Abstract

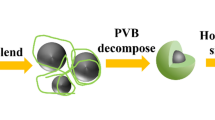

The thermoelectric skutterudite Ba0.3Co4Sb12 is a promising candidate for waste heat recovery applications. Recently, it was demonstrated that the addition of silver nanoparticles (AgNP) to Ba0.3Co4Sb12 increases both the thermoelectric figure of merit and electrical conductivity. This study is the first to examine the effect of AgNP addition on the material’s mechanical properties. This study also found that the Young’s modulus, E, shear modulus, G, and bulk modulus, B, decreased linearly with increasing volume fraction porosity, P. Resonant ultrasound spectroscopy was employed to measure the elastic moduli, and Vickers indentation was used to determine the hardness, H, and fracture toughness, K C. Trends in the mechanical properties as a function of grain size, porosity, and the AgNP are discussed in terms of the pertinent literature. While K C was independent of AgNP addition, porosity, and grain size, both E and H decreased linearly with increasing porosity. In addition, this study is the first to identify (i) the Ag3Sb phase formed and (ii) the enhanced densification that occurs when the AgNP is sintered with Ba0.3Co4Sb12 powders, where both effects are consistent with the eutectic and peritectic reactions observed in the binary phase diagram Ag–Sb. These eutectic/peritectic reactions may also be linked to the enhancement of electrical conductivity previously observed when Ag is added to Ba0.3Co4Sb12. Also, similar beneficial eutectic/peritectic reactions may be available for other systems where conductive particles are added to other antimonides or other thermoelectric systems.

Similar content being viewed by others

References

Ioffe AF (1960) Physics of semicondutors. Infosearch Limited, London, p 313

Shi X, Yang J, Salvador JR, Chi M, Cho JY, Wang H, Bai S, Yang J, Zhang W, Chen L (2011) Multiple-filled skutterudites: high thermoelectric figure of merit through separately optimizing electrical and thermal transports. J Am Chem Soc 133:7837–7846

Segerlind LG (1984) Applied finite element analysis, 2nd edn. Wiley, New York

Hutton D (2004) Fundamentals of finite element analysis. McGraw-Hill, Boston

Zienkiewicz OC, Taylor RL (2005) The finite element method for solid and structural mechanics, 6th edn. Elsevier Butterworth-Heinemann, Boston

Wachtman JB, Cannon WR, Matthewson MJ (2009) Mechanical properties of ceramics. Wiley-VCH, Hoboken

Ren F, Case ED, Timm EJ, Schock HJ (2008) Hardness as a function of composition for n-type LAST thermoelectric material. J Alloy Compd 455:340–345

Zhou X, Wang G, Zhang L, Chi H, Su X, Sakamoto J, Uher C (2012) Enhanced thermoelectric properties of Ba-filled skutterudites by grain size reduction and Ag nanoparticle inclusion. J Mater Chem 22:2958–2964

Androulakis J, Lin C-H, Kong H-J, Uher C, Wu C-I, Hogan T, Cook BA, Caillat T, Paraskevopoulos KM, Kanatzidis MG (2007) Spinodal decomposition and nucleation and growth as a means to bulk nanostructured thermoelectrics: enhanced performance in Pb(1 − x)Sn(x)Te-PbS. J Am Chem Soc 129:9780–9788

Zhao LD, He J, Hao S, Wu C-I, Hogan TP, Wolverton C, Dravid VP, Kanatzidis MG (2012) Raising the thermoelectric performance of p-type PbS with endotaxial nanostructuring and valence-band offset engineering using CdS and ZnS. J Am Chem Soc 134:16327–16336

Zhou M, Li J-F, Kita T (2008) Nanostructured AgPb(m)SbTe(m + 2) system bulk materials with enhanced thermoelectric performance. J Am Chem Soc 130:4527–4532

Alleno E, Chen L, Chubilleau C, Lenoir B, Rouleau O, Trichet MF, Villeroy B (2009) Thermal conductivity reduction in CoSb3–CeO2 nanocomposites. J Electron Mater 39:1966–1970

