Abstract

The growth of the polyextremophile red microalga Galdieria sulphuraria ACUF 064 was evaluated under mixotrophy and heterotrophy in a 13-L lab-scale stirred photobioreactor, using buttermilk as a carbon source. Beforehand, G. sulphuraria ACUF 064 growth on glucose, galactose and lactose was evaluated. No significant differences were observed in terms of growth when lactose, glucose or galactose was used as a carbon source. Overall, the biomass yield on carbon was 70% higher in mixotrophy than heterotrophy for galactose (2.0 gx gC−1) and lactose (2.0 gx gC−1), while it was similar for glucose (1.5 gx gC−1). At the same time, the yield of biomass on nitrogen for cultures grown in lactose was the lowest in comparison to all the other tested substrates. This was also supported by a higher C-phycocyanin content, with 5.9% wC-PC/wx as the highest value in mixotrophy. A preliminary experiment in flasks under mixotrophic conditions with different buttermilk dilutions revealed that a dilution ratio of 40% v/v of buttermilk (corresponding to 2.0 gC L−1) was optimal for biomass production. Finally, G. sulphuraria ACUF 064 was grown in the optimal buttermilk dilution ratio in a 13 L photobioreactor. The highest biomass productivity was also obtained in mixotrophy (0.55 gx L−1 d−1), corresponding to a carbon removal of 61%. Overall, lactose-containing substrates such as buttermilk hold promise as a substrate for the growth of G. sulphuraria while revalorizing an industrial effluent.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The dairy sector is among the most polluting agri-food industries due to its large water consumption and consequently, the large volumes of wastewater produced (Raghunath et al. 2016). Reducing waste or adding value to by-products from milk processing is a pivotal strategy to enhance industrial food-related sustainability (Olabi et al. 2015). Buttermilk is one of the most important by-products of dairy industries and it is made of the aqueous phase released during the churning of cream in butter processing. Between 6.5% and 7.0% of milk produced worldwide is used for the preparation of butter which results in about 3.2 million t year−1 of buttermilk generated (Kumar et al. 2019). Europe is one of the largest contributors with an estimated production of buttermilk of 2 million t year−1 (Ali 2019).

Buttermilk is generally classified as sweet (or cultured) buttermilk and whey buttermilk (Ali 2019). The most important differences between whey buttermilk and cultured buttermilk are the absence of casein and the low phospholipid content (Konrad et al. 2013). The chemical composition of sweet buttermilk is quite similar to that of skimmed milk for lactose (48.7–53.8% w/w) and protein (31.5–33.1% w/w) and presents a lower fat content (5.7–13.1% w/w) than buttermilk from cheese (Sodini et al. 2006; Lambert et al. 2016). Due to its bioactive properties, buttermilk is currently used in the formulation of different products for consumption. In cheese, the increase of sweet-cream buttermilk content significantly modifies its composition, resulting in a softer and moister curd. Cheese containing more than 25% of sweet-cream buttermilk would not be acceptable from a sensorial point of view. It can also be used as a powder in the food industry, which implies the application of energy-costly steps such as evaporation and spray-drying processes. Although several studies have reported different uses of buttermilk in several food products, such as in yoghurt, bakery or cheese (Dewettinck et al. 2008; Vanderghem et al. 2010; Fuller et al. 2013; Gassi et al. 2016), biotechnological applications with buttermilk remain limited (Bahrami et al. 2015).

Due to the large number of organic compounds, buttermilk represents a valuable carbon source useful in bioprocessing. Vigliengo and Reinheimer (2009) found that whey or buttermilk could be suitable medium ingredients for biomass production of thermophilic lactic acid bacteria or other microbes. Some microalgae obtain energy by using alternatively light or organic substrates, and their cultivation represents a valid strategy for the treatment of effluents (Jain et al. 2022). In this scenario, the red extremophile species belonging to the Galdieria genus are among the most suitable microalgae for the valorisation of buttermilk. Galdieria sulphuraria is a polyextremophile unicellular microalga able to grow at temperatures up to 56 °C and a pH between 0.5 and 4. Additionally, G. sulphuraria presents a versatile metabolism since it can grow autotrophically, heterotrophically or mixotrophically (Oesterhelt et al. 1999).

The mixotrophic metabolism consists of the combined use of an organic carbon source and light energy for chemoheterotrophic and photoautotrophic growth. In mixotrophy, it was observed that the biomass productivity was two-fold higher than in autotrophy (Abiusi et al. 2021, 2022a; Curien et al. 2021; Canelli et al. 2023), and pigment production was higher than in heterotrophy (Sloth et al. 2006). Mixotrophic growth has been proposed to overcome autotrophy limits for biomass productivity (Tredici 2010). Galdieria sulphuraria can use several carbon sources (up to 50 different) (Gross and Schnarrenberger 1995), including lactose, showing a wide flexibility in carbon consumption (Tischendorf et al. 2007; Zimermann et al. 2020). Mixotrophic metabolism and versatility in organic carbon source assimilation make G. sulphuraria very interesting in bioremediation processes. On the other side, heterotrophy is a tool to overcome the costly light-based bioremediation processes using microalgae. The heterotrophic production results in higher biomass concentrations and higher growth rates, and therefore higher substrate removal rates (Barros et al. 2019). However, contamination by bacteria and fungi is a notable issue when the medium contains organic carbon (Di Caprio 2020). The cultivation of extremophilic microalgae is a strategy to limit the growth of competitors and predators such as bacteria, improving the efficacy of microalgae-based treatment (Abiusi et al. 2022b).

The main interest in G. sulphuraria lies in the production of the high-value blue phycobiliprotein C-phycocyanin (C-PC), allophycocyanin, and chlorophyll (Albertano et al. 2000). Phycocyanins are used as dyes in diagnostic histochemistry, as colourants in the cosmetics and food industry and, as therapeutic agents due to their antioxidant properties in the pharma sector (Pagels et al. 2019). Commercially, C-PC is produced by the cyanobacterium Spirulina (Arthrospira) platensis in phototrophic cultures, with all the problems derived from light efficiency use (Tredici 2010). The cultivation of G. sulphuraria in mixotrophy on a large scale could overcome this bottleneck and it could be used as an alternative source of C-PC. Additionally, G. sulphuraria could potentially be used as an ingredient for human consumption due to its interesting chemical and nutritional characteristics (Graziani et al. 2013).

