Abstract

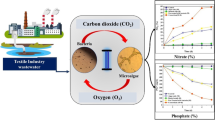

Microalgae and cyanobacteria are effective platforms for environmental remediation (phycoremediation), particularly of air and water. There is limited scope to deploy suspension cultures due to space, cost and maintenance challenges—driving an imperative towards biofilm-based treatment systems; however, these systems are ill-equipped for rapid and mobile deployment. In this study we explored the main technical challenges to developing cheap, accessible and low-maintenance engineered biofilm systems (biocomposites) comprising cyanobacteria (Synechococcus elongatus) immobilised to a range of textiles (n = 4) by natural or synthetic latex binders (n = 16), chitosan or shellac. Biocomposite viability (measured as net CO2 uptake) was assessed over 20 days in semi-batch trials. No maintenance was required during this period as the humidity within the reactor was sufficient to support metabolism. Two commercial natural latex binders (AURO 320 and 321) supported strong growth within the biocomposite, outperforming suspension controls. There was variation in textiles performance, with an 80/20 polyester-cotton blend performing most consistently. Biocomposite formulation was varied in terms of binder solids content and cell loading rate, with 5% solids and 2.5% cell loading the most effective combination. We demonstrate the technical feasibility of fabricating functional textile-based cyanobacteria biocomposites and discuss this within the context of developing decentralised wastewater treatment services.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The growing global human population is placing increasing demands on water resources—demands which are unlikely to be met with current centralised treatment systems and practices (Lofrano and Brown 2010; Verstraete and Vlaeminck 2011). If the water industry is to keep pace, major technological innovations rather than incremental and piecemeal shifts in treatment practices are required (Thomas and Ford 2006; Tanner et al. 2018). The urgency for technology and process transition is heightened when viewed from a climate change context, with municipal wastewater treatment accounting for approximately 3% of global electricity consumption and 5% of non-CO2 greenhouse gas emissions (Li et al. 2015).

Decentralised (or point-source) systems present an alternative option, but to be effective they must be affordable, ensure both human and environmental safety, be user friendly (effectively zero maintenance), be fully compliant with effluent discharge regulations, and (ideally) should make a tangible contribution to the circular economy (Muñoz and Guieysse 2006; Grant et al. 2012; Li et al. 2015; Cuellar-Bermudez et al. 2017; Oladoja 2017). Phycoremediation (the use of algae or cyanobacteria for environmental clean-up) is one approach that could deliver many of these requirements, with the capacity to combine wastewater and atmospheric remediation within a single treatment option, all the while generating biomass for bioprocessing (Olguín 2003; Rawat et al. 2011; Kumar et al. 2018; Ansari et al. 2019).

Due to their broad abiotic tolerances and metabolic flexibility, the use of cyanobacteria in wastewater treatment is well established (Oswald and Gotass 1957), forming an important part of mixed community activated sludge systems (Martins et al. 2011). However, targeted treatment processes based primarily on cyanobacteria are still under development. The very nature of suspension-based cultivation (generally conducted in high rate algae pond systems) remains one of the main challenges facing the roll-out of microalgae and cyanobacteria treatment processes, with operational issues including poor batch-to-batch consistency, high economic cost of biomass separation, and contamination by non-target species (Christenson and Sims 2011), notwithstanding the substantial land requirement. Closed photobioreactors (PBRs) have been employed to mitigate abiotic variation and contamination (Mata et al. 2010; Tredici et al. 2015); however, capital and operational costs are prohibitive (Huang et al. 2017; Acién et al. 2018).

The need for suspension-based systems is being subverted with the advent of a range of biofilm reactors (Boelee et al. 2014; Zhuang et al. 2018; Peng et al. 2020a; Waqas et al. 2020; Yang et al. 2020), treating domestic (Gou et al. 2020), industrial (Johnson et al. 2018; Hillman and Sims 2020) and even marine wastewaters (Peng et al. 2020b). However, these systems still require sufficient operator competency to culture and maintain a metabolically active biofilm (David et al. 2015; Hamano et al. 2017). Iterations of these systems that reduce, or ideally eliminate, the need for regular culture maintenance is desirable in terms of process cost, accessibility and acceptability. Attempts in this direction include trialling phototrophic granular biomass (photogranules) (Kumar and Venugopalan 2015; Trebuch et al. 2020) which, while promising in the context of a wastewater treatment plant, would not necessarily be suitable if the ambition for decentralisation extended as far as treatment systems for individual properties. Given such a scenario, a more radical vision of a biofilm reactor is needed. For instance, twin-layer systems using simple irrigation protocols show promise in cell retention and growth (Shi et al. 2007; Liu et al. 2013; Naumann et al. 2013; Shi et al. 2014) however, evaporation poses a problem that demands increased operator involvement.

Engineered, concentrated biofilms, also known as living biocomposites, are gaining traction in atmospheric and low flow wastewater bioremediation applications (Estrada et al. 2015; In-na et al. 2020). These biocomposites comprise living microbes immobilised within a semi-porous matrix (binder), forming a biocoating, which is then applied to a structural scaffold (de-Bashan and Bashan 2010), theoretically supporting greater biomass loading per unit area with minimal cell loss (Flickinger et al. 2007). Unlike natural biofilm or twin-layer systems, the use of immobilised biomass allows greater flexibility in reactor design, enabling increased reaction rates due to improved cell density, robustness, and greater reuse of biomass (Eroglu et al. 2015). Successful immobilisation has been demonstrated to improve O2 production (an indicator of photosynthetic activity) between 7 and 10× compared with suspension cultures (Bernal et al. 2014). However, the efficacy of biocomposites can be affected by many factors during preparation, including, but not limited to the coating formulation, substrate properties and the extent of biomass loading (Flickinger et al. 2017) although novel fabrication methods show promise (Fidaleo et al. 2014; Bernal et al. 2017; Chen et al. 2020).

The current study drew inspiration from the EU H2020 Living Architecture project, which sought to develop highly distributed autonomous wastewater treatment systems for individual properties (Armstrong et al. 2017). We have extended the scope of the Living Architecture brief by evaluating some of the key technical constraints to immobilising cyanobacteria as biocomposites. Using two strains of Synechococcus elongatus (PCC 7942 and CCAP 1479/1A), we screened a range of binders formulated from latex, petroleum, shellac or chitosan, with four affordable and easily accessible textile scaffolds (a woven 80/20 polyester-cotton blend, a woven 100% bamboo, a non-woven 40/60 wool-polyester blend, and a non-woven 100% polyester). Binders were screened for toxicity and adhesive properties, with biocomposite viability determined by measuring net photosynthetic CO2 uptake over a 20-day experimental period.

Materials and methods

Cell cultivation

Synechococcus elongatus PCC 7942 was grown in Blue-Green Medium (BG11) (Stanier et al. 1971), and S. elongatus CCAP 1479/1A in Jaworski’s Medium (JM) (Šoštarič et al. 2012) without cyanocobalamin, thiamine HCl, and biotin, in 10 L polycarbonate (Nalgene) carboys with constant air supply at 18 °C ± 2 °C, and a 16L:8D photoperiod (mean irradiance of 35 μmol photons m-2 s-1) using 30 W daylight-type fluorescent tubes (Sylvania Luxline Plus, n = 6).

