Abstract

With the growing human population, greenhouse gases and global temperature are increasing calling for sustainable biorefineries to convert low-value side streams into high-value products. In this study, the remaining hemicellulosic sugary waste fraction of a wheat straw biorefinery approach, without any pretreatment, was applied as a medium supplement for Chlorella vulgaris cultivation. Next to oligomeric and monomeric sugars, the waste stream contained hydrolysis by-products, such as furfural, 5-hydroxymethylfurfural and acetic acid. Despite the presence of these growth inhibitors, C. vulgaris cultivation was possible. Addition of 2.5% (v/v) of wheat straw hydrolysate to BG11-medium boosted chlorophyll content in C. vulgaris by 40% compared to photoautotrophically grown cells solely cultivated on defined media. As of now, this is the highest chlorophyll content obtained from a cultivation of C. vulgaris on a medium supplemented with a waste stream. Overall, our results demonstrate that wheat straw hydrolysate increases chlorophyll biosynthesis, improving the nutritional value of C. vulgaris biomass for food and feed applications. Hence, valorization of this hemicellulosic sugary fraction results in an additional high-valued product contributing towards the wheat straw biorefinery.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The human population is rising steadily and with it the demand for novel food and feed sources with high nutritional value, as well as the emission of anthropogenic CO2. This effect is enhanced via increasing global temperatures leading to less available water and less arable land (Fereres et al. 2011; Peter et al. 2021), whereas the constant need to produce more food and feed for the supply of livestock and dairy production is expanded (Chong et al. 2021). To circumvent these issues, sustainably grown superfoods high in bioactive properties, are required and gaining in public popularity (Fernandes et al. 2021; Pereira et al. 2021). In recent years, microalgal research and industrial cultivation thereof have expanded significantly, providing a promising solution to tackle those bottlenecks in the food supply chain. Microalgae provide a wide variety of nutritional values, such as a high protein content (18 – 65%), containing all essential amino acids needed for human nutrition (Tibbetts et al. 2015) and a significant amount of poly-unsaturated fatty acids, e.g. eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) (Barkia et al. 2019). They also contain a variety of pigments, such as β-carotene (Wang et al. 2022), astaxanthin (Kumar et al. 2022), lutein (Xie et al. 2021), adonixanthin (Doppler et al. 2022) and chlorophylls (da Silva Ferreira and Sant’Anna 2016). Compared to synthetically manufactured pigments, the ones derived from algal biomass are claimed to exhibit two to ten times higher bioactivity (Patel et al. 2022). Recent studies describe the potential of chlorophyll in pharmaceutical, cosmetic, food and feed applications (Solymosi and Mysliwa-Kurdziel 2017), providing antitumor and antioxidative properties (Hayes and Ferruzzi 2020), increasing hemoglobin content in blood (García et al. 2017), as well as promoting wound healing and reducing inflammatory processes (Pucci et al. 2021; de Andrade et al. 2022). Mixing microalgae biomass, or extracts thereof, into animal feed has proven to positively affect gut health, immune system and the resistance to diseases in cattle and aquaculture (Camacho et al. 2019).

Estimations of current suppliers and producers suggest, that about 19,000 t of dry microalgal biomass are produced annually, with a market value of about US$ 5.7 billion. The market value of algal-derived pigments was estimated to be US$ 452.4 million in 2025 (Patel et al. 2022) underlining their increasing market potential. Microalgae biomass production can be performed by biotechnological approaches solely, not competing for arable land unlike state-of-the-art food and feed supply chains.

Still, researchers agree that photoautotrophic cultivations usually not economically feasible. Consequently, the future should be based on a mixotrophic cultivation mode (Salati et al. 2017; Patel et al. 2021). Mixotrophic cultivation is the combination of photoautotrophic and heterotrophic growth regimes. Hence it decreases the limits of steady microalgal growth in (i) photoautotrophic growth due to photoinhibition, by being able to grow on organic carbon sources, and in (ii) heterotrophic growth due to carbon depletion, as light energy utilization to fixate inorganic carbon (CO2) is possible. It allows faster growth whilst reaching higher cell densities, being the simplest way to increase biomass and product yields (Patel et al. 2021).

Different waste streams have been screened as potential nutrient and carbon sources, to make mixotrophic growth economically and ecologically sustainable. Waste- and side-streams of industrial processes have been described as substrates for microalgal cultivation multiple times (Benedetti et al. 2018), e.g. dairy waste (Abreu et al. 2012), sweet sorghum bagasse (Arora and Philippidis 2021) or liquid waste from biogas production (Sendzikiene and Makareviciene 2022). Another branch of industry producing fermentable streams are biorefinery approaches, processing ligno- and hemicellulosic biomass for extraction of value-added compounds. One of those lignocellulosic biomasses is wheat straw as it is abundantly available, with 1.8 million tonnes per year being produced in Austria alone (Serna-Loaiza et al. 2019). One strategy to deconstruct lignocellulosic biomass into lignin, cellulose and a hemicellulosic fraction, is liquid hot water (LHW) hydrolysis (Serna-Loaiza et al. 2021a). This process results mainly in breaking down hemicellulose and a minor proportion of lignin by using only water as a reaction reagent. The resulting liquid fraction from this process contains monomeric and oligomeric fermentable sugars, namely C5 and C6 compounds. However, sugar degradation products, like 5-hydroxymethylfurfural (HMF), furfural and acetic acid also result from this reaction (Serna-Loaiza et al. 2021b). These LHW degradation products are traditionally regarded as growth inhibitors, slowing or hindering yeast cultivation of e.g. Saccharomyces cerevisiae (Hong et al. 2021) or Pichia pastoris (Yee et al. 2018). Chlorella vulgaris is a suitable organism for cultivation in these inhibitor-containing side-streams, as it is able to metabolize acetate and generally regarded as microalgae suitable for wastewater applications (Wirth et al. 2020). Pentoses, found in hydrolysates derived from hemicellulose, have been described as potential substrate supplements for microalgal cultivation with positive effects on lipid (Leite et al. 2016) and carbohydrate (de Freitas et al. 2019) accumulation in microalgal species. Hydrolysates of bark residues have already been successfully used as substrates in multiple microalgal strains, such as C. vulgaris, Chlorella sorokiniana and Acutodesmus (Scenedesmus) obliquus (Beigbeder et al. 2019). Cyperus esculentus hydrolysate used as substrate for C. vulgaris cultivation even led to better growth when being compared to a defined medium containing glucose in the same concentration, showing great potential of using hydrolysates from lignocellulosic origin as substrate for microalgal cultivation (Wang et al. 2013).

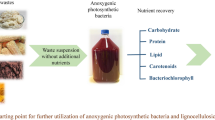

The scope of this study was (i) to find a sustainable application for the liquid sugary fraction after LHW hydrolysis of wheat straw, by producing C. vulgaris biomass, high in chlorophyll a and b contents, for industrial applications, and (ii) to use WSH without prior pretreatment as substrate for cultivation (Fig. 1). This would culminate in an improved version of a biorefinery approach, starting from wheat straw, resulting in the generation of multiple products, like lignin, cellulose, C. vulgaris biomass, via consumption of the hemicellulosic sugar fraction, and spent-medium supernatant consisting of oligomeric sugars.

Schematic representation of the study design. LHW pretreatment of wheat straw results in a liquid hemicellulosic sugary fraction and a solid fraction containing lignin and cellulose. The sugary fraction was used for Chlorella vulgaris biomass production. The spent-media could potentially be used in further applications. (LHW—Liquid Hot Water Hydrolysation)

In this study, different concentrations of wheat straw hydrolysate (WSH) were screened in mixotrophic and heterotrophic cultivation regimes and compared to state-of-the-art photoautotrophic cultivation. The best-performing screening run was consequently scaled up to cultivation in a 2 L stirred tank photobioreactor. The produced microalgal biomass was analyzed in terms of protein content and total chlorophyll content to determine its potential for further applications as food and feed.

Materials and methods

Microalgae strain and inoculum preparation

The green alga Chlorella vulgaris (UTEX 2714) was obtained from the Culture Collection of Algae at the University of Texas at Austin. The medium used was BG11 (Touloupakis et al. 2023) at a pH of 7.5 and 1.0 g L−1 NaNO3. The inoculum was cultivated in 14 h light- (100 µmol photons m−2 s−1) and 10 h darkness-cycles at 23 °C, with 3% (v/v) CO2 enriched air, shaking at 100 rpm in a Minitron shaker (Infors HT, Switzerland).

