Abstract

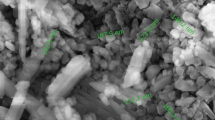

This paper reviews a literature survey on the usage of volcanic particle materials as an alternative filler material in polymer composites. Also, it highlights different types of volcanic particle materials and their potential effect on the performance of polymer composites. The review begins with Fourier transform infrared (FTIR), X-ray diffraction (XRD), and scanning electron microscopy (SEM) analysis of different volcanic materials. Then, it reviews the thermal and mechanical properties of polymer composites that filled with different volcanic particle materials such as volcanic ash, pumice, perlite, and tuff. Reviewed articles have demonstrated that volcanic particle materials can serve as a polymer composite filler. However, there are several factors such as volcanic particle type, size, surface treatment, dispersion, filler concentration, and interfacial interaction with polymer matrix that should be considered and optimized to achieve a balanced polymer composite with its desired properties. Further, the review provides some insights on the gap in the research of volcanic particle material in polymer composites. In particular, the research of volcanic particle materials in different kind of polymers especially bio-based and recycled ones according to the cost-effective and green applications was suggested to be focused.

Graphical abstract

Reproduced with permission from reference [44]. Copyright [2000, Elsevier]

Reproduced with permission from reference [34]. Copyright [2016, Wiley]

Reproduced with permission from reference [36]. Copyright [2006, Elsevier]

Reproduced with permission from reference [64]. Copyright [2020, IOP Science]

Reproduced with permission from reference [10]. Copyright [2019, Elsevier]

Reproduced with permission from reference [17]. Copyright [2019, Elsevier]

Reproduced with permission from reference [41]. Copyright [2016, JCHPS]

Reproduced with permission from reference [36]. Copyright [2006, Elsevier]

Reproduced with permission from reference [65]. Copyright [2006, SpringerLink]

Reproduced with permission from reference [15]. Copyright [2019, IOP Science]

Reproduced with permission from reference [34]. Copyright [2016, Wiley]

Reproduced with permission from reference [68]. Copyright [2015, Wiley]

Reproduced with permission from reference [10]. Copyright [2019, Elsevier]

Reproduced with permission from reference [76]. Copyright [2016, European Physical Society]

Reproduced with permission from reference [34]. Copyright [2016, Wiley]

Reproduced with permission from reference [41]. Copyright [2016, JCHPS]

Reproduced with permission from reference [77]. Copyright [2016, European Physical Society]

Reproduced with permission from reference [78]. Copyright [2014, European Physical Society]

Reproduced with permission from reference [17]. Copyright [2019, Elsevier]

Reproduced with permission from reference [18]. Copyright [2020, De Gruyter]

Reproduced with permission from reference [65]. Copyright [2006, SpringerLink]

Reproduced with permission from reference [10]. Copyright [2019, Elsevier]

Reproduced with permission from reference [19]. Copyright [2020, MDPI]

Reproduced with permission from reference [35]. Copyright [2011, Elsevier]

Reproduced with permission from reference [78]. Copyright [2014, European Physical Society]

Reproduced with permission from reference [73]. Copyright [2018, DergiPark]

Reproduced with permission from reference [15]. Copyright [2019, IOP Science]

Reproduced with permission from reference [76]. Copyright [2016, European Physical Society]

Reproduced with permission from reference [94]. Copyright [2016, Wiley]

Reproduced with permission from reference [78]. Copyright [2014, European Physical Society]

Reproduced with permission from reference [68]. Copyright [2015, Wiley]

Reproduced with permission from reference [18]. Copyright [2020, De Gruyter]

Reproduced with permission from reference [15]. Copyright [2019, IOP Science]

Reproduced with permission from reference [19]. Copyright [2020, MDPI]

Reproduced with permission from reference [17]. Copyright [2019, Elsevier]

Reproduced with permission from reference [18]. Copyright [2020, De Gruyter]

Reproduced with permission from reference [49]. Copyright [2015, Foundation for Materials Science and Engineering]

Reproduced with permission from reference [107]. Copyright [2018, Wiley]

Similar content being viewed by others

Data availability

Data sharing is not applicable to this article as no datasets were generated or analyzed during the current study.

