Abstract

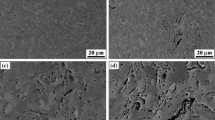

The mechanical characteristics of graphene and coconut shell ash (CSA) particles added to aluminium 6061 metal matrix composites (MMC) are examined in this work. In the process of fabricating composites, stir casting is used, with CSA fluctuations ranging from 0 to 8% and a constant graphene content of 0.6%. Scanning electron microscopy (SEM) micrographs were obtained to provide detailed insights into the microstructure of different aluminium matrix composites (AMCs) reinforced with graphene nanoparticles (0.6% C) and varying percentages of coconut shell ash (CSA) at different concentrations (2%, 4%, 6%, and 8% CSA). The hardness results show a consistent increase with higher coconut shell ash (CSA) content in aluminium (Al6061) composites, while keeping the nanographene content constant at 0.6%. The tensile test results for aluminium (Al6061) composites reinforced with 0.6% nanographene and varying percentages of coconut shell ash (CSA) in 2% increments up to 8%. The tensile strength and yield strength generally increase with higher CSA content, indicating improved mechanical properties.

Similar content being viewed by others

References

D.L. McDanels, Analysis of stress-strain, fracture and ductility behaviour of aluminium matrix composites containing discontinuous SiC reinforcement. Metall. Trans. A 16, 1105–1115 (1985)

H.C. BrianRalph, W.B. Yuen, Lee, the processing of metal matrix composites: an overview. J. Mater. Process. Technol. 63(1–3), 339–353 (1997)

S.V.S. NarayanaMurty, B. Nageswara Rao, B.P. Kashyap, On the hot working characteristics of 6061Al–SiC and 6061–Al2O3 particulate reinforced metal matrix composites. Compos. Sci. Technol. 63(1), 119–135 (2003)

B. Previtali, D. Pocci, CataldoTaccardo application of traditional investment casting process to aluminium matrix composites. Compos. Part A Appl. Sci. Manuf. 39(10), 1606–1617 (2008)

S. Das, S. Das, K. Das, RETRACTED: Abrasive wear of zircon sand and alumina reinforced Al–4.5 wt% Cu alloy matrix composites: a comparative study. Compos. Sci. Technol. 67(3–4), 746–751 (2007)

A. Kumar, S. Lal, S. Kumar, Fabrication and characterization of A359/Al2O3 metal matrix composite using electromagnetic stir casting method. J. Mater. Res. Technol. 2(3), 250–254 (2013)

M. Hossein-Zadeh, O. Mirzaee, P. Saidi, Structural and mechanical characterization of Al-based composite reinforced with heat treated Al2O3 particles. Mater. Des. (1980–2015) 54, 245–250 (2014)

B.C. Kandpal, H. Singh, Fabrication and characterisation of Al2O3/aluminium alloy 6061 composites fabricated by stir casting. Mater. Today.: Proc. 4, 2783–2792 (2017)

C. Reddy, Evaluation of mechanical behavior of alalloy/Al2O3 metal matrix composites with respect to their constituents using Taguchi technique. Int. J. Emerg. Technol. Appl. Eng., Technol. Sci. 4, 26–32 (2011)

M.H. Rahman, H.M. Al Rashed, Characterization of silicon carbide reinforced aluminum matrix composites. Proced. Eng. 90, 103–109 (2014)

R.K. Bhushan, S. Kumar, S. Das, Fabrication and characterization of 7075 Al alloy reinforced with SiC particulates. Int. J. Adv. Manuf. Technol. 65, 611–624 (2015)

J. Yang, C. Cady, M.S. Hu, F. Zok, Effects of damage on the flow strength and ductility of a ductile A1 alloy reinforced with SiC particulates. Actametall. mater. 38(12), 2613–2619 (1990)

S. Valdez, B. Campillo, R. Perez, L. Martínez, Synthesis and microstructural characterization of Al–Mg alloy–SiC particle composite. Mater. Lett. 62, 2623–2625 (2008)

N.G. Siddeshkumar, C. Durga Prasad, R. Suresh, K.R. Varun, S. Patro, S. Kore, S.R. Pawar, T.A. Sudarshan, Investigation of mechanical and metallurgical properties of friction welded joints for dissimilar metals (HSS M2 and EN8 Steel). J Inst Eng (India): Ser D (2024). https://doi.org/10.1007/s40033-024-00658-z

V. Lakkannavar, K.B. Yogesha, C. Durga Prasad, M. Mruthunjaya, R. Suresh, A review on tribological and corrosion behavior of thermal spray coatings. J Inst Eng (India): Ser D (2024). https://doi.org/10.1007/s40033-024-00636-5

N. Praveen, U.S. Mallik, A.G. Shivasiddaramaiah, C. Rajashekhar Hosalli, D. Prasad, S. Bavan, Machinability study of Cu-Al-Mn shape memory alloys using Taguchi method. J. Inst Eng (India): Ser D (2024). https://doi.org/10.1007/s40033-023-00629-w

