Abstract

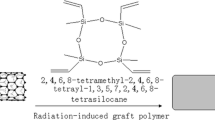

Electrophoretic deposition (EPD) in water using a continuous filament process was used to modify E-type glass fibers (GFs) by depositing multiwall carbon nanotubes (MWCNTs) onto their surface. The oxidized MWCNTs behaved as negatively charged particles and migrated toward the positive electrode, containing the GFs. This electrokinetic motion was confirmed by measuring the point of zero charge and Z-potential. The influence of the main EPD parameters on the morphology and electrical properties of the MWCNT-coated GFs is investigated. The most uniform coverage was achieved by using an electric field of 4.5 kV/m for 30 min under a warm bath temperature (~ 50 °C). Higher intensity of the electric field or longer deposition times was not beneficial for the homogeneity of the deposit. The application of these electroconductive MWCNT-modified fibers as smart materials was demonstrated by conducting relaxation-induced piezoresistive experiments in monofilament polymer composites using these MWCNT-modified fibers.

Similar content being viewed by others

References

Avilés F, Kú-Herrera JJ, Oliva-Avilés AI (2018) Deposition of carbon nanotubes on fibers. In: Rafiee R (ed) Carbon nanotube-reinforced polymers. Elsevier, Amsterdam, pp 117–144

Tzounis L, Kirsten M, Simon F, Mäder E, Stamm M (2014) The interphase microstructure and electrical properties of glass fibers covalently and non-covalently bonded with multiwall carbon nanotubes. Carbon 73:310–324

Zhang J, Liu J, Zhuang R, Mäder E, Heinrich G, Gao S (2011) Single MWNT-glass fiber as strain sensor and switch. Adv Mater 23:3392–3397

Kú-Herrera JJ, Pacheco-Salazar OF, Ríos-Soberanis CR, Domínguez-Rodríguez G, Avilés F (2016) Self-sensing of damage progression in unidirectional multiscale hierarchical composites subjected to cyclic tensile loading. Sensors 16:400

Zhang J, Zhuang R, Liu J, Scheffler C, Mäder E, Heinrich G, Gao S (2014) A single glass fiber with ultrathin layer of carbon nanotube networks beneficial to in situ monitoring of polymer properties in composite interphases. Soft Mater 12:115–120

Sebastian J, Schehl N, Bouchard M, Boehle M, Li L, Lagounov A, Lafdi K (2014) Health monitoring of structural composites with embedded carbon nanotube coated glass fiber sensors. Carbon 66:191–200

Tzounis L, Liebscher M, Petinakis E, Paipetis AS, Mäder E, Stamm M (2016) CNT-grafted glass fibers as a smart tool for the epoxy cure monitoring, UV-sensing and thermal energy harvesting in model composites. RSC Adv 6:55514–55525

Kú-Herrera JJ, Cauich JV, Avilés F (2014) On the role of fiber coating in the deposition of multiwall carbon nanotubes onto glass fibers. Nanosci Nanotechnol Lett 6:932–935

Kú-Herrera JJ, Avilés F, Nistal A, Cauich-Rodríguez JV, Rubio F, Rubio J, Bartolo-Pérez P (2015) Interactions between the glass fiber coating and oxidized carbon nanotubes. Appl Surf Sci 330:383–392

Boccaccini AR, Cho K, Roether JA, Thomas BJC, Minay EJ, Shaffer MSP (2006) Electrophoretic deposition of carbon nanotubes. Carbon 44:3149–3160

An Q, Rider AN, Thostenson ET (2013) Hierarchical composite structures prepared by electrophoretic deposition of carbon nanotubes onto glass fibers. ACS Appl Mater Interfaces 5:2022–2032

Tamrakar S, An Q, Thostenson ET, Rider AN, Haque BZ, Gillespie JW Jr (2016) Tailoring interfacial properties by controlling carbon nanotube coating thickness on glass fibers using electrophoretic deposition. ACS Appl Mater Interfaces 8:1501–1510

Besra L, Liu M (2007) A review on fundamentals and applications of electrophoretic deposition (EPD). Prog Mater Sci 52:1–61

Cho J, Boccaccini AR, Shaffer MSP (2009) Ceramic matrix composites containing carbon nanotubes. J Mater Sci 44:1934–1951. https://doi.org/10.1007/s10853-009-3262-9

Thostenson ET, Li WZ, Wang DZ, Ren ZF, Chou TW (2002) Carbon nanotube/carbon fiber hybrid multiscale composites. J Appl Phys 91:6034–6037

Wang Y, Xu Z, Chen L, Jiao Y, Wu X (2011) Multi-scale hybrid composites-based carbon nanotubes. Polym Compos 32:159–167

Downs WB, Baker RTK (1991) Novel carbon fiber-carbon filament structure. Carbon 29:1173–1179

Morgan H, Green NG (2003) AC electrokinetics: colloids and nanoparticles. Research Studies Press Ltd, Baldock

Jones TB (1995) Electromechanics of particles. Cambridge University Press, New York

Zhang J, Zhuang R, Liu J, Mäder E, Heinrich G, Gao S (2010) Functional interphases with multi-walled carbon nanotubes in glass fibre/epoxy composites. Carbon 48:2273–2281

