Abstract

Due to very significant improvements in the mechanical performance of solid wood, densification after partial or full delignification has received renewed attention. While studies predominantly focus on isolated cases, e.g., one wood species densified in one anatomical direction, systematic investigations of the effect of wood structure on the densification process are seldom performed. The present study compares the deformation patterns of one representative softwood (spruce) and hardwood (poplar), respectively, in transverse compression. In terms of variables, the native and partially delignified state, wet and dry conditions, and three different orientations of wood grain are considered. It shows that the structural inhomogeneity of spruce wood, with low-density earlywood and high-density latewood, governs its densification pattern and hinders defect-free densification. Contrarily, diffuse-porous poplar is structurally more homogeneous, which together with more efficient softening by delignification leads to favorable densification behavior. Overall, delignification led to a significant softening of both wood species in transverse compression, which greatly enhanced the softening effect of high wood moisture content.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Wood is one of the oldest building materials used for many thousands of years on almost all continents. Due to its natural growth, light weight and high strength-to-weight ratio, higher than that of some steels, it has been used for houses, ships, cars and airplanes [1]. The Ansaldo A.1 "Balilla" biplane of 1918 is a perfect example of the skillful and clever use of wood in early engineering. Six different species (spruce, elm, walnut, alder, rosewood and pine) were used for different parts of the aircraft, making it light, yet elastic and resistant, and thus suitable for flight [2]. After a significant decline due to the preferred use of metals and fossil-based polymers and composites, wood presently experiences a revival. The fact that wood can be sustainably grown and the favorable carbon balance and environmental footprint of wood products supports this trend. When compared to tensile and hardness properties of high-performance materials, wood shows clearly inferior mechanical performance, which has inspired various strategies for performance improvement, among which densification seems very promising. This goal can be achieved by a variety of different methods [3, 4]. Besides well-known processes such as thermo-mechanical (TM) [5, 6], thermo-hydro-mechanical (THM) [7, 8] and viscoelastic thermal compression (VTC) [9], a lot of research has been recently done on the densification of partially or completely delignified wood. As a result of delignification combined with densification, the typical modulus of elasticity (MOE) of densified wood ranges between 30 and 50 GPa and tensile strength amounts to 300–550 MPa, which corresponds to improvement of a factor 3–4 compared to untreated wood [4]. Thereby, it is assumed that four occurring phenomena are responsible allowing mechanical improvements higher than that caused by densification alone. First, it is assumed that a partial or complete extraction of amorphous wood polymers reduces the rigidity of the wood cell wall. Thus, wood can be densified to a higher extent without damaging the cellular structure [10, 11]. Second, due to the delignification, cell walls exhibit a more flexible character. It was shown that after complete delignification, cell walls are interlocking with each other, which was suggested to be a reason for the improvements in tensile stiffness and strength [12, 13]. Third, delignification increases the relative percentage of strength-giving cellulose [14, 15]. Forth, due to the extraction of hemicelluloses and lignin, OH groups of the cellulose chains are exposed which in turn facilitates the formation of additional hydrogen bonds between cellulose chains [14, 16]. The variables of delignification–densification procedures reported in the literature include delignification chemistry, which may be acidic [12] or alkaline [17], extent of delignification (chemical solution concentration, temperature and duration) [11, 16, 18, 19] and wood species (hardwood or softwood). With regard to the mechanical densification procedure as such Shams et al. [10, 20, 21] report effects of varying examined pressure and holding time as well as the effects of delignification and resin impregnation on densification, which improves the malleability of wood and thus facilitates compression. Besides these studies, in-depth information on the deformation patterns in wood leading to densification and the effect of lignin removal on these deformation patterns are scarce.

