Abstract

While there is a large body of literature on the micromechanical behavior of metal matrix composites (MMCs) under uniaxial applied stress, very little is available on multi-phase MMCs. In order to cast light on the reinforcement mechanisms and damage processes in such multi-phase composites, materials made by an Al-based piston alloy and containing one- and two-ceramic reinforcements (planar-random oriented alumina fibers and SiC particles) were studied. In situ compression tests during neutron diffraction experiments were used to track the load transfer among phases, while X-ray computed tomography on pre-strained samples was used to monitor and quantify damage. We found that damage progresses differently in composites with different orientations of the fiber mat. Because of the presence of intermetallic network, it was observed that the second ceramic reinforcement changed the load transfer scenario only at very high applied load, when also intermetallic particles break. We rationalized the present results combining them with the previous investigations and using a micromechanical model.

Similar content being viewed by others

References

Clyne TW, Withers PJ (1993) An introduction to metal matrix composites. Cambridge solid state science series. Cambridge University Press, Cambridge

Dlouhy A, Eggeler G, Merk N (1995) A micromechanical model for creep in short fibre reinforced aluminium alloys. Acta Metall Mater 43(2):535–550

Dragone TL, Nix WD (1990) Geometric factors affecting the internal stress distribution and high temperature creep rate of discontinuous fiber reinforced metals. Acta Metall Mater 38(10):1941–1953

Requena G, Degischer HP (2006) Creep behaviour of unreinforced and short fibre reinforced AlSi12CuMgNi piston alloy. Mater Sci Eng A 420(1):265–275

Garces G, Bruno G, Wanner A (2007) Load transfer in short fibre reinforced metal matrix composites. Acta Mater 55(16):5389–5400

Garces G, Bruno G, Wanner A (2006) Residual stresses in deformed random-planar aluminium/Saffil® short-fibre composites. Mater Sci Eng A 417(1):73–81

Garces G, Bruno G, Wanner A (2006) Internal stress evolution in a random-planar short fiber aluminum composite. Scr Mater 55(2):163–166

Michaud V, Mortensen A (2001) Infiltration processing of fibre reinforced composites: governing phenomena. Compos Part A Appl Sci Manuf 32(8):981–996

Oh KH, Han KS (2007) Short-fiber/particle hybrid reinforcement: effects on fracture toughness and fatigue crack growth of metal matrix composites. Compos Sci Technol 67(7):1719–1726

Wang Y-q, Song J-i (2011) Dry sliding wear behavior of Al2O3 fiber and SiC particle reinforced aluminium based MMCs fabricated by squeeze casting method. Trans Nonferr Met Soc China 21(7):1441–1448

Friend CM, Horsfall I, Burrows CL (1991) The effect of particulate: fibre ratio on the properties of short-fibre/particulate hybrid MMC produced by preform infiltration. J Mater Sci 26(1):225–231. https://doi.org/10.1007/BF00576056

Mondal AK, Kumar S (2009) Dry sliding wear behaviour of magnesium alloy based hybrid composites in the longitudinal direction. Wear 267(1):458–466

Schröder J, Kainer KU (1991) Magnesium-base hybrid composites prepared by liquid infiltration. Mater Sci Eng A 135:33–36

Skleničkal V, Kuchařová K, Kvapilová M, Svoboda M (2015) Factors influencing creep resistance in discontinuously reinforced magnesium metal matrix composites. Met Mater 53(4):221–229

Cabeza S, Mishurova T, Garces G, Sevostianov I, Requena G, Bruno G (2017) Stress-induced damage evolution in cast AlSi12CuMgNi alloy with one- and two-ceramic reinforcements. J Mater Sci 52(17):10198–10216. https://doi.org/10.1007/s10853-017-1182-7

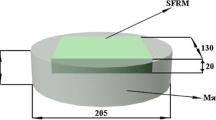

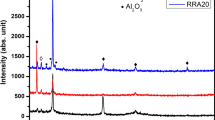

Evsevleev S, Mishurova T, Cabeza S, Koos R, Sevostianov I, Garcés G, Requena G, Fernandez R, Bruno G (2018) The role of intermetallics in stress partitioning and damage evolution of AlSi12CuMgNi alloy. Mater Sci Eng A 736:453–464