An Q, Rider AN, Thostenson ET (2012) Electrophoretic deposition of carbon nanotubes onto carbon-fiber fabric for production of carbon/epoxy composites with improved mechanical properties. Carbon 50:4130–4143

Diba M, Fam DWH, Boccaccini AR, Shaffer MSP (2016) Electrophoretic deposition of graphene-related materials: a review of the fundamentals. Prog Mater Sci 82:83–117

Dickerson JH, Boccaccini AR (2012) Nanostructure science and technology: electrophoretic deposition of nanomaterials. Springer, New York

Zhou G, Byun J-H, Wang Y-Q, Cha H-J, Lee J-U, Jung B-M, Song J-II, Kim B-S, Chou T-W (2015) Mechanism of sonication-assisted electrophoretic deposition of carbon nano-fiber on carbon fabrics. Compos Sci Technol 107:29–35

Zhang X-W, Pan Y, Zheng Q, Yi X-S (2000) Time dependence of piezoresistance for the conductor-filled polymer composites. J Polym Sci B 38:2739–2749

Vidhate S, Chung J, Vaidyanathan V, D’Souza N (2009) Time dependent piezoresistive behavior of polyvinylidene fluoride/carbon nanotube conductive composite. Mater Lett 63:1771–1773

Lekawa-Raus A, Koziol KKK, Windle AH (2014) Piezoresistive effect in carbon nanotube fibers. ACS Nano 8:11214–11224

Zhang M, Chen J, Lu C (2016) Influence of strain rate on the piezoresistive behavior of conductive polyamide composites. Compos Sci Technol 133:1–6

Ramirez M, Chung DDL (2016) Electromechanical, self-sensing and viscoelastic behavior of carbon fiber tows. Carbon 110:8–16

Avilés F, May-Pat A, Canché-Escamilla G et al (2014) Influence of carbon nanotube on the piezoresistive behavior of multiwall carbon nanotube/polymer composites. J Intell Mater Syst Struct 27:92–103

Avilés F, Cauich-Rodríguez JV, Moo-Tah L, May-Pat A, Vargas-Coronado R (2009) Evaluation of mild acid oxidation treatments for MWCNT functionalization. Carbon 47:2970–2975

Appel C, Ma LQ, Rhue RD, Kennelley E (2003) Point of zero charge determination in soils and minerals via traditional methods and detection of electroacoustic mobility. Geoderma 113:77–93

Ma P-C, Siddiqui NA, Mäder E, Kim J-K (2011) Correlation between electrokinetic potential, dispersibility, surface chemistry and energy of carbon nanotubes. Compos Sci Technol 71:1644–165128

ASTM Standard D638-14 (2015) Standard test method for tensile properties of plastics. ASTM International, West Conshohocken. https://doi.org/10.1520/d0638-14

Hamaker HC (1940) Formation of a deposit by electrophoresis. Trans Faraday Soc 35:279–287

Su Y, Zhitomirsky I (2013) Electrophoretic deposition of graphene, carbon nanotubes and composite films using methyl violet dye as a dispersing agent. Colloids Surf A 436:97–103

Shi K, Zhitomirsky I (2013) Electrophoretic nanotechnology of graphene–carbon nanotube and graphene–polypyrrole nanofiber composites for electrochemical supercapacitors. J Colloid Interface Sci 407:474–481

Diba M, García-Gallastegui A, Taylor RNK, Pishbin F, Ryan MP, Shaffer MSP, Boccaccini AR (2014) Quantitative evaluation of electrophoretic deposition kinetics of graphene oxide. Carbon 67:656–661

Wang Z, Cui Y-T, Xu Z-B, Qu J (2008) Hot water-promoted ring-opening of epoxides and aziridines by water and other nucleopliles. J Org Chem 73:2270–2274

Tanoglu M, Ziaee S, McKnight SH, Palmese GR, Gillespie JW Jr (2001) Investigation of properties of fiber/matrix interphase formed due to the glass fiber sizings. J Mater Sci 36:3041–3053. https://doi.org/10.1023/A:1017979126129

Gorowara RL, Kosik WE, McKnight SH, McCullough RL (2001) Molecular characterization of glass fiber surface coatings for thermosetting polymer matrix/glass fiber composites. Compos A Appl Sci Manuf 32:323–329

Lai Y-H, Sathyamoorthi S, Bain RM, Zare RN (2018) Microdroplets accelerate ring opening of epoxides. J Am Soc Mass Spectrom 29:1036–1043

Dresselhaus MS, Dresselhaus G, Saito R, Jorio A (2005) Raman spectroscopy of carbon nanotubes. Phys Rep 409:47–99

Zhao Q, Wagner HD (2004) Raman spectroscopy of carbon-nanotube-based composites. Philos Trans R Soc Lond Ser A Math Phys Eng Sci 362:2407–2424

Gao S-L, Zhuang R-C, Zhang J, Liu J-W, Mäder E (2010) Glass fibers with carbon nanotube networks as multifunctional sensors. Adv Func Mater 20:1885–1893