Binder adjustments

A selection of binders was screened for suitability for cyanobacteria immobilisation. Ten synthetic acrylic, styrene and polyurethane latex binders were selected from a library of proprietary and commercial binders, gifted by Prof. Michael Flickinger, North Carolina State University, USA, having previously been assessed for microbial immobilisation. Six plant-based binders (AURO Paint Company, UK and Germany) were similarly selected (Bernal et al. 2014; In-na et al. 2020). The initial percentage solids content of the liquid binders was determined by oven drying to a constant mass at 100 °C. The binders were adjusted to pH 7 using 0.1 M or 0.5 M acetic acid, or 0.1 M or 0.5 M ammonium hydroxide (Table 1). Shellac (orange, pure, flake, Fisher Scientific, CAS-9000-59-3, MDL no. 148309) was ground to a fine powder by mortar and pestle and dissolved in 90% ethanol at 50 °C. Chitosan (99.9%, ACROS Organics, CAS-9012-76-4, MDL no. MFCD00161512) was dissolved at 18 °C in 0.3 M acetic acid.

Toxicity testing

The binders were initially screened for cell growth impacts. One millilitre of binder was added to 1 mL of 7-10 days old culture (n=3) in a multiwell plate. In separate wells, 1 mL of binder and 1 mL of growth medium were combined to screen for interactions. One millilitre of cells diluted with 1 mL of sterile de-ionised water (dH2O) was run as a baseline for cell growth. Each treatment replicate was mixed daily by forward and reverse pipetting for 7 days, when cell density was determined using an improved Neubauer haemocytometer with a Leica DMi 8 microscope with bright field contrast at 400× magnification and viewed using LasX software. The most suitable binder for each strain was carried forward for subsequent adhesion testing, wherein the range of percentage solids contents was expanded to 2.5, 7.5, and 10% (>10% solids inhibits gas exchange (Umar 2018)).

Adhesion testing

The textile substrates were as follows: 1) a woven 80/20 polyester-cotton blend (cotton) purchased from Aow RungRuang Co. Ltd, Bangkok, Thailand; 2) a woven 100% bamboo (bamboo) was purchased from WBL Fabrics, UK; 3) a non-woven 40/60 wool-polyester blend (wool blend); and 4) a non-woven 100% polyester (polyester) were purchased from the Wool Felt Company, UK. The polyester-cotton blend was selected as it exhibited high levels of cyanobacteria attachment in a separate study (In-na et al. unpublished). The textiles were autoclaved, then dried at 105 °C for 3 h and stored in a silica gel desiccator until use. When required, the textiles were cut into 0.5 x 0.5 cm2 pieces. Cyanobacteria were centrifuged at 1720×g for 30 min at 20 °C. If sufficient biomass was not recovered, the supernatant was removed and additional culture was added to the pellet and the centrifugation step was repeated. The cyanobacteria and binders were combined in sterile Eppendorf tubes, first by gentle pipetting and then by vortex mixing. A range of cell-binder formulations (biocoatings) were produced at 1, 2.5, 5, and 10% (v/v) cell content to understand the binder’s robustness. Once combined, 100 μL of each biocoating was pipetted onto the textiles to form biocomposites. In a separate Eppendorf tube, the equivalent volume of culture was added to the same volume of dH2O and counted using a Neubauer haemocytometer to estimate biocoating cell density and hence biocomposite cell loading. The biocomposites were dried in darkness at 20 ± 2 °C for 24 h, then added to 1 mL of growth medium in well plates wrapped in aluminium foil to prevent cell division which would cause an overestimate of the number of cells lost from the biocomposite. The plates were placed on a two-dimensional orbital shaker (Techlifer orbital rotator shaker lab UPC 789458170564), set to 80 rpm. Biocomposites were moved to a new well of fresh medium after 1, 24, and 48 h with the total time spent in the medium being 72 h, allowing for cumulative cell release to be calculated using a Neubauer haemocytometer.

Scanning electron microscopy

The biocomposites were imaged using scanning electron microscopy following adhesion testing. Samples were dried at 105 oC for 3 h, stored in a desiccator before being attached to 12 mm diameter pin stubs using carbon tape and imaged using a Hitachi TM 3000 SEM with a backscattered electrons system. All biocomposites were observed in two or more randomised locations using a 5 or 15 kV accelerating voltage.

CO2 uptake

Informed by the toxicity and adhesion tests, biocomposites were taken forward for CO2 uptake tests. Samples were prepared as described for adhesion testing, but the textiles were cut into 1 × 5-cm strips. Formulations were pipetted 1 cm from the top of the strip so the growth medium could only reach cells by capillary action. Five millilitre of sterile growth medium was pipetted into a 50-mL sterile, clear Wheaton glass serum bottle. Biocomposite samples were then placed into the bottle and suspended using 0.15 mm sterile nylon thread to prevent the cells from being submerged. The bottles were sealed using a rubber butyl stopper and a crimped aluminium cap. Each bottle was flushed with 45 mL of 5% CO2-enriched air using a hypodermic needle to pierce the rubber stopper without breaking the seal. Samples containing the equivalent number of cells in suspension were placed in sealed bottles as controls. The samples were exposed to a mean irradiance of 35 μmol photons m-2 s-1, and a 16L:8D photoperiod using 30 W daylight-type fluorescent tubes (Sylvania Luxline Plus, n = 6) at 18 °C ± 2 °C. Every 2 days, a sample of the headspace was withdrawn using a hypodermic needle and an air-tight syringe and the percentage CO2 content was analysed using a G100 GEOTech CO2 meter. Bottles were then re-flushed with 5% CO2-enriched air. The moles of CO2 fixed by the cells were calculated using equation 1. This was repeated for 20 days and a cumulative total of fixed CO2 was calculated.

Biocomposites comprising 5% solids binder with 2.5% cell content, 10% solids binder with 2.5% cell content, and 5% solids with 10% cell content were tested following initial screening trials (data not shown). Additionally, a 5% solid binder with 2.5% cell content cotton biocomposite was tested with an artificial urine developed by Brooks and Keevil (2003) (1 g peptone L37, 0.005 g yeast extract, 0.1 g lactic acid, 0.4 g citric acid, 2.1 g NaHCO3, 10 g urea, 0.07 g uric acid, 0.8 g creatinine, 0.37 g CaCl2·2H2O, 5.2 g NaCl2, 0.0012 g FeSO4·7H2O, 0.49 gMgSO4·7H20, 3.2 g Na2SO4·10H2O, 0.95 g KH2PO4, 1.2 g K2HPO4, 1.3 g NH4Cl, to 1 L dH2O) rather than a conventional growth medium to better reflect a wastewater scenario.

Statistical analysis

Statistical analyses were conducted using GraphPad Prism 8. Data were tested for normal distribution (Shapiro-Wilk test). For toxicity data, equality of variance was determined using the Brown-Forsythe test and one-way ANOVA with Tukey post hoc testing. For adhesion data, two-way ANOVA was used with Tukey post hoc testing. Sphericity was assumed due to measurements as the experimental design was based on matching, not repeated measures (Maxwell et al. 2017). For CO2 uptake, repeated measures two-way ANOVA with Tukey post hoc testing was conducted. For the adhesion and CO2 data, sphericity was violated; therefore, a Geisser-Greenhouse correction was performed (Greenhouse and Geisser 1959).