Ji X, He J, Alboni P, Su Z, Gothard N, Zhang B, Tritt TM, Kolis JW (2007) Thermal conductivity of CoSb3 nano-composites grown via a novel solvothermal nano-plating technique. Phys Status Solidi RRL 1:229–231

Toprak MS, Stiewe C, Platzek D, Williams S, Bertini L, Muller E, Gatti C, Zhang Y, Rowe M, Muhammed M (2004) The impact of nanostructuring on the thermal conductivity of thermoelectric CoSb3. Adv Funct Mater 14:1189–1196

Mi JL, Zhao XB, Zhu TJ, Tu JP (2008) Thermoelectric properties of Yb 0.15 Co 4 Sb 12 based nanocomposites with CoSb 3 nano-inclusion. J Phys D 41:205403

Yoon S, Kwon O-J, Ahn S, Kim J-Y, Koo H, Bae S-H, Cho J-Y, Kim J-S, Park C (2013) The effect of grain size and density on the thermoelectric properties of Bi2Te3–PbTe compounds. J Electron Mater 42:3390–3396

Tokiai T, Uesugi T, Nosaka M, Hirayama A, Ito K, Koumoto K (1997) Thermoelectric properties of Mn-doped iron disilicide ceramics fabricated from radio-frequency plasma-treated fine powders. J Mater Sci 32:3007–3011. doi:10.1023/A:1018609508637

Case ED (2012) Thermal fatigue and waste heat recovery via thermoelectrics. J Electron Mater 41:1811–1819

Case ED (2012) Chapter 16, Thermo-mechanical properties of thermoelectric materials. In: Rowe DM (ed) Thermoelectrics and its energy harvesting: modules, systems and applications. CRC Press, Taylor and Francis Group, Boca Raton, pp 16-1 to 16-29

Lee H, Vashaee D, Wang DZ, Dresselhaus MS, Ren ZF, Chen G (2010) Effects of nanoscale porosity on thermoelectric properties of SiGe. J Appl Phys 107:094308

Yang L, Wu JS, Zhang LT (2004) Synthesis of filled skutterudite compound La0.75Fe3CoSb12 by spark plasma sintering and effect of porosity on thermoelectric properties. J Alloy Compd 364:83–88

He Q, Hu S, Tang X, Lan Y, Yang J, Wang X, Ren Z, Hao Q, Chen G (2008) The great improvement effect of pores on ZT in Co1−xNixSb3 system. Appl Phys Lett 93:042108

Wen P, Duan B, Zhai P, Li P, Zhang Q (2013) Effect of thermal annealing on the microstructure and thermoelectric properties of nano-TiN–Co4Sb11.5Te0.5 composites. J Mater Sci: Mater Electron 24:5155–5161

Pilchak AL, Ren F, Case ED, Timm EJ, Schock HJ, Wu C-I, Hogan TP (2007) Characterization of dry milled powders of LAST (lead–antimony–silver–tellurium) thermoelectric material. Philos Mag 87:4567–4591

Ren F, Case ED, Ni JE, Timm EJ, Lara-Curzio E, Trejo RM, Lin C-H, Kanatzidis MG (2009) Temperature-dependent elastic moduli of lead telluride-based thermoelectric materials. Philos Mag 89:143–167

Ni JE, Case ED, Khabir KN, Stewart RC, Wu C-I, Hogan TP, Timm EJ, Girard SN, Kanatzidis MG (2010) Room temperature Young’s modulus, shear modulus, Poisson’s ratio and hardness of PbTe–PbS thermoelectric materials. Mater Sci Eng B 170:58–66

Schmidt RD, Ni JE, Case ED, Sakamoto JS, Kleinow DC, Wing BL, Stewart RC, Timm EJ (2010) Room temperature Young’s modulus, shear modulus, and Poisson’s ratio of Ce0.9Fe3.5Co0.5Sb12 and Co0.95Pd0.05Te0.05Sb3 skutterudite materials. J Alloy Compd 504:303–309

