Abstract

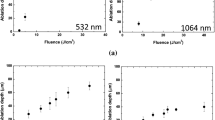

A 248 nm, 23 ns pulsed excimer laser was used to compare the ablation characteristics of single crystal wafers of the polytypes 4H-SiC and 6H-SiC over a wide range of energy fluence (0.8–25 J cm−2). Photothermal models based on Beer–Lambert equation using thermal diffusivity and absorption coefficient, energy balance, and heat transfer were presented to predict the ablation mechanisms. Micromachining of trenches was demonstrated at 7 J cm−2 to demonstrate the potential of UV laser ablation. Results indicate that the ablation process is characterized by two well-defined threshold fluences: (a) decomposition threshold ~1 J cm−2 and (b) melting threshold ~1.5 J cm−2 for both polytypes. Contrary to the modeling expectations, the ablation rates were lower and did not increase rapidly with energy fluence. Four types of ablation mechanisms—chemical decomposition, vaporization, explosive boiling, and plasma shielding—either singly or in combination occur as a function of energy fluence. The predictions of photothermal models were not in good agreement with the experimental data implying that a complex interplay among various physical phenomena occurs during ablation. Micromachined trench exhibited ripple patterns, microcracks and recast layers, most of which could be eliminated by a subsequent chemical cleaning process. It is concluded that excimer laser ablation is an effective but slow material removal process for SiC wafers compared to other lasers such as 1064 nm Nd:YAG.

Similar content being viewed by others

References

Östling M, Koo SM, Zetterling CM, Khartsev S, Grishin A (2004) Thin Solid Films 469–470:444

Dong Y, Zorman C, Molian P (2003) J Micromech Microeng 13:680

Young DJ, Jiangang D, Zorman C, Ko WH (2004) IEEE Sens J 4:464

Jepps NW, Page T (1983) In: Krishna P (ed) Progress in crystal growth and characterization. Pergamon Press, Oxford

Méndez D, Aouni A, Araújo D, Bustarret E, Ferro G, Monteil Y (2005) Mater Sci Forum 483–485:555

Zhang J, Sugioka K, Wada S, Tashiro H, Toyoda K, Midorikawa K (1998) Appl Surf Sci 127–129:793

Mehregany M, Zorman C (1999) Thin Solid Films 355–356:518

Pearton SJ, Abernathy CR, Gila BP, Ren F, Zavada JM, Park YM (2004) Solid State Electron 48:827

Palma C, Sapia C (2000) J Electron Mater 29:607

Kim S, Bang BS, Ren F, D’Etremont J, Blumenfeld W, Cordock T, Pearson SJ (2004) J Electron Mater 33:477

Schlaf M, Sands D, Key PH (2000) Appl Surf Sci 154–155:83

Zekentes K, Zergioti I, Klini A, Constantindis G (2006) Mater Sci Forum 527–529:1119

Battula A, Theppakuttai S, Chen S (2006) J Microlith Microfab Microsys 5:011009-1

Zhang J, Sugioka K, Wada S, Tashiro H, Toyoda K (1997) Appl Phys A 64:367

Itoh N (1997) Nucl Instrum Methods B 122:405

Lambrecht WRL, Segall B, Suttrop W, Yoganathan M, Devaty RP, Choyke WJ, Edmond JA, Powell JA, Alouani M (1993) Appl Phys Lett 63:2747

Logothetidis S, Petalas J (1996) J Appl Phys 80:1768

Sridhara SG, Devaty RP, Choyke WJ (1998) J Appl Phys 84:2963

Blank TV, Goldberg YA, Kalinina EV, Konstantinov OV, Konstantinov AO, Hall′en A (2005) Semicond Sci Technol 20:710

Philipp HR, Taft EA (1960) In: O’Connor JR, Smiltens J (eds) Silicon carbide—a high temperature semiconductor. Pergamon Press, Oxford, London, New York, Paris

Levinshtein ME, Rumyantsev SL, Shur MS (2001) Properties of advanced semicondutor materials. Wiley, New York

Zetterling C-M (2002) Process technology for silicon carbide. INSPEC, London

Nilsson O, Mehling H, Horn R, Fricke J, Hofmann R, Muller SG, Eckstein R, Hofmann D (1997) High Temp High Press 29:73

Desbiens J-P, Masson P (2007) Sens Actuators A 136:554

Tseng AA, Chen Y-T, Ma K-J (2004) Opt Lasers Eng 41:827

Reitano R, Baeri P (1996) Nucl Instrum Methods Phys Res B 116:369

von der Linde D, Sokolowski-Tinten K, Bialkowski J (1997) Appl Surf Sci 109–110:1