Ku-Herrera JJ, La Saponara V, Avilés F (2018) Selective damage sensing in multiscale hierarchical composites by tailoring the location of carbon nanotubes. J Intell Mater Syst Struct 29:553–562

Behabtu N, Young CC, Tsentalovich DE, Kleinerman O, Wang X, Ma AWK, Bengio EA, ter Waarbeek RF et al (2013) Strong, light, multifunctional fibers of carbon nanotubes with ultrahigh conductivity. Science 339:182–186

Liu L, Ma P-C, Xu M, Khan SU, Kim JK (2012) Strain-sensitive Raman spectroscopy and electrical resistance of carbon nanotube-coated glass fibre sensors. Compos Sci Technol 72:1548–1555

Hao B, Ma Q, Yang S, Mäder E, Ma P-C (2016) Comparative study on monitoring structural damage in fiber-reinforced polymers using glass fibers with carbon nanotubes and graphene coating. Compos Sci Technol 129:38–45

Ho H, Drzal LT (1995) Non-linear numerical study of the single-fiber fragmentation test. Part I: test mechanics. Compos Eng 5:1231–1244

Nairn JA (1992) A variational mechanics analysis of the stresses around breaks in embedded fibers. Mech Mater 13:131–154

Wang X, Fu X, Chung DDL (1999) Strain sensing using carbon fiber. J Mater Res 14:790–802

Lee SI, Yoon DJ, Lee SS, Park JM (2005) Cure monitoring and stress-strain sensing of single-carbon fiber composites by the measurement of electrical resistance. Key Eng Mater 297–300:676–684

Mullet M, Fievet P, Szymczyk A, Foissy A, Reggiani JC, Pagetti J (1999) A simple and accurate determination of the point of zero charge of ceramic membranes. Desalination 121:41–48

Sun Z, Nicolosi V, Rickard D, Bergin SD, Aherne D, Coleman JN (2008) Quantitative evaluation of surfactant-stabilized single-walled carbon nanotubes: dispersion, quality and its correlation with zeta potential. J Phys Chem C 112:10692–10699

Esumi K, Ishigami M, Nakajima A, Sawada K, Honda H (1996) Chemical treatment of carbon nanotubes. Carbon 34:279–281

Acknowledgements

This work was supported by CONACYT Grant No. 220513 and a project of infrastructure No. 268595, both under the direction of FA. Technical advice and support from Dr. Juan Cauich, Santiago Duarte, Rossana Vargas, Jesús Kú and Marco Cen (all from CICY) is acknowledged. Use of the Raman (Witec) equipment at CINVESTAV-Mérida under Dr. JJ Alvarado’s direction is greatly appreciated, as well as the technical support of José Bante and Oswaldo Gómez. Assistance of Rene Maas with image editing is also strongly appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Appendix: Measurements of point of zero charge and Z-potential of the oxidized MWCNTs

Appendix: Measurements of point of zero charge and Z-potential of the oxidized MWCNTs

The point of zero charge (PZC) is the pH value at which a particle immersed within an electrolyte exhibits zero net electrical charge on its surface [32, 54]. To determine the PZC of the oxidized MWCNTs, samples containing 5 mg of oxidized MWCNTs in 40 ml of DW at different pH values (between 3 and 10) were prepared. The pH of the DW used was first adjusted between 3 and 10 by adding proper amounts of HCl or NaOH. 5 mg of oxidized MWCNTs were then dispersed in the prepared solutions by ultrasonic agitation (70 W at 42 kHz) for 2 h. After 24 h, the final pH value of each MWCNT/DW solution was measured using an Oakton ion 510 series digital instrument. The final pH values of the MWCNT/DW solution were plotted as a function of their initial pH values (without MWCNTs). The PZC of the MWCNTs corresponds to the pH value where the final pH value (with MWCNTs) is the same as the initial one (without MWCNTs), i.e., the intersection of the plot with a 45° straight line. Following this procedure, according to Fig. 12, the PZC of the oxidized MWCNTs employed was 7.0. The DW employed had a pH of 7.9, implying that the MWCNTs (with a lower PZC) will behave as particles with negative charge (anions) and will thus be collected at the positive electrode [32].

The electrical charge and stability of the MWCNTs in solution were also measured by means of the Z-potential. To determine the Z-potential of the oxidized MWCNTs, a 0.0125 wt% MWCNT/DW solution was prepared by 2 h of ultrasonic dispersion (100 W at 42 kHz). 1 ml of the prepared solution was transferred to the immersion cell of a Zetasizer Nano ZS equipment (Malvern, ZEN3600). Five samples were measured and the average Z-potential measured was − 22.0 ± 4.8 mV. The negative value of the zeta potential may be caused by the acid oxidation [55, 56] and indicates that the MWCNTs behave as anions, in agreement with the PZC results.

Rights and permissions

About this article

Cite this article

Can-Ortiz, A., Oliva-Avilés, A.I., Gamboa, F. et al. Electrophoretic deposition of carbon nanotubes onto glass fibers for self-sensing relaxation-induced piezoresistivity of monofilament composites. J Mater Sci 54, 2205–2221 (2019). https://doi.org/10.1007/s10853-018-2965-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2965-1