Results

Binder toxicity

The toxicity data for both S. elongatus strains were normally distributed (Shapiro-Wilk test, P > 0.05), with significant differences between control cultures and 5% solids AURO binders (S. elongatus PCC 7942: ANOVA, F6,17 = 483.3, P < 0.001; S. elongatus CCAP 1479/1A: ANOVA, F6,14 = 70.67, P < 0.001), synthetic binders (S. elongatus PCC 7942: ANOVA, F10,35 = 10.3, P < 0.001; S. elongatus CCAP 1479/1A: ANOVA, F10,22 = 82.09, P < 0.001), and natural binders (shellac and chitosan) (S. elongatus PCC 7942: ANOVA, F2,9 = 128.7, P < 0.001; S. elongatus CCAP 1479/1A: ANOVA, F2,6 = 224.6, P < 0.001).

Of the AURO binders, only AURO 320 and 321 supported significantly improved growth, whereas AURO 160, 251, 261 and 379 returned cell densities significantly lower than controls (P < 0.05); therefore, in this context, they were classed as toxic (Fig. 1). On this basis, only AURO 320 and 321 were considered for follow-on CO2 fixation trials. None of the synthetic binders supported improved growth relative to controls with a singular exception of binder-9 with S. elongatus CCAP 1479/1A; however, this was not deemed to be a sufficiently large growth improvement to justify automatic inclusion in subsequent CO2 trials. The shellac and chitosan treatments had significantly decreased cell densities for both strains, with shellac killing the cultures.

Cell density (cells per mL, mean ± SD) of Synechococcus elongatus PCC 7942 (panels a–c) and S. elongatus CCAP 1479/1A (panels d–f) after a 7-day contact toxicity test with binders of 5% solids content. Significant differences are indicated on individual graphs by different letters. Refer to Table 1 for binder details

Effects of AURO binder solids content

There was a significant increase in growth with respect to controls for S. elongatus PCC 7942 with AURO 320 (ANOVA, F4,13 = 23.06, P < 0.001), with the best growth support by the 2.5% solids treatment (P < 0.001). Similarly for S. elongatus CCAP 1479/1A with AURO 321 (ANOVA, F4,10 = 5.182, P = 0.016) (Fig. 2), although in this case the best growth was with the 7.5% solids treatment (P = 0.001).

Cell density (cells per mL, mean ± SD) of a Synechococcus elongatus PCC 7942 with AURO 320 and b S. elongatus CCAP 1479/1A with AURO 321, after a seven day contact toxicity test with varying percentage binder solids content. Significant differences are indicated on individual graphs by different letters

Adhesion

Scanning electron micrographs of representative S. elongatus PCC 7942 biocomposites are presented in Fig. 3, showing variation in biocoating integrity. Figure 3a illustrates the densely packed nature of the biocoating, but also shows that the biocoatings cannot be regarded as monolayers. Equally, poorly coated areas of the fibres are seen (Fig. 3b and c), as well as a more complex 3D architecture where the pore space between fibres has allowed the biocoating to penetrate further into the textile structure (Fig. 3d). Significant interactions between textile type and binder solids content affected cell retention when a 1% cell loading was used (two-way ANOVA: F12 = 4.267, P = < 0.001), with textile type (two-way ANOVA: F3 = 15.93, P < 0.001) and solids content (two-way ANOVA: F4 = 31.38, P < 0.001) having significant effects. Cells’ retention was not significantly different for the bamboo at any binder solids content, but the other textiles experienced significant losses (Fig. 4), particularly for higher solids contents, with wool and polyester having the poorest cell retention properties.

Scanning electron micrographs of Synechococcus elongatus PCC 7942 biocomposites made with 5% solids content and 2.5% cell loading: a cotton, arrow indicates that the biocoating was several cells thick, scale bar = 10 μm; b bamboo, black arrow indicates a cell attached to the bamboo fibre, the hatched arrow indicates a section of biocoating (binder with cells), scale bar = 5 μm; c wool, scale bar = 10 μm, and d polyester, arrow indicates a fracture in the biocoating, scale bar = 10 μm

Cell retention (mean ± SD) of Synechococcus elongatus PCC 7942 immobilised within AURO 320 on woven 80/20 polyester-cotton blend (cotton), woven 100% bamboo (bamboo), non-woven 40/60 wool-polyester blend (wool blend), and non-woven 100% polyester (polyester) biocomposites after 72 h. Different cell loading levels were trialled: a 1%, b 2.5%, c 5%, and d 10%. Different letters indicate significant differences within textiles for each cell loading level

When a 2.5% cell loading was used there was no significant interaction between textile and binder solids content (two-way ANOVA: F12 = 1.732, P = 0.096). Cell retention was significantly reduced for all textiles at any binder solids content relative to the control (Fig. 4). For cotton and bamboo, there was a general trend of improved cell retention with increasing solids content, but this was not evident for either the wool blend or the polyester.

There was a significant interaction between textile and binder (two-way ANOVA: F12 = 4.365, P = < 0.001) when 5% cell loading was used, with textile type (two-way ANOVA: F3 = 11.40, P < 0.001) and binder solids content (two-way ANOVA: F4 = 16.16, P < 0.001) having significant effects. There was no significant release for either cotton or bamboo at any solids content (Fig. 4); however, the wool and polyester textiles experienced significant cell loss at 7.5 and 10% solids.

There was also a significant interaction between textile and binder at the highest cell loading (10%) (two-way ANOVA: F12 = 5.052, P < 0.001), with textile (two-way ANOVA: F3 = 14.26, P < 0.001) and binder solids (two-way ANOVA: F4 = 27.12, P < 0.001) both significant factors. The bamboo had no significant cell loss and the cotton only had significant loss at 2.5% solids, whereas the wool blend had significant release at 7.5 and 10% solids content and the polyester at 2.5, 7.5, and 10% solids content.

In the equivalent adhesion tests with S. elongatus CCAP 1479/1A, there was also a significant interaction between textile and binder solids content at a cell loading of 1% (two-way ANOVA: F12 = 14.3, P < 0.001). Textile (two-way ANOVA: F3 = 48.55, P < 0.001) and binder solids content (two-way ANOVA: F4 = 151.7, P < 0.001) were significant factors. All textiles experienced some cell loss although the bamboo was unaffected by the binder solids content. The other textiles experienced increased cell loss at high binder solids content (either 7.5 or 10% solids) (Fig. 5). The wool blend and the polyester treatments performed very poorly at higher solids content, in some instances (polyester 7.5 and 10%) causing all cells to be released. A markedly different pattern was observed at a cell loading of 2.5%. There was no significant interaction between textile and binder solids (two-way ANOVA: F12 = 1.533, P = 0.153). Whereas all treatments did release cells, this was either not worsened at higher solids content or, in the case of cotton, cell retention tended to improve.

Cell retention (mean ± SD) of Synechococcus elongatus CCAP 1479/1A immobilised within AURO 320 on woven 80/20 polyester-cotton blend (cotton), woven 100% bamboo (bamboo), non-woven 40/60 wool-polyester blend (wool blend), and non-woven 100% polyester (polyester) biocomposites after 72 h. Different cell loading levels were trialled: a 1%, b 2.5%, c 5%, and d 10%. Different letters indicate significant differences within textiles for each cell loading level

The 5 and 10% cell loading treatments returned very similar patterns in terms of cell release. In both cases, there were significant interactions between textile and binder solids (5% cell loading—two-way ANOVA: F12 = 3.307, P = 0.002; 10% cell loading— two-way ANOVA: F12 = 5.708, P < 0.001). Textile was a significant factor (5% cell loading—two-way ANOVA: F3 = 9.607, P < 0.001; 10% cell loading—two-way ANOVA: F3 = 13.99, P < 0.001) as was binder solids content (5% cell loading—two-way ANOVA: F4 = 20.99, P < 0.001; 10% cell loading—two-way ANOVA: F4 = 21.74, P < 0.001). The cotton and bamboo textiles had no significant cell losses at any binder solids content at either cell loading levels. The performance of the wool blend was almost identical between the cell loading rates, with only the 7.5 and 10% binder solids losing cells. Whereas the polyester textile did tend to lose cells at higher binder solids, this loss was not quite as high at the 7.5% cell loading level.

