Abstract

Rapid deterioration of harvested macroalgal biomass is a challenge for macroalgal industry and can be overcome with the inexpensive ensiling preservation. To improve silage quality, Saccharina latissima and Alaria esculenta biomass was subjected to ensiling conditions following a 2 × 4 factorial design, with 2 prewilting treatments (no-prewilting and prewilted to 300 g DM kg−1 fresh biomass) and 4 additive treatments (no additive, formic acid, single and two species of Lactobacillus inoculant), and ensiled for 3 or 12 months at 15 °C. Acetate was the main fermentation product in these seaweed silages. Prewilting reduced the acetate, mannitol, and NH3 content in silages. In S. latissima silages without additives, prewilting led to less acidification (pH = 5.7). Also, prewilting caused protein and phlorotannin degradation. When treated with formic acid, the silage pH was below 4 regardless of the biomass’s moisture content. The use of Lactobacillus spp. inoculants was essential for lactate production in seaweed silages, and it significantly lowered silage pH in S. latissima and prewilted A. esculenta compared to silages with no additives. A high level of the phlorotannin content was preserved (> 90%) in the 3-month A. esculenta silages without prewilting. However, major reduction of antioxidant activity was observed in 12-month silages in both seaweed species. In conclusion, ensiling is a viable method for preserving Alaria and Saccharina biomass. Prewilting restricted silage fermentation, and both formic acid and bacterial additives facilitated silage acidification. However, there was no clear benefit of these treatments in preserving the antioxidant activity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Brown marine macroalgae or seaweeds are characterized by their fast growth and their high contents in carbohydrates (e.g., alginate), minerals, and phlorotannin, which are valuable components for feed, food, pharmaceuticals, and biofuels application (Penalver et al. 2020). In particular, large amounts of brown seaweeds are processed into bioactive extracts for food and pharmaceuticals industry due to its antioxidant properties (Cherry et al. 2019; Penalver et al. 2020). In feed, seaweed extracts are included in the diets of monogastric animals for health benefits, and the dairy industry is exploring the use of intact seaweeds as alternative feed ingredients (Makkar et al. 2016; Gaillard et al. 2018). Ecologically, macroalgae aquaculture is a sustainable production of biomass with the advantages of not requiring fertilizer, arable land, or freshwater. The commercial cultivation of seaweeds is a globally growing industry, which accounted with 32.3 million tonnes of fresh weight for 28% of the entire aquaculture sector worldwide (FAO 2020). In Norway, there is a growing aquaculture activity for the two brown macroalgae Saccharina latissima (thereafter called Saccharina) and Alaria esculenta (thereafter called Alaria), with an estimated potential of producing 150–200 t fresh biomass per hectare per year (Broch et al. 2019; Fiskeridirektoratet 2020). Meanwhile, the rapid post-harvest deterioration of macroalgal biomass is a known limitation to its further utilization as nutrients and bioactive ingredients.

Ensiling is a common agricultural method to preserve forage for livestock. During ensilage, the freshly harvested biomass is preserved by anerobic fermentation in which epiphytic lactic acid bacteria (LAB) convert sugars into lactate (pKa of 3.86) and decrease the pH. The increased acidity and osmotic pressure arrest the microbial activities, and the nutrient content is preserved. Ensiling requires low mechanical and energy inputs. This is of great advantage for the preservation of harvested seaweeds in countries with climate conditions unfavorable for sun-drying and high labor costs (e.g., Norway). Moreover, ensiling potentially enables a year-round supply with biomass, batch process, and the possibility to avoid drying in several downstream processes which are designed to use wet biomass (Alvarado-Morales et al. 2013; Bach et al. 2014).

However, studies have shown difficulties in reaching adequate acidification of silage with the brown seaweeds Ascophyllum nodosum and Fucus vesiculosus due to the high moisture content, low fermentable carbohydrates, and lack of the natural epiphytic LAB (Black 1955; Herrmann et al. 2015; Campbell et al. 2020). For Saccharina, the high carbon to nitrogen ratio (C:N) of the biomass supports an adequate fermentation activity to reach a low silage pH, but nutrients losses were reported during ensilage (Herrmann et al. 2015; Cabrita et al. 2017; Campbell et al. 2020). Hence, common management strategies of moisture reduction and the use of silage additives were recommended to improve silage quality (Herrmann et al. 2015).

So far, there are only a few studies available that used either chemical or LAB additives in Saccharina silages (Cabrita et al. 2017; Campbell et al. 2020; Novoa-Garrido et al. 2020). However, it is challenging to compare these results due to the differences in seaweed biomass and ensiling conditions. Besides, the silage production of Alaria has not been studied yet despite this alga’s commercial significance. Moreover, the effects of additives were found to differ in silages made of fresh and prewilted seaweed biomass (Gallagher et al. 2021).

The aim of the present study was to increase our knowledge of ensiled seaweed biomass with respect to its quality (fermentation pattern), antioxidant activity, and chemical composition in the different ensiling conditions, managed by means of moisture reduction (prewilting) and the use of common ensiling additives, in order to make a decisive approach towards ensiling. One hypothesis tested was that LAB additive will promote the lactic fermentation process in seaweed biomass. A second hypothesis tested was that lower moisture content will substantially affect the fermentation pattern.

Material and method

Seaweed cultivation

Saccharina latissima and Alaria esculenta were grown at the commercial floating aquaculture facility of Lofoten Blue Harvest in Austre Vågan on Lofoten, Norway (N68, E15). The seeding material was prepared from locally collected parental material by Hortimare AS (Bergen, Norway). Ropes were seeded before deployed to the sea in October 2017, and the macroalgae were allowed to grow for 8 months until they were harvested in June 2018. The biomass was washed with seawater on the vessel right after harvest and then packed in Styrofoam boxes to be transported (4–7 °C) to the Research Station of Nord University in Bodø. Upon arrival and within 24 h after harvest, the macroalgae were transferred to 600 L water tanks with running seawater set to 7 ± 1 °C and constant aeration to mitigate potential degradation. The macroalgae were maintained at 150 µmol photons m−2 s−1, measured at the water surface of the tanks, until further treated for silage preparation within 48 h.