Wheat straw hydrolysate

The wheat straw used in this work was harvested in 2019 (Margarethen am Moos, State of Lower Austria) and stored under dry conditions and at room temperature. The straw was milled in a cutting mill using a 2 mm mesh. The raw material composition was 2.13, 0.67, 35.31, 21.94, 0.72, 17.35, 20.45, and 1.09% (w/w) (dry basis) for arabinan, galactan, glucan, xylan, mannan, lignin, extractives, and ash, respectively (Serna-Loaiza et al. 2021b), with a moisture content of 7.16% (w/w). The feedstock used in this work corresponds to the batch used in the study reported for the lignocellulosic characterization. The LHW pretreatment was carried out in triplicate in a stainless-steel high-pressure autoclave (Zirbus, HAD 9/16, Germany) with a capacity of 1 L with a stirrer set to 200 rpm. The initial wet mass of wheat straw was approximately 32.31 g, with a solid/liquid ratio of 1 g of dry solid per 11 g of solvent. The moisture content of the solid was subtracted from the prepared solvent. The reactor was heated to 160 °C and cooled after the 90 min holding time. These conditions were selected based on a previous study (Serna-Loaiza et al. 2021a) where LHW temperature and time were optimized to obtain the highest concentration of sugars, with the lowest concentration of degradation products and solubilized lignin. In the cited study, triplicates of the extraction were performed (< 0.3% deviation between repetitions) and the deviation in the measured sugar and degradation product concentrations was below 10%. The solid/liquid ratio was selected to ensure that all the wheat straw would be submerged and covered with water, given its low apparent density, and thus ensure a homogeneous mixing during pretreatment. The solid and liquid fractions were separated using a hydraulic press (Hapa, HPH 2.5) and a centrifuge (Sorvall, RC 6 +) at 24,104 ×g for 20 min. The final supernatant was concentrated using a rotavapor at 60 mbar and 50 °C down to a concentration factor of 4.47 g of raw extract per g of concentrated extract. The composition of the hydrolysate was determined with 89 mg L−1 phosphate at a pH of 5.70, with nitrate and nitrite being below the limit of detection (5 mg L−1). Table 1 depicts the composition and concentrations of the contained sugar fractions in the wheat straw hydrolysates and the corresponding degradation products generated as part of the hydrolysis.

The sugar and degradation product composition of each set of dilutions can be found in online resource 1.

Shakeflask screening experiments

For photoautotrophic cultivations, C. vulgaris was cultivated at 14 h light- (100 µmol photons m−2 s−1) and 10 h darkness-cycles at 23 °C in a 3.0% CO2 enriched atmosphere in the Minitron shaker (Infors HT). The hydrolysates were diluted to 2.5%, 5.0%, 12.5% and 17.5% (v/v) with BG11 pH 7.5 medium for heterotrophic and mixotrophic growth experiments. 50 mL of the corresponding dilution was aseptically added to 250 mL Erlenmeyer flasks before inoculation to a starting optical density at 600 nm (OD600) of 0.10. The mixotrophic growth parameters matched the photoautotrophic parameters in terms of temperature, illumination, CO2 and shaking. Heterotrophic cultivations were performed in 24 h darkness, at 23 °C, shaking at 100 rpm, with no additional CO2 atmosphere. To assess the impact of unknown constituents and the dark brown coloring of the WSH on the microalgal growth and biomass composition, the monomeric sugar content and furan concentration were mimicked in a defined synthetic hydrolysate (SH) stock and handled like WSH. Sampling was done in regular intervals (weekly) for 4 weeks. One mL aliquots were centrifuged at 10,000 ×g and 4 °C for 10 min and the supernatant was used to quantify carbon and furan concentrations, by HPLC analysis described below. The harvested biomass at the end of cultivation was lyophilized and analyzed in terms of total chlorophyll content per dry cell weight (DCW) and the chlorophyll productivities (specific and volumetric) over the cultivation time. The suitability of WSH as medium supplement was assessed in terms of biomass growth and composition. Depending on these outcomes, the best performing runs were upscaled into stirred tank photobioreactor cultivations. Each screening experiment was carried out in biological triplicates and regularly tested for axenicity with agar plates and microscopic analysis.

Cultivation in a stirred tank photobioreactor

For photobioreactor cultivations (PBR), Minifors bioreactors (Infors HT, Switzerland) with a 2 L working volume, were used. The illumination for photoautotrophic and mixotrophic cultivations (14 h light / 10 h darkness) was provided by an external 220 mm × 220 mm LED panel (Aigostar, China) with a total luminous flux of 1300 lm. Illumination inside the reactor was 100 µmol photons m−2 s−1 in BG11 pH 7.5 medium, checked with an ULM 500 Light Meter, equipped with an US-SQS/L sensor (Walz, Germany). pH was measured with an in-line EasyFerm pH electrode (Hamilton, USA), and controlled at 7.5 ± 0.4 (to account for the day and night shifts in CO2 uptake and corresponding pH shifts) throughout the whole process via addition of 2 M Na2CO3 and 1 M HCl. Temperature was set to 23 °C and the agitation to 300 rpm in a constant manner. Aeration flow of the 3% (v/v) CO2-enriched air was in total 300 mL min−1 (0.2 vvm) for photoautotrophic and mixotrophic cultivations. No additional CO2 was supplied for heterotrophic cultivation as airflow was kept at 300 mL min−1. The photobioreactor vessel was covered in aluminum foil to prevent surrounding light from influencing the cultivation. The off-gas concentrations of CO2 and O2 were monitored by BlueSens Gas sensors (BlueSens Gas analytics, Germany). For inoculation, the preculture was added through a septum to reach an OD600 of 0.10. Sampling was done in regular intervals (twice a week) for 4 weeks via sampling port. The samples were analyzed for OD600 and afterward centrifuged at 10,000 ×g and 4 °C for 10 min. The supernatant was stored for carbon, furan, nitrate and phosphate quantification at -20 °C. The harvested biomass at the end of cultivation was lyophilized and analyzed in terms of total chlorophyll- and protein content.

Determination of photosynthetically active radiation

The photosynthetically active radiation (PAR) in the shakeflasks containing different concentrations of WSH was measured with an ULM 500 Light Meter, equipped with an US-SQS/L sensor (Walz, Germany), to account for the loss in light penetration due to the dark color of the WSH. Shakeflasks containing 50 mL of the WSH-dilutions were placed into the Minitron shaker. The ULM 500 Light Meter probe was submerged into the varying WSH-media dilutions to determine the reduction of PAR. This setup was chosen to represent the placement of the shakeflasks in the shaker.

Determination of biomass concentration

Cell growth was determined by measuring OD600 on a Nanodrop One photometer (Thermo Fisher Scientific, USA). By weighing the dried biomass corresponding to certain OD600 measurements, the correlation between DCW and OD600 was established in the following Eq. 1:

where DCW = dry cell weight (g L−1) and OD600 = optical density at 600 nm.

Determination of growth rates

The growth rates were calculated using the following Eq. 2:

where μ = growth rate (day−1) and DCWx = dry cell weight (g L−1) at timepoint tx (day).

Determination of productivities

The biomass volumetric production rate was calculated according to the following Eq. 3:

where rX = volumetric biomass production rate (mg L−1 day−1) and DCWx = dry cell weight (mg L−1) at timepoint tx (day).

The volumetric total chlorophyll and protein production, labelled “product” were calculated as follows in Eq. 4:

where rproduct = volumetric product production rate (mg L−1 day−1) and rX = volumetric biomass production rate (mg L−1 day−1).

Quantification of carbon sources and furans

The supernatant of the sampled aliquots was analyzed for monomeric sugars using HPAEC-PAD (ICS-5000, Thermo Scientific, USA) with deionized water as eluent. Oligomeric sugars were hydrolyzed (diluted sulfuric acid, 4% (w/w)) at 120 °C and analyzed as monomers. A sugar recovery standard was used to account for losses. Furfural, HMF, and acetic acid were determined using HPLC (LC-20A HPLC system, Shimadzu, Japan) by UV and RI detection with a Shodex SH1011 analytic column at 50 °C with 5 mM H2SO4 as mobile phase at a flow velocity of 0.6 mL min−1 running for 60 min isocratically. The carbon source and furans were quantified by measuring standards of pure substances (Merck, Germany) and establishing a calibration curve.

