Abstract

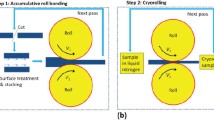

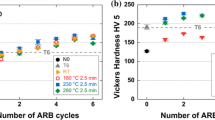

Tensile tests and strain-rate jump tests were carried out at several temperatures below room temperature on Cu processed by accumulative roll-bonding (ARB). The temperature dependences of the flow stress and the activation volume were determined. In contrast to conventional coarse-grained materials where the activation volume increases with increasing temperature, the ARB processed copper by 8 cycles with ultrafine-grains showed inverse temperature dependence of activation volume, i.e., decreased activation volume with increasing temperature. This inverse temperature dependence of the activation volume is discussed in terms of thermally activated dislocation bow-out from grain-boundaries.

Similar content being viewed by others

References

Meyers MA, Mishra A, Benson DJ (2006) Prog Mater Sci 51:427–556

Azushima A, Kopp R, Korhonen A, Yang DY, Micari F, Lahoti GD, Groche P, Yanagimoto J, Tsuji N, Rosochowski A, Yanagida A (2008) CIRP Ann-Manuf Technol 57:716–735

Valiev RZ (2007) J Mater Sci 42:1483–1490. doi:10.1007/s10853-006-1281-3

Zhilyaev AP, McNelley TR, Langdon TG (2007) J Mater Sci 42:1517–1528. doi:10.1007/s10853-006-0628-0

Langdon TG (2007) J Mater Sci 42:3388–3397. doi:10.1007/s10853-006-1475-8

Mishra A, Richard V, Gregori F, Asaro RJ, Meyers MA (2005) Mater Sci Eng A 410–411:290–298

Takata N, Yamada K, Ikeda K, Yoshida F, Nakashima H, Tsuji N (2007) Mater Trans 48:2043–2048

Edalati K, Fujioka T, Horita Z (2008) Mater Sci Eng A 497:168–173

Ito Y, Horita Z (2009) Mater Sci Eng A 503:32–36

Hanazaki K, Shigeiri N, Tsuji N (2010) Mater Sci Eng A 527:5699–5707

Kunimine T, Takata N, Tsuji N, Fujii T, Kato M, Onaka S (2009) Mater Trans 50:64–69

Huang X, Hansen N, Tsuji N (2006) Science 312:249–251

Wang YM, Hamza AV, Ma E (2006) Acta Mater 54:2715–2726

Wang YM, Cheng S, Wei QM, Ma E, Nieh TG, Hamza A (2004) Scr Mater 51:1023–1028

Conrad H (1965) In: Zackay VF (ed) High-Strength Materials. John Wiley & Sons, Inc, New York

Bochniak W (1995) Acta Metall Mater 43:225–233

Conrad H, Yang D (2002) J Electron Mater 31:304–312

Conrad H (2003) Mater Sci Eng A 341:216–228

Cheng S, Spencer JA, Milligan WW (2003) Acta Mater 51:4505–4518

Kato M, Fujii T, Onaka S (2008) Mater Trans 49:1278–1283

Kato M (2009) Mater Sci Eng A 516:276–282

Tsuji N, Saito Y, Utsunomiya H, Tanigawa S (1999) Scr Mater 40:795–800

Tsuji N (2006) In: Altan BS, Miskioglu I, Purcek G, Mulyukov RR, Artan R (eds) Severe plastic deformation: towards bulk production of nanostructured materials. NOVA Science Publishers, New York

Kunimine T, Fujii T, Onaka S, Tsuji N, Kato M, in press

Shen YF, Lu L, Dao M, Suresh S (2006) Scr Mater 55:319–322

Dalla Torre FH, Pereloma EV, Davies CHJ (2006) Acta Mater 54:1135–1146

Estrin Y, Kim HS, Nabarro FRN (2007) Acta Mater 55:6401–6407

Frost HJ, Ashby MF (1982) Deformation-Mechanism Maps. Pergamon, Oxford

Acknowledgements

This research was supported by a Grant-in-Aid for Scientific Research on Innovative Areas “Bulk Nanostructured Metals” (22102006) from the Ministry of Education, Culture, Sports, Science and Technology (MEXT) of Japan. T. Kunimine is grateful for the support of the Global COE Program (Education and Research Center for Material Innovation) in Tokyo Institute of Technology, MEXT, Japan.

Author information

Authors and Affiliations

Corresponding author

Appendix. Derivation of Eq. 3 from Eq. 2

Appendix. Derivation of Eq. 3 from Eq. 2

Eq. 2 can be rewritten as

where \( \eta = L_{\text{GB}} /(2r) > 0 \) and \( \delta \eta = w^{\ast} /(2r) > 0 \). The authors also have \( \eta = L_{\text{GB}} /(2r) = \sin \theta \) where θ is the critical bow-out angle. Since the activation distance w* of the pinning point is naturally much shorter than the average distance \( L_{\text{GB}} \) between pinning points, the authors have \( \left| {\delta \eta /\eta } \right| \ll 1 \).

The function \( \sin^{ - 1} \left( \eta \right) \) in the right side of Eq. 11 is given by the series written as

where \( \left( {2n - 1} \right)!! = \left( {2n - 1} \right)\left( {2n - 3} \right) \ldots \, 3 \cdot 1 \) and \( \left( {2n} \right)!! = \left( {2n} \right)\left( {2n - 2} \right) \ldots \, 4 \cdot 2. \) When \( \left| {\delta \eta /\eta } \right| \ll 1 \), we have

When θ is not so large, for example, θ < 1, the higher-order terms of \( \eta^{2n} \), such as \( \eta^{6} \), \( \eta^{8} \), \( \eta^{10} \),…, can be regarded much smaller than \( \eta^{0} = 1 \). Hence, we have

When \( 0 < \delta \eta /\eta \ll 1 \) is satisfied and the higher-order terms of \( \eta^{2n} \) are neglected, we also have

From Eqs. 11, 15 and 16, the authors have

Using \( \eta = L_{\text{GB}} /(2r) \), \( \delta \eta = w^{\ast} /(2r) \) and \( r = L_{\text{GB}} /(2\sin \theta ) \), Eq. 3 can be obtained from Eq. 17.

Rights and permissions

About this article

Cite this article

Kunimine, T., Aragaki, T., Fujii, T. et al. Inverse temperature dependence of activation volume in ultrafine-grained copper processed by accumulative roll-bonding. J Mater Sci 46, 4302–4307 (2011). https://doi.org/10.1007/s10853-010-5243-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-5243-4