Migliori A, Sarrao JL (1997) Resonant ultrasound spectroscopy: applications to physics, materials measurements, and nondestructive evaluation. Wiley-VCH, New York

Schmidt RD, Case ED, Lehr GJ, Morelli DT (2013) Room temperature mechanical properties of polycrystalline YbAl3, a promising low temperature thermoelectric material. Intermetallics 35:15–24

Lawn BR, Cook RF (2012) Probing material properties with sharp indenters: a retrospective. J Mater Sci 47:1–22. doi:10.1007/s10853-011-5865-1

Underwood EE (1969) Stereology, or the quantitative evaluation of microstructures. J Microsc 89:161–180

Case ED, Smyth JR, Monthei V (1981) Grain-size determinations. J Am Ceram Soc 64:C24–C25

Barsoum MW (2003) Fundamentals of ceramics. Taylor & Francis Group, New York

Voronin MV, Osadchii EG (2013) Standard thermodynamic properties of Ag3Sb and Ag6Sb evaluated by EMF measurements. Inorg Mater 49:550–554

Cipriani C, Corazza M, Mazzetti G (1996) Reinvestigation of natural silver antimonides. Eur J Mineral 8:1347–1350

Feschotte P, Monachon F, Durussel P (1992) The binary system Sb–Ag: a revision of the Ag3Sb phase boundaries. J Alloy Compd 186:L17–L18

Okamoto H (2007) Ag–Sb (silver–antimony). J Phase Equilibria 28:403

Hassam S, Bahari Z, Legendre B (2001) Phase diagrams of the Ag–Bi–Sb ternary system. J Alloy Compd 315:211–217

Okamoto H (1993) Ag–Sb (silver–antimony). J Phase Equilibria 14:531–532

Zhang L, Sakamoto J (2013) The microstructural stability and thermoelectric properties of Mm0.9Fe3.5Co0.5Sb12-based skutterudites. Mater Chem Phys 138:601–607

Bukat K, Koscielski M, Sitek J, Jakubowska M, Miozniak A (2011) Silver nanoparticles effect on the wettability of Sn–Ag–Cu solder pastes and solder joints microstructure on copper. Solder Surf Mt Technol 23:150–160

Dharma IGBB, Shukor MHA, Ariga T (2009) Wettability of low silver content lead-free solder alloy. Mater Trans 50:1135–1138

Yoshizawa M, Nakanishi Y, Kumagai T, Oikawa M, Sekine C, Shirotani I (2004) Elastic anomalies of polycrystalline SmRu4P12 associated with metal-insulator transition. J Phys Soc Jpn 73:315–318

Slack GA, Tsoukala VG (1994) Some properties of semiconducting IrSb3. J Appl Phys 76:1665–1671

Morelli DT, Meisner GP (1995) Low temperature properties of the filled skutterudite CeFe4Sb12. J Appl Phys 77:3777–3781

Nolas GS, Morelli DT, Tritt TM (1999) Skutterudites: a phonon-glass-electron crystal approach to advanced thermoelectric energy conversion applications. Annu Rev Mater Sci 29:89–116

Nolas GS, Kaeser M, Littleton RT, Tritt TM (2000) High figure of merit in partially filled ytterbium skutterudite materials. Appl Phys Lett 77:1855–1857

Uher C (2001) Skutterudites: prospective novel thermoelectrics. In: Tritt TM (ed) Semiconductors and semimetals, vol 69. Academic Press, San Diego, pp 139–253

Zhang L, Rogl G, Grytsiv A, Puchegger S, Koppensteiner J, Spieckermann F, Kabelka H, Reinecker M, Rogl P, Schranz W, Zehetbauer M, Carpenter MA (2010) Mechanical properties of filled antimonide skutterudites. Mater Sci Eng B 170:26–31