Quantification of nitrate and phosphate concentration

The supernatant of the aliquoted samples was also analyzed for nitrate and phosphate content during the photobioreactor cultivation. A Dionex IC-6000 ion chromatography system equipped with a conductivity detector unit, combined with an AERS suppressor (all from Thermo Fisher Scientific, USA). An IonPac AS11 column, including a matching guard column, was used as a stationary phase at 30 °C. The mobile phase A was 100% ultrapure water and mobile phase B was 100 mM NaOH. The flow velocity was 2.0 mL min−1. The complete method used was described by Doppler et al. (2021). Nitrate and phosphate standards (Sigma Aldrich, USA) were prepared and used for quantification. Controlling, monitoring and evaluation of the analysis was performed with Chromeleon 7.2.10 Chromatography Data System (Thermo Fisher Scientific).

Chlorophyll extraction and quantification

Fifteen mg of lyophilized biomass were filled into a screw-capped reaction tube containing one 5 mm glass bead and 0.3 g of 1 mm glass beads for cell disruption. The biomass was frozen in liquid nitrogen before disruption with a FastPrep-24 Instrument (MP Biomedicals, USA). The settings chosen were 6.0 m s−1 for 40 s per cycle. The cycles were repeated three times, with a break of 5 min in between. One mL of acetone was added to the disrupted biomass and vortexed until properly mixed. The mixture was centrifuged at 15,000 ×g for 10 min to separate the cell debris from the extracted pigments. The acetone phase was transferred into a 10 mL volumetric flask. This procedure was repeated until the cell debris was colorless and all pigments were extracted. The volumetric flask was filled up to 10 mL with acetone. These extraction steps were done under dimmed light, to preserve pigment content.

The chlorophyll a and b content was quantified as described by Porra et al. (1989). 0.8 mL of the acetone containing the extracted chlorophyll were mixed with 0.2 mL of 2.5 mM NaH2PO4 buffer at pH 7.8 to minimize the conversion of chlorophylls to phaeophytins. The absorption of these samples at 647 nm, 664 nm and 750 nm was measured on a Nanodrop One spectrophotometer (Thermo Fisher Scientific, USA). The chlorophyll a and b content and the sum of those two were calculated according to the formulae described below (Eqs. 5, 6, 7).

where Chla = Chlorophyll a content (μg mL−1), Chlb = Chlorophyll b content (μg mL−1), Chltotal = sum of chlorophyll a and chlorophyll b (μg mL−1), A664 = Absorbance at 664 nm, and A647 = Absorbance at 647 nm.

Protein extraction and quantification

Protein extraction was according to Slocombe et al. (2013). The extraction was based on an alkaline solubilization of the total protein in the microalgal biomass, followed by a precipitation step with trichloracetic acid (TCA). Five mg of lyophilized biomass were weighed into a 1.5 mL Eppendorf tube. 200 µL of 24% (w/v) TCA was added and the biomass was incubated at 95 °C for 15 min. The sample was then diluted to 6% (w/v) TCA by adding 600 µL of ultrapure H2O (Milli-Q, Merck, Germany) and centrifuged at 15,000 ×g and 4 °C for 20 min. The supernatant was discarded and the pellet was resuspended in 500 µL of a mixture containing 48 parts 2% (w/v) Na2CO3 in 0.1 M NaOH, one part 1% (w/v) NaK tartrate.4H2O in ultrapure water and one part 0.5% (w/v) CuSO4.5H2O. After 3 h incubation at 55 °C, the supernatant contained the soluble protein fraction and was analyzed with a BCA assay (Smith et al. 1985). The protein concentrations were determined, by comparing to a known bovine serum albumin concentration (Sigma Aldrich, USA).

Results

The suitability of using WSH as medium supplement for C. vulgaris cultivation to increase biomass productivities and total chlorophyll content was assessed. First, different concentrations of WSH were screened in shakeflask experiments and the best-performing run, in terms of biomass growth and composition, was upscaled to a stirred tank PBR cultivation.

Effect of WSH shading on illumination

The availability of PAR (µmol photons m−2 s−1) in the screened dilutions significantly decreased with the increased percentage of used WSH (Table 2). This resulted from shading effects of the dark brown color of the WSH obtained from Serna-Loaiza et al. (2021b). Using the undiluted WSH resulted in a 91% reduction of photosynthetically active radiation, compared to BG11 as medium. The dilutions tested for mixotrophic growth experiments were ranging from 2.5% to 17.5% (v/v) resulting in a reduction of penetrating light from 22 to 55% compared to using 100% (v/v) BG11. No addition of WSH was done to monitor photoautotrophic conditions.

Screening: Biomass growth

All of the screened dilutions of WSH in mixotrophic experiments outperformed the photoautotrophic control cultivation in terms of final biomass concentration (Fig. 2a). In the SH-supplemented media cultivations, the results matched the respective WSH-supplemented media cultivations in terms of biomass concentration. Biomass productivities increased compared to the photoautotrophic control cultivation by 6, 20, 13 and 14% in 2.5, 5.0, 12.5 and 17.5% (v/v) WSH in the shakeflask cultivations, respectively (Table 3). The best performing WSH dilution concerning biomass productivity was WSH 5.0% with 41.38 mg L−1 day−1, showing a 1.3-fold increase in biomass productivity compared to the photoautotrophic control. By increasing the amount of WSH to 12.5% and 17.5%, we noticed a decrease in mixotrophic growth performance. This trend was not seen in the SH-supplemented media (Fig. 2b), but could be traced back to the reduction of illumination owing to the dark brown color of WSH. The heterotrophic screening experiments showed an increase in biomass productivity in the less diluted WSH media (Fig. 2c). The biomass productivities of heterotrophic cultivations were 3- (WSH 2.5%) to 6-fold (WSH 17.5%) lower than the photoautotrophic control cultivation. The SH experiments showed a different trend, with decreasing productivities while increasing the sugar and furan concentration (Fig. 2d).

Comparison of screening experiments in regards to biomass growth with different dilutions in a) WSH mixotrophic growth b) SH mixotrophic growth c) WSH heterotrophic growth and d) in SH heterotrophic growth; (PA – photoautotrophic control, WSH – wheat straw hydrolysate; SH – synthetic hydrolysate; Mix – mixotrophic mode; Het – heterotrophic mode) Error bars indicate standard deviation (n = 3)

In mixotrophic cultivations, the SH experiments performed better in terms of biomass productivities ranging from 37.62 to 44.53 mg L−1 day−1, compared to biomass productivities in the WSH experiments ranging from 34.83 to 41.38 mg L−1 day−1 (Table 3).

The maximum growth rates (day−1), determined in the exponential growth phases during mixotrophic screening experiments, were decreasing with the increase of % (v/v) WSH in the medium from 0.478 day−1 at WSH 2.5% to 0.405 day−1 in WSH 17.5% (Table 3). Contrary, the growth rates in the SH were increasing with the increase of monomeric sugar content from 0.438 day−1 at SH 2.5% to 0.477 day−1 at SH 17.5% (Table 3). The heterotrophic cultivations were about 40% slower in growth compared to photoautotrophic control cultivations, with the slowest being WSH 5.0% followed by WSH 2.5%.

Compared to SH cultivations, the acetate uptake in WSH supplemented cultivations (heterotrophic and mixotrophic) showed no noticeable effects on biomass growth and productivities.

Growth rates (day−1) and biomass productivities (mg L−1 day−1) are shown in Table 3 for all screening experiments. Growth rates and biomass and chlorophyll productivities for PBR cultivations are presented in online resource 2 and chlorophyll productivities for screening experiments are presented in online resource 3.

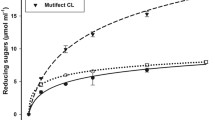

Screening: Biomass composition

With increasing amounts of WSH used in the mixotrophic screening, the total chlorophyll content decreased significantly. The highest chlorophyll content using WSH as medium supplement for mixotrophic cultivation was obtained at a concentration of 2.5% (Fig. 3a), which was equal to the photoautotrophic control cultivation. Thus, a WSH concentration of 2.5% was chosen for upscaling the cultivations. The total chlorophyll content of the SH supplemented media in all screened concentrations was comparable to the photoautotrophic control (Fig. 3b). Heterotrophic cultivation led to a decrease in chlorophyll content in all of the screened dilutions, plateauing at a chlorophyll content at WSH 12.5% and WSH 17.5% of around 1.23% DCW (Fig. 3c). Unlike the heterotrophic WSH cultivations, in the heterotrophic SH cultivations, there was no trend visible, with the total chlorophyll content at about 1.10% (Fig. 3d). Supplementing WSH in heterotrophic screening experiments led to an increase in chlorophyll production in all dilutions compared to its synthetic hydrolysate counterpart. This was especially seen, when using 2.5% WSH resulting in a twofold higher specific chlorophyll content than specific chlorophyll content produced in SH 2.5%.