References

Avcu E, Coban O, Bora MO, Fidan S, Sinmazcelik T, Ersoy O (2014) Possible use of volcanic ash as a filler in Polyphenylene Sulfide composites: thermal, mechanical, and erosive wear properties. Polym Compos 35:1826–1833. https://doi.org/10.1002/pc.22847

Akkaya R (2013) Uranium and thorium adsorption from aqueous solution using a novel polyhydroxyethylmethacrylate-pumice composite. J Environ Radioact 120:58–63. https://doi.org/10.1016/j.jenvrad.2012.11.015

Kitis M, Karakaya E, Yigit NO, Civelekoglu G, Akcil A (2005) Heterogeneous catalytic degradation of cyanide using copper-impregnated pumice and hydrogen peroxide. Water Res 39:1652–1662. https://doi.org/10.1016/j.watres.2005.01.027

Kurtulmus E, Karaboyacı M and Yigitarslan S (2013) Production and characterization of a composite insulation material from waste polyethylene teraphtalates. 3rd International Advances in Applied Physics and Materials Science Congress, AIP Conf Proc 1569, 487–491; doi: https://doi.org/10.1063/1.4849321

Mboya HA, Njau KN, Mrema AL, King’ondu CK (2019) Influence of scoria and pumice on key performance indicators of Portland cement concrete. Constr Build Mater 197:444–453. https://doi.org/10.1016/j.conbuildmat.2018.11.228

Felekoglu B (2012) A method for improving the early strength of pumice concrete blocks by using alkyl alkoxy silane (AAS). Constr Build Mater 28:305–310. https://doi.org/10.1016/j.conbuildmat.2011.07.026

Sari D, Pasamehmetoglu AG (2005) The effects of gradation and admixture on the pumice lightweight aggregate concrete. Cem Concr Res 35:936–942. https://doi.org/10.1016/j.cemconres.2004.04.020

Samarzija-Jovanovic S, Jovanovic V, Markovic G, Zekovic I, Marinovic-Cincovic M (2014) Properties of vulcanized polyisoprene rubber composites filled with opalized white tuff and precipitated silica. Hindawi Publ Corp, Sci World J 2014:1–9. https://doi.org/10.1155/2014/913197

Correcher V, Gomez-Ros JM, Dogan T, Garcia-Guinea J, Topaksu M (2017) Optical, spectral and thermal properties of natural pumice glass. Radiat Phys Chem 130:69–7570. https://doi.org/10.1016/j.radphyschem.2016.08.002

Raji M, Nekhlaoui S, Amrani El HassaniEssassi IEEM, Essabir H, Rodrigue D, Bouhfid R, Qaiss A (2019) Utilization of volcanic amorphous aluminosilicate rocks (perlite) as alternative materials in lightweight composites. Compos Part B 165:47–54. https://doi.org/10.1016/j.compositesb.2018.11.098

Atagür M, Sarikanat M, Uysalman T, Polat O, Elbeyli IY, Seki Y, Sever K (2018) Mechanical, thermal, and viscoelastic investigations on expanded perlite–filled high-density polyethylene composite. J Elastomers Plast 50:747–761. https://doi.org/10.1177/0095244318765045

Doğan M, Yüksel H, Kizilduman BK (2021) Characterization and thermal properties of chitosan/perlite nanocomposites. Int J Mater Res 112:5. https://doi.org/10.1515/ijmr-2020-8007

Allameh-Haery H, Kisi E, Fiedler T (2016) Novel cellular perlite–epoxy foams: effect of density on mechanical properties. J Cell Plast 53:1–18. https://doi.org/10.1177/0021955X16652110

Allameh-Haery H, Wensrich CM, Fiedler T, Kisi E (2016) Novel cellular perlite-epoxy foams: effects of particle size. J Cell Plast 53:1–26. https://doi.org/10.1177/0021955X16670528