Experimental design

Ensiling treatments followed a 2 × 2 × 4 factorial design with two prewilting treatments (no-prewilting and prewilted to 300 g DM kg−1 fresh biomass), two chopping times (20 s and 1 min), and four additive treatments (no additive, formic acid, single and two species of Lactobacillus inoculant) (n = 3). However, since the chopping time did not have an effect on our results, this factor was removed, and the results were pooled for statistical analysis as a 2 × 4 factorial design (n = 6).

Silage preparation

The silage preparation framework is shown in Fig. 1. Macroalgal biomass was washed in three sequential water baths with decreasing salinity: 100% seawater, 70% seawater and freshwater (10 s at each step). Some of the excess water was drained by hand squeezing. Pre-ensiling samples were collected before washing (n = 1) and after draining (n = 1) and stored at − 40 °C until further analysis. For the prewilting treatment, half of the washed and drained biomass was processed with its original moisture content (noPW). The other half of the washed and drained biomass was oven-dried at 37 ± 4 °C (using a fan) to reach approximately 300 g dry matter per kg biomass (PW). The PW and noPW biomass were then chopped using a butcher’s cutter (TONDO5, ADE Germany GmbH, Germany) in batches of 3 kg to a particle size of about 1–4 cm2.

After chopping, 1 kg of noPW biomass and the equivalent weight of PW biomass (Alaria: 310 g, Saccharina: 280 g) were placed in vacuum plastic bags as small-scale lab silos (Lavezzini, Fiorenzuola d’Arda, Italy; dimentions 20 × 60 cm). Different additives were added to each lab silos under the following treatments, CON: no additives = control, FA: 4 g formic acid per bag (WVR, Norway), LABh: 5 × 109 CFU Lactobacillus plantarum R2 Biocenol™ (CCM 8674) per bag, and LABm: 2.5 × 109 CFU L. plantarum (CCM 8674) and 2.5 × 109 CFU Lactobacillus fermentum R3 Biocenol™ (CCM 8675) per bag. Both LAB strains were isolated from the intestinal content of farmed healthy juvenile rainbow trout (Fečkaninová et al. 2019). The LAB inoculants were prepared fresh prior to ensiling. After adding the additives, the lab silos were gently massaged by hand to homogenize the macroalgal material with the ensiling additives, and vacuum-sealed using a heat-sealing mechanism. All silages were ensiled in the dark in a temperature-controlled room at 15 ± 1 °C for 3 or 12 months, simulating summer temperature conditions in Norway. At each sampling time, six lab silos per treatment were opened to terminate fermentation, and the biomass was transferred to another bag and stored at − 40 °C until further analysis.

Chemical composition analysis

Seaweed samples were extracted by blending 80 g of biomass with 750 mL of dH2O twice for 40 s with an interval break of 40 s in a 4-L blender with stainless steel container (Warning Commercial, USA). The blended juice was poured into two 50-mL tubes and centrifuged at 2300 × g for 20 min at 10 °C. Silage pH was determined by the average pH of supernatant from the two tubes using pH meter (PHM240; Radiometer Medical ApS, Denmark) for each sample. For fermentation product analysis, 8 mL of supernatant was mixed with 2 mL of 25% meta-phosphoric acid (MPA) and stored at − 20 °C. Short-chain fatty acids (SCFA) including acetate, propionate, butyrate, valerate, iso-butyrate, iso-valerate, and caproate were measured by the gas chromatography methods described in Kristensen et al. (1996). Ammonia (NH3) content was measured using the commercial kit based on glutamate dehydrogenase (AM 1015; Randox Laboratories Ltd., UK) and the Cobas Mira auto-analyzer (Roche Diagnostics, Switzerland). L-lactate content was measured using YSI 2900 Biochemistry Analyzer (YSI Inc., USA) with membrane-immobilized substrate specific oxidases (L-lactate oxidase). To measure mannitol content, the same supernatant used for measuring pH was further extracted with 1:2 water-EtOH solution under constant stirring. After centrifugation, the supernatant was analyzed with an enzymatic fluorimetric method, equivalent to the method used for determination of glutamic acid (Larsen and Fernández 2017), to determine D-mannitol concentration after reaction with mannitol dehydrogenase. Dry matter (DM) content was determined by freeze drying the frozen samples (− 82 °C, 0.77 mbar). Dried samples from the same treatments were pooled together and milled to pass 1.0 mm filter for ash, nitrogen (N), carbon (C), and neutral detergent fiber (aNDF) analysis. Crude ash was determined after incinerated at 525 °C for 6 h (AOAC International, 2000). N and C content was measured by the Dumas method (Hansen, 1989), using Vario MAX CN (Elementar Analysesysteme GmbH, Germany). The aNDF content was analyzed using neutral detergent extraction according to Mertens (2002) with a Fibertec M6 System (Foss, Denmark) using heat-stable amylase and corrected for ash. The iodine (I) and heavy metal contents including lead (Pb), cadmium (Cd), mercury (Hg), arsenic (As), and inorganic As (iAs) were measured in a commercial laboratory by the inductively coupled plasma (ICP-MS) method. To make extracts, 1 g of freeze-dried samples were mixed with acid solution (39% HNO3 + 1.8% HCl) followed by a pressured microwave digestion (up to 235 °C, 1.5 to 2 h). For iodine, the extraction was carried out with tetramethylammonium hydroxide. The iAs was determined using hydride generation atomic absorption spectrometry (HG-AAS).