Xiong DB, Okamoto NL, Inui H (2013) Enhanced thermoelectric figure of merit in p-type Ag-doped ZnSb nanostructured with Ag3Sb. Scr Mater 69:397–400

Hashin Z (1962) The elastic moduli of heterogeneous materials. J Appl Mech 29:143–150

Halpin JC (1992) Primer on composite materials analysis. Technomic Publishing Company Inc., Lancaster

Bedolla E, Lemus-Ruiz J, Contreras A (2012) Synthesis and characterization of Mg–AZ91/AlN composites. Mater Des 38:91–98

Couturier R, Ducret D, Merle P, Disson JP, Joubert P (1997) Elaboration and characterization of a metal matrix composite: Al/AlN. J Eur Ceram Soc 17:1861–1866

Ni JE, Ren F, Case ED, Timm EJ (2009) Porosity dependence of elastic moduli in LAST (lead–antimony–silver–tellurium) thermoelectric materials. Mater Chem Phys 118:459–466

Rice RW (1998) Porosity of ceramics. Marcel Dekker, New York

Ramakrishan N, Arunachalam VS (1993) Effective elastic moduli of porous ceramic materials. J Am Ceram Soc 76:2745–2752

Boccaccini AR (1994) Comment on “Effective Elastic Moduli of Porous Ceramic Materials”. J Am Ceram Soc 77:2779–2781

Rice RW (1995) Comment on ‘Effective Elastic Moduli of Porous Ceramic Materials”. J Am Ceram Soc 78:1711

Dunn ML, Ledbetter H (1995) Poisson’s ratio of porous and microcracked solids: theory and application to oxide superconductors. J Mater Res 10:2715–2722

Kim HS, Bush MB (1999) The effects of grain size and porosity on the elastic modulus of nanocrystalline materials. Nanostructured Mater 11:361–367

Zawrah MF, Abdel-kader H, Elbaly NE (2012) Fabrication of Al2O3–20vol% Al nanocomposite powders using high energy milling and their sinterability. Mater Res Bull 47:655–661

Chang Q, Chen DL, Ru HQ, Yue XY, Yu L, Zhang CP (2010) Toughening mechanisms in iron-containing hydroxyapatite/titanium composites. Biomaterials 31:1493–1501

Fujieda T, Uno M, Ishigami H, Kurachi M, Wakamatsu N, Doi Y (2012) Addition of platinum and silver nanoparticles to toughen dental porcelain. Dent Mater J 31:711–716

Fan X, Case ED, Yang Q, Nicholas JD (2013) Room temperature hardness of gadolinia-doped ceria as a function of porosity. J Mater Sci 48:6977–6985. doi:10.1007/s10853-013-7506-3

Ramadass N, Mohan S, Reddy SR (1983) Studies on the metastable phase retention and hardness in zirconia ceramics. Mater Sci Eng 60:65–72

Mangalaraja RV, Ananthakumar S, Uma K, Jiménez RM, López M, Camurri CP (2009) Microhardness and fracture toughness of Ce0.9Gd0.1O1.95 for manufacturing solid oxide electrolytes. Mater Sci Eng A 517:91–96

Shao Y, Du R, Wu X, Song F, Xu X, Jiang C (2013) Effect of porosity on the crack pattern and residual strength of ceramics after quenching. J Mater Sci 48:6431–6436. doi:10.1007/s10853-013-7444-0

Ravi V, Firdosy S, Caillat T, Lerch B, Calamino A, Pawlik R, Nathal M, Sechrist A, Buchhalter J, Nutt S (2008) Mechanical properties of thermoelectric skutterudites. Proc Am Inst Phys Conf, Space Technol Appl Int Forum, Albuquerque, NM, pp 10–14

Eilertsen J, Subramanian MA, Kruzic JJ (2013) Fracture toughness of Co4Sb12 and In0.1Co4Sb12 thermoelectric skutterudites evaluated by three methods. J Alloy Compd 552:492–498

Rogl G, Rogl P (2011) Mechanical properties of skutterudites. Sci Adv Mater 3:517–538

