Abstract

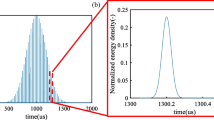

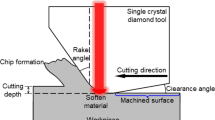

In this study, a 355-nm pulsed laser was used to cut 350-μm-thick silicon carbide wafers. The surface morphology and changes in the elemental composition and structure of the cutting line after processing were analyzed using lasers with various laser power, pulse repetition frequency, scanning speed, and scanning repetition settings; they were also compared with those observed for a test piece made using a diamond wheel. An average laser power of 6 W, pulse repetition frequency of 60 kHz, and scanning speed of 5 mm/s minimized oxidation and achieved a groove width of 18.6 μm—15.1 μm narrower than the diamond-cut groove. X-ray photoelectron spectroscopy revealed that the heat-affected zone and the oxygen content of the surface recast layer increased when the laser energy and number of repetitions increased or when the scanning speed decreased. Oxygen content increased from 15.93% (diamond cutting) to up to 47.81%.

Similar content being viewed by others

References

Gubbi J, Buyya R, Marusic S, Palaniswami M (2013) Internet of Things (IoT): A vision, architectural elements, and future directions. Futur Gener Comput Syst 29:1645–1660. https://doi.org/10.1016/j.future.2013.01.010

TechNews (2018) 2018-hype-cycle-for-emerging-technologies, Technews. https://technews.tw/2018/08/27/gartner-2018-hype-cycle-for-emerging-technologies/

Panetta K (2019) 5 Trends Appear on the Gartner Hype Cycle for Emerging Technologies. Gartner. 2019, August 29. https://www.gartner.com/smarterwithgartner/5-trends-appear-on-the-gartner-hype-cycle-for-emerging-technologies-2019/

Panetta K (2020) 5 Trends Drive the Gartner Hype Cycle for Emerging Technologies. Gartner. 2021, March 8. https://www.gartner.com/smarterwithgartner/5-trends-drive-the-gartner-hype-cycle-for-emerging-technologies-2020/

Pecholt B, Gupta S, Molian P (2001) Review of laser microscale processing of silicon carbide. J Laser Appl 23:012008. https://doi.org/10.2351/1.3562522

Huang Z, Lü TY, Wang HQ, Zheng JC (2015) Thermoelectric properties of the 3C, 2H, 4H, and 6H polytypes of the wide-band-gap semiconductors SiC. GaN, and ZnO, AIP Adv 5:097204. https://doi.org/10.1063/1.4931820

Righi MC, Pignedoli CA, Borghi G, Felice RD, Bertoni CM, Catellani A (2002) Surface-induced stacking transition at SiC(0001). Phys Rev B 66:045320. https://doi.org/10.1103/PhysRevB.66.045320

Leone C, Genna S, Tagliaferri V (2021) An integrated approach for the modelling of silicon carbide components laser milling process. Int J Adv Manuf Technol 116:2335–2357. https://doi.org/10.1007/s00170-021-07516-2

Meng B, Zheng J, Yuan D, Xu S (2019) Machinability improvement of silicon carbide via femtosecond laser surface modification method. Appl Phys A 125:69. https://doi.org/10.1007/s00339-018-2377-8

Chen PC, Miao WC, Ahmed T, Pan YY, Lin CL, Chen SC, Kuo HC, Tsui BY, Lien DH (2022) Defect Inspection Techniques in SiC. Nanoscale Res Lett 17:30. https://doi.org/10.1186/s11671-022-03672-w

Shi H, Song Q, Hou Y, Yue S, Li Y, Zhang Z, Li M, Zhang K, Zhang Z (2022) Investigation of structural transformation and residual stress under single femtosecond laser pulse irradiation of 4H–SiC. Ceram Int 48:24276–24282. https://doi.org/10.1016/j.ceramint.2022.03.063