Fitzpatrick ME, Withers PJ, Baczmanski A, Hutchings MT, Levy R, Ceretti M, Lodini A (2002) Changes in the misfit stresses in an Al/SiCp metal matrix composite under plastic strain. Acta Mater 50(5):1031–1040

Winand HMA, Whitehouse AF, Withers PJ (2000) An investigation of the isothermal creep response of Al-based composites by neutron diffraction. Mater Sci Eng A 284(1):103–113

Young ML, Rao R, Almer JD, Haeffner DR, Lewis JA, Dunand DC (2009) Load partitioning in Al2O3–Al composites with three-dimensional periodic architecture. Acta Mater 57:2362–2375

Roy S, Gibmeier J, Kostov V, Weidenmann KA, Nagelb A, Wanner A (2012) Internal load transfer and damage evolution in a 3D interpenetrating metal/ceramic composite. Mater Sci Eng A 551:272–279

Roy S, Gibmeier J, Kostov V, Weidenmann KA, Nagel A, Wanner A (2011) Internal load transfer in a metal matrix composite with a three-dimensional interpenetrating structure. Acta Mater 59:1424–1435

Rack A, Zabler S, Müller BR, Riesemeier H, Weidemann G, Lange A, Goebbels J, Hentschel M, Görner W (2008) High resolution synchrotron-based radiography and tomography using hard X-rays at the BAMline (BESSY II). Nucl Instrum Methods Phys Res Sect A Accel Spectrom Detect Assoc Equip 586(2):327–344

Paganin D, Mayo SC, Gureyev TE, Miller PR, Wilkins SW (2002) Simultaneous phase and amplitude extraction from a single defocused image of a homogeneous object. J Microsc Oxf 206:33–40

Weitkamp T, Haas D, Wegrzynek D, Rack A (2011) ANKAphase: software for single-distance phase retrieval from inline X-ray phase-contrast radiographs. J Synchrotron Radiat 18:617–629

Cabeza S, Mishurova T, Bruno G, Garces G, Requena G (2016) The role of reinforcement orientation on the damage evolution of AlSi12CuMgNi + 15% Al2O3 under compression. Scr Mater 122:115–118

Hoelzel M, Gan W, Hofmann M, Randau C, Seidl G, Juttner P, Schmahl W (2013) Rotatable multifunctional load frames for neutron diffractometers at FRM II—design, specifications and applications. Nucl Instrum Methods Phys Res Sect A Accel Spectrom Detect Assoc Equip 711:101–105

Wern H (2000) XEC. 1.0 edn. Hochschule für Technik und Wirtschaft Saarbrücken, Saarbrücken

Kröner E (1958) Berechnung der elastischen Konstanten des Vielkristalls aus den Konstanten des Einkristalls. Z Phys 151(4):504–518

Hutchings MT, Krawitz AD (1992) Measurement of residual and applied stress using neutron diffraction. Springer Netherlands, Dordrecht

Garces G, Bruno G, Wanner A (2006) Residual stresses in random-planar aluminium/Saffil short-fibre composites deformed in different loading modes. J Mater Res 97(10):1312–1319

Dutta M, Bruno G, Edwards L, Fitzpatrick ME (2004) Neutron diffraction measurement of the internal stresses following heat treatment of a plastically deformed Al/SiC particulate metal–matrix composite. Acta Mater 52(13):3881–3888

Bruno G, Ceretti M, Girardin E, Giuliani A, Manescu A (2004) Relaxation of residual stress in MMC after combined plastic deformation and heat treatment. Scr Mater 51:999–1004

Sevostianov I, Giraud A (2013) Generalization of Maxwell homogenization scheme for elastic material containing inhomogeneities of diverse shape. Int J Eng Sci 64(Supplement C):23–36

Mishurova T, Cabeza S, Bruno G, Sevostianov I (2016) Average phase stress concentrations in multiphase metal matrix composites under compressive loading. Int J Eng Sci 106:245–261

Fernández-Gutiérrez R, Requena GC (2014) The effect of spheroidisation heat treatment on the creep resistance of a cast AlSi12CuMgNi piston alloy. Mater Sci Eng A 598(Supplement C):147–153

Chen CL, Richter A, Thomson RC (2010) Investigation of mechanical properties of intermetallic phases in multi-component Al–Si alloys using hot-stage nanoindentation. Intermetallics 18(4):499–508