Pharr GM, Herbert EG, Gao Y (2010) The indentation size effect: a critical examination of experimental observations and mechanistic interpretations. Annu Rev Mater Res 40:271–292

Nix WD, Gao H (1998) Indentation size effects in crystalline materials: a law for strain gradient plasticity. J Mech Phys Solids 46:411–425

Bull SJ, Page TF, Yoffe EH (1989) An explanation of the indentation size effect in ceramics. Philos Mag Lett 59:281–288

Sangwal K (2009) Review: indentation size effect, indentation cracks and microhardness measurement of brittle crystalline solids—some basic concepts and trends. Cryst Res Technol 44:1019–1037

Sangwal K (2000) On the reverse indentation size effect and microhardness measurement of solids. Mater Chem Phys 63:145–152

Rice RW (2000) Mechanical properties of ceramics and composites. Marcel Dekker, New York

Lawn BR (1993) Fracture of brittle solids, 2nd edn. Cambridge University Press, New York

Armstrong RW (2011) The hardness and strength properties of WC–Co composites. Matereials 4:1287–1308

Monroe LD, Smyth JR (1978) Grain size dependence of the fracture energy of Y2O3. J Am Ceram Soc 61:538–539

Rhoades WH, Baldoni JG, Wei GC (1986) Final report for ORN contract N00014-82-C-0452. GTE Laboratory

Yasuda K, Kim SD, Kanemichi Y (1990) Influence of grain size and temperature on fracture toughness of MgO sintered body. J Ceram Soc Jpn 98:1103–1108

Veldkamp JDB, Hattu N (1979) On the fracture toughness of brittle materials. Philips J Res 34:1–25

Rice RW (1996) Grain size and porosity dependence of ceramic fracture energy and toughness at 22°C. J Mater Sci 31:1969–1983. doi:10.1007/BF00356616

Yao W, Liu J, Holland TB, Huang L, Xiong Y, Schoenung JM, Mukherjee AK (2011) Grain size dependence of fracture toughness for fine grained alumina. Scr Mater 65:143–146

Vekinis G, Ashby MF, Beaumont PWR (1990) R-curve behavior of Al2O3 ceramics. Acta Metall Mater 38:1151–1162

Swanson PL, Fairbanks CJ, Lawn BR, Mai YW, Hockey BJ (1987) Crack-interface grain bridging as a fracture-resistance mechanism in ceramics. J Am Ceram Soc 70:279–289

Foulk JW III, Cannon RM, Johnson GC, Klein PA, Ritchie RO (2007) A micromechanical basis for partitioning the evolution of grain bridging in brittle materials. J Mech Phys Solids 55:719–743

Bennison SJ, Lawn BR (1989) Role of interfacial grain-bridging sliding friction in the crack resistance and strength of nontransforming ceramics. Acta Metall 37:2659–2671

Schmidt RD, Case ED, Ni JE, Trejo RM, Lara-Curzio E, Korkosz RJ, Kanatzidis MG (2013) High-temperature elastic moduli of thermoelectric SnTe1±x–ySiC nanoparticulate composites. J Mater Sci 48:8244–8258. doi:10.1007/s10853-013-7637-6

Hasselman DPH, Fulrath RM (1965) Effect of spherical tungsten dispersions on young’s modulus of a glass. J Am Ceram Soc 48:548–549

Lowrie R, Gonas AM (1967) Single crystal elastic properties of tungsten from 24° to 1800°C. J Appl Phys 38:4505–4509

Macfarlane RE, Rayne JA (1965) Anomalous temperature dependence of shear modulus c44 for platinum. Phys Lett 18:91–92

Neighbours J, Alers G (1958) Elastic constants of silver and gold. Phys Rev 885:707–712

Chang YA, Himmel L (1966) Temperature dependence of the elastic constants of Cu, Ag, and Au above room temperature. J Appl Phys 37:3567–3572

Acknowledgements

The authors acknowledge the financial support of the Department of Energy, Revolutionary Materials for Solid State Energy Conversion Center, an Energy Frontiers Research Center funded by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences under award number DE-SC0001054.