In the last years, the cultivation of G. sulphuraria on several organic wastes from the food industry has been explored. G. sulphuraria 074G growth on food waste from restaurants and bakeries was evaluated (Sloth et al. 2017), as well as on granular starch derived from potatoes (Rahman et al. 2020). Zimermann et al. (2020) tested whether the carbon contained in whey permeate was used by G. sulphuraria SAG 107.79 for growth. Exploiting the same strain, Russo et al. (2021) assessed another milk by-product, called “scotta”, derived from second cheese whey. Corn stover hydrolysates have been recently supplied to G. sulphuraria UTEX 29.19 (Portillo et al. 2022), while digestate and hydrolyzed straw were investigated for the SAG 21.92 strain (Pleissner et al. 2021). With a few exceptions, the growth of G. sulphuraria on carbon sources containing disaccharides, such as lactose, had not been deeply explored before. The use of complex carbohydrates (di-, tri, and polysaccharides) depends on the presence of hydrolytic enzymes. While polysaccharides are generally converted into simpler sugars in the extracellular environment, di- and trisaccharides can only be metabolized in the cytosol, therefore requiring specific carriers (Tischendorf et al. 2007).

The present study aimed to assess the possibility of using buttermilk as a carbon source for both mixotrophic and heterotrophic cultivation of G. sulphuraria ACUF 064 to obtain high-value biomass and a treated effluent with a lowered organic load. First, the effect of lactose, glucose and galactose on growth and C-PC accumulation was assessed both under mixotrophy and heterotrophy. Then, the dilution ratio of buttermilk in the synthetic medium for biomass production was evaluated in lab-scale batch experiments. Finally, the growth of G. sulphuraria ACUF 064 and its phycocyanin content were evaluated both mixotrophically and heterotrophically in a 13-L photobioreactor.

Materials and methods

Microalgal strain, media and cultivation conditions

Galdieria sulphuraria ACUF 064, kindly provided by “Federico II” Naples University, was cultivated photo-autotrophically in 250-mL Erlenmeyer flasks containing 100 mL of modified Allen’s medium (Allen and Stanier 1968). The medium used for flask and reactor cultivation contained the following components (mol L−1): 12.2 × 10–3 H3PO4, 80.0 × 10–3 (NH4)2SO4, 6.5 × 10–3 MgSO4 × 7H2O, 4.7 × 10–4 CaCl2⋅2H2O, 6.3 × 10–4 FeNaEDTA, 0.2 × 10–3 Na2EDTA⋅2H2O, 1.7 × 10–3 NaCl, 8.1 × 10–3 KCl, 8.0 × 10–4 H3BO3, 8.1 × 10–5 MnCl2⋅4H2O, 8.2 × 10–5 ZnCl2, 3.2 × 10–5 CuSO4⋅5H2O, 1.7 × 10–5 Na2MoO4⋅2H2O and 1.7 × 10–5 CoCl2⋅6H2O. pH was adjusted to 1.6 with 2 M H2SO4.

Axenic autotrophic stock cultures were incubated in 250-mL flasks containing 100 mL of culture, in an incubator (Multitron II, Infors HT, Switzerland) operated at 37 °C, 2% v/v CO2, 60% of humidity, 125 rpm, under a photon flux density of 100 μmol photons m−2 s−1 and with a photoperiod 16:8 (day: night). These cultures were used for the experiments described below.

Carbon source flask experiments

Galdieria sulphuraria ACUF 064 cultures, containing either lactose, galactose or glucose (5 gC L−1), were grown mixotrophically and heterotrophically. In particular, a 10-day pre-adaptation period for each carbon source was used to adapt G. sulphuraria ACUF 064 from autotrophy to mixotrophy and heterotrophy. Mixotrophic flask experiments were carried out into 250-mL Erlenmeyer flasks containing 150 mL of modified Allen’s medium. Cultures were inoculated at a 0.2 OD750 with the pre-acclimated culture and incubated at the same conditions reported above. The same conditions were used for the heterotrophic experiment, but the flasks were wrapped in aluminium foil. For both experiments, OD750 was measured in samples taken after 0, 22, 27, 46, 70, 75 and 94 h from inoculation. Dry weight (gx L−1) and cell count (cells mL−1) determinations were performed in samples taken after 0, 22, 70 and 94 h from inoculation. An aliquot of 15 mL was aseptically taken after 0, 46, 75 and 94 h after inoculation and centrifuged at 4700 rpm for 10 min. The supernatant fractions were stored at − 20 °C and used for total organic carbon (TOC) and total nitrogen (TN) determinations, while the pellet, washed with demineralized water, was cooled to − 20 °C, lyophilized and stored. The C-phycocyanin content was measured on a lyophilized pellet obtained from the last sampling time for each flask. The specific growth rate (µ) was obtained after plotting the logarithm of the DW over time and fitting a linear equation to the data points. The slope of the linear function was the specific growth rate. The heterotrophic and mixotrophic biomass yield per carbon consumed (Y x/C) was calculated as follows:

where Cn – Cn+1 stands for the carbon concentration (gC L−1) at times tn and tn+1.

The biomass yield on nitrogen consumed (Yx/N) was calculated as described above, considering the nitrogen concentrations (gN L−1). Experiments were performed in duplicate.

Assessment of optimal buttermilk dilution for biomass production

Buttermilk samples, kindly provided by “Caseificio del Cigno SPA” located in Agnadello (CR), Italy, were pre-treated as follows: frozen buttermilk samples were thawed and centrifuged at 4700 rpm, for 10 min at 7° C. After centrifugation, the liquid phase was largely separated from the solid upper organic phase (mainly fat) and then immediately used for trials. Three different buttermilk dilutions were obtained by adding 20, 40 and 60% (v/v) of buttermilk into sterilized modified Allen’s medium. The nitrogen and phosphate concentrations in Allen’s medium were adjusted for each dilution based on the nitrogen and phosphate already present in buttermilk. This was done differently for the reactor experiments, where Allen’s medium was simply concentrated to the final working volume of the experiment. In the flask experiments, one culture containing lactose instead of buttermilk was used as a positive control, and one culture with buttermilk at 20% v/v and deprived of nitrogen in the synthetic medium was used to assess the carbon removal with minimal medium requirements. The test was performed in flasks and in mixotrophy for 7 days, in duplicate, to assess the effect on G. sulphuraria ACUF 064 growth, in terms of biomass concentration (Cx) at the end of the trial, overall productivity (rx) and TOC concentration measured immediately after inoculation and at end of the trial. The overall productivity (rx) was calculated according to Eq. 2:

where Cxn and Cx(n+1) are the biomass concentration at times tn and tn+1.

The pH of the resulting medium was adjusted to 1.6 – 1.8 with 2 M H2SO4 and the cultivation was done as described in the previous section. A preliminary characterization of centrifuged buttermilk was carried out and is reported in Table 1S in supplementary section. It is important to notice the wide variability detected of total carbon concentration, between 3 and 5 gC L−1.