Sevostianov I, Kachanov M (2015) On the possibility to represent effective properties of a material with inhomogeneities in terms of concentration parameters. International Journal of Solids and Structures 52(Supplement C):197–204

Hill R (1963) Elastic properties of reinforced solids: some theoretical principles. J Mech Phys Solids 11(5):357–372

Wu TT (1966) The effect of inclusion shape on the elastic moduli of a two-phase material. Int J Solids Struct 2(1):1–8

Chen F, Sevostianov I, Giraud A, Grgic D (2017) Accuracy of the replacement relations for materials with non-ellipsoidal inhomogeneities. Int J Solids Struct 104(Supplement C):73–80

Maxwell JC (1873) A treatise on electricity and magnetism. Clarendon Press, Oxford

Sevostianov I (2014) On the shape of effective inclusion in the Maxwell homogenization scheme for anisotropic elastic composites. Mech Mater 75(Supplement C):45–59

Requena G, Garcés G, Rodríguez M, Pirling T, Cloetens P (2009) 3D Architecture and Load Partition in Eutectic Al–Si Alloys. Adv Eng Mater 11(12):1007–1014

Bugelnig K, Sket F, Germann H, Steffens T, Koos R, Wilde F, Boller E, Requena G (2018) Influence of 3D connectivity of rigid phases on damage evolution during tensile deformation of an AlSi12Cu4Ni2 piston alloy. Mater Sci Eng A 709(Supplement C):193–202

Kushch VI, Sevostianov I (2016) Maxwell homogenization scheme as a rigorous method of micromechanics: Application to effective conductivity of a composite with spheroidal particles. Int J Eng Sci 98(Supplement C):36–50

Acknowledgements

SE, IS, GG and GB acknowledge financial support from the DFG (Project number BR 5199/3-1). Authors thank Robert Koos (MLZ/FRMII, TU Munich, Germany) and Robert Wimpory (HZB, Berlin, Germany) for their support during neutron diffraction measurements on the STRESS-SPEC and E3 beamlines.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

The components of Wu’s tensor \( \varvec{\varGamma} \) for an isolated spheroidal inhomogeneity (with semi-axes \( a_{1} = a_{2} = a,\;a_{3} \)) of the aspect ratio \( \gamma = {a \mathord{\left/ {\vphantom {a {a_{3} }}} \right. \kern-0pt} {a_{3} }} \), with bulk and shear moduli \( K_{1} \) and \( G_{1} \), embedded in the matrix with bulk and shear moduli \( K_{0} \) and \( G_{0} \), are as follows:

where the functions \( f_{0} \) and \( f_{1} \) are given by

and the following notations are used

The components of the transversely isotropic (\( x_{3} \) is the axis of symmetry) tensor \( Q^{\varOmega } \) entering (f) are as follows:

where \( f_{0} \) and \( f_{1} \) are calculated for the aspect ratio of the domain \( \varOmega \). In [42], the Maxwell scheme was completed expressing the aspect ratio of the domain \( \varOmega \) in terms of the sums of components of tensors \( Q_{ijkl} \) for individual inhomogeneities: for a composite with transversely isotropic microstructure, the effective inclusion is a spheroid with aspect ratio

if it is smaller than 1 (case relevant to the present study). This hypothesis was numerically verified in [45].

The procedure of averaging of the transversely isotropic fourth-rank tensor \( \varGamma_{ijkl} \) over orientations has been discussed in detail in [34]. In the case of 3-D random orientation, the resulting tensor is isotropic and has only two independent components

The tensor \( \varGamma_{ijkl} \) averaged over 2D random orientations is transversely isotropic with the axis of symmetry normal to the plane of random orientations. The resulting tensor has six independent components (note that stress concentration tensor is not symmetric and \( \bar{\varGamma }_{1133} \ne \bar{\varGamma }_{3311} \)):

Rights and permissions

About this article

Cite this article

Evsevleev, S., Cabeza, S., Mishurova, T. et al. Stress-induced damage evolution in cast AlSi12CuMgNi alloy with one- and two-ceramic reinforcements. Part II: effect of reinforcement orientation. J Mater Sci 55, 1049–1068 (2020). https://doi.org/10.1007/s10853-019-04069-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04069-4