Abstract

Cyber-physical systems (CPS) offer great potential for the digital transformation of industrial value creation in the context of Industry 4.0. They unify and integrate several technological approaches, including big data analysis and artificial intelligence, enhancing real-time monitoring and control of manufacturing processes. An extensive knowledge base formed by various disciplines, including information systems, engineering, and computer science, already exists for CPS. However, this knowledge has not been holistically captured and structured to date. To address this research gap, this study conducts a large-scale literature review of 2365 papers representing the current state of the research and then develops a novel categorization on industrial CPS with 10 sections, 32 areas, and 246 fields. The categorization is presented in hierarchical graphical form and can also be utilized as a web tool. To conclude, a perspective on future research needs and potentials to enhance Industry 4.0 in both research and practice are offered.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Industrial value creation is undergoing significant changes as part of the digital transformation with Industry 4.0 as the guiding term (Lasi et al., 2014), which emerged from a German funding initiative in 2013 with a number of program equivalents worldwide (Li, 2018). Cyber-physical systems (CPS), in addition to other technologies and concepts, are of particular relevance for this process (Zhang et al., 2021). With their general concept of, “[…] integrations of computation with physical processes. Embedded computers and networks monitor and control the physical processes, usually with feedback loops where physical processes affect computations and vice versa” (Lee, 2006, p. 1), CPS offer extensive application potentials within the industrial domain (Oks et al., 2017). In this, they contribute to the realization of use cases like the real-time monitoring and control of systems and processes, predictive maintenance, and the expansion of human-machine collaboration, among others, and therefore drive the optimization of production, products, and services with increased effectiveness and efficiency (Colombo et al., 2017).

However, as CPS are utilized both in industry and many other application domains, they qualify as general purpose technology (Bresnahan, 2010). As is to be expected with a technology/a concept that is associated with vast potentials and a wide range of application possibilities, CPS attract research interest from a variety of scientific disciplines and are utilized by numerous communities of practitioners. CPS are therefore constantly being assessed from different perspectives, including the technological (hardware, software, architectures, information systems, etc.), the process-oriented (applications, procedures, operations, etc.), the organizational (value creation, cost-benefit considerations, business models, etc.), the socio-technical (human-computer interaction (HCI), work design, etc.) and others (Geisberger & Broy, 2015). As a result, an extensive knowledge base on the subject of CPS and their application in the industrial domain has already been established. However, this knowledge base is very diverse and wide-ranging and therefore complex and difficult to determine.

It is therefore the motivation of this research, in order to exploit the full potential of CPS for the further establishment of Industry 4.0 (Vogel-Heuser & Hess, 2016), to disclose and examine the current state of knowledge on CPS and to categorize all CPS related and relevant topics within the industrial application domain, which is highly relevant and of great value to both the research and practice-oriented communities. This paper addresses the aforementioned research demand with the following two objectives: (I) Describe and analyze the state of research on CPS. (II) Develop and graphically present a categorization of CPS related and relevant topics in the context of Industry 4.0. This includes all subjects, technologies, concepts, and procedures that are related or relevant to industrial value creation. Both objectives are addressed in a comprehensive manner, based on a large-scale literature review. Concerning the first objective, the state of research is not thematically restricted to allow the derivation of analogies from other disciplines. This takes into account that CPS are studied and elaborated by a large number of disciplines, particularly in the area of basic research, of which the resulting knowledge cannot be strictly divided according to application domains. An exclusive focus on the area of manufacturing would therefore leave out relevant knowledge. Upon the second objective, the categorization is exclusively focused on CPS related and relevant topics in the context of Industry 4.0. This focus is feasible since for this objective it is no longer a matter of knowledge collection but of the subsequent step of arranging it in a structured, hierarchical, and comprehensive manner. The system of a categorization is therefore suitable, as it allows to present a vast amount of topics in a well-arranged form while also showing their interrelationships.

Thus, this paper provides an overview of research on CPS with pertinence for the Industry 4.0 domain and a categorization of all relevant topics for industrial CPS. It differs from a research survey paper in that it identifies and categorizes the topics but does not describe and analyze them in full depth, as this is done through narrowly defined concept-specific reviews as presented in related work chapter in Section 2.2.

The paper is structured as follows: After the introduction, the theoretical foundations of CPS in the industrial context are laid and related work is presented in Section 2. The third Section presents the methodological approach for the literature review and the subsequent analysis and development steps. The resulting state of research and categorization are presented in Section 4 in particular in graphical form. In Section 5 the paper closes with conclusions and an outlook regarding further consolidation and research needs in the field of industrial CPS.

2 Cyber-Physical Systems as an Enabler for Industry 4.0

This Section lays the groundwork for this research; the theoretical foundations of CPS are presented in 2.1 and additional related work is introduced that also seeks to structure industrial CPS in 2.2.