Photobioreactor setup and operation

Experiments in mixo- and heterotrophic conditions were conducted in batch mode in a 13-L stirred tank bioreactor (NW200, Infors HT, Switzerland), controlled through Labfors 4 benchtop (Infors HT, Switzerland), for 8 days. A picture of the photobioreactor setup is reported in Fig. 1. The bioreactor has a cylindrical shape, with an inner diameter of 200 mm and a maximum height of 445 mm. The reactor was used at a working volume of 8 L. During mixotrophy, half of the lateral surface of the reactor was illuminated using a vertical light panel (ReaLight-24, Ontwikkelwekplaats WUR, NL) placed 8 cm far from the reactor. Incident light intensity on the reactor surface was calibrated by measuring 24 points equally distributed on the inner surface of the empty reactor with a light meter (LI-250A, LI-COR, USA). Light intensity was provided in a continuous mode starting from 100 to 200 μmolph m−2 s−1 and was adjusted accordingly to the biomass growth by keeping a constant specific light supply rate (qph) between 5.8 and 1.8 μmolph gx−1 s−1, as referenced in previous studies by Abiusi et al. (2021). During heterotrophic cultivation, the reactor was kept in the darkness.

The reactor was equipped with a dissolved oxygen (DO) sensor (InPro 6800 Series, Mettler Toledo, USA) and a pH probe (EasyFerm Bio HB K8 325, Hamilton, USA). The DO probe was calibrated at 0% and 100% DO. Zero-point oxygen calibration was performed by immersing the probe into a 15 mL tube containing 2–5 mg of Na2S2O4 dissolved in deionised water. The 100% saturation point was performed leaving overnight the probe inside the reactor under maximal aeration (1 L min−1). The pH probe was calibrated by using the two standard buffer solutions at pH 2 and pH 4 (VWR Chemicals, USA). The pH was continuously measured and controlled at 1.6 by automatic base addition (2 M NaOH) with a cascade loop.

The temperature of the reactor, monitored constantly with a probe inserted in the culture medium, was kept at 37 °C by the heat exchange between the surface of the culture vessel and a water jacket. The temperature of the water jacket was regulated by an external water bath. To prevent evaporation, the reactor was equipped with a condenser (4 °C). Stirring was controlled in a cascade loop where agitation changed from 100 to 250 rpm to keep a DO of 20%. Air enriched with 2% v/v carbon dioxide, sterilized by 0.2 μm pore size filter (Whatman PolyVENT, PTFE filters,) was provided at a flow rate of 0.5—1 L min−1 (according to minimum DO of 20%) using mass flow controllers (Smart TMF 5850S, Brooks Instruments, USA). Both mixotrophic and heterotrophic experiments were performed as follows: once the empty reactor vessel was autoclaved at 121 °C for 15 min, it was aseptically filled with medium filtered through a 0.22 μm pore size filter (Sartobran Capsule 0.2 µm, Sartorius, USA). Consequently, the DO sensor was inserted in the reactor vessel and left overnight for 100% DO calibration. After calibration, buttermilk was added to reach a concentration of 2.0 gC L−1, corresponding to about 40% of the total volume, and immediately inoculated with a fresh culture of G. sulphuraria ACUF 064 pre-adapted on lactose (mixotrophically or heterotrophically, according to the experimental set) to OD750 of 0.3. Daily sampling was done at the same time, except for the exponential phase, where multiple samplings were performed. Concurrently, 15 mL samples were treated and stored for TOC, TN and C-PC content determinations, as previously described. During the cultivation, the DO was monitored and its increase over the setpoint was used as a reference that substrate was depleted. At this point, the experiment was diluted and a new repetition was started. The heterotrophic and mixotrophic biomass yield per carbon unit Yx/C and per nitrogen unit Yx/N consumption, the specific growth rate during exponential growth (μ) and overall productivity (rx) were calculated as reported above.

Offline analysis

Cell concentrations were determined by using a Coulter Multisizer III (Beckman Coulter Inc., USA) with a 50 μm aperture tube. Samples set at an OD750 of 0.3–0.8 were 100 times diluted in ISOTON II diluent and the number of cells was analysed in 1 mL in the diameter range between 2 and 10 μm, corresponding to the size of G. sulphuraria cells.

Dry weight concentration (DW) was calculated by measuring the weight difference between pre-weighted empty filters and filters containing biomass. Shortly, an aliquot of the culture (2 − 5 mL) was diluted into 25 mL of deionised water and filtered over a pre-weighted Whatman GF/F glass microfiber filter (diameter of 55 mm, pore size of 0.7 μm). Pre-weighted filters and filters with biomass were washed with deionised water (25 mL) and dried at 105 °C overnight, cooled down in a desiccator with silica for at least 2 h, and finally weighed on a scale (Cubis MCE225S-2S00-I, Sartorius Lab Instruments, Germany). DW measurements were performed in duplicate.

The TOC and TN content in the supernatant was measured by using a TOC-L analyzer (Shimadzu, Japan). The supernatant was diluted in demineralized water to reach a carbon content of 100–1000 ppm and a nitrogen content of 10–100 ppm. The optical density was measured at 620 and 750 nm. The samples were diluted with modified Allen’s medium until an OD750 of 0.2–0.8.

The average absorption cross-section (ax, m2 gx−1) in the PAR region (400–700 nm) of the spectrum was determined as described by de Mooij et al. (2015). Briefly, the absorbance was measured with a UV–VIS/double beam spectrophotometer (Shimadzu, Japan) equipped with an integrating sphere (ISR-2600) and using cuvettes with an optical path of 2 mm. The absorbance from 740 to 750 nm was subtracted from the whole spectrum, and the average absorbance was normalised to the DW concentration of the sample. To monitor any possible contamination during cultivation, observations were done with a light microscope and captures were taken. In detail, 10 μL of undiluted culture samples taken before, during and after the reactor run were placed on a glass microscope slide and used for observation in a light microscope (DM 2500, Leica Microsystems, Germany) equipped with a camera (DFC450, Leica Microsystems, Germany) for image capturing, at 40X and 100X magnitude lens.

Phycocyanin extraction and quantification

Phycocyanin from G. sulphuraria ACUF 064 was quantitatively extracted by bead beating (Precellys 24, Bertin Technologies, France) 10 mg of lyophilised biomass as described by Abiusi et al. (2022a). The C-phycocyanin (C-PC) concentration was calculated by measuring the absorbance at 620 nm and 652 nm of the supernatant and converting it into concentration using the Kursar and Alberte (1983). The concentration of C-PC was then normalised to the DW of G. sulphuraria to obtain the C-PC content.

Statistical analysis

One-way analysis of variance (ANOVA) and Tukey’s HSD post hoc test for means separation were performed using the STATISTICA ETL software (version 10, StatSoft. inc., USA). The significance level was set at p ≤ 0.01.