Antioxidant activity analysis

Pre-ensiling and ensiled seaweed samples (3 and 12 months) were freeze dried at − 55 °C, milled to pass 1.0-mm screen using a cell mill (Cyclotec 193 Sample Mill; Tecator, Sweden), and extracted by mixing 50–150 mg of milled powder with 1 mL of 70% (v/v) aqueous acetone with constant shaking at room temperature for 60 min, followed by centrifugation (10,000 × g, 6 min, 4 °C). The extraction step was repeated four to six times to extract more than 95% of the soluble phlorotannins from the macroalgal samples according to Koivikko et al. (2005). The collected supernatant was used to measure the total soluble phlorotannins (TSP) and the 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical scavenging capacity, photometrically using Multiskan Sky microplate spectrophotometer (Thermo Scientific, USA). The absorbance was read at 730 nm for TSP assay and 520 nm for DPPH assay. The TSP contents were analyzed following a modified protocol described by Rautenberger et al. (2015), using phloroglucinol to set up the standard curve. Briefly, the extract was incubated with freshly prepared 1 N Folin-Ciocalteu phenol reagent (Merck KGaA, Germany) for 5 min, and then, the 20% (w/v) NaCO3 was added to the mixture and incubated for 60 min at room temperature. The DPPH assay was performed following the Rautenberger et al. (2015), modified from Fukumoto and Mazza (2000). Briefly, the extract was diluted to different concentrations (1:1–1:160) using 70% (v/v) acetone and incubated with freshly prepared 165 µM DPPH (Sigma-Aldrich, Germany) for 18 h in dark at room temperature. The 50% inhibition of DPPH radical reduction (DPPH-IC50) was calculated and expresses as mg DM seaweed mL−1 DPPH.

Statistics

Data was subjected to two-way analysis of variance with the fixed effects of silage additive treatment, prewilting treatment, and their interactions using the analysis of variance model (aov) program of R studio (Version 1.2.5033, RStudio, Inc., USA). As mentioned above, the fixed effect of chopping time (20 s, 1 min) from the original design was omitted from the original model, and there were 6 replicates per treatments. For TSP and DPPH-IC50, the storage time (3 and 12 months) was included as the third fixed effect, without their interaction in the model. Effects were considered significant when p value ≤ 0.05, and a trend when 0.05 ≤ p value ≤ 0.10. Differences between means within the separated level of the prewilting treatments were tested using the Tukey’s multiple comparison test (p < 0.05). The data are presented as mean ± standard deviation from the biological replicates unless otherwise stated.

Result

Chemical characteristics of pre-ensiling seaweeds

The average DM content (n = 3) was 93.1 ± 6.8 g kg−1 fresh matter in Alaria, and 84.3 ± 4.9 g kg−1 fresh matter in Saccharina before washing. The pH was neutral, and the C and mannitol contents were similar in both seaweed species (Table 1). In Alaria, the N and aNDF contents were 2 times higher, the TSP content was 4 times higher, and the DPPH radical scavenging capacity was 18 times stronger compared to Saccharina (Table 1). Washing and draining numerically reduced the ash content from 33.1 to 29.9% DM in Alaria, and from 28.7 to 23.9% DM in Saccharina.

Silage pH, fermentation products, and mannitol content in 3-month silages

The silage pH and fermentation products were significantly affected by prewilting and silage additives (Tables 2 and 3). The total SCFA content was lower in PW-Alaria (noPW: 24.8 ± 4.3 g kg−1 DM, PW: 12.9 ± 4.5 g kg−1 DM), and PW-Saccharina (noPW:37.9 ± 8.8 g kg−1 DM, PW: 13.6 ± 4.3 g kg−1 DM). This reduction of total SCFA content led to a higher pH in Saccharina-CON (noPW: 4.56, PW: 5.71), but not in Alaria-CON (noPW: 4.84, PW: 4.68). The mannitol content was also lower in the PW-Alaria (noPW: 112.2 ± 14.2 g kg−1 DM, PW: 46.0 ± 9.2 g kg−1 DM) and PW-Saccharina (noPW: 236.8 ± 27.1 g kg−1 DM, PW: 208.5 ± 23.4 g kg−1 DM). The iso-butyrate and iso-valerate, potentially derived from degraded protein (valine and leucine), were only detected in the PW silages in both seaweed species.

In noPW-Alaria, the pH was similar in CON, LABh, and LABm, and the FA reached the lowest pH (3.69) with a significantly lower content of total SCFA, acetate, propionate, and NH3 compared to CON. In PW-Alaria, the pH was significantly lower in FA, LABh, and LABm, and the L-lactate content was significantly higher in LABh and LABm which led to a higher content of total SCFA. In noPW-Saccharina silages, the pH and NH3 contents were significantly lower in FA, LABh, and LABm, and the total SCFA content was the lowest in FA treatment. In Saccharina-PW silages, the effects of additives were similar to the noPW silages, except for a similar content of total SCFA in CON and FA. The L-lactate content was significantly higher in LABh and LABm in both noPW- and PW-Saccharina compared to CON.

TSP and DPPH radical scavenging capacity in 3- and 12-month silages

There was a strong reduction in the TSP content and the DPPH radical scavenging capacity of the silages over storage time (Tables 2 and 3). In Alaria, the average TSP content decreased from 27.9 g kg−1 DM in the pre-ensiling biomass to 19.5 ± 6.4 g kg−1 DM after 3-month storage and to 4.8 ± 1.4 g kg−1 DM after 12-month storage (p < 0.001). The DPPH-IC50 value increased from 2.2 to 20.7 ± 18.6 mg DM mL−1 after 3-month storage and to 39.3 ± 23.3 mg DM mL−1 after 12-month storage (p < 0.001). In Saccharina, the TSP content decreased from 7.4 g kg−1 DM in the pre-ensiled biomass to 3.0 ± 0.34 g kg−1 DM after 3-month storage, and to 1.5 ± 0.4 g kg−1 DM after 12-month storage (p < 0.001). The average DPPH-IC50 increased from 39.3 mg DM mL−1 in the pre-ensiling biomass to 46.0 ± 18.3 mg DM mL−1 after 3-month storage and remained at 44.7 ± 15.8 mg DM mL−1 after 12-month storage (p = 0.013).