Comparison of the total chlorophyll contents (%) (w/w) DCW−1 of the screening experiments in a) WSH mixotrophic cultivation b) SH mixotrophic cultivation c) WSH heterotrophic cultivation and d) SH heterotrophic cultivation; (PA – photoautotrophic control, WSH – wheat straw hydrolysate; SH – synthetic hydrolysate; Mix – mixotrophic mode; Het – heterotrophic mode) Error bars indicate standard deviation (n = 3)

The total chlorophyll productivities (mg L−1 day−1) were calculated according to Eq. 4. The highest chlorophyll productivity was reached in the cultivation supplemented with WSH 2.5%, showing a 7% increase compared to the photoautotrophic control and a 6% increase compared to the second highest WSH 5.0%. This was only topped by mixotrophic cultivations supplemented with SH, since the volumetric biomass productivities were higher than in the WSH-supplemented medium. With decreasing amounts of PAR illuminating the culture, less chlorophyll was produced (Fig. 3a).

PBR: Biomass growth and nutrient uptake

Contrary to the screening experiments in shakeflasks, the photoautotrophic PBR cultivation outperformed the mixotrophic PBR cultivation with WSH in regards of biomass growth (Fig. 4). In the PBR cultivation, the PA control exhibited higher biomass productivity of 67.88 mg L−1 day−1 compared to 53.44 mg L−1 day−1 in the mixotrophic WSH 2.5% PBR cultivation. However, the mixotrophic SH cultivation was the best performing PBR cultivation resulting in 25% higher final DCW (g L−1) and biomass productivity (mg L−1 day−1) compared to the photoautotrophic control. PBR cultivation of C. vulgaris in heterotrophic mode in WSH media was in accordance with the results of the screening experiments, in terms of final biomass concentrations of 0.12 g L−1 and biomass productivity 2.98 mg L−1 day−1.

Comparison of dry cell weight (DCW in g L−1) in different cultivation modes in a stirred tank photobioreactor – PBR. PBR cultivations were done using 2.5% of WSH-stock or SH-stock for mixotrophic and heterotrophic cultivations (PA – photoautotrophic control, WSH – wheat straw hydrolysate; SH – synthetic hydrolysate; Mix – mixotrophic mode; Het – heterotrophic mode) Error bars reflect the error of the calibration curve

The maximum growth rate (day−1) was determined in the exponential growth phase during the first eight days of cultivation according to Eq. 2. The growth rates in mixotrophic cultivations with WSH at 0.329 day−1 and SH at 0.362 day−1 were slightly lower than the photoautotrophic control at 0.365 day−1. The heterotrophic cultivations exhibited an immense decrease in maximum growth rates in both the WSH Het 0.078 day−1 by 69% and 85% in SH Het 0.035 day−1 compared to the photoautotrophic control.

In all the medium-supplemented PBR cultivations, all of the monomeric sugars were consumed by C. vulgaris in the first eight days of cultivation This was also true for both the furan compounds, which were under limit of detection in both heterotrophic and mixotrophic cultivation, after day 8. In the WSH-supplemented media, the complete acetate content was metabolized after 8 days as well. In the SH Mix cultivation 62% of nitrogen and phosphorous compounds of the medium were metabolized, compared to 59% in the photoautotrophic control. In WSH Mix 51% of nitrogen and phosphorous were metabolized. In the heterotrophic PBR cultivations, the nitrogen and phosphorous content decreased by 28% in WSH and 24% in SH supplemented medium, respectively. Oligomeric sugars were not metabolized by C. vulgaris.

PBR: Biomass composition

The composition of the biomass obtained from stirred tank photobioreactor cultivations was analyzed in terms of total chlorophyll and protein content per DCW generated.

The total chlorophyll content of the photoautotrophic control decreased by 34% compared to the shakeflask experiments (Fig. 5a), while the biomass concentration at the end of cultivation was twofold higher. Chlorophyll productivity resulted in a net increase of 55% from 1.17 to 1.81 mg L−1 day−1. The mixotrophic cultivation of C. vulgaris supplemented with 2.5% WSH, resulted in an increase of biomass concentration at the end of cultivation and an increase in total chlorophyll content per cell, resulting in total chlorophyll productivity of 2.35 mg L−1 day−1. This was only exceeded by the mixotrophic SH-supplemented cultivation yielding in 2.63 mg L−1 day−1 of total chlorophyll. The protein content (Fig. 5b) showed a different trend, where all of the specific protein contents % (w/w) DCW−1 are similar at about 17.55 – 18.24%, while mixotrophic WSH-supplemented cultivation boosted the protein content to 23.15% (w/w) DCW−1, this is a net increase of approximately 30% compared to the photoautotrophic control.

A Total chlorophyll content % (w/w) DCW−1 at the end of cultivation in stirred tank photobioreactor. b Protein content % (w/w) DCW.−1 in lyophilized biomass at the end of cultivation in stirred tank photobioreactor. (PA – photoautotrophic control, WSH – wheat straw hydrolysate; SH – synthetic hydrolysate; Mix – mixotrophic mode; Het – heterotrophic mode) Errors bars indicate standard deviation of extraction (n = 3)

Discussion

In this study, hydrolysates obtained from LHW pretreatment of wheat straw were assessed for medium supplementation in C. vulgaris cultivation with regard to their impact on biomass growth and biomass composition. This was done to valorize an additional fraction of a wheat straw biorefinery approach to generate a more ecological and economical process. Chlorella vulgaris was chosen as it is very adaptable to different stress conditions, salt concentrations (Dolganyuk et al. 2020), light environments (Fierro Ulloa et al. 2023), osmotic pressure (Gustavs et al. 2010) and growth inhibitors such as acetic acid (de Andrade et al. 2022).

Effect of WSH shading on illumination

Illumination is a very frequently discussed topic in C. vulgaris cultivation, studying the duration of day- and night-cycles, the wavelength of the applied light, and the PAR (Bonnanfant et al. 2021). The utilized light, including photoperiod and intensity, is proportional to microalgal growth (Patel et al. 2022).

Comparing the mixotrophic screening experiments among themselves, the WSH dilutions exhibited similar growth behavior to the corresponding SH dilutions, therefor making the reduced light availability, in the screened dilutions, non-influential for microalgal growth. Khalili et al. (2015) postulates that decreasing the PAR from 110 to 80 µmol photons m−2 s−1 (Table 2) leads to an increase of biomass productivity by approximately 60% depending on the light source. The subsequent reduction of PAR from 110 to 50 µmol photons m−2 s−1 leads to a decrease in biomass productivity in C. vulgaris by 36% (Khalili et al. 2015). By decreasing the amount of light reaching the center of the shakeflask or glass vessel, the cells experience a light gradient. This phenomenon is called “the flashing light effect” (Kok 1956; Terry 1986) and describes microalgal cells travelling through the cultivation vessel and experiencing high-light conditions on the outer perimeter of the glass vessel and low-light conditions at the center of the culture due to self-shading. This flashing light effect might have been caused by the dark color of WSH already at low biomass concentrations, which could lead to an increase of biomass productivity in mixotrophic shakeflasks compared to the photoautotrophic control, even though light penetration was decreased (Abu-Ghosh et al. 2016).

Small scale screening experiments: biomass growth and composition

In the mixotrophic screening approaches using WSH streams, final biomass concentrations were higher than for the photoautotrophic control. This is in order with current research, that mixotrophic cultivations result in higher biomass concentrations (Salati et al. 2017; Patel et al. 2019, 2021). Adding sugar to microalgal cultivation boosts growth rates allowing higher volumetric productivities. The biomass productivities in 2.5% and 5.0% supplemented SH mixotrophic cultures were 8% higher than in the corresponding WSH-supplemented cultures. This might be suggesting either a reduction of growth depending on light, or inhibition by an unidentified component of the WSH (Liu et al. 2022). A subsequent decrease in biomass productivities by increasing the WSH concentration to 12.5% and 17.5% is partially traced back to a decrease in PAR by half, the increase in furan concentration and high sugar concentrations. SH 12.5% and SH 17.5% mixotrophic cultivations exhibited the same growth behavior suggesting a growth inhibition either due to one component, or the combination of both furans (Table 1). Microalgal growth can also be hindered or limited by high sugar concentrations in the cultivation medium (Andreeva et al. 2021), suggesting a combination of low light environment (Santana et al. 2017). Other factors, preventing microgalgal growth are either the presence of furans or the high concentration of non-metabolizeable oligomeric sugars present in 12.5% and 17.5% WSH-supplemented media.