Results

Carbon sources flask experiments

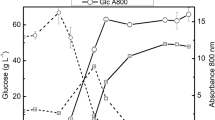

Prior to the experiments with buttermilk, we evaluated the growth of G. sulphuraria ACUF 064 individually in glucose, galactose and lactose. The initial TOC and TN concentrations were estimated to be sufficient (5 gC L−1 and 2 gN L−1) to collect enough data during the exponential phase. In Fig. 2, dry weight (DW) and TOC concentration at 0, 2, 3 and 4 days after inoculation in mixotrophy (panel A) and heterotrophy (panel B) are shown. In Fig. 1S (supplementary section), TN concentration in mixotrophy (panel A) and heterotrophy (panel B) is reported. G. sulphuraria ACUF 064 registered the highest values of biomass dry weight in mixotrophy, being 8.4 gx L−1 on galactose and 8.0 gx L−1 on glucose. Growth on lactose 4 days after inoculation was lower leading to a biomass dry weight concentration of 4.3 gx L−1 in mixotrophy. In heterotrophy, values of DW were 6.2 and 5.6 gx L−1 for glucose and galactose, respectively, being slightly lower than in mixotrophy. For lactose, the DW obtained was the lowest (3.6 gx L−1).

DW measurements (expressed as gx L−1) and TOC concentrations (expressed as gC L−1) of Galdieria sulphuraria ACUF 064 cultivated in flask under mixotrophy (panel A) and heterotrophy (panel B) using glucose, galactose and lactose at a concentration of 5 gC L.−1. Error bars indicate the standard deviation of replicates (n = 2)

Besides the DW, the specific growth rate (μ), the cell concentration, the biomass yield on nitrogen and carbon and the C-PC content were also monitored and the results are reported in Table 1. In mixotrophy, the µ estimated from DW measurements did not differ significantly between all the different substrates. From the cell counts, the highest concentration was observed on glucose (3.03·108 cellsּ mL−1), compared to galactose (2.51 × 108 cellsּ mL−1) and lactose (2.21 × 108 cellsּ mL−1). In heterotrophy, the highest µ were observed with glucose (1.06 day−1) and galactose (1.02 day−1), while the growth rate for lactose was significantly lower than in all the different conditions tested. Also in heterotrophy, the highest cell concentration was observed for the cultures grown on glucose (1.97 × 108 cellsּ mL−1) and in decreasing order, on galactose (1.87 × 108 cellsּ mL−1) and then on lactose (1.43 × 108 cellsּ mL−1). The cultures grown in heterotrophy showed a lower cell concentration than the cultures grown in mixotrophic conditions, most likely due to the additional growth from CO2 assimilation.

The measured carbon and nitrogen contents in the media at the beginning and the end of the experiment were used to estimate the yields of biomass. Considering that no carbon limitation occurred in any sample (as shown in Fig. 2), the yields of biomass on carbon (Yx/C) consumed were higher in mixotrophic conditions compared to heterotrophic conditions for each substrate. Under mixotrophy, the highest Yx/C were observed in lactose (1.9 gx gC−1) and galactose (1.9 gx gC−1), compared to glucose (1.6 gx gC−1). An opposite trend was observed in heterotrophy, where the highest Yx/C observed for glucose was decreased by 13%, while the Yx/C for galactose and lactose were also reduced by 33% and 47%, respectively. Concerning the yield of biomass per nitrogen (Yx/N), the highest yield under mixotrophy was observed for galactose (9.9 gx gN−1), followed by glucose (8.2 gx gN−1) and then lactose (7.6 gx gN−1). The Yx/N in heterotrophy were generally higher (46% and 5% higher for glucose and lactose), except for galactose, where the yield decreased by 12%. Overall, the nitrogen used in cultures grown with glucose was more efficiently used to generate new biomass than in cultures grown with lactose. Besides, it is worth mentioning that nitrogen limitation did not occur (Fig. 1S).

The accumulation of C-PC differs depending on the substrate used. The C-PC content was highest when G. sulphuraria ACUF 064 was grown on lactose and under mixotrophic conditions, reaching a value of 5.9% wC-PC wx−1. Instead, the C-PC content when G. sulphuraria ACUF 064 was grown on glucose (4.3% wC-PC wx−1) and galactose (3.7% wC-PC wx−1) was 27% and 37% lower, respectively. The C-PC content was more than twofold reduced in heterotrophy compared to mixotrophy for all the different tested substrates. Still, the highest content in C-PC occurred after using lactose (2.3% wC-PC wx−1), while equally decreased by 36% for both glucose and galactose. The results emphasise that G. sulphuraria ACUF 064, when cultivated on lactose, showed a significantly higher C-PC content in mixotrophy than in heterotrophy if compared to cultivation on glucose or galactose.

Growth of G. sulphuraria on different buttermilk dilution ratios

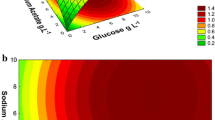

Three different medium dilutions were obtained by adding buttermilk into modified Allen’s medium at 20, 40 and 60% v/v in flasks, while one flask containing lactose was used as a positive control. Also, one flask with buttermilk at 20% v/v and deprived of nitrogen in the synthetic medium was used to assess the carbon removal with minimal medium requirements. The different dilutions were tested in mixotrophy to define a buttermilk ratio that promotes the highest biomass productivity for G. sulphuraria. The biomass concentration (Cx) and productivity (rx) after 7 days of cultivation, the TOC concentration measured at the beginning and end of the experiment and the relative carbon removal are reported in Table 2. The TN concentration measured at the beginning and end of the experiment is reported in Fig. 2S in the supplementary section. The TOC concentration in the supernatant, measured immediately after inoculation, reveals values of 1.7, 2.0 and 5.2 gC L−1 in cultures diluted with 20%, 40% and 60% v/v of buttermilk, respectively. The Cx measured 7 days after inoculation was 3.9 and 4.3 gx L−1 at 20% and 40% v/v dilution, while Cx was 1.6 gx L−1 at 60% v/v. The carbon concentration at 60% v/v was unexpectedly higher than the other dilutions, which might have inhibited the growth. The highest biomass concentration was obtained with the control experiment with lactose (5.3 gx L−1) as well as the highest productivity (0.75 gx L−1 day−1), while the highest productivity in buttermilk was observed with a dilution of 20% (0.54 gx L−1 day−1). The biomass productivity decreased with an increasing ratio of buttermilk down to 0.17 gx L−1 day−1 at 60% v/v. When nitrogen was limited, the productivity decreased by 30% compared to the replete nitrogen experiment. Nevertheless, the productivity observed for 20% v/v buttermilk and with limited nitrogen was higher than the culture at 60% v/v. Similar to the productivity, the highest carbon removal observed was 69% and it was observed at 20% v/v, while it decreased down to 7% at a buttermilk dilution of 60% v/v. When nitrogen was limited, the carbon removal achieved in buttermilk was 40%. Despite the best result of carbon removal was observed at 20% v/v of buttermilk, a similar biomass productivity was obtained at 40% v/v. The use of this dilution ratio would be preferred since a higher amount of effluent would be treated.