Due to the structural and mechanical anisotropy of wood, and its specific cellular structure with distinct growth zones of variable density, the choice of anatomical direction for densification is of significance with regard to the maximum densification which can be achieved, and also the avoidance of structural damage to the wood during densification. While the majority of studies chose radial compression for densification [12, 16], also tangential compression was reported [15, 17]. However, due to the specific annual ring structure of spruce wood chosen for the latter study, overall densification was limited and considerable damage led to substantial reduction in transverse tensile strength of densified veneers, even though excellent performance parallel to the fiber direction was achieved [22]. This highlights the fact that, in order to exploit the full potential of densified wood, cell wall damage arising during compression must be kept at a minimum level [23], and maximum densification must be achieved. For this purpose, we aim to contribute fundamental knowledge on deformation patterns during transverse compression in different anatomical directions for one representative softwood and hardwood species, respectively, in the present study. Thereby, the aim is to investigate whether the different wood species have a favorable direction of compression in which the specimens can be densified to a high degree without damage (cracks, delamination) occurring. Additionally, these deformation patterns will be compared for untreated and partially delignified wood in order to provide a better understanding of the effect of delignification on deformation and densification patterns, as it is assumed that a partial delignification reduces the stiffness and strength of the wood. Thereby, the aim is to investigate whether partial delignification softens the wood and thus reduces potential damage regardless of the direction of compression.

Materials and methods

Raw material

The raw materials in the present study were spruce and poplar wood stored at 20 °C and 65% relative humidity with an average air-dried (~ 12% moisture content (MC)) density of ~ 0.47 and ~ 0.36 g cm−3, respectively. Specimens with the dimensions of 100 mm length (axial) by 50 mm width and 6 mm height were prepared from one board to ensure matching within species. For each species, specimens were cut in their height in parallel to the ring orientation (0°, tangential load direction), 45° and perpendicular to the ring orientation (90°, radial load direction).

Alkaline treatment

Partial extraction of amorphous wood polymers, in particular hemicelluloses and lignin, was conducted according to previous studies [17, 22] with minor adaptions. Oven-dried specimens were placed into a desiccator and were subsequently impregnated with an aqueous solution of 2.5 mol L−1 sodium hydroxide (NaOH) (Carl Roth GmbH + Co. KG, Karlsruhe, Germany) and 0.4 mol L−1 sodium sulfite (Na2SO3) (Carl Roth GmbH + Co. KG, Karlsruhe, Germany). To ensure complete impregnation, specimens were kept under vacuum for 24 h. Twenty specimens of each species were then put into a customary stainless steel pressure cooker (Sicomatic® classic, WMF Group GmbH, Geislingen/Steige, Germany). Alkaline solution was poured into the pressure cooker until specimens were completely covered. To ensure complete contact between wood and alkaline solution, batches of five specimens each were separated with stainless steel meshes. Chemical treatment took place at ~ 119 °C and a pressure of ~ 0.19 MPa for 4 h. Subsequently, the treated veneers were repeatedly washed in deionized water (DW) until the washing water reached a stable pH of ~ 7 and were then stored under completely water saturated (WS) conditions until further use. After chemical treatment, specimens exhibited a mass loss of ~ 20% and ~ 34% for spruce and poplar, respectively. These values are in good agreement with previous literature, where a similar treatment procedure was conducted for spruce and poplar veneers [17]. FTIR analysis [17] showed that the applied alkaline treatment extracts a distinct amount of hemicelluloses, while lignin is seemingly less affected. However, the Klason lignin analysis in the study mentioned above indicates that also a part of the acid-insoluble lignin is extracted.

Evaluation of compression behavior

Before the compression test was conducted, specimens with the dimensions of 15 × 15 × ~ 6 mm3 (length × width × height) were prepared from the WS partially delignified wood specimens. One half of the cut samples was left under WS conditions; the other half was first dried by means of freeze-drying for 24 h and then put into a climate chamber (CC) (20 °C, 65% rel. humidity) for two weeks. Freeze-drying was performed in order to prevent collapse of specimens softened by lignin removal. For reference, untreated wood samples with the same dimensions were prepared. One half was impregnated with DW until they were completely WS, and the other half was stored with the dried partially delignified wood samples. The two levels of MC chosen here, i.e., complete saturation and ~ 12% MC, were chosen because most densification studies performed are carried out with some level of MC between these two extremes. A detailed test matrix of the different pre-treatments and pre-conditionings can be found in Table 1.