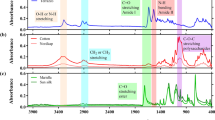

CO2 uptake for S. elongatus PCC 7942 biocomposites

For biocomposites with 5% solids content and 2.5% cell loading, there was a significant interaction between textile and time (days) in terms of CO2 consumption (two-way ANOVA: F40 = 6.871, P < .0001), with textile (two-way ANOVA: F4 = 9.192, P < 0.001) and time (two-way ANOVA: F10 = 909.4, P = 0.016) significant factors for S. elongatus PCC 7942 (Fig. 6a). Cotton and polyester had significantly more CO2 uptake per cell than the suspension control from days 2 and 6 respectively. However, there was no significant difference in CO2 uptake per cell between textiles within each time point.

Cumulative uptake (mean ± SD) of CO2 per cell for Synechococcus elongatus PCC 7942 immobilised within AURO 320 over a 20-day period on woven 80/20 polyester-cotton blend (cotton), woven 100% bamboo (bamboo), non-woven 40/60 wool-polyester blend (wool blend), and non-woven 100% polyester (polyester) biocomposites with varying binder solids content, cell loading, and growth media; a 5% solids with 2.5% cell loading in BG11, b 10% solids with 2.5% cell loading in BG11, c 5% solids with 10% cell loading in BG11, and d 5% solids and 2.5% cell loading with either artificial urine or BG11. Different letters indicate significant differences within time points on individual graphs

There was a significant interaction between textile and time in terms of CO2 uptake for S. elongatus PCC 7942 with 10% solids content AURO 320 (two-way ANOVA: F40 = 6.871, P < 0.001), with textile (two-way ANOVA: F4 = 9.192, P = 0.002) and time (two-way ANOVA: F10 = 909.4, P < 0.001) significant factors (Fig. 6b). The CO2 uptake of the suspension control was significantly higher than the biocomposites at each time point. The bamboo was the poorest performing biocomposite.

For S. elongatus PCC 7942 biocomposites with 5% solids content and 10% cell loading, textile and time had significant interactions (two-way ANOVA: F40 = 14.68, P < 0.001), with both time (two-way ANOVA: F10 = 631.8, P < 0.001) and textile (two-way ANOVA: F4 = 17.98, P = 0.001) significant factors (Fig. 6c). From day eight onwards, cells immobilised to cotton or bamboo had significantly lower cumulative CO2 uptake than the suspension control, whereas the wool and polyester were not significantly different to the control. The CO2 uptake of all treatments (including the controls) was markedly reduced compared with preceding trials.

For the S. elongatus PCC 7942 biocomposites fabricated with 5% solids content and 2.5% cell loading, there were significant interactions between textile, time and growth media (two-way ANOVA: F30 = 49.88, P < 0.001), with time (two-way ANOVA: F10 = 1053.00, P < 0.001), textile and media (two-way ANOVA: F3 = 77.98, P < 0.001) all significant factors (Fig. 6d). From day four onwards, BG11 treatments had greater cumulative CO2 uptake than their respective suspension and cotton controls. With artificial urine, cumulative CO2 uptake was not significantly different either in suspension or immobilised. From day six, cumulative CO2 uptake with BG11 was significantly increased with respect to all other treatments regardless of immobilisation state. Suspension cultures failed to significantly increase cumulative CO2 after day four in artificial urine and day six in BG11, in contrast to immobilised samples which had significant increases in cumulative CO2 at all time points until day 16.

CO2 uptake for S. elongatus CCAP 1479/1A biocomposites

There was a significant interaction between textile and time for biocomposites made with 5% solids content and 2.5% cell loading (two-way ANOVA: F40 = 5.325, P < 0.001), with time (two-way ANOVA: F10 = 646.7, P < 0.001) and textile (two-way ANOVA: F4 = 4.987, P = 0.018) significant factors. From days 4–18, there were no significant differences in cumulative CO2 uptake between suspended and immobilised cultures, with the exception of the wool blend on day 20 (Fig. 7a). Over time, only the wool and polyester made significant increases in cumulative CO2 uptake.

Cumulative uptake (mean ± SD) of CO2 per cell for Synechococcus elongatus CCAP 1479/1A immobilised within AURO 321 over a 20 day period on woven 80/20 polyester-cotton blend (cotton), woven 100% bamboo (bamboo), non-woven 40/60 wool-polyester blend (wool blend), and non-woven 100% polyester (polyester) biocomposites with varying binder solids content, cell loading, and growth media; a 5% solids with 2.5% cell loading in BG11, b 10% solids with 2.5% cell loading in BG11, c 5% solids with 10% cell loading in BG11, and d 5% solids and 2.5% cell loading with either artificial urine or BG11. Different letters indicate significant differences within time points on individual graphs

For biocomposites fabricated with 10% solids and a 2.5% cell loading (Fig. 7b), there was a significant interaction between textile and time (two-way ANOVA: F40 = 6.249, P < 0.001), with time (two-way ANOVA: F10 = 1426.00, P < 0.001) and textile (two-way ANOVA: F4 = 8.404, P = 0.003) significant factors. There was no significant difference in cumulative CO2 uptake between textiles. From days 8 and 10 onwards, the bamboo and polyester had significantly lower cumulative CO2 uptake than the suspension control.

There was a significant interaction between textile and time (two-way ANOVA: F40 = 1.564, P = 0.038) with time (two-way ANOVA: F10 = 536.0, P < 0.001) being significant, but not textile (two-way ANOVA: F40 = 1.564, P = 0.158) for biocomposites made with 5% solids content and 10% cell loading (Fig. 7c). Only the cotton biocomposite did not have significantly different cumulative CO2 uptake compared to the suspension culture. However, from day eight onwards, there was no significant difference in cumulative CO2 uptake between the suspension culture or textiles.

In the final experiment, with biocomposites made with 5% solids content and 2.5% cell loading, there were significant interactions between textile, time and the growth media (two-way ANOVA: F30 =8.613, df = 30, P < 0.001), with time (two-way ANOVA: F10 = 326.1, P < 0.001) and textile and media (two-way ANOVA: F3 = 13.68, P = 0.016) significant factors (Fig. 7d). The use of artificial urine with the immobilised biocomposites did not cause a significant change in cumulative CO2 uptake compared to the equivalent JM treatment until day 18. The impact of artificial urine on the suspension or immobilised samples was less clear over time. The suspended samples had significantly greater cumulative CO2 uptake on days 4 and 8. Biocomposites exposed to either artificial urine or JM had significant increases at each subsequent measurement over the full experimental period, but the suspension treatment did not make significant increases on after days 2 and 10 respectively.

