Abstract

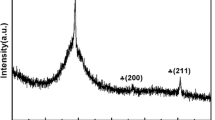

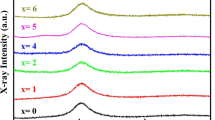

Microstructure fracture and mechanical properties of Cu-based bulk metallic glass alloys were investigated. Centrifugal casting into copper molds were used to manufacture basic Cu47Ti33Zr11Ni9, and modified Cu47Ti33Zr11Ni7Si1Sn1 alloys. Although the alloys show an amorphous structure, TEM images revealed the formation of nanoparticles. At room temperature compression tests reveal fracture strength of 2000 MPa, elastic modulus of 127 GPa, and 1.8% fracture strain for the unmodified basic alloy. Whereas the modified alloy exhibits a fracture strength of 2179 MPa, elastic modulus reaches 123 GPa, and 2.4% fracture strain. So, with the addition of 1 at.% Si and Sn, the fracture strength improves by 9% and the fracture strain improves by 25%, but the fracture behavior under compression conditions exhibits a conical shape similar to that produced by tensile testing of ductile alloys. A proposed fracture mechanism explaining the formation of the conical fracture surface was adopted. The formation of homogeneously distributed nano-size (2–5 nm) precipitates changes the mode of fracture of the metallic glass from single to multiple shear plane modes leading to the conical shape fracture surface morphology.

Similar content being viewed by others

References

Zhang T, Inoue A, Masumoto T (1991) Mater Trans JIM 32(11):1005

Inoue A (1998) Acta Mater 48(1):279

Gilbert CG, Ritchie RO, Johnson WL (1997) Appl Phys Lett 71:476

Conner D, Rosakis AJ, Johnson WL, Owen DM (1997) Scr Mater 37(9):1373

Zhang QS, Zhang HF, Deng YF, Ding BZ, Hu ZQ (2003) Scr Mater 49(4):273

El-Hadek MA, Kassem M (2008) Int J Mech Mater Des 4(3):279

Hays CC, Kim CP, Johnson WL (2000) Phys Rev Lett 84(13):2901

Glade SC, Löffler JF, Bossuyt S, Johnson W (2001) J Appl Phys 89:1573

Bae DH, Lim HK, Kim SH, Kim DH, Kim WT (2002) Acta Mater 50(7):1749

Schroers J (2007) Acta Mater 56(3):471

Park ES, Lim HK, Kim WT, Kim DH (2002) J Non-Cryst Solids 298(1):15

Choi-Yim H, Busch R, Johnson WL (1998) J Appl Phys 83(12):7993

Spaepen F, Taub A (1983) Amorphous metallic alloys. Butterworth, London

Nishiyama N, Inoue A (1997) Mater Trans JIM 38(5):464

Volkert CA, Lilleodden ET (2006) Phil Mag 86(33–35):5567

El-Hadek MA, Kaytbay S (2008) Strain. doi:https://doi.org/10.1111/j.1475-1305.2008.00552.x

Bruck HA, Christman T, Rosakis AJ, Johnson W (1994) Scr Metall Mater 30(4):429

Scudino S, Surreddi KB, Sager S, Sakaliyska M, Kim JS, Löser W, Eckert J (2008) J Mater Sci 43(13):4518. doi:https://doi.org/10.1007/s10853-008-2647-5

Bhowmick R, Majumdar B, Misra DK, Ramamurty U, Chattopadhyay K (2007) J Mater Sci 42(22):9359. doi:https://doi.org/10.1007/s10853-007-1856-7

Donovan PE (1988) Mater Sci Eng 98:487

Lowhaphandu P, Montgomery SL, Lewandowski JJ (1999) Scr Mater 41(1):19

Wright WJ, Saha R, Nix WD (2001) Mater Trans JIM 42:642

Wright WJ, Hufnagel TC, Nix WD (2003) J Appl Phys 93(3):1432

Donovan PE (1989) Acta Mater 37:445

Chen D, Takeuchi A, Inoue A (2007) J Mater Sci 42(20):8662. doi:https://doi.org/10.1007/s10853-007-1830-4

Zhang ZF, Eckert J, Schultz L (2003) Acta Mater 51(4):1167

Liu CT, Heatherly L, Easton DS, Carmichael CA, Schneibel JH, Chen CH (1998) Metall Mater Trans A 29(7):1811

Qiu K, Hao DZ, Ren YL, Zhang H (2007) J Mater Sci 42(9):3223. doi:https://doi.org/10.1007/s10853-006-0238-x

Bian Z, He G, Chen GL (2002) Scr Mater 46(6):407

Kim HS, Bush MB, Esstrin Y (2000) Acta Mater 48(2):493

Palmqvist S (1963) Jernkontoreets Ann 147:107

Chen H, He Y, Shiflet GJ, Poon SJ (1994) Nature 367:541

He Y, Shiflet GJ, Poon SJ (1995) Acta Mater 43(1):83

Gao MC, Hackenberg RE, Shiflet GJ (2003) Appl Phys Lett 83(13):2575

Leamy HJ, Wang TT, Chen HS (1972) Metall Mater Trans B 3(3):699

Calin M, Eckert J, Schultz L (2003) Scr Mater 48(6):653

Bian Z, Chen GL, He G, Hui XD (2001) Mater Sci Eng A 316(1–2):135

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

El-Hadek, M.A., Kassem, M. Failure behavior of Cu–Ti–Zr-based bulk metallic glass alloys. J Mater Sci 44, 1127–1136 (2009). https://doi.org/10.1007/s10853-008-3194-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3194-9