Densification was carried out with a universal testing machine (Zwick‐Roell 20 kN, ZwickRoell, Ulm, Germany) equipped with a 20-kN load cell (ZwickRoell, Ulm, Germany). The pressing speed was 5 mm min−1 and the strain was measured via the crosshead travel. Specimens were compressed until the specimen’s thickness reached 1 mm. Five specimens were tested for each ring orientation, pre-treatment and pre-conditioning. Obtained stress–strain curves for each variant were then averaged and plotted as one stress–strain curve.

Microscopic analysis

Incident light microscopy (Olympus digital microscope DSX 1000, Shinjuku, Tokyo, Japan) was carried out before and after compression. Since the specimens were compressed at room temperature, the WS samples did not dry during compression and therefore showed considerable spring-back once the applied load was removed. To ensure that the microscopic analysis was not distorted by the distinct spring-back, it was decided to analyze only CC samples. A flat and clean surface was provided by sanding. Specimens were first roughly sanded using sandpaper with a grit number P 240 followed by a fine sanding with sandpaper (P 600). Sanding was performed using a commercial disc sander.

Determination of dimensional changes

The degree of compression was defined based on the formula:

where \(\mathrm{DoC}\) is the degree of compression of the compressed specimens, \({\mathrm{T}}_{\mathrm{uc}}\) is the thickness of uncompressed specimens, and \({\mathrm{T}}_{\mathrm{c}}\) is the thickness of compressed specimens. The thickness of the specimens was determined by image analysis of micrographs.

Results and discussion

Compression and deformation patterns of untreated wood

Figure 1 shows a schematic stress–strain relationship of wood in transverse compression. Like all cellular solids [24], wood under transverse compression shows an initial linear elastic phase until the onset of cell collapse by buckling [25,26,27]. The point at which cells start to buckle plastically is termed stress at proportional limit. This first phase is then followed by a distinct plateau region during which cells progressively fold in. Finally, upon complete collapse, the wood transitions into the densification region in which stress again increases as the bulk cell wall material is compressed.

Schematic stress–strain relationship of wood under transverse compression (modified graph from [26])

When the applied stress is removed, a certain elastic spring-back is observed. Spring-back can be minimized by applying temperature [7] or impregnation with resins [28]. No such efforts were undertaken in the present study, because the primary interest was in deformation patterns instead of maximum and stable densification. In general, all specimens tested here follow the deformation pattern of cellular solids as revealed by the respective stress–strain graphs (Fig. 2, 5, 6 and 9). At a MC of roughly 12%, spruce wood (Fig. 2a) exhibited the highest proportional limit (PL) stress when loaded tangentially. Afterward, the curve slightly dropped during the plastic phase and, as the specimens reached a strain of about 40%, stress again increased significantly.

Microscopic analysis of specimens showing similar behavior during tangential compression [29, 30] indicated that the measured gross deformation appeared to be a combination of cell wall bending and bending of the latewood as a single layer. Thus, during buckling of the latewood, the stress decreases with increasing compressive strain until readjustment of the position of the collapsed latewood and its interaction with the earlywood layers results in a stabilized structure that causes the steep increase in compressive stress in the densification region [29]. The deformation pattern shown in Fig. 3 confirms these findings. As seen in the micrograph of tangentially compressed wood (Fig. 3d), low-density earlywood undergoes very high shear deformation compared to the much more rigid latewood bands up to a degree where delamination at the latewood–earlywood interface takes place (red arrows).

Micrographs showing untreated spruce wood structure before (top) and after (bottom) force application in tangential a & d, 45° to the ring orientation b & e and radial c & f direction. Blue arrows indicating the direction of compression and approx. DoC. Red arrows indicating damages of the wood structure due to compression

The averaged curve of specimens loaded in radial direction displays a similar slope of the elastic region compared to tangential loading. After exceeding the PL stress, the curve exhibited an irregular saw-tooth shape during the collapse phase. A similar shape of the curve was also identified by Bodig [30], who stated that each tooth represents a “micro-stress–strain curve” of consecutively collapsing earlywood layers. After reaching a compression strain of about 30%, the densification phase started. Differently from tangential and radial loading, compression at an intermediate angle of 45° results in a moderate slope in the elastic region, followed by an early switch to collapse at low PL stress. Clearly, the cellular structure of wood shows low resistance toward shear deformation. When comparing microscopy corresponding to the stress–strain curves in Fig. 2a, tangential compression is initiated by buckling failure of strong and dense latewood bands in combination with shear deformation in low-density earlywood. By contrast, at an angle of 45° and in radial compression, the majority of deformation is experienced by earlywood, resulting in significantly lower stress levels.