Discussion

The objective of this study was to investigate some of the main technical steps required to develop robust, low cost, low maintenance living cyanobacterial biocomposite systems that could be deployed for a range of phycoremediation applications. As a system, the biocomposites are inherently simple, comprising three core elements: a scaffold to provide the physical means of supporting the structure (in this study this role was fulfilled using a range of commercially sourced textiles), a binder (ideally porous) to secure the cells to the scaffold while allowing for the diffusion of water and gases across the thin polymer film, and an appropriate microorganism. Textiles were chosen as they are cheap, easily obtained and could extend the technical life of the textile product if discarded fabrics are repurposed as biocomposites. Textiles also have the added benefit of being highly porous scaffolds with a large surface area for biocoating adhesion. Their physical flexibility would also allow textile biocomposites to be deployed in a range of physical spaces and could deliver remediation using both dead-end and tangential flow (in addition to the capillary action and wicking demonstrated here), although the latter would be favoured.

We chose to test a range of textiles, ranging from 100% natural fibres (bamboo) to fully synthetic (100% polyester), and incorporating two textile blends (a 40/60 wool-polyester blend and an 80/20 polyester-cotton blend); however, other scaffolds have been tested (Akhtar et al. 2004; Bernal et al. 2014; Eroglu et al. 2015). Polyester was chosen as it is ubiquitous throughout the textiles industry and biocomposites could offer an additional recycled product. Furthermore, we have separately demonstrated that polyester is amenable to conversion to cyanobacterial biocomposites for carbon capture applications, particularly the 80/20 blend used here (In-na et al. unpublished); although we acknowledge the need to drastically reduce plastics use and subsequent release into the environment (Barnes et al. 2009). The wool blend was chosen against the backdrop of a collapse in the wool price (currently trading at a 6-year low, 18 August, 2020, www.tradingeconomics.com), with many UK wool producers having to destroy their fleeces. At the opposite end of the scale we chose bamboo, and despite it being an expensive material, the growing demand for bamboo clothing is driving increased production that should, in time, reduce wholesale prices.

Binder choice was guided by prior experience. A range of synthetic binders were screened, and although we previously documented toxicity issues when used in combination with eukaryote microalgae (In-na et al. 2020), they had not been assayed against cyanobacteria. However, the outcomes were very similar, with all binders proving toxic with the exception of PD-0413 (binder 9). Nonetheless, we elected not to promote this binder for further testing due to its unknown properties and focused more effort on the AURO latex coatings, which are more accessible.

AURO coatings are formulated from exclusively natural ingredients and are hypoallergenic; they were chosen on the premise that they should have lower toxicity to the cyanobacteria. This assumption was not entirely justified as four of the six AURO binders returned cell densities below the controls. Without a detailed reverse engineering of the formulations, it is not possible to identify where the issues lie; however, comparing the published constituents reveals that binders 160, 251, and 261 all contain metal soaps (to promote coating drying) which are water-insoluble compounds comprising alkaline earth or heavy metals (the manufacturer does not declare which metals are involved) contained within carboxylic acids (Robinet and Corbeil-a 2003; Noble 2019). We also cannot discount the possibility that the impact on cell growth was not due to the polymer film being impermeable, thereby impeding gas and water exchange. Binder 379, which has shellac as a constituent of the formulation, also supported poor growth. Given that the shellac-only treatment killed all of the cyanobacteria, it is not unreasonable to deduce that the shellac had a role in the poor performance of this binder.

The two AURO emulsion coatings (320 and 321) successfully supported strong cyanobacteria growth (with some variation between the strains). These observations corroborate our previous findings with these coatings when used in combination with a loofah sponge scaffold (In-na et al. 2020), consistently outperforming suspension controls, often by orders of magnitude. Other than not containing metal soaps or shellac, the reasons for such consistent growth promotion remain speculative. Both binders list ammonia as part of the formulation, which potentially could be exploited by S. elongatus as an additional nitrogen source (Ludwig and Bryant 2012), although nitrogen limitation is unlikely to have been an issue in the short (72 hour) toxicity tests. The other notable differences are the inclusion of Replebin® (In-na et al. 2020) (a plant alcohol ester with organic acids) as a proprietary ingredient, and titanium dioxide as a pigment. We have no further details on the chemical composition of Replebin® and speculation would be unhelpful; however, a potential role—albeit paradoxical—for TiO2 cannot be discounted. TiO2 is increasingly used in photochemistry based water treatment to kill cyanobacteria and destroy their cyanotoxins (He et al. 2020; Pestana et al. 2020); yet a recent study has found that colloidal TiO2 and cyanobacteria extracellular polymeric substances (EPS) interact, promoting colloidal stability, reducing photochemical damage (Xu et al. 2020), and potentially enhancing the adsorption of organic molecules, particularly those with phosphate and nitrogen moieties. Further investigation into the functional aspects of the AURO 320 and 321 binders is clearly warranted.

Despite previous studies successfully immobilising microalgae and cyanobacteria in chitosan (Aguilar-May et al. 2007; Aguilar-May and Del Pilar Sánchez-Saavedra 2009; Eroglu et al. 2015), there was a significant reduction in growth during toxicity testing, potentially due to suboptimal acetic acid pH of 3.13 experienced during the curing process. A more structure approach to developing chitosan within a biocomposite architecture would probably address these issues.

The second determinant of a successful binder is its capacity to retain the cells once the biocoating is formed. SEM imaging revealed variation in the coverage of the textile fibres by AURO 320 and 321, and that the manual application approach used here does not deliver a cellular monolayer with the topographically complex textiles. The polyester-cotton and bamboo textiles were both woven; the diameter and spacing of the weave affects the inter-yarn pore size, subsequently affecting the swelling ability of the textile as the liquid flows between the pores, with tighter weaves allowing less swelling (Gibson et al. 1999)—hence reducing mechanical stress on the binder, particularly during drying (Jons et al. 1999). Additionally, the hydrophobicity of woven fabrics is influenced by its roughness, structure, and geometry, with rougher surfaces being more hydrophobic (Melki et al. 2019). Wettability is also influenced by pore structure. The non-woven textiles (the 40/60 wool-polyester blend and the 100% polyester) had larger pores, which should result in a rougher surface structure with greater wettability than the woven textiles, thereby increasing interactions between the surface and the growth medium (Zhu et al. 2006) and potentially affecting latex film formation (Khosravi et al. 2014). When coating latex onto porous substrates, the water can leave through evaporation and wicking, with the extent of wicking affected by the textile’s hydrophobicity. We would therefore expect that the biocoatings would have better coverage and deeper penetration with the non-woven textiles. Increasing the solids content of the binder would have ameliorated this effect and helped create more even films with improved adhesive properties.

Interestingly, the ammonia in the AURO binders may have physically affected the cotton and bamboo. Ammonium is utilised in the cotton industry to penetrate the cellulose by breaking hydrogen bonds, with the resulting fibres having improved stability and abrasion resistance (Dornyi et al. 2008). Additionally, the increased cell density in the adhesion test may also have affected film formation by increasing viscosity and prevented levelling of the film (Desjumaux et al. 2000).

The viability of the biocomposites was determined by net CO2 uptake over a 20-day semi-batch trial, with reference to the equivalent cell density in suspension culture. The biocomposites with 5% solids content and 2.5% cell loading performed well, easily surpassing the controls, although over time there was some slippage of the biocoating from the wool blend and polyester biocomposites into the liquid media pool. Latex films can begin to disintegrate after just 10 days, primarily due to photodegradation but also from microbial activity (Lambert et al. 2013). Furthermore, there is potential for swelling of rubber latex of up to 20% under exposure to continuous moisture which could contribute to biocoating failure and subsequent release of cells (Cesar et al. 2020).