Zhang B, He S, Yang Q, Liu H, Wang L, Chen F (2020) Femtosecond laser modification of 6H–SiC crystals for waveguide devices. Appl Phys Lett 116:111903. https://doi.org/10.1063/1.5145025

Inoue F, Phommahaxay A, Podpod A, Suhard S, Hoshino H, Moeller B, Sleeckx E, Rebibis KJ, Miller A, Beyne E (2019) Advanced Dicing Technologies for Combination of Wafer to Wafer and Collective Die to Wafer Direct Bonding, IEEE Xplore 18939298, https://doi.org/10.1109/ECTC.2019.00073

Kim E, Shimotsuma YS, Sakakura M, Miura K (2017) 4H-SiC wafer slicing by using femtosecond laser double-pulses. Opt Mater Express 7:2450–2460. https://doi.org/10.1364/OME.7.002450

Hooper A, Ehorn J, Bread M, Bassett C (2015) Review of Wafer Dicing Techniques for Via-Middle Process 3DI/TSV Ultrathin Silicon Device Wafers, IEEE Xplore 15304216, https://doi.org/10.1109/ECTC.2015.7159786

Bai S, Sugioka K (2011) Recent Advances in the Fabrication of Highly Sensitive Surface-Enhanced Raman Scattering Substrates: Nanomolar to Attomolar Level Sensing. Light Adv Manuf 2:13. https://doi.org/10.37188/lam.2021.013

Liu H, Lin W, Hong M (2021) Hybrid laser precision engineering of transparent hard materials: challenges, solutions and applications. Light Sci Appl 10:162. https://doi.org/10.1038/s41377-021-00596-5

Stealth laser dicing engine lineup (2016) DISCO Tech Rev. https://www.disco.co.jp/eg/solution/technical_review/doc/TR16-04_Stealth%20laser%20dicing%20engine%20lineup_20160610.pdf

Kivistö S, Amberla T, Konnunaho T, Kangastupa J, Sillanpää J (2013) X-Lase CoreScriber, picosecond fiber laser tool for high-precision scribing and cutting of transparent materials. Phys Procedia 41:589–591. https://doi.org/10.1016/j.phpro.2013.03.120

Antti M, Ville H, Jorma V (2012) Precise online auto-focus system in high speed laser micromachining applications. Phys Procedia 39:807–813. https://doi.org/10.1016/j.phpro.2012.10.104

Cvetković S, Morsbach C, Rissing L (2011) Ultra-precision dicing and wire sawing of silicon carbide (SiC). Microelectron Eng 88:2500–2504. https://doi.org/10.1016/j.mee.2011.02.026

Xie X, Huang F, Wei X, Hu W, Ren Q, Yuan X (2013) Modeling and optimization of pulsed green laser dicing of sapphire using response surface methodology. Opt Laser Technol 45:125–131. https://doi.org/10.1016/j.optlastec.2012.07.015

Fornaroli C, Holtkamp J, Gillner A (2013) Dicing of thin Si wafers with a picosecond laser ablation process. Phys Procedia 41:603–609. https://doi.org/10.1016/j.phpro.2013.03.122

Shi KW, Kar YB, Talik NA, Yew LW (2017) Ultraviolet Laser Diode Ablation Process for CMOS 45 nm Copper Low-K Semiconductor Wafer. Procedia Eng 284:360–369. https://doi.org/10.1016/j.proeng.2017.04.106

Miyamoto I, Cvecek K, Okamoto Y, Schmidt M (2014) Internal modification of glass by ultrashort laser pulse and its application to microwelding. Appl Phys A 114:187–208. https://doi.org/10.1007/s00339-013-8115-3

Takekuni T, Okamoto Y, Fujiwara T, Okada A, Miyamoto I (2015) Effects of Focusing Condition on Micro-welding Characteristics of Borosilicate Glass by Picosecond Pulsed Laser. Key Eng Mater 656–657:461–467. https://doi.org/10.4028/www.scientific.net/KEM.656-657.461

