Abstract

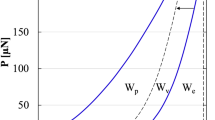

The viscoelastic thermal compression (VTC) of low-density hybrid poplar (Populus deltoides × Populus trichocarpa) from fast growing trees was performed in order to produce specimens with three different degrees of densification (63, 98, and 132%). The morphology and density profile of the VTC specimens were studied. Three different methods for the preparation of specimens for microscopy were used in order to find a technique that makes it possible to examine the VTC wood microscopically in the completely deformed state. It was found that the abrasive surface preparation of oil-embedded blocks was the most promising technique. Microscopic observation revealed that the deformations in the VTC wood were mostly the result of the viscous buckling of cell walls without fracture. The volume of the void areas in the specimens decreased with the degree of densification. The results showed that the density profile of the VTC wood varied with the degree of densification as a consequence of different temperature and moisture gradients formed before and during wood compression. The density profile is also visible on the cross-section of the VTC specimens.

Similar content being viewed by others

References

Blomberg J, Persson B (2004) Plastic deformation in small clear pieces of Scots pine (Pinus sylvestris) during densification with the CaLignum process. J Wood Sci 50:307–314

Blomberg J, Persson B, Bexell U (2006) Effects of semi-isostatic densification on anatomy and cell-shape recovery on soaking. Holzforschung 60:322–331

Bodig J (1965) The effect of anatomy on the initial stress-strain relationship in transverse compression. For Prod J 15:197–202

Bodig J (1966) Stress-strain relationship for wood in transverse compression. J Mater 1:645–666

Bodig J, Jayne BA (1982) Mechanics of wood and wood composites. Van Nostran-Reinhold, New York

Bucur V, Garros S, Barlow CY (2000) The effect of hydrostatic pressure on physical properties and microstructure of spruce and cherry. Holzforschung 54(1):83–92

Dinwoodie JM (2000) Timber: its nature and behaviour. BRE, London

Heger F, Groux M, Girardet F, Welzbacher C, Rapp AO, Navi P (2004) Mechanical and durability performance of THM—densified wood. In: Proc Final Workshop COST Action E22 ‘Environmental Optimization of Wood Protection’ Lisboa—Portugal, 22, 23 March, pp 1–10

Inoue M, Norimoto M, Otsuka Y, Yamada T (1990) Surface compression of coniferous wood lumber. A new technique to compress the surface layer. Mokuzai Gakkaishi 36(11):969–975

Inoue M, Norimoto M, Tanahashi M, Rowell MR (1993) Steam or heat fixation of compressed wood. Wood Fiber Sci 25(3):224–235

Jourez B, Riboux A, Leclercq A (2001) Anatomical characteristics of tension wood and opposite wood in young inclined stems of poplar (Populus Euroamericana cv ‘Ghoy’). IAWA J 22(2):133–157

Kamke FA, Casey LJ (1988) Fundamentals of flakeboard manufacture: internal-mat conditions. Forest Prod J 38(6):38–44

Kamke FA, Sizemore H (2005) Viscoelastic thermal compression of wood. US Patent Application No. US2005/006004AI, 13 Jan., 2005

Kennedy RW (1968) Wood in transverse compression. For Prod J 18:36–40

Koch G, Puls J, Bauch J (2003) Topochemical characterisation of phenolic extractives in discoloured beechwood (Fagus sylvatica L.). Holzforschung 57:339–345

Kollmann FP, Kuenzi EW, Stamm AJ (1975) Principles of wood science and technology. Vol. II: wood based materials. Springer, Heidelberg

Kultikova EV (1999) Structure and properties relationships of densified wood. Master thesis. Virginia Tech, Blacksburg

Kunesh RH (1961) The inelastic behavior of wood: a new concept for improved panel forming processes. For Prod J 11:395–406

Lenth CA (1999) Wood material behavior in severe environments. Ph.D. dissertation. Virginia Tech, Blacksburg