Alghadi AM, Tirkes S, Tayfun U (2020) Mechanical, thermo-mechanical and morphological characterization of ABS based composites loaded with perlite mineral. Mater Res Express 7:015301. https://doi.org/10.1088/2053-1591/ab551b

Tekin N, Kadıncı E, Demirbaş Ö, Alkan M, Kara A, Doğan M (2006) Surface properties of poly(vinylimidazole)-adsorbed expanded perlite. Microporous Mesoporous Mater 93:125–133. https://doi.org/10.1016/j.micromeso.2006.02.009

de Gerhardt Oliveira A, Jandorno JC, da Dutra Rocha EB, de Furtado Sousa AM, da Nazareth Silva AL (2019) Evaluation of expanded perlite behavior in PS/Perlite composites. Appl Clay Sci 181:105223. https://doi.org/10.1016/j.clay.2019.105223

Lapčík L, Vašina M, Lapčíková B, Staněk M, Ovsík M, Murtaja Y (2020) Study of the material engineering properties of high-density poly(ethylene)/perlite nanocomposite materials. Nanotechnol Rev 9:1491–1499. https://doi.org/10.1515/ntrev-2020-0113

Szadkowski B, Marzec A, Rybinski P, Zukowski W, Zaborski M (2020) Characterization of ethylene–propylene composites filled with perlite and vermiculite minerals: mechanical, barrier, and flammability properties. Materials 13(3):585. https://doi.org/10.3390/ma13030585

Sahraeian R, Esfandeh M (2017) Mechanical and morphological properties of LDPE/perlite nanocomposite films. Polym Bull 74:1327–1341. https://doi.org/10.1007/s00289-016-1779-z

Bush AL (2001) Construction Materials: Lightweight Aggregates. Encycl Mater: Sci Technol, ISBN: 0-08-0431526, 1550-1559

Kucharczyk W, Dusiński D, Żurowski W, Gumiński R (2018) Effect of composition on ablative properties of epoxy composites modified with expanded perlite. Compos Struct 183:654–662. https://doi.org/10.1016/j.compstruct.2017.08.047

Masłowski M, Miedzianowska J, Strzelec K (2019) Hybrid straw/perlite reinforced natural rubber biocomposites. J Bionic Eng 16:1127–1142. https://doi.org/10.1007/s42235-019-0124-2

Sahraeian R, Hashemi SA, Esfandeh M, Ghasemi I (2012) Preparation of nanocomposites based on LDPE/Perlite: mechanical and morphological studies. Polym Polym Compos 20:639–646. https://doi.org/10.1177/096739111202000708

Członka S, Kairyte A, Miedzinska K, Strakowska A (2021) Polyurethane composites reinforced with walnut shell filler treated with perlite, montmorillonite and halloysite. Int J Mol Sci 22:7304. https://doi.org/10.3390/ijms22147304

Tekin N, Dinçer A, Demirbaş Ö, Alkan M (2010) Adsorption of cationic polyacrylamide (C-PAM) on expanded perlite. Appl Clay Sci 50:125–129. https://doi.org/10.1016/j.clay.2010.07.014

Papa E, Medri V, Murri AN, Laghi L, De Aloysio G, Bandini S, Landi E (2018) Characterization of alkali bonded expanded perlite. Constr Build Mater 191:1139–1147. https://doi.org/10.1016/j.conbuildmat.2018.10.086

Rashad AM (2016) A synopsis about perlite as building material - a best practice guide for Civil Engineer. Constr Build Mater 121:338–353. https://doi.org/10.1016/j.conbuildmat.2016.06.001

Lemougna PN, Wang K, Tang Q, Nzeukou AN, Billong N, Melo UC, Xue-min C (2018) Review on the use of volcanic ashes for engineering applications. Res, Conserv Recycl 137:177–190. https://doi.org/10.1016/j.resconrec.2018.05.031