Compared to spruce wood, with distinctly contrasting low-density earlywood and high-density latewood bands, the annual ring structure of poplar, with pores embedded in fibrous tissue distributed across entire annual rings, is much less conspicuous (Fig. 4). In accordance with this more homogeneous anatomy, also the deformation pattern as represented by stress–strain curves exhibits fewer differences compared to spruce (Fig. 2b).

Comparing poplar specimens in the elastic region, radially loaded specimens exhibited the steepest slope with highest PL stress. Tangentially loaded specimens showed an upward curvature as load was applied followed by a straight line until the PL stress was reached. The slope in the elastic region was almost similar to that of samples which were loaded at an angle of 45° relative to the ring orientation. Specimens loaded at 45° showed very similar shape for both species, confirming the dominance of shear deformation, whereas the relation of stress levels between specimens loaded tangentially and radially observed for spruce (tangential > > radial) was inverted for poplar (radial > > tangential). Here, it is proposed that the radially oriented wood rays, which are found in abundance in poplar, act as reinforcement when specimens are compressed radially [31, 32], resulting in significantly increased PL stress and plateau stress. Contrary to spruce wood, the micrographs of poplar wood show a more homogeneous compression pattern, regardless of load direction (Fig. 4). Moreover, no clear cracks of the cell walls or delamination between neighboring cells were found after compression. This, in turn, can be explained by the anatomy of diffuse-porous hardwoods, where distinct differences between early- and latewood layers are absent.

In terms of DoC, all specimens (spruce and poplar) showed only modest densification due to significant spring-back in the absence of temperature treatment and also due to compression treatment at low MC of 12%. For spruce, DoC was roughly 25% tangentially up to 50% radially, whereas poplar wood experienced less spring-back with DoC slightly > 50% for all anatomical directions.

Compression at elevated levels of wood MC reveals a clear and well-known softening effect of water (Fig. 5) [33]. For both species, but especially for spruce, the stress–strain curves appear smoothed and reduced levels of stress at PL and plateau stress are observed. Notably, a saw-tooth pattern is no longer observed in radial compression of spruce, similar to findings reported for Douglas-fir [34]. Furthermore, a distinct stress peak after the phase of elastic formation of tangentially compressed spruce is also absent, highlighting the softening effect of high levels of MC. Other than that, the anatomically caused differences between species for different compression directions observed at 12% MC persist also at water saturation (Fig. 5).

Compression and deformation patterns after partial delignification

For both wood species studied, the partial removal of lignin resulted in a softening of the material, which exhibited significantly reduced MOE and stress at PL (Fig. 6).

Also, the partial removal of cell wall substance led to a minor reduction in volume for spruce, and a significant reduction for poplar, as is evident from microscope images in the uncompressed state (Figs. 7 and 8). However, it is assumed that this reduction in volume is not due to shrinkage, but rather due to compression of the softened specimens’ as a result of fixation during sanding. Comparing the images of uncompressed native (Fig. 3) and alkaline-treated spruce wood (Fig. 7), clear differences can be seen. In contrast to the untreated samples, where no damages to the wood structure are visible, the structure of the treated specimens exhibited cracks probably due to drying and/or sanding. It appears that these cracks spread mainly in radial direction, but occasionally also tangentially. The appearance of cracks in alkaline-treated specimens can be considered as an indicator that some of the cell wall matrix (hemicelluloses and lignin) has been successfully dissolved out of the wood, reducing cell wall strength and adhesion between adjacent cells. Looking at tangentially loaded spruce (Fig. 6a), minor changes appeared at the beginning of the elastic region. Instead of a steep slope from the beginning on, the curve exhibited an upward curvature before a straight line followed until the PL stress. In the case of radially loaded specimens, the remarkable irregular saw-tooth shape observed for untreated wood disappeared in the plateau region. This might hint at a homogenization of the compression properties of the individual earlywood layers due to the softening of the cell walls and thus failure occurred relative simultaneously.