Growth of G. sulphuraria on buttermilk in stirred tank photobioreactor

The mixotrophic and heterotrophic metabolism of G. sulphuraria, with buttermilk fed as a carbon source, was more extensively evaluated in a 13-L stirred tank reactor. In this system, cultivation was monitored and maintained at the optimal temperature, pH and light supply rate (in mixotrophy) for G. sulphuraria growth. Additionally, a buttermilk dilution ratio of 40% v/v was used, given the high biomass productivities observed at this concentration in the previous experiment. The biomass dry weight concentration (gx L−1) and TOC concentration (gC L−1) were measured daily and are reported in Fig. 3. After 6 days, the biomass dry weight concentration was highest in mixotrophy, reaching a final value of 1.22 gx L−1, compared to 0.78 gx L−1 found in heterotrophy. After dilution and repetition of the cultivation, the highest concentrations for each cultivation type were achieved in lesser time (2 days). This is explained by a higher specific growth rate observed in the second cultivation repetition, which was 28% higher in mixotrophy compared to heterotrophy (Table 3). On the contrary, the specific growth rate was 20% lower in mixotrophy than heterotrophy in the first batch repetition. In the first batch repetition, the productivity was lower due to the adaptation of the inoculum to the new conditions as well as the low specific growth rates observed. In the second batch repetition, productivities were more than twofold and fourfold higher in mixotrophy and heterotrophy, respectively, being the highest productivity observed in mixotrophy (0.55 gx L−1 day−1).

Regarding carbon consumption, the highest removal rate was observed in the first batch repetition in mixotrophy (68%), achieving a similar result in the second. In heterotrophy, the carbon removal was 38% in the first batch repetition and it was improved in the second batch repetition (55%). The Yx/C remained constant in each repetition, being 45% higher in mixotrophy compared to heterotrophy (Table 3). The absorption spectrum was also monitored over the culture to gain information on the pigmentation changes. At the end of the first repetition, the ax was higher in mixotrophy, being 76.6 m2 kg−1 in the first repetition and 96.5 m2 kg−1 in the second repetition (Table 3). The ax in heterotrophy was lower (58.7 and 41.8 m2 kg−1 in the first and second repetition, respectively) due to the dispensable use of photosynthetic activity and consequently, the size reduction of photosynthetic membranes. The ax was relatively constant during the second repetition in heterotrophy, while it seemed to increase in mixotrophy probably due to an increased need for photosynthetic activity.

The C-PC content, as expected, was higher in mixotrophy than in heterotrophy, reaching 2.18 and 1.19% wC-PC wx−1, at the end of the first and second repetitions. In heterotrophy, the C-PC content was lower (0.58 and 0.52% wC-PC wx−1 in the first and second repetition, respectively), in line with the changes in ax. The mismatch between ax and C-PC content in the second repetition of the mixotrophic experiments is explained by an increased ratio of carotenoids over chlorophyll and phycocyanin (Fig. 3S).

During the cultivation, light microscopy observations were done to evaluate the presence of contaminants. After the end of the second repetition, an outbreak of fungal populations became visible in the culture (Fig. 4). The fungal contamination was observed independently of the trophic strategy, coincidentally 8 days after the start of the cultivation. The observation of hyphae at the end of the second repetition is likely derived from the growth of spores that were originally present at the beginning of the cultivation. In a different heterotrophic batch experiment, the presence of fungal contamination was detected after 8 days, in particular after the start of a new batch repetition. In this case, the presence of filamentous fungi led to an overestimation of the DW. (Fig. 4S).

Microscope images of Galdieria sulphuraria ACUF 064 during cultivation in the photobioreactor in mixotrophy or heterotrophy with buttermilk. Pictures at 40X magnification of mixotrophic cultivation: at day 0 (panel a) and day 8th (panel b); in panel c, Image with fungal contamination was observed after the second batch repetition in mixotrophy (100X magnification). Pictures at 40X magnitude of heterotrophic cultivation: at day 0 (panel d) and day 8.th (panel e); in panel f, Image with fungal contamination observed after the second batch repetition in heterotrophy (100X magnification)

Discussion

Carbon sources flask experiment

The carbon source flask experiment carried out in this study shows that the specific growth rate (μ) of G. sulphuraria ACUF 064 on lactose resembled the one observed on glucose or galactose both under mixotrophy and heterotrophy. Despite the known variability among species from the same genus, and even within strains, G. sulphuraria ACUF 064 showed a similar specific growth rate on glucose and galactose, as reported in previous literature for other strains. Overall, the heterotrophic μ registered in this study was similar to that observed for G. sulphuraria 74G when sucrose (disaccharide), glucose and galactose were the carbon sources used (Gross & Schnarrenberger 1995). The μ observed during the heterotrophic experiment for G. sulphuraria ACUF 064 were similar to those reported by Schmidt et al. (2005) for G. sulphuraria 74G. In their study, μ values of 1.10 day−1, 1.08 day−1, and 1.01 day−1 for glucose, fructose and sucrose, respectively, were obtained. Sloth et al. (2006) reported for G. sulphuraria 74G on glucose, fructose or glycerol similar growth rates. The µ was 1.2 day−1 in all three cases, independently of the light intensity tested (0 and 117 μmol photons m−2 s−1). Also, no significant differences in μ were reported when comparing heterotrophic and mixotrophic growth with xylose as a carbon source (0.97 day−1 and 1.10 day−1, respectively) for G. sulphuraria UTEX2919 (Portillo et al. 2022). When glucose was used, they registered a μ of 1.46 day−1 in heterotrophy and 1.49 day−1 in mixotrophy, a growth rate significantly higher than the ones obtained in this study.

The C-PC content measured in mixotrophy for each carbon source was far from the 10% wC-PC wx−1 obtained in a previous study with the same strain (Abiusi et al. 2022a). This divergence is explained by differences in the cultivation conditions. Experiments by Abiusi et al. (2022a) were performed in chemostat in a stirred reactor and at a low growth rate and light limited conditions, thus favouring the accumulation of C-PC. Interestingly, the C-PC content we observed both in heterotrophic conditions on glucose and galactose were similar to those registered by Graverholt and Eriksen (2007) with G. sulphuraria 74G in batch with sufficient glucose (1.6% wC-PC wx−1), while the content was higher (2.7% wC-PC wx−1) in fed-batch cultures where glucose supply was limited. The C-PC content of G. sulphuraria ACUF 064 grown with lactose (2.34% wC-PC wx−1) was comparable to the results registered when glucose was depleted or limited. As explained in previous studies, phycocyanin accumulation can be triggered under glucose limitation (Sloth et al. 2006; Graverholt and Eriksen 2007; Portillo et al. 2022; Sørensen et al., 2013). Furthermore, Sloth et al., (2006) reported that the substrate structure could also affect the biomass yield and the C-PC content. G. sulphuraria 74G showed a higher biomass yield on substrate, as well as a higher specific C-PC content in mixotrophy with glycerol (triol with three carbon atoms) than with glucose (sugar with six carbon atoms). Hence, in line with these observations, and due to the structural complexity of lactose (sugar with twelve carbon atoms), the specific carbon uptake of G. sulphuraria ACUF 064 was lower for lactose, resulting in a lower growth rate and a higher C-PC content.