Siddique R (2011) Effect of volcanic ash on the properties of cement paste and mortar. Resour Conserv Recycl 56:66–70. https://doi.org/10.1016/j.resconrec.2011.09.005

Kabra S, Katara S, Rani A (2013) Characterization and study of Turkish Perlite. Int J Innov Res Sci Eng Technol 2(9):4319–4326

Onar AN, Balkaya N, Akyüz T (1996) Phosphate removal by adsorption. Environ Technol 17:207–213. https://doi.org/10.1080/09593331708616378

Mekonnen DT, Alemayehu E, Lennartz B (2021) Adsorptive removal of phosphate from aqueous solutions using low-cost volcanic rocks: kinetics and equilibrium approaches. Materials 14(5):1312. https://doi.org/10.3390/ma14051312

Ramesan MT, Jose C, Jayakrishnan P, Anilkumar T (2018) Multifunctional ternary composites of poly (Vinyl Alcohol)/cashew tree gum/pumice particles. Polym Compos 39:38–45. https://doi.org/10.1002/pc.23899

Yılmaz K, Akgoz A, Cabuk M, Karaagac H, Karabulut O, Yavuz M (2011) Electrical transport, optical and thermal properties of polyaniline–pumice composites. Mater Chem Phys 130:956–961. https://doi.org/10.1016/j.matchemphys.2011.08.017

Gök A, Göde F, Türkaslan BE (2016) Synthesis and characterization of polyaniline/pumice (PAn/Pmc) composite. Mater Sci Eng, B 133:20–25. https://doi.org/10.1016/j.mseb.2006.04.040

Almiron J, Roudet F, Duquesne S (2019) Influence of volcanic ash, rice husk ash, and solid residue of catalytic pyrolysis on the flame-retardant properties of polypropylene composites. J Fire Sci 37(4–6):434–451. https://doi.org/10.1177/0734904119867912

Kufel A, Kuciel S (2019) Composites based on polypropylene modified with natural fillers to increase stiffness. Tech Trans 1:187–195. https://doi.org/10.4467/2353737XCT.19.013.10053

Tarverdi K, Madoyan Z (2014) Preparation and properties of polypropylene and PA 6 composites reinforced with Armenian tuff stone. Eur Sci J Nov /SPECIAL/ edition vol.2 ISSN: 1857–7881 (Print) e - ISSN 1857–7431

Elmastaş N (2012) A mine becoming increasingly important for economy of Turkey: pumice. J Int Soc Res 5:197–206

Jayakrishnan P, Ramesan MT (2016) Synthesis, characterization and properties of poly (vinyl alcohol)/ chemically modified and unmodified pumice composites. Journal of Chemical and Pharmaceutical Sciences, Special Issue 1:97–104. ISSN: 0974–2115

Eroğlu G, Şahiner M (2020) Dünyada ve Türkiye’de Pomza. Report, Maden Tetkik ve Arama Genel Müdürlüğü. https://www.maden.org.tr/resimler/ekler/3f09b21324d1ed3_ek.pdf

Ramesan MT, George A, Jayakrishnan P, Kalaprasad G (2016) Role of pumice particles in the thermal, electrical and mechanical properties of poly(vinyl alcohol)/poly(vinyl pyrrolidone) composites. J Therm Anal Calorim 126:511–519. https://doi.org/10.1007/s10973-016-5507-6

Akbal FÖ, Akdemir N, Onar AN (2000) FT-IR spectroscopic detection of pesticide after sorption onto modified pumice. Talanta 53:131–135. https://doi.org/10.1016/S0039-9140(00)00380-5

Hossain KMA (2003) Blended cement using volcanic ash and pumice. Cem Concr Res 33:1601–1605. https://doi.org/10.1016/S0008-8846(03)00127-3

Yavuz M, Çabuk M (2007) Electrorheological properties of pumice/silicone oil suspension. J Mater Sci 42:2132–2137. https://doi.org/10.1007/s10853-006-1296-9