Prewilting negatively affected the TSP content the DPPH radical scavenging capacity (Tables 2 and 3). The average TSP content in noPW-Alaria was 2 times higher after 3-month storage (noPW: 25.5 ± 1.9 g kg−1 DM, PW: 13.4 ± 1.8 g kg−1 DM) and was 1.5 times higher after 12-month storage (noPW: 5.86 ± 1.9 g kg−1 DM, PW: 3.7 ± 1.8 g kg−1 DM). The average DPPH-IC50 in PW-Alaria was 5 times higher after 3-month storage (noPW: 5.44 ± 1.5 mg DM mL−1, PW: 36.1 ± 14.8 mg DM mL−1) and was 1.5 times higher after 12-month storage (noPW: 24.9 ± 12.2 mg DM mL−1, PW: 36.1 ± 22.8 mg DM mL−1). The average TSP content in noPW-Saccharina was 8.5% higher after 3-month storage and was 15.3% higher after 12-month storage compared to PW-Saccharina. The average DPPH-IC50 in PW-Saccharina was 32.6% higher after 3-month storage and was 17.8% higher after 12-month storage compared to noPW-Saccharina.

The expected negative correlation between TSP content and DPPH-IC50 values was observed only in the Alaria silages (p < 0.05), but not Saccharina silages. In noPW-Alaria, the highest TSP and lowest DPPH-IC50 were in CON silages after 3- and 12-month storage. In PW-Alaria, there was no significant difference in the TSP content, and the DPPH-IC50 was significantly lower in FA after 12-month storage. In Saccharina, the highest TSP content was found in both PW-CON and noPW-CON, and the DPPH-IC50 was significantly lower in noPW-LAB and PW-FA after 3- and 12-month storage.

Chemical composition, iodine, and heavy metal content in 3-month silages

The triplicates from each ensiling treatments in the original design were pooled into one sample for chemical composition analysis, and the results shown in Table 4 were the average of 2 samples, replicates resulting from the omitted factor of chopping time. The ash, C, and N contents in the silages were in the same range of those in the pre-ensiling biomass (Tables 1 and 4). The aNDF content was numerically higher in silages than in the pre-ensiling biomass in both seaweed species (Tables 1 and 4). Furthermore, the aNDF in PW-Alaria (23.6 ± 0.4% DM) was higher than noPW-Alaria (17.6 ± 0.7% DM). For iodine and heavy metal content, all 6 replicates from each ensiling treatments were pooled for analysis and presented in Table 4. The average iodine content was higher in Alaria (931.3 mg kg−1 DM) than in Saccharina (628.8 mg kg−1 DM). The Pb, Cd, and Hg contents were numerically higher in PW-Alaria (Pb: 0.4 mg kg−1 DM, Cd: 1.7 mg kg−1 DM, Hg: 0.006 mg kg−1 DM), than in noPW-Alaria (Pb: 0.28 mg kg−1 DM, Cd: 1.5 mg kg−1 DM, Hg: < 0.005 mg kg−1 DM). The Pb content was numerically higher in PW-Saccharina (0.35 mg kg−1 DM) than in noPW-Saccharina (0.24 mg kg−1 DM).

Discussion

Silage-making is a complicated biological process where the growth of desirable bacteria (e.g. Lactobacillus spp.) compete with undesirable bacteria responsible for the biomass spoilage (e.g. Enterobacteriaceae family and Clostridium genus). The silage outcome is affected by many factors such as the moisture content, the chemical composition, and the epiphytic bacteria of the harvested biomass (McDonald et al. 1991). In this study, common silage practices of prewilting and addition of silage additives were used to overcome the known difficulties in ensiling macroalgal biomass (Herrmann et al. 2015; Schiener et al. 2015; Cabrita et al. 2017). The silage pH, fermentation products, and mannitol content were measured to evaluate and better understand the silage quality and fermentation process in seaweed. The TSP and DPPH scavenging capacity were measured to assess the preservation of antioxidant activity in seaweed biomass after ensiling and long-term storage. The chemical composition was measured to estimate the level of fiber (aNDF), protein (N), carbohydrate, and ash content in the silages as essential parameters to evaluate for ruminant feed application. And finally, the iodine and heavy metal contents were measured for safety concerns in feed and food applications.

Pre-ensiling biomass

The DM content of pre-ensiling Alaria and Saccharina in present study was low but within the previously reported range of 5 to 36% DM in macroalgae (Zhang & Thomsen 2019) and was lower than that of the wild biomass collected in a close region (Tayyab et al. 2016; Novoa-Garrido et al. 2020). The chemical composition was within the range of the reported seasonal variation (Table 1) (Schiener et al., 2015). Rinsing the seaweed biomass with water led to a lower ash content, as observed previously, thus rinsing is recommended in the seaweed silage making procedure (Novoa-Garrido et al. 2020).

Silage pH, fermentation products, and mannitol content

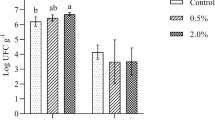

There was no excessive production of propionate, butyrate, and NH3 in any silage, indicating limited spoiling bacterial activity, and thus a well fermented silage (Tables 2 and 3). The total SCFA was higher in Saccharina silages than in Alaria silages, as expected from Saccharina’s higher C:N ratio. However, the total fermentation products were low in both seaweed silages (0.5–5% of DM) compared to common legume silages (0.8–11% DM) reported by Kung et al. (2018), indicating a lower fermentation activity when ensiling seaweeds. Unlike terrestrial crops silages, where lactate is the major fermentation product, acetate was the major component in our seaweed silages, in accordance with results reported in a previous study (Novoa-Garrido et al. 2020). High acetate and low lactate content in silages indicated limited lactic acid bacteria fermentation, and it can be explained by (1) the lack of epiphytic LAB in seaweed (< 103 CFU g−1 fresh biomass) (Uchida et al. 2004; Herrmann et al. 2015), (2) the low fermentation temperature (15 °C) used in present study, and (3) the high moisture content of biomass (DM < 30%) which prolonged the fermentation period required for the silage pH to be sufficiently low to favor the growth of Lactobacillus spp.