When the solids content was increased to 10% to prevent slippage, the CO2 uptake was reduced compared to the suspension controls. The increased thickness of the binder and the reduced number of pores will have reduced light penetration, gas and nutrient exchange through mass transfer limitation (Pires et al. 2013; Miranda et al. 2017), which we confirmed in our previous work (In-na et al. 2020). Future iterations of these biocomposites should focus on maximising pore number and size (i.e., permeability) without compromising the structural integrity of the biocoating or by exceeding the cell size of the immobilised organism. A number of options exist to achieve this, including incorporating water soluble fillers within the binder (Lyngberg et al. 2001) and, at a more technical level, including halloysite nanoclays (Chen et al. 2020).

To increase CO2 uptake, more biomass was loaded into the system; however, the CO2 uptake per cell was significantly reduced when compared with the 2.5% biocoatings. Increasing cell loading in immobilised systems is not necessarily a panacea for poor performance, as demonstrated in alginate immobilised systems (Chevalier and de la Noüe 1985; Lau et al. 1997; Hameed 2007). In scenarios where resource limitation will become an issue (such as the single addition of nutrients in the current study), by increasing cell loading you only exacerbate resource competition. Whereas we did not specifically measure nutrient levels, it is reasonable to assume a degree of limitation given the 20 day duration without nutrient renewal. This would have reduced pigment synthesis, compromised photosynthetic efficiency, and therefore reduced CO2 fixation (Ruan et al. 2018). In the context of wastewater remediation, this may be less of an issue as nutrient deficiency is less likely outside of static systems as tested here.

To better reflect the performance of the biocomposites when exposed to effluent, the defined growth media were replaced with a basic artificial urine. Both S. elongatus strains had reduced CO2 uptake with the artificial urine. Most cyanobacteria have one or more genes that transport and catabolise urea to ammonia and CO2 which can then be used for metabolism (Veaudor et al. 2019). Li and co-workers compared the proteomic response of Synechococcus sp. WH8102 when grown on either nitrate or urea, with the urea treatments having greater RuBisCO activity but reduced carbonic anhydrase activity, suggesting a higher carboxylation efficiency which reduces demand for CO2 (Li et al. 2019b). The artificial urine had sufficient phosphate; therefore, deviation from stochiometric balance does not explain the observations. Once optimised biocomposites are developed, there is need for further optimisation based on real effluent.

Aside from the materials components of the biocomposites, careful selection (and potentially adaptation) of the immobilised organism is also needed. We have observed substantive differences in performance between two strains of the same species, with S. elongatus PCC 7942 better equipped for immobilised existence. We documented similar variation (albeit with S. elongatus CCAP 1479/1A delivering the better results) using loofah sponge-based biocomposites for carbon capture. For biocomposites to reach their potential, there is an imperative to incorporate species with established phycoremedation pedigree in addition to convenient laboratory strains. In conjunction with this, there is a need for individual, informed tailoring of biocomposites and photobioreactor design for their specific utilisations which can be determined using a model-based approach (Li et al. 2019a).

Conclusion

We set out to explore the technical constraints to fabricating textile-based cyanobacteria biocomposites that could be deployed for a range of environmental remediation applications. In particular, these approaches (pending further optimisation) could become an effective treatment option for highly distributed wastewater treatment infrastructure, potentially within the context of individual properties. This study drew inspiration from the EU H2020 project Living Architecture (Armstrong et al. 2017), which had the goal of developing similar highly distributed wastewater treatment infrastructure; however, the Living Architecture technology is deeply embedded within the mindset of suspension-based treatment systems. We sought to circumvent this approach by developing engineered immobilised biocomposites that would accelerate the maturation of the Living Architecture vision and lead to the miniaturisation (i.e., intensification) of the Living Architecture infrastructure, which will be vital if it is to deliver on its promise.

Data availability

At request to the corresponding author.

References

Acién F, Molina E, Reis A, Torzillo G, Zittelli G, Sepúlveda C, Masojídek J (2018) Photobioreactors for the production of microalgae. In: Gonzalez-Fernandez C, Munoz R (eds) Microalgae-Based Biofuels and Bioproducts. Elsevier, Amsterdam pp 1–44

Aguilar-May B, Del Pilar Sánchez-Saavedra M (2009) Growth and removal of nitrogen and phosphorus by free-living and chitosan-immobilized cells of the marine cyanobacterium Synechococcus elongatus. J Appl Phycol 21:353–360

Aguilar-May B, Del Pilar Sánchez-Saavedra M, Lizardi J, Voltolina D (2007) Growth of Synechococcus sp. immobilized in chitosan with different times of contact with NaOH. J Appl Phycol 19:181–183

Akhtar N, Iqbal J, Iqbal M (2004) Removal and recovery of nickel(II) from aqueous solution by loofa sponge-immobilized biomass of Chlorella sorokiniana: Characterization studies. J Hazard Matger 108:85–94

Ansari FA, Ravindran B, Gupta SK, Nasr M, Rawat I, Bux F (2019) Techno-economic estimation of wastewater phycoremediation and environmental benefits using Scenedesmus obliquus microalgae. J Environ Manage 240:293–302

Armstrong R, Ferracina S, Caldwell G, Ieropoulos I, Rimbu G, Adamatzky A, Phillips N, De Lucrezia D, Imhof B, Hanczyc MM, Nogales J, Garcia J (2017) Living Architecture (LIAR): Metabolically engineered building units. In: Heisel F, Hebel D (eds) Cultivated Building Materials: Industrialized Natural Resources for Architecture and Construction. Birkhauser, Berlin, pp 170–177

Barnes DKA, Galgani F, Thompson RC, Barlaz M (2009) Accumulation and fragmentation of plastic debris in global environments. Phil Trans Roy Soc B 364:1985–1998

Bernal OI, Mooney CB, Flickinger MC (2014) Specific photosynthetic rate enhancement by cyanobacteria coated onto paper enables engineering of highly reactive cellular biocomposite “leaves”. Biotechnol Bioeng 111:1993–2008

Bernal OI, Bharti B, Flickinger MC, Velev OD (2017) Fabrication of photoreactive biocomposite coatings via electric field-assisted assembly of cyanobacteria. Langmuir 33:5304–5313

Boelee NC, Janssen M, Temmink H, Taparavičiūtė L, Khiewwijit R, Jánoska Á, Buisman CJN, Wijffels RH (2014) The effect of harvesting on biomass production and nutrient removal in phototrophic biofilm reactors for effluent polishing. J Appl Phycol 26:1439–1452

Brooks T, Keevil CW (2003) A simple artificial urine for the growth of urinary pathogens. Lett Appl Microbiol 24:203–206

Cesar MB, Borges FA, Bilck AP, Yamashita F, Paulino CG, Herculano RD (2020) Development and characterization of natural rubber latex and polylactic acid membranes for biomedical application. J Polym Environ 28:220–230

Chen Y, Krings S, Booth JR, Bon SAF, Hingley-Wilson S, Keddie JL (2020) Introducing porosity in colloidal biocoatings to increase bacterial viability. Biomacromolecules 21:4545–4558

Chevalier P, de la Noüe J (1985) Wastewater nutrient removal with microalgae immobilized in carrageenan. Enzym Microb Technol 7:621–624

Christenson L, Sims R (2011) Production and harvesting of microalgae for wastewater treatment, biofuels, and bioproducts. Biotechnol Adv 29:686–702

Cuellar-Bermudez SP, Aleman-Nava GS, Chandra R, Garcia-Perez JS, Contreras-Angulo JR, Markou G, Muylaert K, Rittmann BE, Parra-Saldivar R (2017) Nutrients utilization and contaminants removal. A review of two approaches of algae and cyanobacteria in wastewater. Algal Res 24:438–449