Yadav A, Kbashi H, Kolpakov S, Gordon N, Zhou K, Rafailov EU (2017) Stealth dicing of sapphire wafers with near infra-red femtosecond pulses. Appl Phys A 123:369. https://doi.org/10.1007/s00339-017-0927-0

Suzuki N, Nakamura T, Kondo Y, Tominaga S, Atsumi K, Ohba T (2020) Damage-Less Singulation of Ultra-Thin Wafers using Stealth Dicing, IEEE 70th ECTC, https://doi.org/10.1109/ECTC32862.2020.00169

Mishchik K, Chassagne B, Javaux-Léger C, Hönninger C, Mottay E, Kling R, Lopez J (2016) Dash line glass- and sapphire-cutting with high power USP laser. Proc SPIE 9740:97400W-W97401. https://doi.org/10.1117/12.2209274

Salvatori S, Ponticelli GS, Pettinato S, Genna S, Guarino S (2020) High-Pressure Sensors Based on Laser-Manufactured Sintered Silicon Carbide. Appl Sci 10:7095. https://doi.org/10.3390/app10207095

Mills B, Grant-Jacob JA (2021) Lasers that learn: The interface of laser machining and machine learning. Ins Eng Technol 15:207–224. https://doi.org/10.1049/ote2.12039

Anderson T, Ren F, Pearton SJ, Mastro MS, Holm RT, Henry RL, Charles REJ, Lee JY, Lee KY, Kim J (2006) Laser ablation of via holes in GaN and AlGaN∕GaN high electron mobility transistor structures. J Vacuum Sci Technol B 24:2246. https://doi.org/10.1116/1.2335435

Li D, Cheng G, Yang Z, Wang Y (2013) Ultrafast Laser Machine Based on All-fiber Femtosecond Laser System. Adv Mater Res 652–654:2374–2377. https://doi.org/10.4028/www.scientific.net/AMR.652-654.2374

Du DH, Naoki I, Kazuyoshi F (2013) A study of near-infrared nanosecond laser ablation of silicon carbide. Int J Heat Mass Transf 65:713–718. https://doi.org/10.1016/j.ijheatmasstransfer.2013.06.050

Huang Y, Wu X, Liu H, Jiang H (2017) Fabrication of through-wafer 3D microfluidics in silicon carbide using femtosecond laser. J Micromech and Microeng 27:065005. https://doi.org/10.1088/1361-6439/aa68cb

Wang Y, Li C, Sun S, Jiang F, Liu S (2019) Experiment and study in laser-chemical combined machining of silicon carbide on grooves microstructure. Mater Res Express 6:075106. https://doi.org/10.1088/2053-1591/ab18ec

Pecholt B, Vendan M, Dong Y, Molian P (2008) Ultrafast laser micromachining of 3C-SiC thin films for MEMS device fabrication. Int J Adv Manuf Technol 39:239–250. https://doi.org/10.1007/s00170-007-1223-5

Zheng QZ, Fan ZJ, Jiang GD, Pan AF, Yan ZX, Lin QY, Cui JL, Wang WJ, Mei XS (2019) Mechanism and morphology control of underwater femtosecond laser microgrooving of silicon carbide ceramics. Opt Express 27:26264–26280. https://doi.org/10.1364/OE.27.026264

Dong Y, Molian P (2004) Coulomb explosion-induced formation of highly oriented nanoparticles on thin films of 3C–SiC by the femtosecond pulsed laser. Appl Phys Lett 84:1. https://doi.org/10.1063/1.1637948

Choi I, Jeong HY, Shin H, Kang G, Byun M, Kim H, Chitu AM, Im JS, Ruoff RS, Choi SY, Lee KJ (2016) Laser-induced phase separation of silicon carbide. Nat Commun 7:13562. https://doi.org/10.1038/ncomms13562