Microalgal pigments, especially chlorophyll a, are of utmost importance for photosynthetic activity. These chlorophyll pigments are contained in chloroplasts, in the photosystem I (PSI) and photosystem II (PSII) and largely responsible for the photosynthetic capacity of a cell (Lehmuskero et al. 2018). Chlorophyll biosynthesis is a light-independent process in C. vulgaris (Orus and Martinez 1991), due to the light independency of one of the key-enzymes, protochlorophyllide a oxidoreductase (Armstrong 1998). Therefor pigment production also occurs in complete darkness. This supports the hypothesis, that unidentified compounds of the WSH increased chlorophyll content, as specific chlorophyll content was enhanced in both mixotrophic by 1.4-fold and heterotrophic cultivations by 2.9-fold, compared to SH-supplemented cultivations. This was supported by the data obtained from heterotrophically grown WSH-supplemented cultures in screening experiments. They exhibited higher chlorophyll contents than their screened SH counterparts, suggesting a positive allelopathic effect of the WSH on chlorophyll biosynthesis also in darkness. Heterotrophic cultivations generally result in lower pigment content, than mixotrophic or photoautotrophic cultivations, as chlorophyll content is an indicator of photosynthetic capacity. Light intensities below photosaturation are promoting primary pigment production, including chlorophyll a, whereas high irradiance reduces it (Maroneze et al. 2019). A phenomenon called photoacclimation describes the adaptation of microalgae to a sub-saturating light regime. It refers to increasing the number of photosystems and thereby increasing chlorophyll content up to an additional 0.5% (w/w) (Mulders et al. 2014). This could also promote chlorophyll content in C. vulgaris grown WSH-supplemented medium, as irradiation was reduced compared to cultivations in SH-supplemented medium or photoautotrophic cultivation.

PBR cultivations: Biomass growth

The higher growth rates throughout all illuminated PBR cultivations over illuminated shakeflasks can be explained by better CO2 diffusion, mass transfer and mixing stimulating C. vulgaris growth (Doppler and Spadiut 2021). In mixotrophic cultivations growth rates of 0.43 day−1 for C. vulgaris grown on 5 g L−1 glucose and 5 g L−1 galactose (Abreu et al. 2012), 0.38 day−1 on vinasse (Melo et al. 2018) or 0.24 day−1 on food waste (Wang et al. 2020) have been reported. In this study comparable growth rates of C. vulgaris in the exponential growth phase (0 – 8 days) of mixotrophic cultivations were achieved, with growth rates of 0.33 day−1 in WSH 2.5% and 0.36 day−1 in the SH 2.5%.

The complete metabolization of acetate in mixotrophic and heterotrophic cultivation of C. vulgaris on WSH-supplemented media did not lead to an increase in biomass production compared to SH-supplemented cultures, contrary to literature (Wirth et al. 2020; de Andrade et al. 2022).

The heterotrophic C. vulgaris cultivation in PBRs decreased tremendously in terms of biomass productivities and growth rates compared to the screened shakeflasks. For heterotrophic PBR cultivations, total darkness for the duration of cultivation was maintained, whereas in shakeflask cultivations, total darkness could not be guaranteed due to sterile sampling in an illuminated laminar flow hood. Short light flashes of 5 min per day are referred to activate heterotrophic metabolism in cyanobacterial species (Anderson and McIntosh 1991), potentially explaining the increased growth in shakeflask experiments. For heterotrophically grown C. vulgaris on waste streams maximum specific growth rates ranging from 0.81 day−1 on enzymatically treated, buffered broken rice hydrolysate with (Cai et al. 2021) to about 2.4 day−1 in enzymatically hydrolyzed sweet sorghum extract (Wu et al. 2022) have been reported. These results display a much a higher heterotrophic growth compared to this studys’ PBR cultivation supplemented with WSH 0.078 day−1 and SH 0.035 day−1, most likely due to the higher monomeric glucose available in these waste streams obtained from enzymatic hydrolysis.

Literature is scarce on the effect of volatile organic compounds (VOCs), such as furfural and HMF regarding the growth of different microalgal species. Currently, there are no assessments of furan toxicity on C. vulgaris. Yu et al. (1990) describe the inhibition of furfural and HMF on growth and photosynthetic activity of multiple Spirulina species in concentrations as low as 2 mM furfural and 2 mM HMF. In this study the concentrations used were 110 mM HMF and 220 mM furfural in 2.5% WSH and 0.77 M HMF and 1.54 M furfural in WSH 17.5%, which suggests that C. vulgaris is much more resistant to furanic compounds than Spirulina species. Both furfural and HMF-concentrations were under limit of detection after 8 days of cultivation, implying an underlying metabolism for both compounds, which, to the authors’ knowledge, has never been described in microalgal species before. Yet, the underlying mechanism is not known to the authors and is currently under investigation.

HMF-contents in different food products range from 0.34 mg kg−1 in honey to 262—547 mg kg−1 in ground coffee up to 91.3 – 3,060 mg kg−1 in instant coffee (Husøy et al. 2008). The Federal Institute of Risk Assessment of Germany (BfR) estimates the average intake of HMF to 3 – 40 mg per person per day and deems that concentration unproblematic for human health (BfR 2011). This uptake is way above the used HMF concentration in this study, making the obtained C. vulgaris supposedly safe for food and feed applications. Furfural contents in different types of coffee range from 3 – 219 mg kg−1 in coffee beans, 5.8 – 122 mg kg−1 in ground coffee and 3.3 – 172 mg kg−1 for instant coffee (Liu et al. 2023). The maximum acceptable daily intake of furfural is 16.15 µg per kg bodyweight per day (Liu et al. 2023), making it crucial to remove furfural completely before utilizing the obtained C. vulgaris biomass in food and feed applications.

There are literature reports on advantageous effects (positive allelopathy) or effects counteracting (negative allelopathy) microalgal growth and photosynthetic activity by certain VOCs (Xu et al. 2017; Zuo 2019). In wheat straw several VOCs have been identified, such as vanillic acid, vanillin, benzoic acid, coumaric acid, ferulic acid (Collins et al. 2014), potentially being positive allelopaths and therefore increasing chlorophyll content and microalgal growth. Aqueous wheat straw extracts, especially their phenolic and flavonoid components, have been recently described as positive allelopaths on growth and protein content of bermudagrass weed (Alghamdi et al. 2022). Several phenolic acids promote similar mechanisms as phytohormones, such as microalgal growth, pigment production, protein production or lipid accumulation (Liu et al. 2022). Benzoic acid is a known signaling molecule in Chlorella species, increasing biomass productivities (Liu et al. 2022). Adding 300 µg L−1 benzoic acid to Chlorella regularis cultivations was shown to increase heterotrophic growth by 75% compared to a culture without benzoic acid (Fu et al. 2021). This may be attributed to the increased growth of C. vulgaris in WSH-supplemented media compared to SH-supplemented media in heterotrophic growth regime.

Side streams from lignocellulosic biorefinery approaches have been utilized multiple times as substrate for cultivations of different microorganisms. But the sugary fractions have always been pretreated before cultivations to enable microbial growth and prevent inhibition by acetate and furanic compounds. For example, the acetate fraction was removed to enable growth of Sulfolobus acidocaldarius on the remaining hemicellulosic sugars after LHW pretreatment (Beisl et al. 2019), or recently Trichoderma reseii (Daza-Serna et al. 2023). Detoxification by basic overliming and adsorption, enabled growth of Rhodococcus opacus on a lignocellulosic autohydrolysate obtained from pine and sweetgum (Wei et al. 2015) or Synchecocystis sp. on the purified acetate fraction of WSH (Beisl et al. 2019). The monomeric sugars, acetate and the furan compounds have been metabolized during both heterotrophic and mixotrophic C. vulgaris cultivation. To the authors’ knowledge, this is the first time the remaining hemicellulosic sugary fraction after liquid hot water hydrolysation of a lignocellulosic biomass, has been successfully used as medium supplement without prior removal of the present growth inhibitors, HMF and furfural.

PBR cultivations: Biomass composition

By doubling the biomass concentration in PBR cultivations compared to shakeflasks, light penetration was decreased. This led to a decrease in protein content, similarly shown by Seyfabadi et al. (2010). The photoautotrophic control cultivation exhibited a protein content of 17.55% (w/w) DCW−1. Reported values are much lower when compared to photoautotrophic cultivation regimes from literature, for instance compared to 34% (w/w) (Seyfabadi et al. 2010), or 38.4 – 59.5% (w/w) (Cai et al. 2022a) obtained in similar photoautotrophic cultivation regimes. The WSH-supplemented media cultivation led to a protein content of 23.15% (w/w) DCW−1 with a lower biomass growth and lower nitrogen consumption compared to the photoautotrophic control. A decrease in nitrogen availability was referred to a decrease of protein content in C. vulgaris cultivation (Lai et al. 2019).