These observations are supported by the biomass yield on carbon or nitrogen unit. The low Yx/C and the high TOC concentration at the end of the experiment, indicate a low efficiency of G. sulphuraria ACUF 064 in converting lactose into biomass, compared to simpler sugars such as glucose and galactose. The high Yx/C observed in mixotrophy compared to heterotrophy is explained by the additional use of light and carbon dioxide assimilation for biomass synthesis. At the same time, the low Yx/N values coupled with high Yx/C values indicate that more nitrogen was consumed per gram of carbon consumed. This implies that more nitrogen is accumulated either in the form of chlorophylls, phycobiliproteins or proteins. The more than two-fold increase of C-PC content in mixotrophy in comparison to heterotrophy might indicate that nitrogen is channelled to the synthesis of C-PC. The use of certain carbon sources in heterotrophy was shown to exert a downregulation of the genes involved in photosynthesis and pigment synthesis. As a matter of fact, a different response in the transcription of genes involved in pigment synthesis was observed when glycerol or glucose was used (Perez Saura et al. 2022). In other studies, it was hypothesised that glucose and fructose repress C-PC synthesis in more extent than glycerol (Sloth et al. 2006). A similar conclusion was reached when xylose was used as a carbon source instead of glucose since a higher C-PC content was reached. The high C-PC content observed with lactose could suggest that lactose induces a similar effect such as glycerol or xylose.

The phycocyanin content in lactose-fed cultures in heterotrophy disagrees with the results of previous studies by Tischendorf et al. (2007) and Zimermann et al. (2020), who observed an almost complete loss of pigmentation when the strain was grown in the same conditions. Finally, a direct comparison was made with data from Zimermann et al. (2020) between two strains in heterotrophic conditions fed on lactose. In particular, in our heterotrophic flask experiment, the specific growth rate of G. sulphuraria ACUF 064 was lower on lactose than on glucose but the pigmentation was greater, while in the case of G. sulphuraria SAG 107.79 the opposite results were obtained.

Growth of G. sulphuraria on different buttermilk dilution ratios

Galdieria sulphuraria was previously grown on a lactose-rich medium such as whey permeate (Zimermann et al. 2020), but it is the first time that specifically buttermilk was used as a carbon source for growth. In this study, it was shown that a high concentration of effluent could be toxic for the growth of G. sulphuraria (Zimermann et al. 2020). Therefore, the effect of different buttermilk dilution ratios on G. sulphuraria ACUF 064 growth was pre-tested in flasks, showing also a decrease in productivity with an increasing ratio of buttermilk on synthetic medium. The highest productivity was achieved in the positive control, with a medium containing only lactose and free of organic molecules. The lowest productivity achieved at 60% v/v might infer an inhibitory effect by specific compounds contained in buttermilk. A similar result was obtained in growth experiments of G. sulphuraria on whey permeate (Zimermann et al. 2020), where dilutions higher than 20% v/v resulted in a longer adaptation phase. Growth was inexistent at dilutions ratios higher than 30% v/v. The removal of nitrogen from synthetic medium limited the growth of G. sulphuraria, but not the carbon removal. Overall, the low biomass productivity and carbon removal observed at 60% v/v dilution might indicate the presence of inhibitory compounds for G. sulphuraria in buttermilk. Hancock et al. (2002) reported that the antibacterial activity exhibited by buttermilk proteins such as whey proteins and caseins could affect negatively the microalgal growth or affect positively by limiting bacterial contamination. Further investigation would be necessary to confirm whether there are toxic molecules that hamper the growth of G. sulphuraria.

Growth of G. sulphuraria on buttermilk in stirred tank photobioreactor

Mixotrophic and heterotrophic experiments were performed on a lab-scale photobioreactor (13-L photobioreactor) with the aim to assess the growth performance of G. sulphuraria and carbon removal in buttermilk. In contrast to flask experiments, parameters such as light supply rate during mixotrophy or the oxygen concentration during heterotrophy were monitored and controlled to an optimal setpoint. In that way, the carbon contained in buttermilk was expected to be the only limiting component for growth. A dilution ratio of 40% v/v was used since it was shown a high biomass productivity in flasks experiments, as described above. Compared to autotrophy, heterotrophy is known to lead to high biomass production (Barros et al. 2019). Mixotrophy involves the simultaneous assimilation of sugar and the fixation of carbon for growth. The maximal carbon removal obtained in the photobioreactor was 68% in mixotrophy. Similar results were obtained in the flasks at a dilution of 20% v/v. Overall, these results indicate that about 30% of the carbon present in buttermilk cannot be easily assimilated by G. sulphuraria and needs to be removed by different means. Mixotrophy was the best strategy for buttermilk since it led to a higher specific growth rate, biomass productivity and biomass yield on carbon. The higher yields observed in mixotrophy compared to heterotrophy are influenced by the photoautotrophic growth and their extent. The yields of biomass on carbon found for buttermilk were still lower compared to the yields found for lactose. This might be explained by an increased occurrence of futile cycles or overflow metabolism when buttermilk is used where energy is spilt in other metabolic processes than growth.

The growth rates found in the photobioreactor in the second repetition were similar to those measured for G. sulphuraria 74G, in heterotrophy, fed on food and bakery waste (Sloth et al. 2017). The authors found μ values of 0.69 and 0.60 day−1 in restaurant and bakery waste, respectively. In that case, both substrates had been subjected to a hydrolyzation pre-treatment to convert complex sugars into monomers, predominantly glucose. In a recent study, Pleissner et al. (2021), using G. sulphuraria SAG21.92, found a μ of 1.0 day−1 in heterotrophy in the presence of 100% (v/v) of hydrolysed digestate supplemented with glucose in excess (50 g L−1). In experiments carried out by Rahman et al. (2020), instead, G. sulphuraria 74G was grown in the presence of corn and potato starch where lower growth rates were found compared to our study (0.3 – 0.4 day−1). The lower growth rate observed with buttermilk in the first repetition reinforces the fact that cultures needed a long adaptation phase to hydrolyse the different carbon molecules in buttermilk at the expense of an additional metabolic effort.

The use of acidic and high-temperature conditions is usually regarded as an advantage over microbial competitors such as bacteria. Nevertheless, fungal optimal growth temperatures are found above 30 °C and optimal pH conditions range between 3 and 8 (Laezza et al. 2022). In our trials with the photobioreactor, fungal contamination became visible at the end of the second repetition, while no evidence was observed during the first repetition. Abiotic factors such as mechanical stirring or aeration could have influenced the growth of fungi since they were not previously observed in our flask tests. The cultivation time in flasks was lower than in the photobioreactor, which might explain why fungi were not observed. The co-cultivation of microalgae and fungi is a relatively new topic which has been poorly researched. It is still not clear whether the interaction between them could imply an improvement in the growth of microalgae. A recent study reported a mutual growth benefit between G. sulphuraria and the fungus Penicillium citrinum at conditions optimal for the growth of G. sulphuraria (Salvatore et al. 2023). Therefore, further studies on the symbiotic relationship between microalgae and fungi are needed for the remediation and valorisation of industrial effluents.