Zhao Y, Zhao YL, Wang LK (2020) Application of femtosecond laser micromachining in silicon carbide deep etching for fabricating sensitive diaphragm of high temperature pressure sensor. Sens Actuators A Phys 309:112017. https://doi.org/10.1016/j.sna.2020.112017

Hönig S, Süß F, Jain N, Jemmali R, Behrendt T, Mainzer B, Koch D (2020) Evaluation of preparation and combustion rig tests of an effusive cooled SiC/SiCN panel. Appl Ceram Technol 17:4. https://doi.org/10.1111/ijac.13501

Sun L, Han C, Wu N, Wang B, Wang Y (2018) High temperature gas sensing performances of silicon carbide nanosheets with an n–p conductivity transition. R Soc Chem 8:13697–13707. https://doi.org/10.1039/C8RA02164C

Chandrasekar MS, Srinivasan NR (2016) Role of SiOx on the photoluminescence properties of β-SiC. Ceram Int 42:8900–8908. https://doi.org/10.1016/j.ceramint.2016.02.145

Huang Y, Tang F, Guo Z, Wang X (2019) Accelerated ICP etching of 6H-SiC by femtosecond laser modification. Appl Surf Sci 488:853–864. https://doi.org/10.1016/j.apsusc.2019.05.262

Kamble MM, Waman VS, Mayabadi AH, Ghosh SS, Gabhale BB, Rondiya SR, Rokade AV, Khadtare SS, Sathe VG, Shripathi T, Pathan HM, Gosavi SW, Jadkar SR (2014) Hydrogenated Silicon Carbide Thin Films Prepared with High Deposition Rate by Hot Wire Chemical Vapor Deposition Method. J Coat 2014:905903. https://doi.org/10.1155/2014/905903

Tian Q, Huang N, Yang B, Zhuang H, Wang C, Zhai Z, Li J, Jia X, Liu L, Jiang X (2017) Diamond/β-SiC film as adhesion-enhanced interlayer for top diamond coatings on cemented tungsten carbide substrate. J Mater Sci Technol 33:1097–1106. https://doi.org/10.1016/j.jmst.2017.06.005

Kim JG, Jung EJ, Kim Y, Makarov Y, Choi DJ (2014) Quality improvement of single crystal 4H SiC grown with a purified β-SiC powder source. Ceram Int 40:3953–3959. https://doi.org/10.1016/j.ceramint.2013.08.041

Acknowledgements

The authors would like to thank the Taiwan Instrument Research Institute (TIRI) Ms. Nancy Chu for supporting the use of high-resolution FE-SEM (Hitachi S-4300). The Taiwan semiconductor Research Institute (TSRI) for XPS analysis. The Southern Taiwan University of Science and Technology (STUST) for supporting the UV-vis-NIR spectrometer, and of scanning electron microscope from Department of Materials and Mineral Resources Engineering, National Taipei University of Technology (NTUT).

Funding

This work was financially supported by the National Science and Technology Council (NSTC) of Taiwan, with project numbers: 110–2622-E-492–016 and 111–2221-E-492–009.

Author information

Authors and Affiliations

Contributions

W.T.: conceptualization, validation, investigation, methodology, formal analysis. C.X.: validation, investigation, analysis. S.F.: formal analysis, investigation, validation. S.F. and W.T.: advisor, conceptualization, validation, investigation, writing—original draft. W.T. and S.F.: advisor, resources, validation, investigation, writing—original draft. W.T.: methodology, supervision, validation, writing—original draft.

Corresponding author

Ethics declarations

Conflicts of Interest

Authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tseng, SF., Luo, CX. & Hsiao, WT. Characterization analysis of 355 nm pulsed laser cutting of 6H-SiC. Int J Adv Manuf Technol 130, 3133–3147 (2024). https://doi.org/10.1007/s00170-023-12802-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12802-2