Budzik G, Galina H, Heneczkowski M, Mossety-Leszczak B, Oleksy M (2018) Non-combustible epoxy composites [in Polish]. Mater Eng 5:1372–1377

Demirbas Ö, Alkan M, Dogan M (2002) The Removal of victoria blue from aqueous solution by adsorption on a low-cost material. Adsorption 8:341–349. https://doi.org/10.1023/A:1021589514766

Vuluga Z, Paceagiu J, Iorga M, Coarna M (2015) Influence of siliceous materials on the elasticity modulus and thermal conductivity of polymeric composite materials. Rom J Mater 45(4):370–376

Gündüz L, Bekar M, Şapcı N (2007) Influence of a new type of additive on the performance of polymer-lightweight mortar composites. Cem Concr Compos 29:594–602. https://doi.org/10.1016/j.cemconcomp.2007.03.007

Sarı A, Karaipekli A (2008) Preparation, thermal properties and thermal reliability of capric acid/expanded perlite composite for thermal energy storage. Mater Chem Phys 109:459–464. https://doi.org/10.1016/j.matchemphys.2007.12.016

Zhang D, Tian S, Xiao D (2007) Experimental study on the phase change behavior of phase change material confined in pores. Sol Energy 81:653–660. https://doi.org/10.1016/j.solener.2006.08.010

Özkan ŞG and Tuncer G (2001) Pomza Madenciliğine Genel Bir Bakış. 4. Endüstriyel Hammaddeler Sempozyumu, İzmir, Türkiye

Ersoy B, Sariisik A, Dikmen S, Sariisik G (2010) Characterization of acidic pumice and determination of its electrokinetic properties in water. Powder Technol 197:129–135

Siddique R, (2012) Properties of concrete made with volcanic ash (Review). Resources, Conservation and Recycling 66: 40–44. http://dx.doi.org/https://doi.org/10.1016/j.resconrec.2012.06.010

Biagdassarov N, Ritter F, Yanev Y (1999) Kinetics of perlite glasses degassing: TG and DSC analysis. Glastech Ber Glass Sci Technol 72(9):277–290

Bideci ÖS, Bideci A, Gültekin AH, Oymael S, Yıldırım H (2014) Polymer coated pumice aggregates and their properties. Composites 67:239–243. https://doi.org/10.1016/j.compositesb.2013.10.009

Karaipekli A, Sari A, Kaygusuz K (2009) Thermal characteristics of paraffin/expanded perlite composite for latent heat thermal energy storage. Energy Sour, Part A 31:814–823. https://doi.org/10.1080/15567030701752768

Sever K, Atagür M, Tunçalp M, Altay L, Seki Y, Sarıkanat M (2018) The effect of pumice powder on mechanical and thermal properties of polypropylene. J Thermoplast Compos Mater 32(8):1092–1106

Kallergis G, Pisania M, Simitzis J (2013) Manufacture and characterization of heat resistant and insulating new composites based on novolac resin – carbon fibers – perlite. Macromol Symp 331–332:137–143. https://doi.org/10.1002/masy.201300073

Li TT, Chuang YC, Huang CH, Lou CW, Lin JH (2015) Applying vermiculite and perlite fillers to sound-absorbing/thermal-insulating resilient PU foam composites. Fibers Polym 16(3):691–698. https://doi.org/10.1007/s12221-015-0691-8

Dike AS (2020) Modification of pumice mineral and its use as additive for poly (Lactic Acid) based bio-composite materials. AKU J Sci Eng 20:111–117. https://doi.org/10.35414/akufemubid.618993

Khorzughy SH, Eslamkish T, Ardejani FD, Heydartaemeh MR (2015) Cadmium removal from aqueous solutions by pumice and nano-pumice. Korean J Chem Eng 32(1):88–96. https://doi.org/10.1007/s11814-014-0168-2

Rahmaniar ST, Prasetya HA, Marlina P, Purbaya M, Chalid M, Hasan A (2020) The effect of pumice and clay composition in natural rubber-ethylene propylene diene monomer blends towards its curing characteristics and physic-mechanical properties. Mater Sci Eng 980:012003. https://doi.org/10.1088/1757-899X/980/1/012003