Author information

Authors and Affiliations

Corresponding author

Appendix A: Effect of nanoparticle addition on the elastic modulus of a composite material

Appendix A: Effect of nanoparticle addition on the elastic modulus of a composite material

The effect of the nanoparticle additions on the Young’s modulus, E C, of a nanocomposites material can be predicted from numerous models. In this Appendix, we list relationships for four composite models, namely rule of mixtures (ROM), Reuss constant strain (RCS), Hashin particulate (HP), and Halpin–Tsai (HT) [90]. For each model, the Young’s modulus of the composite, E C, is the based on E r, the elastic modulus of the nanoparticle reinforcement phase, V r, the volume fraction reinforcement phase, E m, the Young’s modulus of the matrix phase, and, V m, the volume fraction matrix phase. Expressions for the four models can be written as

In the HT model, a/b is the aspect ratio (length/thickness) for the reinforcing phase and q is a boundary condition parameter given by

Table 8 summarizes the Young’s modulus change due to the addition of both micron-sized and nanosized-metallic particles to brittle matrices in studies by Hasselman [91] and by Fujieda et al. [64]. Table 8 gives the measured composite modulus, E C, for the addition of 0.10, 0.20, 0.30, and 0.40 volume fraction of tungsten particles with diameters of approximately 30 µm to a borosilicate glass [91], along with the predicted values of modulus calculated by the ROM, RCS, HP, HT models and the modulus of tungsten [92]. In addition, Table 8 lists the measured E C, for composite specimens from Fujieda et al. [64], who measured the elastic modulus change induced by adding either 26 wt % platinum nanoparticles (PtNP) [93] or 26 wt % AgNP [94, 95] to a dental porcelain, where the mean diameters of the PtNP and AgNP nanoparticles were 5 nm and 10 nm, respectively. The measured composite moduli, E C, (Table 8) [64, 91] agree quite well with the moduli calculated in this study using the Halpin–Tsai model (HT). Since the metal particles were spherical in both the Hasselman [91] and Fujieda et al. [64] studies, for the purposes of the calculations, we set a/b = 1 in Eq. (11), where a/b is the particle aspect ratio.

The amounts of particle addition in the studies by Fujieda et al. [64] and Hasselman [91] were significantly greater than the 0.0068 volume fraction (0.5 wt %) AgNP added in this study. The four composite models given in this Appendix predict a decrease in E C of about 0.39 % with the 0.5 wt % AgNP addition to the Ba-skutterudite in this study. In recent research by Schmidt et al. [90] applied the four modulus-composite models to a thermoelectric system consisting of a brittle matrix and a brittle reinforcing phase, namely with 0.00, 0.01, 0.02, 0.03, and 0.04 volume fraction of added SiC nanoparticles (SiCNP) in the brittle thermoelectric matrix SnTe1+X , (where x = 0.0 or 0.016), Hashin and the Halpin–Tsai models best described the elastic modulus data. Thus, for the Hasselman [91] and Fujieda et al. [64] studies in which the volume percentage of micro- and nano-particles added was relatively high (from 0.10 to 0.40 volume fraction), as well as the SnTe1+X (with 0.00 to 0.04 volume fraction SiCNP added), the Haplin–Tsai model agrees with the experimental modulus data relatively well. In particular, for 0.5 wt % AgNP in this study, the Haplin–Tsai model predicts a change in E of only 0.35 %, which is consistent with the E values measured in this study for the Ba-skutterudite with and without added AgNP.

Rights and permissions

About this article

Cite this article

Schmidt, R.D., Case, E.D., Lobo, Z. et al. Influence of silver nanoparticle addition, porosity, and processing technique on the mechanical properties of Ba0.3Co4Sb12 skutterudites. J Mater Sci 49, 7192–7212 (2014). https://doi.org/10.1007/s10853-014-8427-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8427-5