Micrographs showing partially delignified spruce wood structure before (top) and after (bottom) force application in tangential a & d, 45° to the ring orientation b & e and radial c & f direction. Blue arrow in uncompressed wood c indicating compression due to sample fixation for sanding. Blue arrows in compressed wood d-f indicating the direction of compression and approx. DoC. Red arrows indicating damages of the wood structure due to compression

Micrographs showing partially delignified poplar wood structure before (top) and after (bottom) force application in tangential a & d, 45° to the ring orientation b & e and radial c & f direction. Blue arrow in uncompressed wood a & c indicating compression due to sample fixation for sanding. Blue arrows in compressed wood d-f indicating the direction of compression and approx. DoC. Red arrows indicating damages of the wood structure due to compression

Particularly in tangentially compressed spruce, a remarkable reduction in spring-back after compression is observed. Although the samples were compressed to approximately the same thickness, treated spruce remained in a much more compressed state (DoC: ~ 42%) compared to its native equivalents (DoC: ~ 25%). This indicates that compressed alkaline-treated specimens exhibited greater dimensional stability compared to native samples, which is consistent with previous results [17]. Similar to non-compressed samples, chemically treated specimens exhibited more cracking than their native counterparts after densification. In addition to radial cracks, it is clear that one latewood layer was completely damaged (Fig. 7d red arrows). Such cracks were not found in untreated specimens. However, in compressed native wood, cell separation was mostly located near the transition zone between early- and latewood. Beside these differences, some similarities, regardless of treatment, can also be observed. In both cases, the latewood layers acted like columns and buckled into the earlywood layers when compression force was applied. This behavior agrees very well with results from previous literature [29, 30].

With regard to poplar wood, partial lignin removal causes a similar degree of softening compared to spruce wood, whereas the general shape of the stress–strain curves and microscopic deformation patterns remains very similar to those of untreated poplar. In contrast to untreated specimens where distinct differences between the stress–strain curves can be observed depending on the load direction, the differences between the stress–strain curves became smaller after partial extraction of hemicelluloses and lignin (Fig. 6b). This might indicate a homogenization of the whole bulk material. However, despite the treatment, radially compressed poplar exhibited the highest and tangentially compressed poplar the lowest MOE and PL stress.

Contrary to spruce wood, partially delignified poplar wood did not exhibit extensive cracks or delamination between neighboring cells, with the exception of tangentially compressed specimens (Fig. 8d red arrows). As already mentioned regarding untreated poplar specimens, the more homogeneous cellular structure of poplar might be the explanation for the efficient densification without the occurrence of cracks. Moreover, the precedent partial extraction of amorphous wood polymers results in an almost uniform compression pattern, regardless of load direction, as can be seen in Fig. 8 d-f. Similar to spruce wood, a reduction in spring-back was observed for all three compression directions. Thus a DoC between ~ 63 and ~ 66% remained after the pressure was released and specimens’ storage for several weeks before further examination.

As already observed with untreated specimens, water saturation of specimens before compression shows a strong softening effect for partially delignified specimens, regardless of wood species and compression direction (Fig. 9). Again, stress–strain curves appear smoothed and reduced levels of stress at PL and plateau stress are observed for both species. Notably, the distinct stress drop during the plastic phase of tangentially compressed spruce is also absent (Fig. 9a). However, the load direction-dependent compression behavior of spruce is retained even after partial delignification and an increase in MC. In contrast, the combination of partial delignification and increase of MC in poplar leads to almost complete homogenization of wood properties under compressive loading (Fig. 9b). This becomes clear as differences between anatomical direction become very small and stress–strain curves almost completely overlap during most of the elastic and plastic phase.