Conclusion

The results of the present study revealed that buttermilk, when adequately diluted, can be used as a substrate for biomass production. This is beneficial in environmental terms, providing a solution for treatment and avoiding disposal, allowing for the recovery of material. G. sulphuraria ACUF 064 proved to be able to use lactose as a carbon source, despite its complexity compared to simpler sugars such as glucose and galactose. Even though the growth of G. sulphuraria on buttermilk was slower than on optimal substrates, the obtained biomass still accumulated C-PC. This confirms the potential of microalgal cultivation to recover buttermilk or lactose-enriched effluents to support the G. sulphuraria ACUF 064 growth while obtaining a valuable product. For such purposes, mixotrophy proved to be the most suitable cultivation mode. Nevertheless, considering the complexity and heterogeneity of buttermilk, extensive investigations are needed to evaluate whether any organic compounds (and at which concentrations) have a hampering effect on the growth of G. sulphuraria. In addition, further research is needed to improve the biomass production and phycocyanin content through optimization of light supply, pre-treatment of buttermilk or the use of other operational strategies such as chemostats or the adoption of fed-batch approaches. Finally, further research is required to understand the interactions between G. sulphuraria and other microbes such as fungi and how they affect the growth of G. sulphuraria.

Data availability

The raw data generated during this research is available by the corresponding author upon request without reservation.

References

Abiusi F, Trompetter E, Hoenink H, Wijffels RH, Janssen M (2021) Autotrophic and mixotrophic biomass production of the acidophilic Galdieria sulphuraria ACUF 064. Algal Res 60:102513

Abiusi F, Moñino Fernández P, Canziani S, Janssen M, Wijffels RH, Barbosa M (2022a) Mixotrophic cultivation of Galdieria sulphuraria for C-phycocyanin and protein production. Algal Res 61:102603

Abiusi F, Trompetter E, Pollio A, Wijffels RH, Janssen M (2022b) Acid tolerant and acidophilic microalgae: An underexplored world of biotechnological opportunities. Front Microbiol 13:820907

Albertano P, Ciniglia C, Pinto G, Pollio A (2000) The taxonomic position of Cyanidium, Cyanidioschyzon and Galdieria: an update. Hydrobiologia 433:127–143

Ali AH (2019) Current knowledge of buttermilk: Composition, applications in the food industry, nutritional and beneficial health characteristics. Int J Dairy Technol 72:169–182

Bahrami M, Ahmadi D, Beigmohammadi F, Hosseini F (2015) Mixing sweet cream buttermilk with whole milk to produce cream cheese. Irish J Agric Food Res 54:73–78

Barros A, Pereira H, Campos J, Marques A, Varela J, Silva J (2019) Heterotrophy as a tool to overcome the long and costly autotrophic scale-up process for large-scale production of microalgae. Sci Rep 9:13935

Canelli G, Abiusi F, Vidal Garcia A, Canziani S, Mathys A (2023) Amino acid profile and protein bioaccessibility of two Galdieria sulphuraria strains cultivated autotrophically and mixotrophically in pilot-scale photobioreactors. Innov Food Sci Emerg Technol 84:103287

Curien G, Lyska D, Guglielmino E, Westhoff P, Janetzko J, Tardif M, Hallopeau C, Brugière S, Dal Bo D, Decelle J, Gallet B, Falconet D, Carone M, Remacle C, Ferro M, Weber APM, Finazzi G (2021) Mixotrophic growth of the extremophile Galdieria sulphuraria reveals the flexibility of its carbon assimilation metabolism. New Phytol 231:326–338

de Freitas Mascarello A, Isabel Pinto G, Souza de Araújo I, Caragnato LK, Lopes da Silva AL, Freire dos Santos L (2019) Technological and biological properties of buttermilk: A minireview. In: Gigli I (ed) Whey - Biological Properties and Alternative Uses. IntechOpen, London. pp 1–9

de Mooij T, Janssen M, Cerezo-Chinarro O, Mussgnug J, Kruse O, Ballottari M, Bassi R, Bujaldon S, Wollman F-A, Wijffels R (2015) Antenna size reduction as a strategy to increase biomass productivity: A great potential not yet realized. J Appl Phycol 27:1063–1077

Dewettinck K, Rombaut R, Thienpont N, Le TT, Messens K, Van Camp J (2008) Nutritional and technological aspects of milk fat globule membrane material. Int Dairy J 18:436–457

Di Caprio F (2020) Methods to quantify biological contaminants in microalgae cultures. Algal Res 49:101943

Fuller KL, Kuhlenschmidt TB, Kuhlenschmidt MS, Jiménez-Flores R, Donovan SM (2013) Milk fat globule membrane isolated from buttermilk or whey cream and their lipid components inhibit the infectivity of rotavirus in vitro. J Dairy Sci 96:3488–3497

Gassi JY, Blot M, Beaucher E, Robert B, Leconte N, Camier B, Rousseau F, Bourlieu C, Jardin J, Briard-Bion V, Lambert S, Gésan-Guiziou G, Lopez C, Gaucheron F (2016) Preparation and characterisation of a milk polar lipids enriched ingredient from fresh industrial liquid butter serum: Combination of physico-chemical modifications and technological treatments. Int Dairy J 52:26–34

Graverholt OS, Eriksen NT (2007) Heterotrophic high-cell-density fed-batch and continuous-flow cultures of Galdieria sulphuraria and production of phycocyanin. Appl Microbiol Biotechnol 77:69–75

Graziani G, Schiavo S, Nicolai MA, Buono S, Fogliano V, Pinto G, Pollio A (2013) Microalgae as human food: Chemical and nutritional characteristics of the thermo-acidophilic microalga Galdieria sulphuraria. Food Funct 4:144–152

Gross W, Schnarrenberger C (1995) Heterotrophic growth of two strains of the acido-thermophilic red alga Galdieria sulphuraria. Plant Cell Physiol 36:633–638

Hancock JT, Salisbury V, Ovejero-Boglione MC, Cherry R, Hoare C, Eisenthal R, Harrison R (2002) Antimicrobial properties of milk: Dependence on presence of xanthine oxidase and nitrite. Antimicrob Agents Chemother 46:3308–3310

Holzmüller W, Kulozik U (2016) Quantification of MFGM proteins in buttermilk and butter serum by means of a stain free SDS-PAGE method. J Food Compos Anal 49:102–109

Jain M, Khan SA, Sharma K, Jdhao PR, Pant KK, Ziora ZM, Blaskovich MAT (2022) Current perspective of innovative strategies for bioremediation of organic pollutants from wastewater. Bioresour Technol 344:126305