The complete acetate fraction was metabolized during mixotrophic and heterotrophic C. vulgaris cultivation. Acetate is transported into the microalgal cell and metabolized to acetyl-CoA (Perez-Garcia et al. 2010), which could then be used in the chlorophyll biosynthesis pathways. Providing acetate as a carbon source is referred to increase the chlorophyll a content in C. vulgaris (Huang et al. 2017), which might have additionally contributed to the higher chlorophyll contents in WSH cultivations, compared to SH cultivations and the photoautotrophic control. Roach et al. (2013) postulates, that the addition of acetate to Chlamydomonas reinhardtii mixotrophic cultivations protects cells from photoinhibition by modulation of the photosystem II and slowing the decrease of the maximum quantum yield in the PSII. Compared to photoautotrophic cultivations, this could lead to a decrease in degradation of chlorophyll molecules.

Comparing the chlorophyll content of 3.09% (w/w) DCW−1 of the SH mixotrophic PBR cultivation, with 2.66% (w/w) DCW−1 of the photoautotrophic PBR cultivation hints that there might be some beneficiary effects due to the volatile compounds, such as furfural and HMF. Sugar supplementation is generally regarded as reducing chlorophyll content in microalgae (Patel et al. 2021).

Zuo et al. (2012) described the effect of longifolene, another VOC, on the pigment content of C. reinhardtii, showing an increase in chlorophyll content and subsequently the photosynthetic activity. Vanillic acid derived from cassava crop hydrolysate has been shown to increase chlorophyll a content 3.46-fold in Euglena gracilis compared to a control (Tan et al. 2021). Zuo et al. (2012) suggested the need for increased antioxidant capacities within microalgal cells to prepare for environmental stressors or the subsequent production of reactive oxygen species within the cells. VOCs, extracted by liquid hot water pretreatment of wheat straw, could explain the increase of chlorophyll content in WSH cultivations compared to SH cultivations in both shakeflask cultivations by 10% and PBR cultivations by 30%.

In heterotrophic C. vulgaris cultivations, similar chlorophyll contents to 1.91% (w/w) DCW−1 obtained in this study, have been achieved, 0.92% (w/w) DCW−1 by cultivation on 0.1% glucose and 0.25% yeast extract (Schüler et al. 2020) or 1.67% (w/w) DCW−1 on broken rice hydrolysate (Cai et al. 2022b). In recent studies, chlorophyll contents of C. vulgaris grown mixotrophically ranged from 0.60% (w/w) DCW−1 grown on cheese whey (Abreu et al. 2012), 1.41% (w/w) DCW−1 grown on 0.1% glucose and 0.25% yeast extract (Schüler et al. 2020) to 1.49% (w/w) DCW−1 grown on 60 g L−1 glucose and 3 g L−1 yeast extract (Kim et al. 2020). To the authors knowledge, the chlorophyll content 4.40% (w/w) DCW−1 obtained in this study, is the highest ever reported for C. vulgaris grown on a waste stream. Also, furfural and HMF have been removed completely during C. vulgaris cultivation. Still, the underlying metabolic pathways, including intermediate metabolites, have to be identified before using the generated biomass in food and feed applications.

Conclusions

We show that hydrolysates obtained from LHW pretreatment of wheat straw is a suitable medium supplement for Chlorella vulgaris cultivation without the need of any prior removal of degradation products HMF and furfural. Despite containing inhibitors, WSH obtained from LHW pretreatment increased both the total specific chlorophyll and protein content in C. vulgaris PBR cultivation compared to the photoautotrophic control. To the authors knowledge, the total chlorophyll content obtained was the highest achieved by cultivation on a media supplemented with a waste stream as of now. This indicated the improved photosynthetic activity, compared to cultures not supplemented with the WSH stream. However, further studies are required to (i) fully understand the beneficial properties of WSH on C. vulgaris metabolism, especially concerning the furan metabolism and (ii) better comprehend the mechanisms underlying the stimulation of chlorophyll a and b production. As all of these experiments were based on the use of BG11, a commercially available and costly medium, further steps in the direction of supplementing nitrogen and phosphorous from alternative sources should be taken into account. As of now, the potentially beneficiary effects of VOCs on C. vulgaris growth and physiology have not been studied in detail. Once the metabolism of furans in C. vulgaris is fully understood, not only chlorophyll but the whole biomass can be utilized for food and feed applications. For complete valorization of the wheat straw hydrolysate, the remaining oligomeric sugars in the supernatant could be used for further cultivation of a microorganism able of oligomeric carbon metabolization e.g. Trichoderma reseii. To conclude it has been shown that the biorefinery approach, stemming from wheat straw as a starting substrate, results in an additional value-added product, namely C. vulgaris biomass rich in chlorophyll.

Data availability

The data obtained in this study is available on request from the corresponding author.

References

Abreu AP, Fernandes B, Vicente AA, Teixeira J, Dragone G (2012) Mixotrophic cultivation of Chlorella vulgaris using industrial dairy waste as organic carbon source. Bioresour Technol 118:61–66

Abu-Ghosh S, Fixler D, Dubinsky Z, Iluz D (2016) Flashing light in microalgae biotechnology. Bioresour Technol 203:357–363

Alghamdi SA, Al-Nehmi AA, Ibrahim OHM (2022) Potential allelopathic effect of wheat straw aqueous extract on Bermudagrass noxious weed. Sustainability 14:15989

Anderson SL, McIntosh L (1991) Light-activated heterotrophic growth of the cyanobacterium Synechocystis sp. strain PCC 6803: a blue-light-requiring process. J Bacteriol 173:2761–2767

Andreeva A, Budenkova E, Babich O, Sukhikh S, Dolganyuk V, Michaud P, Ivanova S (2021) Influence of carbohydrate additives on the growth rate of microalgae biomass with an increased carbohydrate content. Mar Drugs 19:381

Armstrong GA (1998) Greening in the dark: light-independent chlorophyll biosynthesis from anoxygenic photosynthetic bacteria to gymnosperms. J Photochem Photobiol B 43:87–100

Arora N, Philippidis GP (2021) Insights into the physiology of Chlorella vulgaris cultivated in sweet sorghum bagasse hydrolysate for sustainable algal biomass and lipid production. Sci Rep 11:6779

Barkia I, Saari N, Manning SR (2019) Microalgae for high-value products towards human health and nutrition. Mar Drugs 17:304

Beigbeder J-B, Boboescu IZ, Damay J, Duret X, Bhatti S, Lavoie J-M (2019) Phytoremediation of bark-hydrolysate fermentation effluents and bioaccumulation of added-value molecules by designed microalgal consortia. Algal Res 42:101585

Beisl S, Quehenberger J, Kamravamanesh D, Spadiut O, Friedl A (2019) Exploitation of wheat straw biorefinery side streams as sustainable substrates for microorganisms: A feasibility study. Processes 7:pr7120956

Benedetti M, Vecchi V, Barera S, Dall’Osto L (2018) Biomass from microalgae: the potential of domestication towards sustainable biofactories. Microb Cell Fact 17:173

BfR (2011) 5-HMF-Gehalte in Lebensmitteln sind nach derzeitigem wissenschaftlichen Kenntnisstand gesundheitlich unproblematisch. https://www.bfr.bund.de/cm/343/5_hmf_gehalte_in_lebensmitteln_sind_nach_derzeitigem_wissenschaftlichen_kenntnisstand_gesundheitlich_unproblematisch.pdf. Accessed 20.04. 2023

Bonnanfant M, Marec H, Jesus B, Mouget JL, Pruvost J (2021) Investigation of the photosynthetic response of Chlorella vulgaris to light changes in a torus-shape photobioreactor. Appl Microbiol Biotechnol 105:8689–8701

Cai Y, Liu Y, Liu T, Gao K, Zhang Q, Cao L, Wang Y, Wu X, Zheng H, Peng H, Ruan R (2021) Heterotrophic cultivation of Chlorella vulgaris using broken rice hydrolysate as carbon source for biomass and pigment production. Bioresour Technol 323:124607

Cai Y, Zhai L, Fang X, Wu K, Liu Y, Cui X, Wang Y, Yu Z, Ruan R, Liu T, Zhang Q (2022a) Effects of C/N ratio on the growth and protein accumulation of heterotrophic Chlorella in broken rice hydrolysate. Biotechnol Biofuels Bioprod 15:102