Mannitol is the primary photosynthetic product in brown seaweeds and is nearly indigestible in monogastric animals with an unknown digestibility in ruminants. Meanwhile, mannitol has been widely applied in the food and pharmaceutical industries, and thus is an interesting component to preserve (Mišurcová 2011). The mannitol content in the pre-ensiling Alaria and Saccharina (before wash) was similar to a previous study (Stévant et al. 2017). After 90-day ensiling storage, an unchange mannitol content was observed in the noPW-Alaria in the present study and in other brown seaweed silages reported by Herrmann et al. (2015). To the authors’ best knowledge, this is the first time the reduction of mannitol in PW-Alaira and the increase of mannitol in Saccharina silages is reported. These differences in the mannitol contents between seaweed species might be explained by the different level of sugar metabolites including mannitol and fructose in different brown seaweed species as shown in the metabolome profiling (Hamid et al. 2019). The profile of these fermentable sugars can affect the mannitol content in silages, due to the ability of some microorganisms to ferment fructose to mannitol (Groisillier et al. 2013) or mannitol to lactate (Plaisance & Hammer 1921) during silage fermentation. Further research on the fermentable carbohydrate composition of the seaweed and seaweed silages is needed to explain the change of mannitol content during ensiling.

The prewilting and additives treatment significantly affected the seaweed silage fermentation (p < 0.01). Reducing moisture content by prewilting is a normal practice in agriculture to facilitate the fermentation process (Borreani, et al, 2018), and it makes the handling and transportation of seaweed biomass easier. When the moisture content is reduced, the silage fermentation can reach the stable stage with less acidification because of the increased osmotic pressure (McDonald et al., 1991). In the present study, the DM content (g kg−1 fresh matter) was 116.9 ± 7.2 in noPW-Alaria, 295.5 ± 11.9 in PW-Alaria, 93.5 ± 9.1 in noPW-Saccharina, and 277.6 ± 16.5 in PW-Saccharina. When using the earlier published equation for grass silages ‘pH = 0.00359 DM + 3.44’ (Haigh, 1987) to calculate the theoretically desirable pH, the desired pH would be about 3.8 for our noPW silages and about 4.5 for our PW silages. In noPW silages, the pH was above the desired 3.8 in CON- and LAB-Alaria, and in CON-Saccharina. In PW silages, the pH was close to the desired 4.5 in all silages but CON-Saccharina. A significant reduction of undesirable fermentation products (propionate, caproate, and NH3) was also observed in the PW silages. However, the prewilting treatment in the present study led to an increase of protein and TSP degradation. Further, the acetate content was reduced from a normal range of 1–3% of DM in noPW silages to below 1% of DM in PW silages, which might result in a higher spoilage risk once opened, as acetate plays an important role in aerobic stability (Danner et al. 2003).

It has been reported that applying 0.4% (w/w) formic acid could significantly reduce the silage pH to below 4.0 in Saccharina (Novoa-Garrido et al. 2020), but, to our knowledge, this is the first time such results are reported in Alaria. Our results confirmed that the use of LAB additives had the benefits of facilitating lactate fermentation, regardless of using a one-strain culture or a two-strain culture, as suggested by Novoa-Garrido et al. (2020). In contrast to our findings, Herrmann et al. (2015) reported 50 g kg−1 DM lactate content in 3-month S. latissima silages, and a LAB growth from less than 102 CFU g−1 fresh biomass to 108 CFU g−1 fresh biomass. Cabrita et al. (2017) also reported a high lactate content (200 g kg−1 DM) in S. latissima silage after 9 weeks without the addition of LAB inoculant. The difference in the fermentation patterns can be partially explained by higher ensiling temperature (20 °C), which is more favorable for the growth of LAB, partially by the difference in biomass composition, as well as by different silage processing methods. It should also be considered that in the present study, we analyzed for L-lactate instead of the total lactate content. We based our approach in earlier findings showing that the average ratio of L- and D-lactate is close to 1:1 in whole crop and grass silages, making it possible to use 2 × L-lactate as an estimate for total lactate content. However, this estimation was found to be invalid in Saccharina silages (ratio of L-lactate and total lactate: 0.09) (Johansen et al. 2020) and might not be valid for other seaweed silages as well. To verify that the L-lactate measurement was not inhibited by the complex seaweed matrix, Johansen et al. (2020) spiked seaweed samples with a known amount of L-lactate and observed full recovery. Therefore, the L-lactate content in present study is valid but does not provide information of the total lactate content in silages.

The interactions of prewilting and additives treatments were significant on the DM content and fermentation products (Tables 2 and 3). The DM content in FA was significantly higher than in CON in noPW silages, but not in the PW silages in both Alaria and Saccharina. The same interaction was reported in Palmaria palmata silages using acids-based additive (Gallagher et al. 2021). Also using acids-based additive was reported to increase DM density in wet grass silages (Randby & Bakken 2021). However, this interaction was not seen in our previous publication under a similar setup in Porphyra umbilicalis and S. latissima silages (Novoa-Garrido et al. 2020). Both prewilting and FA additives restricted fermentation activity, indicated by a lower total SCFA and acetate content. However, a similar content in PW-CON and PW-FA indicated that the fermentation restriction did not intensify by combining both prewilting and FA treatments. Finally, the use of LAB inoculants facilitated lactate production in PW-Alaria, however, not in noPW-Alaria. This interaction was not observed in our Saccharina silages, and there is unfortunately a lack of publication for comparison.

TSP and DPPH radical scavenging capacity in 3- and 12-month silages

Phlorotannins are oligomeric and polymeric derivatives of phloroglucinol (1,3,5-trihydroxybenzene) and are only found in brown macroalgae (Wang et al. 2009). Phlorotannins are valuable cellular compounds to preserve in brown seaweeds storage due to their antioxidant properties (Roleda et al. 2019; Gager et al. 2020). Based on the Folin-Ciocalteu assay, the TSP level in pre-ensiling Alaria was nearly 4 × higher than in Saccharina (Table 1), which is similar to previous studies where a range from 2.8 × to 5.0 × was reported (Stévant et al. 2017; Roleda et al. 2019).

There was a loss of 73–88% TSP across all treatments in the 12-month silages in both seaweed species (Tables 2 and 3). The TSP loss was much higher compared to conventional preservation methods as freezing (− 25 °C) and air-drying (20 °C, > 85% DM), where around 25% and 50% TSP loss was observed, respectively in brown seaweeds (Obluchinskaya and Daurtseva 2020). Thus, ensilage is less suitable for long-term storage when TSP is the targeted substance. However, ensilage seems promising for 3-month storage providing that the loss in TSP content remains at the level found in Alaria silages (3%), which is much better than the loss when freezing (11—16%) and drying (25—34%) reported by Obluchinskaya and Daurtseva (2020). Campbell et al. (2020) also reported an unchanged TSP content in F. vesiculosus and S. latissima silages after 3-month storage.