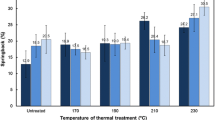

Comparison of modulus of elasticity and stress at proportional limit

The variability of the MOE and the stress at the limit of proportionality (yield stress) is shown in Figs. 10 and 11. Overall, both these mechanical performance indicators follow the same trends. Very clearly, the different compression patterns of native spruce and poplar wood, which were observed in microscopy (Fig. 3 and 4), also show in different values for the mechanical properties determined. In native spruce wood, with its distinct pattern of annual rings consisting of low-density earlywood and high-density latewood, highest stiffness and strength were measured tangentially, whereas radial compression resulted in a stiffness reduction of ~ 20% and a strength reduction of ~ 50%. Consistently, the lowest values for both stiffness and strength are observed at loading at 45°. This is consistent with the general behavior of softwoods loaded transversely at different ring orientations and agrees well with the elastic theory of laminate materials, which implies that a minimum exists at 45° [35]. Overall, the differences between tangential loading, loading at 45° and radial loading persist also after partial delignification, albeit at reduced absolute values. Similarly, testing in wet condition leads to a further reduction of absolute values, but the effect of load direction persists unchanged.

In contrast to spruce wood specimens, poplar wood shows a different load direction dependence, with absolute values tendentially increasing from tangential to 45° and radial load direction, similar to observations made for Yellow birch and Black willow [35]. This again highlights the reinforcing effect of wood rays in hardwoods [36, 37]. While this trend is very clear for specimens tested dry, irrespective whether native or partially delignified specimens were examined, wet specimens deviate from this pattern, particularly in terms of MOE, when samples compressed tangentially and at an angle of 45° are compared to each other. Both in native condition and after partial delignification WS poplar specimens appear softest when tested at an angle of 45°, hinting at a particular weakness of poplar wood shear behavior at high MC.

Conclusions

The different wood anatomy of spruce and poplar wood showed clear effect on their densification behavior. As expected, partial delignification and elevated moisture led to a softening of wood. However, partial delignification did not affect the deformation patterns of the studied species, except for a higher DoC, compared to untreated samples. Structural inhomogeneity in spruce wood hindered homogeneous densification and resulted in inhomogeneous deformations across annual rings, partially leading to internal cracking. Of all anatomical directions, radial compression proved most favorable for spruce. Thereby, earlywood layers were highly compressed without a high extent of internal cracking. Moreover, rays affected compression only slightly. Different to that, it was shown that the wood structure of spruce exhibited extensive cracking and delamination at the latewood–earlywood interface under compression in tangential direction. This was a result of the differences in density between latewood and earlywood layers. Therefore, if species with pronounced density differences between earlywood and latewood are considered to be densified, it is highly recommended to compress them in the radial direction to minimize damage from cracking and delamination. Different to that, the homogeneity in microstructure of poplar enables homogeneous compression deformation in all anatomical directions, which together with its easier delignification underlines the excellent suitability of this species for densification.

References

Wimmers G (2017) Wood: a construction material for tall buildings. Nat Rev Mater 2(12):17051. https://doi.org/10.1038/natrevmats.2017.51

Bernabei M, Capra N, Giovannini L, Tomasi ML (2022) Flying on wood and fabric: the tree species used for the construction of the Ansaldo A.1 “Balilla” biplane (1918). Archaeom 64(1):256–264. https://doi.org/10.1111/arcm.12696

Kollmann FFP, Kuenzi EW, Stamm AJ (1975) Principles of wood science and technology II: wood based materials. Springer-Verlag, Berlin Heidelberg

Jakob M, Mahendran AR, Gindl-Altmutter W, Bliem P, Konnerth J, Müller U, Veigel S (2022) The strength and stiffness of oriented wood and cellulose-fibre materials: a review. Prog Mater Sci 125:100916. https://doi.org/10.1016/j.pmatsci.2021.100916

Stamm AJ, Seborg RM, Millett MA (1948) Method of forming compressed wood structures. US Patent 2(453):679