Cai Y, Zhai L, Wu K, Li Z, Gu Z, Wang Y, Cui X, Zhou T, Ruan R, Liu T, Liu Y, Zhang Q (2022b) Mechanisms of promotion in the heterotrophic growth of Chlorella vulgaris by the combination of sodium acetate and hydrolysate of broken rice. Bioresour Technol 364:127965

Camacho F, Macedo A, Malcata F (2019) Potential industrial applications and commercialization of microalgae in the functional food and feed industries: A short review. Mar Drugs 17:312

Chong JWR, Khoo KS, Yew GY, Leong WH, Lim JW, Lam MK, Ho Y-C, Ng HS, Munawaroh HSH, Show PL (2021) Advances in production of bioplastics by microalgae using food waste hydrolysate and wastewater: A review. Bioresour Technol 342:125947

Collins SRA, Wellner N, Martinez Bordonado I, Harper AL, Miller CN, Bancroft I, Waldron KW (2014) Variation in the chemical composition of wheat straw: the role of tissue ratio and composition. Biotechnol Biofuels 7:121

da Silva Ferreira V, Sant’Anna C (2016) Impact of culture conditions on the chlorophyll content of microalgae for biotechnological applications. World J Microbiol Biotechnol 33:20

Daza-Serna L, Masi A, Serna-Loaiza S, Pfnier J, Stark G, Mach RL, Mach-Aigner AR, Friedl A (2023) Detoxification strategy of wheat straw hemicellulosic hydrolysate for cultivating Trichoderma reesei: a contribution towards the wheat straw biorefinery. Biomass Conv Bioref. https://doi.org/10.1007/s13399-023-04099-8

de Andrade AF, Porto ALF, Bezerra RP (2022) Photosynthetic microorganisms and their bioactive molecules as new product to healing wounds. Appl Microbiol Biotechnol 106:497–504

de Freitas BCB, Brächer EH, de Morais EG, Atala DIP, de Morais MG, Costa JAV (2019) Cultivation of different microalgae with pentose as carbon source and the effects on the carbohydrate content. Environ Technol 40:1062–1070

Dolganyuk V, Belova D, Babich O, Prosekov A, Ivanova S, Katserov D, Patyukov N, Sukhikh S (2020) Microalgae: A promising source of valuable bioproducts. Biomolecules 10:1153

Doppler P, Kornpointner C, Halbwirth H, Remias D, Spadiut O (2021) Tetraedron minimum, first reported member of Hydrodictyaceae to accumulate secondary carotenoids. Life 11:107

Doppler P, Kriechbaum R, Käfer M, Kopp J, Remias D, Spadiut O (2022) Coelastrella terrestris for adonixanthin production: Physiological characterization and evaluation of secondary carotenoid productivity. Mar Drugs 20:175

Doppler P, Spadiut O (2021) Introduction to autotrophic cultivation of microalgae in photobioreactors. In: Robert K, Sandy S (eds) The Autotrophic Biorefinery: Raw Materials from Biotechnology. De Gruyter, Berlin, pp 113–130

Fereres E, Orgaz F, Gonzalez-Dugo V (2011) Reflections on food security under water scarcity. J Exp Bot 62:4079–4086

Fernandes AS, Nascimento TC, Pinheiro PN, de Rosso VV, de Menezes CR, Jacob-Lopes E, Zepka LQ (2021) Insights on the intestinal absorption of chlorophyll series from microalgae. Food Res Int 140:110031

Fierro Ulloa JI, Lu L-D, Bernard O (2023) Theoretical growth rate of microalgae under high/low-flashing light. J Math Biol 86:48

Fu L, Li Q, Chen C, Zhang Y, Liu Y, Xu L, Zhou Y, Li C, Zhou D, Rittmann BE (2021) Benzoic and salicylic acid are the signaling molecules of Chlorella cells for improving cell growth. Chemosphere 265:129084

García JL, de Vicente M, Galán B (2017) Microalgae, old sustainable food and fashion nutraceuticals. Microb Biotechnol 10:1017–1024

Gustavs L, Eggert A, Michalik D, Karsten U (2010) Physiological and biochemical responses of green microalgae from different habitats to osmotic and matric stress. Protoplasma 243:3–14

Hayes M, Ferruzzi MG (2020) Update on the bioavailability and chemopreventative mechanisms of dietary chlorophyll derivatives. Nutr Res 81:19–37

Hong J-W, Gam D-H, Kim J-H, Jeon S-J, Kim H-S, Kim J-W (2021) Process development for the detoxification of fermentation inhibitors from acid pretreated microalgae hydrolysate. Molecules 26:2435

Huang A, Sun L, Wu S, Liu C, Zhao P, Xie X, Wang G (2017) Utilization of glucose and acetate by Chlorella and the effect of multiple factors on cell composition. J Appl Phycol 29:23–33

Husøy T, Haugen M, Murkovic M, Jöbstl D, Stølen LH, Bjellaas T, Rønningborg C, Glatt H, Alexander J (2008) Dietary exposure to 5-hydroxymethylfurfural from Norwegian food and correlations with urine metabolites of short-term exposure. Food Chem Toxicol 46:3697–3702

Khalili A, Najafpour GD, Amini G, Samkhaniyani F (2015) Influence of nutrients and LED light intensities on biomass production of microalgae Chlorella vulgaris. Biotech Bioproc Eng 20:284–290

Kim U, Cho DH, Heo J, Yun JH, Choi DY, Cho K, Kim HS (2020) Two-stage cultivation strategy for the improvement of pigment productivity from high-density heterotrophic algal cultures. Bioresour Technol 302:122840

Kok B (1956) Photosynthesis in flashing light. Biochim Biophys Acta 21:245–258

Kumar S, Kumar R, Diksha KA, Panwar A (2022) Astaxanthin: A super antioxidant from microalgae and its therapeutic potential. J Basic Microbiol 62:1064–1082

Lai Y-C, Chang C-H, Chen C-Y, Chang J-S, Ng IS (2019) Towards protein production and application by using Chlorella species as circular economy. Bioresour Technol 289:121625

Lehmuskero A, Skogen Chauton M, Boström T (2018) Light and photosynthetic microalgae: A review of cellular- and molecular-scale optical processes. Progr Oceanogr 168:43–56

Leite GB, Paranjape K, Hallenbeck PC (2016) Breakfast of champions: Fast lipid accumulation by cultures of Chlorella and Scenedesmus induced by xylose. Algal Res 16:338–348

Liu Q, Zhou P, Luo P, Wu P (2023) Occurrence of furfural and its derivatives in coffee products in China and estimation of dietary intake. Foods 12:200

Liu Y, Zhao Z, Yang H, Fu L, Zhou D (2022) Trace phenolic acids simultaneously enhance degradation of chlorophenol and biofuel production by Chlorella regularis. Water Res 218:118524

Maroneze MM, Zepka LQ, Lopes EJ, Pérez-Gálvez A, Roca M (2019) Chlorophyll oxidative metabolism during the phototrophic and heterotrophic growth of Scenedesmus obliquus. Antioxidants 8:600

Melo RGd, Andrade AFd, Bezerra RP, Correia DS, Souza VCd, Brasileiro-Vidal AC, Viana Marques DdA, Porto ALF (2018) Chlorella vulgaris mixotrophic growth enhanced biomass productivity and reduced toxicity from agro-industrial by-products. Chemosphere 204:344–350

Mulders KJM, Lamers PP, Martens DE, Wijffels RH (2014) Phototrophic pigment production with microalgae: biological constraints and opportunities. J Phycol 50:229–242

Orus M, Martinez F (1991) Chlorophyll a/b ratio and thylakoid stacking modification in response to glucose in Chlorella vulgaris UAM 101. Biochem Physiol Pflanz 187:197–202

Patel AK, Albarico FPJB, Perumal PK, Vadrale AP, Nian CT, Chau HTB, Anwar C, Wani HMud, Pal A, Saini R, Ha LH, Senthilkumar B, Tsang Y-S, Chen C-W, Dong C-D, Singhania RR (2022) Algae as an emerging source of bioactive pigments. Bioresour Technol 351:126910

Patel AK, Joun JM, Hong ME, Sim SJ (2019) Effect of light conditions on mixotrophic cultivation of green microalgae. Bioresour Technol 282:245–253

Patel AK, Singhania RR, Dong C-D, Obulisami PK, Sim SJ (2021) Mixotrophic biorefinery: A promising algal platform for sustainable biofuels and high value coproducts. Renew Sust Energy Rev 152:111669

Pereira AG, Otero P, Echave J, Carreira-Casais A, Chamorro F, Collazo N, Jaboui A, Lourenço-Lopes C, Simal-Gandara J, Prieto MA (2021) Xanthophylls from the sea: Algae as source of bioactive carotenoids. Mar Drugs 19:188