The progressive decline in the DPPH radical scavenging capacity of Saccharina and Alaria over the 12-month ensiling can be ascribed to the gradual degradation of TSP in the samples under the storage conditions. However, the TSP degradation does not necessarily reduce DPPH radical scavenging capacity in the case of the Saccharina silages with additives. This might be explained by a possibly alteration of the phlorotannins’ chemical structure and/or an increase in the functional peptides in the samples due to LAB fermentation (Virtanen et al. 2007; Sun et al. 2009) and soaking in the acids. Unfortunately, it was not possible to compare our results with other studies on ensiled seaweeds as this is the first one conducting DPPH assay in such seaweed products. Further antioxidant activity assays and different analytical methods capable of detecting phlorotannins structures are required to confirm and further explain this enhanced antioxidant activity in seaweed silages due to the known limitation of DPPH assay (Foti 2015; Ford et al. 2019).

Chemical composition, iodine, and heavy metal composition

The aNDF content, which measures the leftover fiber after dissolving protein, sugars, lipids, and other substance in neutral detergent, is routinely analyzed in ruminant feed ingredients as it affects the energy concentration in the feed. Compared to the aNDF content reported in whole plant corn and corn silages (> 400 g kg−1 DM), the aNDF content in our seaweeds and seaweed silages were low, likely due to a different cell wall structure (Gheller et al. 2021). Compared to the pre-ensiling seaweed biomass, the aNDF content was higher in the seaweed silages as seen in previous study (Novoa-Garrido et al. 2020), indicated substance losses during ensiling process. Moreover, loss of small molecules during prewilting might led to the much higher aNDF content in the PW treatment in Alaria. It is worth noting that the higher content of both TSP and aNDF in Alaria has previously been reported to be unfavorable for rumen digestion (Campbell et al. 2020). Further studies are needed to investigate the protein and fiber digestibility of seaweeds in ruminant animals.

Seaweeds can accumulate heavy metals from its surrounding seawater and post a risk to human and animal health when being consumed. The European Union has established recommendations for the maximum levels of heavy metal contents in seaweed in food and feed products in the Official Journal of the European Union (OJEU L78/16, 2018). Following the recommendation, the present study measured the Pb, Cd, Hg, As, and inorganic As content in the silages (Table 4). The level of Hg and Pb in present study was low and is in accordance with previous records of Saccharina and Alaria collected in the Norwegian coasts (Biancarosa et al. 2018; Afonso et al. 2020). The total As content was generally high, but this could be mainly ascribed to the less toxic organic As since iAs was less than 5% of total, which is commonly observed in marine organisms. On the other hand, careful attention should be paid to the Cd content as it was found to exceed the maximum levels regulated by the EU recommendation (OJEU L78/16, 2018) in sample of all silages.

Brown seaweed is a natural source for dietary iodine. Iodine is an essential mineral for thyroid hormones synthesis, but both deficient and excessive iodine intake can disturb the body metabolism (Rohner et al. 2014). In the present study, the iodine content of Saccharina silages (630 mg kg−1 DM) was relatively low compared to the concentrations reported in other investigations, where levels above 2000 mg kg−1 DM and up to 4600 mg kg−1 DM have been reported in both wild harvested and cultivated biomass from central and northern Norway, while a high iodine content was found in Alaria silages (930 mg kg−1 DM) compared to other studies (Biancarosa et al. 2018; Roleda et al. 2018; Afonso et al. 2020). If our silages were subjected to whole food application, the safe consumption level will be limited to 2 g DM per week, according to the recommend iodine consumption for an adult person (Russel 2001).

The prewilting treatment led to numerically higher content of Pb, Cd, and Hg in Alaria, and higher content of Pb in Saccharina. However, the content of heavy metals and iodine were not expected to change during ensilage, as these elements are not supposed to disappear due to silage fermentation. Thus, the differences in concentration between treatments were likely due to the losses of chemical compounds in the effluents or during the prewilting process. Additionally, the concentration of heavy metals and iodine in the DM based unit are expected to be slightly higher than the pre-ensiling biomass due to the loss of carbon in CO2 format during fermentation. Due to the lack of this data on pre-ensiling biomass, the exact change was not available.

Conclusions

The results suggest that ensiling is a viable method for preserving Alaria and Saccharina biomass. The ensiling outcomes were significantly affected by prewilting and additive treatments (p < 0.001). In Alaria, prewilting led to a desirable silage pH of 4.5, a reduction of acetate, proprionate and NH3, and higher production of L-lactate in the LAB treatments. In Saccharina, a reduction of acetate, L-lactate, caproate, and NH3 was observed in PW treatment, and it led to insufficient silage acidification (pH = 5.7) when no additive was applied. Unfortunately, the prewilting process in the present study caused protein and TSP degradation, and a nymerically higher aNDF content indicated the losses of other small molecules. Future studies on alternative moisture reduction methods are therefore needed to minimize the loss. The silage pH dropped to below 3.8 when ensiled with FA in both noPW and PW silages. Adding FA also reduced the acetate and NH3 content in noPW silages. Adding LAB inoculant enabled lactate production except in the noPW-Alaria. The antioxidant activity was preserved at a promising level (> 90%) in noPW-Alaria after 3-month storage; however, major loss of antioxidant activity was observed after 12-month storage in both seaweed silages. The prewilting and additive treatment appeared to negatively affect the TSP preservation, and the FA and LAB additive appeared to enhance the DPPH radical scanvenging capacity in Saccharina silages. Further studies on the carbyhydrate and phlorotannin composition in the silages are needed to explain these changes during ensiling.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Change history

28 February 2022

The original version of this paper was updated to add the missing compact agreement Open Access funding note.