Celik AG, Kilic AM, Cakal GO (2013) Expanded perlite aggregate characterization for use as a lightweight construction raw material”. Physicochem Probl Miner Process 49(2):689–700. https://doi.org/10.5277/ppmp130227

Roulia M, Chassapis K, Kapoutsis JA, Kamitsos EI, Savvidis T (2006) Influence of thermal treatment on the water release and the glassy structure of perlite. J Mater Sci 41:5870–5881. https://doi.org/10.1007/s10853-006-0325-z

Reka AA, Pavlovski B, Lisichkov K, Jashari A, Boev B, Boev I, Lazarova M, Eskizeybek V, Oral A, Jovanovski G, Makreski P (2019) Chemical, mineralogical and structural features of native and expanded perlite from Macedonia. J Croat Geol Surv Croat Geol Soc 72(3):215–221. https://doi.org/10.4154/gc.2019.18

Sahin A, Karsli NG, Sinmazcelik T (2016) Comparison of the mechanical, thermomechanical, thermal, and morphological properties of pumice and calcium carbonate-filled poly(phenylene sulphide) composites. Polym Compos 37:3160–3166. https://doi.org/10.1002/pc.23513

Karaipekli A, Biçer A, Sarı A, Tyagi VV (2017) Thermal characteristics of expanded perlite/paraffin composite phase change material with enhanced thermal conductivity using carbon nanotubes. Energy Convers Manage 134:373–381. https://doi.org/10.1016/j.enconman.2016.12.053

Yavuz M, Gode F, Pehlivan E, Ozmert S, Sharma YC (2008) An economic removal of Cu2+ and Cr3+ on the new adsorbents: pumice and polyacrylonitrile/pumice composite. Chem Eng J 137:453–461. https://doi.org/10.1016/j.cej.2007.04.030

Angelopoulos PM, Kenanakis G, Viskadourakis Z, Tsakiridis P, Vasilopoulos KC, Karakassides MA, Taxiarchou M (2022) Manufacturing of ABS/expanded perlite filament for 3D printing of lightweight components through fused deposition modeling”. Materials 54:14–21. https://doi.org/10.1016/j.matpr.2021.06.351

Karaca E, Omeroglu S, Akcam O (2016) Investigation of the effects of perlite additive on some comfort and acoustical properties of polyester fabrics. J Appl Polym Sci 133(16):44128. https://doi.org/10.1002/app.43128

Tayfun Ü, Kanbur Y (2018) Mechanical, physical and morphological properties of acidic and basic pumice containing polypropylene composites. Sak Univ J Sci 22(2):333–339. https://doi.org/10.16984/saufenbilder.287861

Davachi SM, Heidari BS, Sahraeian R, Abbaspourrad A (2019) The effect of nanoperlite and its silane treatment on the crystallinity, rheological, optical, and surface properties of polypropylene/nanoperlite nanocomposite films. Compos B 175:107088. https://doi.org/10.1016/j.compositesb.2019.107088

Çoban O (2015) Solid particle erosion behavior of volcanic Ash/PVC composites. Acta Phys Pol, A 127:998–1001. https://doi.org/10.12693/APhysPolA.127.998

Çoban O, Bora MÖ, Kutluk T, Fidan S, Sınmazçelik T (2016) Effect of silane as coupling agent on dynamic mechanical properties of volcanic ash filled PPS composites. Acta Phys Pol, A 129:492–494. https://doi.org/10.12693/APhysPolA.129.492

Kutluk T, Çoban O, Bora MÖ, Fidan S, Sınmazçelik T (2016) Silane coupling efficiency on thermal properties of volcanic ash filled PPS composites. Acta Phys Pol, A 129:498–500. https://doi.org/10.12693/APhysPolA.129.498