Perez-Garcia O, De-Bashan LE, Hernandez J-P, Bashan Y (2010) Efficiency of growth and nutrient uptake from wastewater by heterotrophic, autotrophic, and mixotrophic cultivation of Chlorella vulgaris immobilized with Azospirillum brasilense. J Phycol 46:800–812

Peter AP, Chew KW, Koyande AK, Yuk-Heng S, Ting HY, Rajendran S, Munawaroh HSH, Yoo CK, Show PL (2021) Cultivation of Chlorella vulgaris on dairy waste using vision imaging for biomass growth monitoring. Bioresour Technol 341:125892

Porra RJ, Thompson WA, Kriedemann PE (1989) Determination of accurate extinction coefficients and simultaneous equations for assaying chlorophylls a and b extracted with four different solvents: verification of the concentration of chlorophyll standards by atomic absorption spectroscopy. Biochim Biophys Acta - Bioenerg 975:384–394

Pucci C, Martinelli C, Degl’Innocenti A, Desii A, De Pasquale D, Ciofani G (2021) Light-activated biomedical applications of chlorophyll derivatives. Macromolec Biosci 21:2100181

Roach T, Sedoud A, Krieger-Liszkay A (2013) Acetate in mixotrophic growth medium affects photosystem II in Chlamydomonas reinhardtii and protects against photoinhibition. Biochim Biophys Acta - Bioenerg 1827:1183-1190

Salati S, D’Imporzano G, Menin B, Veronesi D, Scaglia B, Abbruscato P, Mariani P, Adani F (2017) Mixotrophic cultivation of Chlorella for local protein production using agro-food by-products. Bioresour Technol 230:82–89

Santana H, Cereijo CR, Teles VC, Nascimento RC, Fernandes MS, Brunale P, Campanha RC, Soares IP, Silva FCP, Sabaini PS, Siqueira FG, Brasil BSAF (2017) Microalgae cultivation in sugarcane vinasse: Selection, growth and biochemical characterization. Bioresour Technol 228:133–140

Schüler L, Greque de Morais E, Trovão M, Machado A, Carvalho B, Carneiro M, Maia I, Soares M, Duarte P, Barros A, Pereira H, Silva J, Varela J (2020) Isolation and characterization of novel Chlorella vulgaris mutants with low chlorophyll and improved protein contents for food applications. Front Bioeng Biotechnol 8:489

Sendzikiene E, Makareviciene V (2022) Application of liquid waste from biogas production for microalgae Chlorella sp. cultivation. Cells 11:1206

Serna-Loaiza S, Dias M, Daza-Serna L, de Carvalho CCCR, Friedl A (2021a) Integral analysis of liquid-hot-water pretreatment of wheat straw: Evaluation of the production of sugars, degradation products, and lignin. Sustainability 14:su14010362

Serna-Loaiza S, Miltner A, Miltner M, Friedl A (2019) A Review on the feedstocks for the sustainable production of bioactive compounds in biorefineries. Sustainability 11:su11236765

Serna-Loaiza S, Zikeli F, Adamcyk J, Friedl A (2021b) Towards a wheat straw biorefinery: Combination of organosolv and liquid hot water for the improved production of sugars from hemicellulose and lignin hydrolysis. Bioresour Technol Rep 14:100667

Seyfabadi J, Ramezanpour Z, Khoeyi Z (2010) Protein, fatty acid, and pigment content of Chlorella vulgaris under different light regimes. J Appl Phycol 23:721–726

Slocombe SP, Ross M, Thomas N, McNeill S, Stanley MS (2013) A rapid and general method for measurement of protein in micro-algal biomass. Bioresour Technol 129:51–57

Smith PK, Krohn RI, Hermanson GT, Mallia AK, Gartner FH, Provenzano MD, Fujimoto EK, Goeke NM, Olson BJ, Klenk DC (1985) Measurement of protein using bicinchoninic acid. Anal Biochem 150:76–85

Solymosi K, Mysliwa-Kurdziel B (2017) Chlorophylls and their derivatives used in food industry and medicine. Mini-Rev Med Chem 17:1194–1222

Tan X, Zhu J, Wakisaka M (2021) Effect of phytochemical vanillic acid on the growth and lipid accumulation of freshwater microalga Euglena gracilis. World J Microbiol Biotechnol 37:217

Terry KL (1986) Photosynthesis in modulated light: Quantitative dependence of photosynthetic enhancement on flashing rate. Biotechnol Bioeng 28:988–995

Tibbetts SM, Milley JE, Lall SP (2015) Chemical composition and nutritional properties of freshwater and marine microalgal biomass cultured in photobioreactors. J Appl Phycol 27:1109–1119

Touloupakis E, Zittelli GC, Benavides AMS, Torzillo G (2023) Growth and photosynthetic performance of Nostoc linckia (formerly N. calcicola) cells grown in BG11 and BG110 media. Photochem Photobiol Sci 22:795–807

Wang J, Hu X, Chen J, Wang T, Huang X, Chen G (2022) The extraction of β-carotene from microalgae for testing their health benefits. Foods 11:502

Wang W, Zhou W, Liu J, Li Y, Zhang Y (2013) Biodiesel production from hydrolysate of Cyperus esculentus waste by Chlorella vulgaris. Bioresour Technol 136:24–29

Wang X, Zhang M-M, Sun Z, Liu S-F, Qin Z-H, Mou J-H, Zhou Z-G, Lin CSK (2020) Sustainable lipid and lutein production from Chlorella mixotrophic fermentation by food waste hydrolysate. J Hazard Mat 400:123258

Wei Z, Zeng G, Huang F, Kosa M, Sun Q, Meng X, Huang D, Ragauskas AJ (2015) Microbial lipid production by oleaginous Rhodococci cultured in lignocellulosic autohydrolysates. Appl Microbiol Biotechnol 99:7369–7377

Wirth R, Pap B, Böjti T, Shetty P, Lakatos G, Bagi Z, Kovács KL, Maróti G (2020) Chlorella vulgaris and Its phycosphere in wastewater: Microalgae-bacteria interactions during nutrient removal. Front Bioeng Biotech 8:557572

Wu K, Fang Y, Hong B, Cai Y, Xie H, Wang Y, Cui X, Yu Z, Liu Y, Ruan R, Zhang Q (2022) Enhancement of carbon conversion and value-added compound production in heterotrophic Chlorella vulgaris using sweet sorghum extract. Foods 11:2579

Xie Y, Xiong X, Chen S (2021) Challenges and potential in increasing lutein content in microalgae. Microorganisms 9:1068

Xu Q, Yang L, Yang W, Bai Y, Hou P, Zhao J, Zhou L, Zuo Z (2017) Volatile organic compounds released from Microcystis flos-aquae under nitrogen sources and their toxic effects on Chlorella vulgaris. Ecotoxicol Environ Saf 135:191–200

Yee KL, Jansen LE, Lajoie CA, Penner MH, Morse L, Kelly CJ (2018) Furfural and 5-hydroxymethyl-furfural degradation using recombinant manganese peroxidase. Enzym Microb Technol 108:59–65

Yu S, Forsberg Å, Kral K, Pedersén M (1990) Furfural and hydroxymethylfurfural inhibition of growth and photosynthesis in Spirulina. Brit Phycol J 25:141–148

Zuo Z (2019) Why algae release volatile organic compounds—The emission and roles. Front Microbiol 10:491

Zuo Z, Zhu Y, Bai Y, Wang Y (2012) Volatile communication between Chlamydomonas reinhardtii cells under salt stress. Biochem Systemat Ecol 40:19–24

Funding

Open access funding provided by TU Wien (TUW). The authors acknowledge the TU Wien Bibliothek for financial support through its Open Access Funding Program.

Author information

Authors and Affiliations

Contributions

Conceptualization: R.K., O.S. & J.K.; Methodology: R.K., S.S.L. & J.K.; Formal analysis and investigation:R.K. & S.S.L.; Writing – original draft preparation: R.K. & S.S.L; Writing – review and editing: A.F., O.S. & J.K.; Funding Acquisition: A.F. & O.S.; Resources: A.F. & O.S.; Supervision: A.F., J.K. & O.S.

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kriechbaum, R., Loaiza, S.S., Friedl, A. et al. Utilizing straw-derived hemicellulosic hydrolysates by Chlorella vulgaris: Contributing to a biorefinery approach. J Appl Phycol 35, 2761–2776 (2023). https://doi.org/10.1007/s10811-023-03082-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-023-03082-0