References

Afonso C, Matos J, Guarda I, Gomes-Bispo A, Gomes R, Cardoso C, Gueifão S, Delgado I, Coelho I, Castanheira I, Bandarra NM (2020) Bioactive and nutritional potential of Alaria esculenta and Saccharina latissima. J Appl Phycol 33:501–513

Alvarado-Morales M, Boldrin A, Karakashev DB, Holdt SL, Angelidaki I, Astrup T (2013) Life cycle assessment of biofuel production from brown seaweed in Nordic conditions. Bioresour Technol 129:92–99

Bach QV, Sillero MV, Tran KQ, Skjermo J (2014) Fast hydrothermal liquefaction of a Norwegian macro-alga: Screening tests. Algal Res 6:271–276

Biancarosa I, Belghit I, Bruckner CG, Liland NS, Waagbø R, Amlund H, Heesch S, Lock EJ (2018) Chemical characterization of 21 species of marine macroalgae common in Norwegian waters: benefits of and limitations to their potential use in food and feed. J Sci Food Agric 98:2035–2042

Black WAP (1955) The preservation of seaweed by ensiling and bactericides. J Sci Food Agric 6:14–23

Borreani G, Tabacco E, Schmidt RJ, Holmes BJ, Muck RE (2018) Silage review: factors affecting dry matter and quality losses in silages. J Dairy Sci 101:3952–3979

Broch OJ, Alver MO, Bekkby T, Gundersen H, Forbord S, Handå A, Skjermo J, Hancke K (2019) The kelp cultivation potential in coastal and offshore regions of Norway. Front Mar Sci 5:529

Cabrita ARJ, Maia MRG, Sousa-Pinto I, Fonseca AJM (2017) Ensilage of seaweeds from an integrated multi-trophic aquaculture system. Algal Res 24:290–298

Campbell M, Ortuño J, Ford L, Davies DR, Koidis A, Walsh PJ, Theodoridou K (2020) The effect of ensiling on the nutritional composition and fermentation characteristics of brown seaweeds as a ruminant feed ingredient. Animals 10:1019

Cherry P, Yadav S, Strain CR, Allsopp PJ, McSorley EM, Ross RP, Stanton C (2019) Prebiotics from seaweeds: an ocean of opportunity? Mar Drugs 17:327

Danner H, Holzer M, Mayrhuber E, Braun R (2003) Acetic acid increases stability of silage under aerobic conditions. Appl Environ Microbiol 69:562

FAO (2020). FAO yearbook. Fishery and Aquaculture Statistics 2018. FAO, Rome

Fečkaninová A, Koščová J, Mudroňová D, Schusterová P, Cingeľová-Maruščáková I, Popelka P (2019) Characterization of two novel lactic acid bacteria isolated from the intestine of rainbow trout (Oncorhynchus mykiss, Walbaum) in Slovakia. Aquaculture 506:294–301

Fiskeridirektoratet (2020) Akvakulturstatistikk: Alger, Antall tillatelser 2014–2020. Directorate of Fisheries, Norway

Ford L, Theodoridou K, Sheldrake GN, Walsh PJ (2019) A critical review of analytical methods used for the chemical characterisation and quantification of phlorotannin compounds in brown seaweeds. Phytochem Anal 30:587–599

Foti MC (2015) Use and abuse of the DPPH•radical. J Agric Food Chem 63:8765–8776

Fukumoto LR, Mazza G (2000) Assessing antioxidant and prooxidant activities of phenolic compounds. J Agric Food Chem 48:3597–3604

Gager L, Connan S, Molla M, Couteau C, Arbona JF, Coiffard L, Cérantola S, Stiger-Pouvreau V (2020) Active phlorotannins from seven brown seaweeds commercially harvested in Brittany (France) detected by 1H NMR and in vitro assays: temporal variation and potential valorization in cosmetic applications. J Appl Phycol 32:2375–2386

Gaillard C, Bhatti HS, Novoa-Garrido M, Lind V, Roleda MY, Weisbjerg MR (2018) Amino acid profiles of nine seaweed species and their in situ degradability in dairy cows. Anim Feed Sci Technol 241:210–222

Gallagher JA, Adams JMM, Turner LB, Kirby ME, Toop TA, Mirza MW, Theodorou MK (2021) Bio-processing of macroalgae Palmaria palmata: metabolite fractionation from pressed fresh material and ensiling considerations for long-term storage. J Appl Phycol 33:533–544

Gheller L, Ghizzi L, Takiya CS, Grigoletto NTS, Silva TBP, Marques JA, Dias MSS, Freu G, Rennó FP (2021) Different organic acid preparations on fermentation and microbiological profile, chemical composition, and aerobic stability of whole-plant corn silage. Anim Feed Sci Technol 281:115083

Groisillier A, Shao Z, Michel G, Goulitquer S, Bonin P, Krahulec S, Nidetzky B, Duan D, Boyen C, Tonon T (2013) Mannitol metabolism in brown algae involves a new phosphatase family. J Exp Bot 65:559–570

Haigh PM (1987) The effect of dry matter content and silage additives on the fermentation of grass silage on commercial farms. Grass Forage Sci 42:1–8

Hamid SS, Wakayama M, Ichihara K, Sakurai K, Ashino Y, Kadowaki R, Soga T, Tomita M (2019) Metabolome profiling of various seaweed species discriminates between brown, red, and green algae. Planta 249:1921–1947

Hansen B (1989) Determination of nitrogen as elementary N, an alternative to Kjeldahl. Acta Agric Scand 39:113–118

Herrmann C, FitzGerald J, O’Shea R, Xia A, O’Kiely P, Murphy JD (2015) Ensiling of seaweed for a seaweed biofuel industry. Bioresour Technol 196:301–313

Johansen M, Weisbjerg MR, Novoa-Garrido M, Kristensen NB, Larsen M (2020) Relationship between L-lactate and DL-lactate in different silage types. In: Virkajärvi P et al. (eds) Meeting the future demands for grassland production: Proceedings of the 28th General Meeting of the European Grassland Federation Helsinki, Finland 19–22 October 2020. Wageningen Academic Publishers, pp 282–284