David C, Bühler K, Schmid A (2015) Stabilization of single species Synechocystis biofilms by cultivation under segmented flow. J Ind Microbiol Biotechnol 42:1083–1089

de-Bashan LE, Bashan Y (2010) Immobilized microalgae for removing pollutants: Review of practical aspects. Bioresour Technol 101:1611–1627

Desjumaux DM, Bousfield DW, Glatter TP, Van Gilder RL (2000) The influence of latex type and concentration on ink gloss dynamics. Prog Org Coat 38:89–95

Dornyi B, Csiszár E, Somlai P (2008) Improving quality of linen-cotton fabrics with liquid ammonia treatment. J Nat Fibers 4:41–57

Eroglu E, Smith SM, Raston CL (2015) Application of various immobilization techniques for algal bioprocesses. In: Moheimani NR, McHenry MP, de Boer K, Bahri PA (eds) Biomass and Biofuels from Microalgae. Springer, Cham, pp 19–44

Estrada JM, Bernal OI, Flickinger MC, Muñoz R, Deshusses MA (2015) Biocatalytic coatings for air pollution control: A proof of concept study on VOC biodegradation. Biotechnol Bioeng 112:263–271

Fidaleo M, Bortone N, Schulte M, Flickinger MC (2014) Ink-jet printing of Gluconobacter oxydans: Micropatterned coatings as high surface-to-volume ratio bio-reactive coatings. Coatings 4:1–17

Flickinger MC, Schottel JL, Bond DR, Aksan A, Scriven L (2007) Painting and printing living bacteria: engineering nanoporous biocatalytic coatings to preserve microbial viability and intensify reactivity. Biotechnol Prog 23:2–17

Flickinger MC, Bernal OI, Schulte MJ, Broglie JJ, Duran CJ, Wallace A, Mooney CB, Velev OD (2017) Biocoatings: challenges to expanding the functionality of waterborne latex coatings by incorporating concentrated living microorganisms. J Coat Technol Res 14:791–808

Gibson P, Rivin D, Kendrick C, Schreuder-Gibson H (1999) Humidity-dependent air permeability of textile materials. Text Res J 69:311–317

Gou Y, Yang J, Fang F, Guo J, Ma H (2020) Feasibility of using a novel algal-bacterial biofilm reactor for efficient domestic wastewater treatment. Environ Technol (United Kingdom) 41:400–410

Grant SB, Saphores J-D, Feldman DL, Hamilton AJ, Fletcher TD, Cook PLM, Stewardson M, Sanders BF, Levin LA, Ambrose RF, Deletic A, Brown R, Jiang SC, Rosso D, Cooper WJ, Marusic I (2012) Taking the “waste” out of “wastewater” for human water security and ecosystem sustainability. Science 337:681

Greenhouse SW, Geisser S (1959) On methods in the analysis of profile data. Psychometrika 24:95–112

Hamano H, Nakamura S, Hayakawa J, Miyashita H, Harayama S (2017) Biofilm-based photobioreactor absorbing water and nutrients by capillary action. Bioresour Technol 223:307–311

Hameed MA (2007) Effect of algal density in bead, bead size and bead concentrations on wastewater nutrient removal. Afr J Biotechnol 6:1185–1191

He X, Wang A, Wu P, Tang S, Zhang Y, Li L, Ding P (2020) Photocatalytic degradation of microcystin-LR by modified TiO2 photocatalysis: A review. Sci Total Environ 743:140694

Hillman KM, Sims RC (2020) Struvite formation associated with the microalgae biofilm matrix of a rotating algal biofilm reactor (RABR) during nutrient removal from municipal wastewater. Water Sci Technol 81:644–655

Huang Q, Jiang F, Wang L, Yang C (2017) Design of photobioreactors for mass cultivation of photosynthetic organisms. Engineering 3:318–329

In-na P, Umar AA, Wallace AD, Flickinger MC, Caldwell GS, Lee JGM (2020) Loofah-based microalgae and cyanobacteria biocomposites for intensifying carbon dioxide capture. J CO2 Utiliz 42:101348

Johnson DB, Schideman LC, Canam T, Hudson RJM (2018) Pilot-scale demonstration of efficient ammonia removal from a high-strength municipal wastewater treatment sidestream by algal-bacterial biofilms affixed to rotating contactors. Algal Res 34:143–153

Jons S, Ries P, McDonald CJ (1999) Porous latex composite membranes: fabrication and properties. J Membr Sci 155:79–99

Khosravi A, King JA, Jamieson HL, Lind ML (2014) Latex barrier thin film formation on porous substrates. Langmuir 30:13994–14003

Kumar R, Venugopalan VP (2015) Development of self-sustaining phototrophic granular biomass for bioremediation applications. Curr Sci 108:1653–1661

Kumar PK, Vijaya Krishna S, Verma K, Pooja K, Bhagawan D, Himabindu V (2018) Phycoremediation of sewage wastewater and industrial flue gases for biomass generation from microalgae. S Afr J Chem Eng 25:133–146

Lambert S, Sinclair CJ, Bradley EL, Boxall ABA (2013) Effects of environmental conditions on latex degradation in aquatic systems. Sci Total Environ 447:225–234

Lau PS, Tam NFY, Wong YS (1997) Wastewater nutrients (N and P) removal by carrageenan and alginate immobilized Chlorella vulgaris. Environ Technol 18:945–951

Li W-W, Yu H-Q, Rittmann BE (2015) Chemistry: reuse water pollutants. Nature 528:29–31

Li T, Podola B, Schultze LKP, Melkonian M (2019a) Design scenario analysis for porous substrate photobioreactor assemblies. J Appl Phycol 31:1623–1636

Li Y-Y, Chen X-H, Xue C, Zhang H, Sun G, Xie Z-X, Lin L, Wang D-Z (2019b) Proteomic response to rising temperature in the marine cyanobacterium Synechococcus grown in different nitrogen sources. Front Microbiol 10:1976

Liu T, Wang J, Hu Q, Cheng P, Ji B, Liu J, Chen Y, Zhang W, Chen X, Chen L, Gao L, Ji C, Wang H (2013) Attached cultivation technology of microalgae for efficient biomass feedstock production. Bioresour Technol 127:216–222

Lofrano G, Brown J (2010) Wastewater management through the ages: A history of mankind. Sci Total Environ 408:5254–5264

Ludwig M, Bryant D (2012) Acclimation of the global transcriptome of the cyanobacterium Synechococcus sp. Strain PCC 7002 to nutrient limitations and different nitrogen sources. Front Microbiol 3:145

Lyngberg OK, Ng CP, Thiagarajan V, Scriven LE, Flickinger MC (2001) Engineering the microstructure and permeability of thin multilayer latex biocatalytic coatings containing E. coli. Biotechnol Prog 17:1169–1179

Martins J, Peixe L, Vasconcelos VM (2011) Unraveling cyanobacteria ecology in wastewater treatment plants (WWTP). Microb Ecol 62:241–256

Mata TM, Martins AA, Caetano NS (2010) Microalgae for biodiesel production and other applications: a review. Renew Sust Energ Rev 14:217–232

Maxwell SE, Delaney HD, Kelley K (2017) Designing experiments and analyzing data: A model comparison perspective, 3rd edn. Routledge, New York