N.G. Siddeshkumar, R. Suresh, C. Durga Prasad, L. Shivaram, N.H. Siddalingaswamy, Evolution of the surface quality and tool wear in the high speed turning of Al2219/n-B4C/MoS2 metal matrix composites. Int. J. Cast Metals Res. 37(1), 22–38 (2023). https://doi.org/10.1080/13640461.2023.2285177

K.V. Shanthala Kollur, C. DurgaManjunath, B. ByraPrasad, K.S. Reddy, P.K. Rudra, C.R. Aprameya, “Evaluation of microstructural and mechanical properties of tribaloy based composite cladding by microwave heating. J. Inst. Eng.: Series, D (2024). https://doi.org/10.1007/s40033-024-00670-3

N. Praveen, U.S. Mallik, A.G. Shivasiddaramaiah, N. Nagabhushana, C. Durga Prasad, S. Kollur, Effect of CNC end milling parameters on Cu-Al-Mn ternary shape memory alloys using taguchi method. J. Inst. Eng.: Ser,D (2023). https://doi.org/10.1007/s40033-023-00579-3

C. Durga Prasad, S. Kollur, C.R. Aprameya, T.V. Chandramouli, T. Jagadeesha, B.N. Prashanth, Investigations on tribological and microstructure characteristics of WC-12Co/FeNiCrMo composite coating by HVOF process. JOM J. Miner., Metals Mater. Soc. (2023). https://doi.org/10.1007/s11837-023-06242-2

S. Gotagunaki, V.S. Mudakappanavar, R. Suresh, C. Durga Prasad, Studies on the mechanical properties and wear behavior of an AZ91D magnesium metal matrix composite utilizing the stir casting method. Metall., Microstruct., Anal. (2023). https://doi.org/10.1007/s13632-023-01017-2

C. Manjunatha, T.N. Sreenivasa, P. Sanjay, C. Durga Prasad, “Optimization of friction stir welding parameters to enhance weld nugget hardness in AA6061-B4C composite material. J. Inst. Eng.: Ser., D (2023). https://doi.org/10.1007/s40033-023-00562-y

C. Durga Prasad, S. Kollur, M. Nusrathulla, G. Satheesh Babu, M.B. Hanamantraygouda, B.N. Prashanth, N. Nagabhushana, Characterisation and wear behaviour of SiC reinforced FeNiCrMo composite coating by HVOF process. Trans. IMF (2023). https://doi.org/10.1080/00202967.2023.2246259

M. Arunadevi, M. Rani, R. Sibinraj, M.K. Chandru, C. Durga Prasad, “Comparison of k-nearest neighbor & artificial neural network prediction in the mechanical properties of aluminum alloys. Mater. Today: Proc. (2023). https://doi.org/10.1016/j.matpr.2023.09.111

G.S. Kulkarni, N.G. Siddeshkumar, C. Durga Prasad, L. Shankar, R. Suresh, Drilling of GFRP with liquid silicon rubber reinforced with fine aluminium powder on hole surface quality and tool wear using DOE. J. Bio- Tribo-Corros. (2023). https://doi.org/10.1007/s40735-023-00771-8

N. Praveen, U.S. Mallik, A.G. Shivasiddaramaih, R. Suresh, C. Durga Prasad, L. Shivaramu, Synthesis and wire EDM characteristics of Cu–Al–Mn ternary shape memory alloys using Taguchi method. J. Inst. Eng.: Ser., D (2023). https://doi.org/10.1007/s40033-023-00501-x

N. Praveen, U.S. Mallik, A.G. Shivasiddaramaih, R. Suresh, L. Shivaramu, C. Durga Prasad, M. Gupta, Design and analysis of shape memory alloys using optimization techniques. Adv. Mater. Process. Technol. (2023). https://doi.org/10.1080/2374068X.2023.2208021

H. Sharanabasva, C. Durga Prasad, M.R. Ramesh, Characterization and wear behavior of NiCrMoSi microwave cladding. J. Mater. Eng. Perform. (2023). https://doi.org/10.1007/s11665-023-07998-z

M. Mathapati, C. Kiran Amate, D. Prasad, M.L. Jayavardhana, T. Hemanth Raju, A review on fly ash utilization. Mater. Today Proc., Sci. 50, 1535–1540 (2022). https://doi.org/10.1016/j.matpr.2021.09.106

Funding

No funding or other financial assistance was given to this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The writers claim that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, L.J., Ganjigatti, J.P., Irfan, G. et al. Effect of Graphene and Coconut Shell Ash on Mechanical Properties of Al6061 Metal Matrix Composites. J. Inst. Eng. India Ser. D (2024). https://doi.org/10.1007/s40033-024-00708-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40033-024-00708-6