: Metall. Mater. Trans. A, 2008, vol. 39A, 1399–409.

E. Giraud, M. Suery, and M. Coret: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 2257–68.

J. Liu, L. Qi, P. Liu, J. Guan, and J. Zhou: Mater. Sci. Eng. A, 2014, vol. 596, pp. 157–64.

A.B. Phillion, S.L. Cockcroft, and P.D. Lee: Mater. Sci. Eng. A, 2008, vol 491, pp. 237–47.

C. Puncreobutr, A.B. Phillion, J.L. Fife, P. Rockett, A.P. Horsfield, and P.D. Lee: Acta Mater., 2014, vol. 79, pp. 292–303.

B. Cai, S. Karagadde, L. Yuan, T.J. Marrow, T. Connolley, and P.D. Lee: Acta Mater., 2014, vol. 76, pp. 371–80.

C. Puncreobutr, A.B. Phillion, J.L. Fife, and P.D. Lee: Acta Mater., 2014, vol. 64, pp. 316–25.

M. Sistaninia, A.B. Phillion, J.M. Drezet, and M. Rappaz: Acta Mater., 2012, vol. 60, p. 6793.

A.B. Phillion, P.D. Lee, E. Maire, and S.L. Cockcroft: Metall. Mater. Trans. A, 2008, vol. 39A, 2459–69.

D. Fabrègue, a. Deschamps, M. Suéry, and W.J. Poole: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1459–67.

O. Ludwig, J.-M. Drezet, C.L. Martin, and M. Suéry: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 1525–35.

A. B. Phillion, R.W. Hamilton, D. Fuloria, A.C.L. Leung, P. Rockett, T. Connolley, and P.D. Lee: Acta Mater., 2011, vol. 59, pp. 1436–44.

C. Puncreobutr, P.D. Lee, K.M. Kareh, T. Connolley, J.L. Fife, and A.B. Phillion: Acta Mater., 2014, vol. 68, pp. 42–51.

S. Terzi, L. Salvo, M. Suéry, N. Limodin, J. Adrien, E. Maire, Y. Pannier, M. Bornert, D. Bernard, M. Felberbaum, M. Rappaz, and E. Boller: Scr. Mater., 2009, vol. 61, pp. 449–52.

K. Hu, A.B. Phillion, D.M. Maijer, and S.L. Cockcroft: Scr. Mater., 2009, vol. 60, pp. 427–30.

L. Sweet, M.A. Easton, J.A. Taylor, J.F. Grandfield, C.J. Davidson, L. Lu, M.J. Couper, and D.H. Stjohn:Metall. Mater. Trans. A, 2013, vol. 44A, pp. 5396–407.

G.K. Sigworth and J. Major: TMS Light Met., 2006, pp. 795–800.

G.K. Sigworth and F. DeHart: Trans. Am. Foundry Soc., 2003, vol. 111, pp. 341–45.

G.K. Sigworth, AMD 305 Final Report, USCAR, 2002.

F. D’Elia, C. Ravindran, D. Sediako, K.U. Kainer, and N. Hort: Mater. Des., 2014, vol. 64, pp. 44–55.

H. Kamguo Kamga, D. Larouche, M. Bournane, and A. Rahem: Mater. Sci. Eng. A, 2010, vol. 527, pp. 7413–23.

K. Liu, X. Cao, and X.-G. Chen: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 2004–16.

K. Liu, X. Cao, and X.G. Chen: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 1231–40.

K. Liu, X. Cao, and X.-G. Chen: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 2498–507.

K. Liu, X. Cao, and X.-G. Chen: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 1566–75.

Y. Birol: J. Alloys Compd., 2009, vol. 486, pp. 173–77.

M. Rappaz, J.-M. Drezet, and M. Gremaud: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 449–55.

H. Nagaumi, S. Suzuki, T. Okane, and T. Umeda: Metall. Mater. Trans. A, 2006, vol. 47A, pp. 2821–27.

L. Sweet, S.M. Zhu, S.X. Gao, J.A. Taylor, and M.A. Easton: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 1737–49.

Acknowledgments

The authors would like to acknowledge the financial support from the Natural Sciences and Engineering Research Council of Canada (NSERC) and from Rio Tinto Aluminum through the NSERC Industrial Research Chair in Metallurgy of Aluminum Transformation at the University of Québec at Chicoutimi. The authors would also like to thank Ms. E. Brideau and Mr. Dany Racine for their assistance during the semisolid tensile tests performed on the Gleeble 3800 thermomechanical simulator.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 27, 2016.

Rights and permissions

About this article

Cite this article

Bolouri, A., Liu, K. & Chen, XG. Effects of Iron-Rich Intermetallics and Grain Structure on Semisolid Tensile Properties of Al-Cu 206 Cast Alloys near Solidus Temperature. Metall Mater Trans A 47, 6466–6480 (2016). https://doi.org/10.1007/s11661-016-3744-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3744-8