Melki S, Biguenet F, Dupuis D (2019) Hydrophobic properties of textile materials: robustness of hydrophobicity. J Text Inst 110:1221–1228

Miranda MCR, Prezotti FG, Borges FA, Barros NR, Cury BSF, Herculano RD, Cilli EM (2017) Porosity effects of natural latex (Hevea brasiliensis) on release of compounds for biomedical applications. J Biomater Sci Polymer Edn 28:2117–2130

Muñoz R, Guieysse B (2006) Algal–bacterial processes for the treatment of hazardous contaminants: A review. Water Res 40:2799–2815

Naumann T, Çebi Z, Podola B, Melkonian M (2013) Growing microalgae as aquaculture feeds on twin-layers: a novel solid-state photobioreactor. J Appl Phycol 25:1413–1420

Noble P (2019) A brief history of metal soaps in paintings from a conservation perspective. In: Casadio F, Keune K, Noble P, Van Loon A, Hendriks E, Centeno SA, Osmond G (eds) Metal Soaps in Art. Springer, Cham, pp 1–22

Oladoja NA (2017) Appropriate technology for domestic wastewater management in under-resourced regions of the world. Appl Water Sci 7:3391–3406

Olguín EJ (2003) Phycoremediation: Key issues for cost-effective nutrient removal processes. Biotechnol Adv 22:81–91

Oswald W, Gotass H (1957) Photosynthesis in sewage treatment. Trans Am Soc Civ Eng 122:73–97

Peng J, Kumar K, Gross M, Kunetz T, Wen Z (2020a) Removal of total dissolved solids from wastewater using a revolving algal biofilm reactor. Water Environ Res 92:766–778

Peng YY, Gao F, Yang HL, Wu HWJ, Li C, Lu MM, Yang ZY (2020b) Simultaneous removal of nutrient and sulfonamides from marine aquaculture wastewater by concentrated and attached cultivation of Chlorella vulgaris in an algal biofilm membrane photobioreactor (BF-MPBR). Sci Total Environ 725:138524

Pestana CJ, Portela Noronha J, Hui J, Edwards C, Gunaratne HQN, Irvine JTS, Robertson PKJ, Capelo-Neto J, Lawton LA (2020) Photocatalytic removal of the cyanobacterium Microcystis aeruginosa PCC7813 and four microcystins by TiO2 coated porous glass beads with UV-LED irradiation. Sci Total Environ 745:141154

Pires JC, Alvim-Ferraz MC, Martins FG, Simões M (2013) Wastewater treatment to enhance the economic viability of microalgae culture. Environ Sci Pollut Res Int 20:5096–5105

Rawat I, Ranjith Kumar R, Mutanda T, Bux F (2011) Dual role of microalgae: Phycoremediation of domestic wastewater and biomass production for sustainable biofuels production. Appl Energy 88:3411–3424

Robinet L, Corbeil-a M-C (2003) The characterization of metal soaps. Stud Conserv 48:23–40

Ruan Z, Prášil O, Giordano M (2018) The phycobilisomes of Synechococcus sp. are constructed to minimize nitrogen use in nitrogen-limited cells and to maximize energy capture in energy-limited cells. Environ Exp Bot 150:152–160

Shi J, Podola B, Melkonian M (2007) Removal of nitrogen and phosphorus from wastewater using microalgae immobilized on twin layers: an experimental study. J Appl Phycol 19:417–423

Shi J, Podola B, Melkonian M (2014) Application of a prototype-scale Twin-Layer photobioreactor for effective N and P removal from different process stages of municipal wastewater by immobilized microalgae. Bioresour Technol 154:260–266

Šoštarič M, Klinar D, Bricelj M, Golob J, Berovič M, Likozar B (2012) Growth, lipid extraction and thermal degradation of the microalga Chlorella vulgaris. New Biotechnol 29:325–331

Stanier RY, Kunisawa R, Mandel M, Cohen-Bazire G (1971) Purification and properties of unicellular blue-green algae (order Chroococcales). Bacteriol Rev 35:171–205

Tanner AS, McIntosh BS, Widdowson DCC, Tillotson MR (2018) The water Utility Adoption Model (wUAM): Understanding influences of organisational and procedural innovation in a UK water utility. J Clean Prod 171:S86–S96

Thomas DA, Ford RR (2006) Barriers to Innovation in the UK Water Industry

Trebuch LM, Oyserman BO, Janssen M, Wijffels RH, Vet LEM, Fernandes TV (2020) Impact of hydraulic retention time on community assembly and function of photogranules for wastewater treatment. Water Res 173:115506

Tredici M, Bassi N, Prussi M, Biondi N, Rodolfi L, Zittelli GC, Sampietro G (2015) Energy balance of algal biomass production in a 1-ha “Green Wall Panel” plant: How to produce algal biomass in a closed reactor achieving a high Net Energy Ratio. Appl Energy 154:1103–1111

Umar A (2018) The screening, fabrication and production of microalgae biocomposites for carbon capture and utilisation. PhD Thesis, Newcastle University

Veaudor T, Cassier-Chauvat C, Chauvat F (2019) Genomics of urea transport and catabolism in cyanobacteria: biotechnological implications. Front Microbiol 10:2052

Verstraete W, Vlaeminck SE (2011) ZeroWasteWater: short-cycling of wastewater resources for sustainable cities of the future. Int Jf Sust Develop World Ecol 18:253–264

Waqas S, Bilad MR, Man Z, Wibisono Y, Jaafar J, Indra Mahlia TM, Khan AL, Aslam M (2020) Recent progress in integrated fixed-film activated sludge process for wastewater treatment: A review. Jf Environ Manage 268:110718

Xu H, Li F, Kong M, Lv X, Du H, Jiang H (2020) Adsorption of cyanobacterial extracellular polymeric substance on colloidal particle: Influence of molecular weight. Sci Total Environ 715:136959

Yang J, Shi W, Fang F, Guo J, Lu L, Xiao Y, Jiang X (2020) Exploring the feasibility of sewage treatment by algal–bacterial consortia. Crit Rev Biotechnol 40:169–179

Zhu L, Perwuelz A, Lewandowski M, Campagne C (2006) Wetting behavior of thermally bonded polyester nonwoven fabrics: The importance of porosity. J Appl Polym Sci 102:387–394

Zhuang LL, Yu D, Zhang J, Liu FF, Wu YH, Zhang TY, Dao GH, Hu HY (2018) The characteristics and influencing factors of the attached microalgae cultivation: A review. Renew Sust Energ Rev 94:1110–1119

Acknowledgements

We thank Dr Abbas Umar for help with laboratory training, Peter McParlin, Charlotte Anderson and Matthew Walker for technical assistance, Dr Juan Nogales for the donation of S. elongatus PCC 7942, Michael Foster for assistance with SEM imaging, and we are especially grateful to Prof. Michael Flickinger for making his synthetic latex binders available for testing.

Funding

PI was supported by a Newcastle University Doctoral Scholarship.

Author information

Authors and Affiliations

Contributions

The research was conceived by all authors, data collection and analysis were conducted by Rachel Hart and Pichaya In-na, the manuscript was written by Rachel Hart and Gary Caldwell and edited and approved by Pichaya In-na, Maxim Kapralov, and Jonathan Lee.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hart, R., In-na, P., Kapralov, M.V. et al. Textile-based cyanobacteria biocomposites for potential environmental remediation applications. J Appl Phycol 33, 1525–1540 (2021). https://doi.org/10.1007/s10811-021-02410-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-021-02410-6