Konrad G, Kleinschmidt T, Lorenz C (2013) Ultrafiltration of whey buttermilk to obtain a phospholipid concentrate. Int Dairy J 30:39–44

Kumar A, Thakur A, Panesar PS (2019) A comparative study on experimental and response surface optimization of lactic acid synergistic extraction using green emulsion liquid membrane. Sep Purif Technol 211:54–62

Laezza C, Salbitani G, Carfagna S (2022) Fungal contamination in microalgal cultivation: Biological and biotechnological aspects of fungi-microalgae interaction. J Fungi 8:1099

Lambert S, Leconte N, Blot M, Rousseau F, Robert B, Camier B, Gassi J-Y, Cauty C, Lopez C, Gésan-Guiziou G (2016) The lipid content and microstructure of industrial whole buttermilk and butter serum affect the efficiency of skimming. Food Res Int 83:121–130

Olabi A, Jinjarak S, Jiménez-Flores R, Walker JH, Daroub H (2015) Compositional and sensory differences of products of sweet-cream and whey buttermilk produced by microfiltration, diafiltration, and supercritical CO2. J Dairy Sci 98:3590–3598

Oesterhelt C, Schnarrenberger C, Gross W (1999) Characterization of a sugar/polyol uptake system in the red alga Galdieria sulphuraria. Eur J Phycol 34:271–277

Pagels F, Guedes AC, Amaro HM, Kijjoa A, Vasconcelos V (2019) Phycobiliproteins from cyanobacteria: Chemistry and biotechnological applications. Biotechnol Adv 37:422–443

Perez Saura P, Chabi M, Corato A, Cardol P, Remacle C (2022) Cell adaptation of the extremophilic red microalga Galdieria sulphuraria to the availability of carbon sources. Front Plant Sci 13:978246

Pleissner D, Lindner AV, Händel N (2021) Heterotrophic cultivation of Galdieria sulphuraria under non-sterile conditions in digestate and hydrolyzed straw. Bioresour Technol 337:125477

Portillo FV-L, Sierra-Ibarra E, Vera-Estrella R, Revah S, Ramírez OT, Caspeta L, Martinez A (2022) Growth and phycocyanin production with Galdieria sulphuraria UTEX 2919 using xylose, glucose, and corn stover hydrolysates under heterotrophy and mixotrophy. Algal Res 65:102752

Raghunath BV, Punnagaiarasi A, Rajarajan G, Irshad A, Elango A, Mahesh Kumar G (2016) Impact of dairy effluent on the environment—a review. In: Prashanthi M, Sundaram R (eds) Integrated Waste Management in India: Status and Future Prospects for Environmental Sustainability. Springer, Cham, pp 239–249

Rahman DY, Sarian FD, van der Maarel MJEC (2020) Biomass and phycocyanin content of heterotrophic Galdieria sulphuraria 074G under maltodextrin and granular starches–feeding conditions. J Appl Phycol 32:51–57

Russo GL, Langellotti AL, Oliviero M, Baselice M, Sacchi R, Masi P (2021) Valorization of second cheese whey through cultivation of extremophile microalga Galdieria sulphuraria. AIMS Environ Sci 8:435–448

Salvatore MM, Carraturo F, Salbitani G, Rosati L, De Risi A, Andolfi A, Salvatore F, Guida M, Carfagna S (2023) Biological and metabolic effects of the association between the microalga Galdieria sulphuraria and the fungus Penicillium citrinum. Sci Rep 13:1789

Sloth JK, Jensen HC, Pleissner D, Eriksen NT (2017) Growth and phycocyanin synthesis in the heterotrophic microalga Galdieria sulphuraria on substrates made of food waste from restaurants and bakeries. Bioresour Technol 238:296–305

Sloth JK, Wiebe MG, Eriksen NT (2006) Accumulation of phycocyanin in heterotrophic and mixotrophic cultures of the acidophilic red alga Galdieria sulphuraria. Enzyme Microb Technol 38:168–175

Sodini I, Morin P, Olabi A, Jiménez-Flores R (2006) Compositional and functional properties of buttermilk: A comparison between sweet, sour, and whey buttermilk. J Dairy Sci 89:525–536

Tischendorf G, Oesterhelt C, Hoffmann S, Girnus J, Schnarrenberger C, Gross W (2007) Ultrastructure and enzyme complement of proplastids from heterotrophically grown cells of the red alga Galdieria sulphuraria. Eur J Phycol 42:243–251

Tredici MR (2010) Photobiology of microalgae mass cultures: Understanding the tools for the next green revolution. Biofuels 1:143–162

Vanderghem C, Bodson P, Danthine S, Paquot M, Deroanne C, Blecker C (2010) Milk fat globule membrane and buttermilks: from composition to valorization. Biotechnol Agron Soc Environ 14:485–500

Vigliengo E, Reinheimer J (2009) Use of whey and buttermilk-based media to obtain biomass of thermophilic LAB. Int J Dairy Technol 62:431–437

Zimermann JDaF, Sydney EB, Cerri ML, de Carvalho IK, Schafranski K, Sydney ACN, Vitali L, Gonçalves S, Micke GA, Soccol CR, Demiate IM (2020) Growth kinetics, phenolic compounds profile and pigments analysis of Galdieria sulphuraria cultivated in whey permeate in shake-flasks and stirred-tank bioreactor. J Water Process Eng 38:101598

Acknowledgements

We would like to thank Michele Locatelli from Caseificio del Cigno S.P.A. for the supply of buttermilk, and our most sincere thanks to Prof. Antonino Pollio from the University of Naples Federico II for his guidance and fruitful discussions on Galdieria cultivation. Finally, we would like to thank two anonymous reviewers for their feedback and critical assessment of the manuscript.

Funding

The contents of this work were financially supported by Algreen B.V.

Author information

Authors and Affiliations

Contributions

Conceptualization, V.M., N.F.L., S.C.; Methodology, N.F.L., F.D.S.; Formal analysis, P.S.O., F.D.S. and N.F.L.; Investigation, P.S.O., F.D.S. and N.F.L.; Resources, S.C.; Data curation, P.S.O. and N.F.L.; writing—original draft preparation, P.S.O.; Writing—review and editing, V.M., N.F.L., S.C. and C.C.; Visualization, P.S.O. and N.F.L.; Supervision, N.F.L., S.C. and C.C.; Project administration, V.M., S.C.; Funding acquisition, S.C. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Conflict of interests

We declare that the authors have no competing interests, as defined by Springer, or other interests that might be perceived to influence the results and/or discussion reported in this manuscript.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Occhipinti, P.S., Del Signore, F., Canziani, S. et al. Mixotrophic and heterotrophic growth of Galdieria sulphuraria using buttermilk as a carbon source. J Appl Phycol 35, 2631–2643 (2023). https://doi.org/10.1007/s10811-023-03012-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-023-03012-0