Namari S, Drosky L, Pudlitz B, Haller P, Sotayo A, Bradley D, Mehra S, O’Ceallaigh C, Harte AM, El-Houjeyri I, Oudjene M, Guan Z (2021) Mechanical properties of compressed wood. Constr Build Mater 301:124269. https://doi.org/10.1016/j.conbuildmat.2021.124269

Navi P, Girardet F (2000) Effects of thermo-hydro-mechanical treatment on the structure and properties of wood. Holzforschung 54(3):287–293. https://doi.org/10.1515/Hf.2000.048

Skyba O, Schwarze FWMR, Niemz P (2009) Physical and mechanical properties of thermo-hygro-mechanically (Thm) - densified wood. Wood Res 54(2):1–18

Kamke F (2006) Densified radiata pine for structural composites. Maderas Cienc Tecnol 8:83–92. https://doi.org/10.4067/S0718-221X2006000200002

Shams MI, Yano H, Endou K (2005) Compressive deformation of wood impregnated with low molecular weight phenol formaldehyde (PF) resin III: effects of sodium chlorite treatment. J Wood Sci 51(3):234–238. https://doi.org/10.1007/s10086-004-0638-y

Wang J, Liu J, Li J, Zhu JY (2021) Characterization of microstructure, chemical, and physical properties of delignified and densified poplar wood. Materials 14(19):5709. https://doi.org/10.3390/ma14195709

Frey M, Widner D, Segmehl JS, Casdorff K, Keplinger T, Burgert I (2018) Delignified and densified cellulose bulk materials with excellent tensile properties for sustainable engineering. ACS Appl Mater Inter 10(5):5030–5037. https://doi.org/10.1021/acsami.7b18646

Frey M, Biffi G, Adobes-Vidal M, Zirkelbach M, Wang Y, Tu K, Hirt AM, Masania K, Burgert I, Keplinger T (2019) Tunable wood by reversible interlocking and bioinspired mechanical gradients. Adv Sci 6(10):1802190. https://doi.org/10.1002/advs.201802190

Han XS, Ye YH, Lam F, Pu JW, Jiang F (2019) Hydrogen-bonding-induced assembly of aligned cellulose nanofibers into ultrastrong and tough bulk materials. J Mater Chem A 7(47):27023–27031. https://doi.org/10.1039/c9ta11118b

Jakob M, Stemmer G, Czabany I, Müller U, Gindl-Altmutter W (2020) Preparation of high strength plywood from partially delignified densified wood. Polymers 12(8):1796. https://doi.org/10.3390/polym12081796

Song J, Chen C, Zhu S, Zhu M, Dai J, Ray U, Li Y, Kuang Y, Li Y, Quispe N, Yao Y, Gong A, Leiste UH, Bruck HA, Zhu JY, Vellore A, Li H, Minus ML, Jia Z, Martini A, Li T, Hu L (2018) Processing bulk natural wood into a high-performance structural material. Nature 554(7691):224–228. https://doi.org/10.1038/nature25476

Jakob M, Czabany I, Veigel S, Müller U, Gindl-Altmutter W (2022) Comparing the suitability of domestic spruce, beech, and poplar wood for high-strength densified wood. Eur J Wood Wood Prod 80(4):859–876. https://doi.org/10.1007/s00107-022-01828-0

Wang J, Fishwild SJ, Begel M, Zhu JY (2020) Properties of densified poplar wood through partial delignification with alkali and acid pretreatment. J Mater Sci 55(29):14664–14676. https://doi.org/10.1007/s10853-020-05034-2

Li K, Zhao L, Ren J, He B (2022) Interpretation of strengthening mechanism of densified wood from supramolecular structures. Molecules 27(13):4167. https://doi.org/10.3390/molecules27134167

Shams MI, Yano H (2011) Compressive deformation of phenol formaldehyde (PF) resin-impregnated wood related to the molecular weight of resin. Wood Sci Technol 45(1):73–81. https://doi.org/10.1007/s00226-010-0310-1

Shams MI, Yano H (2009) A new method for obtaining high strength phenol formaldehyde resin-impregnated wood composites at low pressing pressure. J Trop For Sci 21(2):175–180