Sahin AE, Yildiran Y, Avcu E, Fidan S, Sinmazcelik T (2014) Mechanical and thermal properties of pumice powder filled PPS composites. Acta Phys Pol, A 125:518–520. https://doi.org/10.12693/APhysPolA.125.518

Folorunso O, Dodds C, Dimitrakis G, Kingman S (2012) Continuous energy efficient exfoliation of vermiculite through microwave heating. Int J Miner Process 114–117:69–79. https://doi.org/10.1016/j.minpro.2012.10.003

Cicconi MR, Neuville DR (2019) 22. Natural Glasses. Springer Handbook of Glass, Springer Handbooks

Jing Q, Fang L, Liu H, Liu P (2011) Preparation of surface-vitrified micron sphere using perlite from Xinyang, China. Appl Clay Sci 53:745–748. https://doi.org/10.1016/j.clay.2011.07.005

Heide K, Heide G (2011) Vitreous state in nature – Origin and properties. Chem Erde Geochem 71:305–33. https://doi.org/10.1016/j.chemer.2011.10.001

Deganello G, Liotta L, Longo A, Martorana A, Yanev Y, Zotov N (1998) Structure of natural water containing glasses from Lipari (Italy) and Eastern Rhodopes (Bulgaria): SAXS, WAXS and IR studies. J Non-Cryst Solids 232:547–553. https://doi.org/10.1016/S0022-3093(98)00429-3

Krzyzak A, Kucharczyk W, Gaska J, Szczepaniak R (2018) Ablative test of composites with epoxy resin and expanded perlite: review. Compos Struct 202:978–987. https://doi.org/10.1016/j.compstruct.2018.05.018

Amrani S, Halimi Y, Tahiri M (2014) Composite materials using expanded perlite as a charge and plastic wastes as reinforcement, elaboration and properties. GSTF Int J Chem Sci (JChem) 1(2):1–8. https://doi.org/10.7603/s40837-014-0003-7

Angelopoulos PM, Maliachova C, Papakonstantinou K, Taxiarchou M, Diplas S (2016) Structural and physical characteristics of fine perlite expanded with a novel method in a vertical electric furnace. Mineral Process Extr Metall 125(2):71–80. https://doi.org/10.1080/03719553.2016.1156244

Sahraeian R, Davachi SM, Heidari BS (2019) The effect of nanoperlite and its silane treatment on thermal properties and degradation of polypropylene/nanoperlite nanocomposite films. Compos B 162:103–111. https://doi.org/10.1016/j.compositesb.2018.10.093

Çoban O, Bora MÖ, Kutluk T, Özkoç G (2018) Mechanical and thermal properties of volcanic particle filled PLA/PBAT composites. Polym Compos 39:E1500–E1511. https://doi.org/10.1002/pc.24393

Dong S, Gauvin R (1993) Application of dynamic mechanical analysis for the study of the interfacial region in carbon Fiber/ Epoxy composite materials. Polym Compos 14(5):414–420. https://doi.org/10.1002/pc.750140508

Li Y, Mai YW, Ye L (2005) Effects of fibre surface treatment on fracture-mechanical properties of sisal-fibre composites. Composite Interfaces 12(1–2):141–163. https://doi.org/10.1163/1568554053542151

Sahraeian R, Esfandeh M, Hashemi SA (2013) Rheological, thermal and dynamic mechanical studies of the LDPE/Perlite nanocomposites. Polym Polym Compos 21(4):243–250. https://doi.org/10.1177/096739111302100406

Tian H, Tagaya H (2007) Preparation, characterization and mechanical properties of the polylactide/perlite and the polylactide/montmorillonite composites. J Mater Sci 42:3244–3250. https://doi.org/10.1007/s10853-006-0230-5

Tian H, Tagaya H (2008) Dynamic mechanical property and photochemical stability of perlite/PVA and OMMT/PVA nanocomposites. J Mater Sci 43:766–770. https://doi.org/10.1007/s10853-007-2127-3