Koivikko R, Loponen J, Honkanen T, Jormalainen V (2005) Contents of soluable, cell-wall-bound and exuded phlorotannins in the brown alga Fucus vesiculosus, with implications on their ecological functions. J Chem Ecol 31:195–212

Kristensen NB, Danfær A, Tetens V, Agergaard N (1996) Portal recovery of intraruminally infused short-chain fatty acids in sheep. Acta Agric Scand -A 46:26–38

Kung L, Shaver RD, Grant RJ, Schmidt RJ (2018) Silage review: interpretation of chemical, microbial, and organoleptic components of silages. J Dairy Sci 101:4020–4033

Larsen T, Fernández C (2017) Enzymatic-fluorometric analyses for glutamine, glutamate and free amino groups in protein-free plasma and milk. J Dairy Res 84:32–35

Makkar HPS, Tran G, Heuzé V, Giger-Reverdin S, Lessire M, Lebas F, Ankers P (2016) Seaweeds for livestock diets: a review. Anim Feed Sci Technol 212:1–17

McDonald P, Henderson N, Heron S (1991) The biochemistry of silage, 2nd edn. Chalcombe Publications, Marlow

Mertens DR (2002) Gravimetric determination of amylase-treated neutral detergent fiber in feeds with refluxing in beakers or crucibles: collaborative study. J AOAC Int 85:1217–1240

Mišurcová L (2011) Chemical composition of seaweeds. In: Kim SK (ed) Handbook of marine macroalgae. John Wiley & Sons Ltd, London, pp 171–192

Novoa-Garrido M, Marcos CN, Travieso MDC, Alcaide EM, Larsen M, Weisbjerg MR (2020) Preserving Porphyra umbilicalis and Saccharina latissima as silages for ruminant feeding. Animals 10:1957

Obluchinskaya E, Daurtseva A (2020) Effects of air drying and freezing and long-term storage on phytochemical composition of brown seaweeds. J Appl Phycol 32:4235–4249

Penalver R, Lorenzo JM, Ros G, Amarowicz R, Pateiro M, Nieto G (2020) Seaweeds as a functional ingredient for a healthy diet. Mar Drugs 18:301

Plaisance GP, Hammer BW (1921) The mannitol-producing organisms in silage. J Bacteriol 6:431–443

Randby ÅT, Bakken AK (2021) Effect of acid based additive treatment of low dry matter grass crops on losses and silage quality in bunker silos. Anim Feed Sci Technol 275:114869

Rautenberger R, Huovinen P, Gómez I (2015) Effects of increased seawater temperature on UV tolerance of Antarctic marine macroalgae. Mar Biol 162:1087–1097

Rohner F, Zimmermann M, Jooste P, Pandav C, Caldwell K, Raghavan R, Raiten DJ (2014) Biomarkers of nutrition for development—iodine review. J Nutr 144:1322S-1342S

Roleda MY, Skjermo J, Marfaing H, Jónsdóttir R, Rebours C, Gietl A, Stengel DB, Nitschke U (2018) Iodine content in bulk biomass of wild-harvested and cultivated edible seaweeds: inherent variations determine species-specific daily allowable consumption. Food Chem 254:333–339

Roleda MY, Marfaing H, Desnica N, Jónsdóttir R, Skjermo J, Rebours C, Nitschke U (2019) Variations in polyphenol and heavy metal contents of wild-harvested and cultivated seaweed bulk biomass: health risk assessment and implication for food applications. Food Control 95:121–134

Russel RM (2001) New micronutrient dietary reference intakes from the national academy of sciences. Nutr Today 36:163–171

Schiener P, Black KD, Stanley MS, Green DH (2015) The seasonal variation in the chemical composition of the kelp species Laminaria digitata, Laminaria hyperborea, Saccharina latissima and Alaria esculenta. J Appl Phycol 27:363–373

Stévant P, Marfaing H, Rustad T, Sandbakken I, Fleurence J, Chapman A (2017) Nutritional value of the kelps Alaria esculenta and Saccharina latissima and effects of short-term storage on biomass quality. J Appl Phycol 29:2417–2426

Sun YP, Chou CC, Yu RC (2009) Antioxidant activity of lactic-fermented Chinese cabbage. Food Chem 115:912–917

Tayyab U, Novoa-Garrido M, Roleda MY, Lind V, Weisbjerg MR (2016) Ruminal and intestinal protein degradability of various seaweed species measured in situ in dairy cows. Anim Feed Sci Technol 213:44–54

Uchida M, Amakasu H, Satoh Y, Murata M (2004) Combinations of lactic acid bacteria and yeast suitable for preparation of marine silage. Fish Sci 70:507–517

Virtanen T, Pihlanto A, Akkanen S, Korhonen H (2007) Development of antioxidant activity in milk whey during fermentation with lactic acid bacteria. J Appl Microbiol 102:106–115

Wang T, Jónsdóttir R, Ólafsdóttir G (2009) Total phenolic compounds, radical scavenging and metal chelation of extracts from Icelandic seaweeds. Food Chem 116:240–248

Zhang X, Thomsen M (2019) Biomolecular composition and revenue explained by interactions between extrinsic factors and endogenous rhythms of Saccharina latissima. Mar Drugs 17:107

Acknowledgements

The farmed seaweeds were kindly provided by our industry collaborator Lofoten Blue Harvest. We thank Heidi Hovland Ludviksen, Ingvild Berg, and Bente Sunde from the Faculty of Biosciences and Aquaculture at Nord University for their help in processing the seaweed biomass prior to ensiling, and to Per Magnus Hansen from the Norwegian Institute of Bioeconomy Research for his help in making silages and sample preparation for the antioxidant analysis.

Funding

Open access funding provided by Nord University. This study has been funded by a grant from MABIT (program for Marine Biotechnology in northern Norway) project number AF0083.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yen, Y., Weisbjerg, M.R., Rautenberger, R. et al. Improving fermentation of Saccharina latissima and Alaria esculenta silages with additives for preserving biomass and antioxidants. J Appl Phycol 34, 625–636 (2022). https://doi.org/10.1007/s10811-021-02628-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-021-02628-4