Jakob M, Gaugeler J, Gindl-Altmutter W (2020) Effects of fiber angle on the tensile properties of partially delignified and densified wood. Materials 13(23):5405. https://doi.org/10.3390/ma13235405

Kutnar A, Kamke FA, Sernek M (2009) Density profile and morphology of viscoelastic thermal compressed wood. Wood Sci Technol 43:57–68. https://doi.org/10.1007/s00226-008-0198-1

Gibson LJ (2005) Biomechanics of cellular solids. J Biomech 38(3):377–399. https://doi.org/10.1016/j.jbiomech.2004.09.027

Shams I, Yano H, Endou K (2004) Compressive deformation of wood impregnated with low molecular weight phenol formaldehyde (PF) resin I: effects of pressing pressure and pressure holding. J Wood Sci 50(4):337–342. https://doi.org/10.1007/s10086-003-0570-6

Tabarsa T, Chui YH (2000) Stress-strain response of wood under radial compression. Part I. test method and influences of cellular properties. Wood Fiber Sci 32(2):144–152

Müller U, Gindl W, Teischinger A (2003) Effects of cell anatomy on the plastic and elastic behaviour of different wood species loaded perpendicular to grain. IAWA J 24(2):117–128. https://doi.org/10.1163/22941932-90000325

Yano H, Hirose A, Collins PJ, Yazaki Y (2001) Effects of the removal of matrix substances as a pretreatment in the production of high strength resin impregnated wood based materials. J Mater Sci Lett 20(12):1125–1126. https://doi.org/10.1023/A:1010992307614

Tabarsa T, Chui YH (2001) Characterizing microscopic behavior of wood under transverse compression. Part II. effect of species and loading direction. Wood Fiber Sci 33(2):223–232

Bodig J (1965) The effect of anatomy on the initial stress-strain relationship in transverse compression. For Prod J 15(5):197–202

Reiterer A, Burgert I, Sinn G, Tschegg S (2002) The radial reinforcement of the wood structure and its implication on mechanical and fracture mechanical properties—a comparison between two tree species. J Mater Sci 37(5):935–940. https://doi.org/10.1023/A:1014339612423

Burgert I, Eckstein D (2001) The tensile strength of isolated wood rays of beech (Fagus sylvatica L.) and its significance for the biomechanics of living trees. Trees 15(3):168–170. https://doi.org/10.1007/s004680000086

Huang C, Chui Y, Gong M, Chana F (2020) Mechanical behaviour of wood compressed in radial direction: part II. Influence of temperature and moisture content. J Bioresour Bioprod 5:266–275. https://doi.org/10.1016/j.jobab.2020.10.005

Bodig J (1965) Effect of growth characteristics on the mechanical properties of douglas-fir in radial compression. Holzforschung 19(3):83–88. https://doi.org/10.1515/hfsg.1965.19.3.83

Kennedy RW (1968) Wood in transverse compression. Forest Product Journal 18(3):36–40

Wagenführ R, Wagenführ A (2022) Holzatlas (wood atlas), 7th edn. Carl Hanser Verlag GmbH Co KG, München

Sjostrom E (1993) Wood chemistry: fundamentals and applications. Academic Press Inc., San Diego

Acknowledgements

Open access funding was provided by University of Natural Resources and Life Sciences, Vienna (BOKU).

Funding

Open access funding provided by University of Natural Resources and Life Sciences Vienna (BOKU). This work was financed in the framework of the project “Strong Composite” supported under the umbrella of ERANET Cofund ForestValue by Innosuisse, AKA, Business Finland, Vinnova, BMLFUW. ForestValue has received funding from the European Union’s Horizon 2020 research and innovation program under Grant Agreement 773324.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by MJ. The study was supervised by WGA. The first draft of the manuscript was written by MJ and WGA commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Handling Editor: Stephen Eichhorn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jakob, M., Gindl-Altmutter, W. The effect of partial delignification on the stress–strain relationship in transverse compression. J Mater Sci 58, 1071–1085 (2023). https://doi.org/10.1007/s10853-022-08074-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-08074-y