Lenth CA, Kamke FA (2001) Moisture dependent softening behavior of wood. Wood Fiber Sci 33(3):492–507

Mayer I, Koch G (2007) Element content and pH value in American black cherry (Prunus serotina) with regard to colour changes during heartwood formation and hot water treatment. Wood Sci Technol 41:537–547

Miyamoto K, Suzuki S, Inagaki T, Iwata R (2002) Effects of press closing time on mat consolidation behavior during hot pressing and on linear expansion of particleboard. J Wood Sci 48:309–314

Navi P, Girardet F (2000) Effects of Thermo-Hydro-Mechanical treatment on the structure and properties of wood. Holzforschung 54(3):287–293

Painter G, Budman H, Pritzker M (2006) Prediction of oriented strand board properties from mat formation and compression operating conditions. Part 1. Horizontal density distribution and vertical density profile. Wood Sci Technol 40:139–158

Reiterer A, Stanzl-Tschegg SE (2001) Compressive behaviour of softwood under uniaxial loading at different orientations to the grain. Mech Mater 33:705–715

Sadoh T (1981) Viscoelastic properties of wood in swelling systems. Wood Sci Technol 15:57–66

Schrepfer V, Schweingruber FH (1998) Anatomical structures in reshaped press-dried wood. Holzforschung 52(6):615–622

Sundqvist B, Karlsson O, Westermark U (2006) Determination of formic-acid and acetic acid concentrations formed during hydrothermal treatment of birch wood and its relation to colour, strength and hardness. Wood Sci Technol 40:549–561

Tabarasa T, Chui YH (2001) Characterizing microscopic behavior of wood under transverse compression. Part II. Effect of species and loading direction. Wood Fiber Sci 33(2):223–232

Tjeerdsma BF, Boonastra M, Pizzi A, Tekely P, Militz H (1998) Characterisation of thermally modified wood: molecular reasons for wood performance improvement. Holz Roh- Werkst 56:149–153

Uhmeier A, Morooka T, Norimoto M (1998) Influence of thermal softening and degradation on radial compression behavior of wet spruce. Holzforschung 52(1):77–81

Wang JY, Cooper PA (2005) Effect of grain orientation and surface wetting on vertical density profiles of thermally compressed fir and spruce. Holz Roh- Werkst 63:397–402

Wang S, Winistorfer PM, Young TM, Helton C (2001) Step-closing pressing of medium density fiberboard; Part 1. Influence on the vertical density profile. Holz Roh- Werkst 59:19–26

Winistorfer PM, Moschler WW, Wang S, DePaula E, Bledsoe BL (2000) Fundamentals of vertical density profile formation in wood composites. Part 1. In-situ density measurements of the consolidation process. Wood Fiber Sci 32(2):209–219

Wolcott MP (1989) Modelling viscoelastic cellular materials for the pressing of wood composites. Ph.D. dissertation. Virginia Tech, Blacksburg

Wolcott MP, Shutler EL (2003) Temperature and moisture influence on compression – recovery behaviour of wood. Wood Fiber Sci 35(4):540–551

Wolcott MP, Kamke FA, Dillard DA (1990) Fundamentals of flakeboard manufacture: viscoelastic behavior of the wood component. Wood Fiber Sci 22(4):345–361

Wolcott MP, Kamke FA, Dillard DA (1994) Fundamental aspects of wood deformation pertaining to manufacture of wood-base composites. Wood Fiber Sci 26(4):496–511

Wong ED, Zhang M, Wang Q, Kawai S (1998) Effects of mat moisture content and press closing speed on the formation of density profile and properties of particleboard. J Wood Sci 44:287–295

Acknowledgments

The authors acknowledge the financial support from USDA/CSREES National Research Initiative Grant No. 2006-35504-17444 and of the Slovenian Ministry of Higher Education, Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kutnar, A., Kamke, F.A. & Sernek, M. Density profile and morphology of viscoelastic thermal compressed wood. Wood Sci Technol 43, 57–68 (2009). https://doi.org/10.1007/s00226-008-0198-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-008-0198-1