Çoban O, Bora MÖ, Kutluk T, Fidan S, Sinmazçelik T (2018) Heat treatment effect on thermal and thermomechanical properties of polyphenylene sulfide composites reinforced with silane-treated volcanic ash particles. Polym Compos 39:1612–1619. https://doi.org/10.1002/pc.24106

Kurt Albayrak ZN, and Gencer G (2020) The usability of clay/pumice mixtures modified with biopolymer as an impermeable liner. KSCE J Civil Eng, pISSN 1226–7988, eISSN 1976–3808. doi: https://doi.org/10.1007/s12205-020-1053-7

Sariisik A, Sariisik G (2012) New production process for insulation blocks composed of EPS and lightweight concrete containing pumice aggregate. Mater Struct 45:1345–1357. https://doi.org/10.1617/s11527-012-9836-z

Bora MÖ, Çoban O, Kutluk T, Akagündüz E (2019) The use of volcanic particles in HDPE offers alternative filling material against CaCO3. Part II—scratch properties. Polym Compos 40:2564–2572. https://doi.org/10.1002/pc.25044

Sahin AE, Cetin B, Sinmazcelik T (2021) Investigation of mechanical and tribological behaviour of expanded perlite particle reinforced polyphenylene sulphide. Proc IMechE Part L: J Mater: Design Appl 235:2356–2367. https://doi.org/10.1177/14644207211027342

Singh T (2021) Tribological performance of volcanic rock (perlite)-filled phenolic-based brake friction composites. J King Saud Univ - Eng Sci, (In Press), 2021. https://doi.org/10.1016/j.jksues.2021.12.010

Żmudka S, Budniak I, Kuciel S, Mikuła J (2009) Estimation of the possibilities of Using Vulcanic Tuf as thermoplastic polymer filler. Tech Trans 1:421–428

Mazur K, Kuciel S (2020) Composites based on recycled polystyrene waste with tuff microparticles. Tech Trans 115(4):195–203. https://doi.org/10.4467/2353737XCT.18.067.8379

Alsaadi M, Erkliğ A (2018) Effect of perlite particle contents on delamination toughness of S-glass fiber reinforced epoxy matrix composites. Compos B Eng 141:182–190. https://doi.org/10.1016/j.compositesb.2017.12.059

Fu SY, Feng XQ, Lauke B, Mai YW (2008) Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Composites Part B 39:933–961

Bora MÖ, Çoban O, Kutluk T, Fidan S, Sinmazçelik T (2018) The influence of heat treatment process on mechanical properties of surface treated volcanic ash particles/polyphenylene sulfide composites. Polym Compos 39:1604–1611. https://doi.org/10.1002/pc.24105

Mattausch H, Laske S, Cirar K, Flachberger H and Holzer C (2015) Influence of processing conditions on the morphology of expanded perlite/polypropylene composites. In: AIP Conference Proceedings 1593, 482-486. https://doi.org/10.1063/1.4873826

Akin Öktem G, Tincer T (1993) A study on the yield stress of perlite-filled high-density polyethylenes. J Mater Sci 28:6313–6317. https://doi.org/10.1007/BF01352189

Çoban O, Bora MÖ, Kutluk T (2018) Comparative study of volcanic particle and calcium carbonate filler materials in HDPE for thermal and mechanical properties. Polym Compos 39:E1900–E1907. https://doi.org/10.1002/pc.24883

Aval ST, Davachi SM, Sahraeian R, Dadmohammadi Y, Heidari BS, Seyfi J, Hejazi I, Mosleh I, Abbaspourrad A (2020) Nanoperlite effect on thermal, rheological, surface and cellular properties of poly lactic acid/nanoperlite nanocomposites for multipurpose applications. Polym Testing 91:106779. https://doi.org/10.1016/j.polymertesting.2020.106779

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that there is no conflict of interest regarding the publication of this manuscript.

Additional information

Handling Editor: Maude Jimenez.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Çoban, O., Yilmaz, T. Volcanic particle materials in polymer composites: a review. J Mater Sci 57, 16989–17020 (2022). https://doi.org/10.1007/s10853-022-07664-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07664-0