McGeough J (2002) Micromachining of engineering materials. Marcel Dekker Inc., New York, Basel, pp 219–221

Furzikov NP (1990) Appl Phys Lett 56:1638

Carslaw HS, Jaeger JC (1959) Conduction of heat in solids, 2nd edn. Clarendon, Oxford

Von Allmen MF, Lau SS (1982) In: Poate JM, Mayer JW (eds) Laser annealing of semiconductors. Academic Press, New York

Ready JF (1971) Effects of high-power laser radiation. Academic Press, New York

Ozisik N (1993) Heat conduction. Wiley, New York

Yoo JH, Jeong SH, Greif R, Russo RE (2000) J Appl Phys 88:1638

Kim JJ, Katz DJ (1987) United States Patent 4649002, Kennecott Corporation, Ohio

Song Y, Smith FW (2002) Appl Phys Lett 81:3061

Duanming Z, Dan L, Zhihua L, Li G, Xinyu T, Li L, Ranran F, Dezhi H, Gaobin L (2007) Appl Surf Sci 253:6144

Dan L, Duanming Z (2008) Chin Phys Lett 25:1368

Gorelik T, Urban S, Falk F, Kaiser U, Glatzel U (2003) Chem Phys Lett 373:642

Savvatimskiy AI (2005) Carbon 43:1115

Bauerle D (2000) Laser processing and chemistry. Springer-Verlag, Berlin, New York

Amoruso S (1999) Appl Phys A 69:314

Neri F, Barreca F, Trusso S (2002) Diam Relat Mater 11:273

Yoo JH, Jeong SH, Mao XL, Greif R, Russo RE (2000) Appl Phys Lett 76:783

Craciun V, Bassim N, Singh RK, Craciun D, Hermann J, Boulmer-Leborgne C (2002) Appl Surf Sci 186:288

Martynyuk MM (1974) Sov Phys Tech Phys 19:793

Martynyuk MM (1976) Sov Phys Tech Phys 21:430

Song KH, Xu X (1998) Appl Surf Sci 127–129:111

Shanks HR, Maycock PD, Sidles PH, Danielson GC (1963) Phys Rev 130:1743

Glassbrenner CJ, Slack GA (1964) Phys Rev 134:A1058

Xing WH, Chen X (2003) J Phys D Appl Phys 36:2230

Reid RC (1976) Am Sci 64:146

Carey VP (1992) Liquid–vapor phase phenomena. Hemisphere, Washington

Miotello A, Kelly R (1999) Appl Phys A 69:S67

Kelly R, Miotello A (1996) Appl Surf Sci 96–98:205

Lu Q, Mao SS, Mao X, Russo RE (2002) Appl Phys Lett 80:3072

Russo RE, Mao XL, Liu HC, Yoo JH, Mao SS (1999) Appl Phys A 69 Suppl:S887

Bogaerts A, Chen ZY, Gizbels R, Vertes A (2003) Spectrochim Acta B 58:1867

Chen ZY, Bogaerts A (2005) J Appl Phys 97:063305

Lunney JG, Jordan R (1998) Appl Surf Sci 941:127

Islam MU, Mcgregor G, Campbell G (1992) United States Patent 5138130, National Research Council of Canada, California

Koo JC, Slusher RE (1976) Appl Phys Lett 28:614

Sipe JE, Young JF, Preston JS, Van Driel HM (1983) Phys Rev B 27:1155

McCulloch DJ, Brotherton SD (1995) Appl Phys Lett 66:2060

Dong Y, Molian P (2004) Appl Phys Lett 84:10

Wu XJ, Jia TQ, Zhao FL, Huang M, Xu NS, Kuroda H, Xu ZZ (2007) Appl Phys A 86:491

Bastow TJ (1969) Nature 222:1058

Aussenegg FR, Leitner A, Lippitsch ME (1983) Surface studies with laser. Springer Series in Chemical Physics, Berlin, Springler

Thomas SJ, Harrison RF, Figueira JF (1982) Appl Phys Lett 40:200

Caro RG, Gower MC (1982) J Quant Electron QE-18:1380

Ursu I, MihBilescu IN, Popa AL, Prokhorov AM, Ageev VP, Gorbunov AA, Konov VI (1985) J Appl Phys 58:3909

Yu JJ, Lu YF (2000) Appl Surf Sci 154–155:670

Giust GK, Simpson TW (1997) Appl Phys Lett 70:26

Acknowledgements

This material is based in part upon work supported by the National Science Foundation under Grant Number CMMI-0619115. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, S., Pecholt, B. & Molian, P. Excimer laser ablation of single crystal 4H-SiC and 6H-SiC wafers. J Mater Sci 46, 196–206 (2011). https://doi.org/10.1007/s10853-010-4920-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4920-7