2.1 Foundations of Cyber-Physical Systems

The term CPS was introduced by E. A. Lee in 2006; since then, the topic has been further analyzed and developed in several scientific and practical disciplines (Geisberger & Broy, 2015). In essence, CPS are embedded systems that have both a cyber and a physical sphere between which there is a continuous and iterative information exchange (Alur, 2015). In the physical sphere, sensors are used to record environmental conditions, which are then evaluated in the cyber sphere using local computing power. The information obtained from the data stream can be either exchanged with other entities via communication interfaces or used in the physical sphere to affect the environment according to predefined rules of behavior via actuators (Lu et al., 2016). CPS can therefore be used for monitoring as well as controlling digital, physical, and especially hybrid processes (Jiang et al., 2018). The continuing miniaturization of computer hardware to the point of smart dust, coupled with the ongoing reduction of component costs, enables CPS to be used extensively in a wide range of contexts and conditions (Rajkumar et al., 2010). They can also be operated either completely autonomously or in collaboration and interaction with humans (Gil et al., 2019).

Three dimensions are to be taken into account in the design, development, and operation of CPS, the technical, the human/social, and the organizational (Oks et al., 2017). In the technical dimension, application-specific and requirement-meeting hardware and software have to be orchestrated with an appropriate architecture. Furthermore, the CPS has to be integrated into existing physical and digital infrastructures, and desired interoperability with other systems (Gürdür et al., 2016) should be ensured by means of norms and standards (Hehenberger et al., 2016). The human/social dimension comprises the integration of humans into or the interaction of humans with a CPS. In this dimension, HCI, safety in use, and the consideration of ethical issues in system design are of major importance (Calinescu et al., 2019). The organizational dimension is determined by the insertion of the CPS into the application purpose and context within various institutional structures and frameworks (Oks et al., 2018).

In addition, CPS can be divided into three levels that categorize their application in terms of system size and reach. At the micro level, CPS are used in a personal or small-group individual context, usually limited to a local area. At the meso level, CPS applications are organization-wide and can have interregional system dimensions. At the macro level, CPS are deployed, often as volatile systems of systems (Trunzer et al., 2020), in application scenarios that encompass entire national economies or are even more far-reaching, and are designed transregionally or globally (Oks et al., 2017). Within these levels, CPS are used in various domains in the context of the digital transformation. These include urban development (Smart City), healthcare (Smart Health), mobility (Smart Mobility), building management (Smart Home) and, most prevalently, industrial value creation (Smart Manufacturing) (Geisberger & Broy, 2015). As previous stated, CPS qualify as a general purpose technology because of this wide range of applications across levels and domains (Bresnahan, 2010). The distinctive characteristic of technologies of this kind is that they can be used widely and cross-functionally with a high level of utility. Like previous general purpose technologies, such as the steam engine, assembly lines, or computers, CPS, in combination with other technologies of the digital age, are attributed the potential to unleash a surge in productivity that is qualifying to induce an industrial revolution (Liao et al., 2016; Rosenberg & Trajtenberg, 2009). For this reason, the digital transformation of industrial value creation through CPS is discussed under the guiding term Industry 4.0 (Lu, 2017), which anticipates these far-reaching changes. Among other things, the establishment of CPS is considered to have the potential to address market megatrends, such as increasing individualization, dematerialization, and servitization, as well as increase sustainability by both optimizing existing processes and outputs and innovating new ones (Geisberger & Broy, 2015).

CPS used in the industrial domain are referred to as industrial CPS (Colombo et al., 2017). This term is used inclusively and covers not only CPS used in manufacturing, but also peripheral ones, such as in smart products, which provide relevant data for value creation (Oks et al., 2017). Industrial CPS are therefore broader in scope than cyber-physical production systems (CPPS) (Monostori, 2014). The schematic functioning of industrial CPS, which is shown in Fig. 1, can be described as follows: In the physical sphere, state data is collected throughout the production and product life cycle (Tao et al., 2020). This includes smart (raw) materials/components in the pre-production stage, CPPS in the production stage, and subsequently, smart products in the product in use stage. The recorded data is then used in the cyber sphere in two ways. First, in real-time for monitoring and control of statuses and processes. Threshold values and algorithms are used to detect (imminent) events to react in such a way that corresponding actuators are triggered in the physical sphere according to pre-defined system logic (Jiang et al., 2018). Second, the collected data is processed and aggregated in the form of a digital twin for production plants and (sub-)products in the long term (Biesinger et al., 2019). In addition, the vast, continuously growing data sets are analyzed using big data analytics (Marini & Bianchini, 2016). The insights gained in this way are then used to optimize the real-time methods of monitoring and control, thereby continuously enhancing the performance of the industrial CPS. Based on this scheme, industrial CPS constitute the basis for a large number of use cases in Industry 4.0, including predictive maintenance (Meesublak & Klinsukont, 2020), order and batch size planning (Huang et al., 2021), energy management (Ma et al., 2019), disaster prevention (Lei et al., 2020), and quality control (Colledani et al., 2018), among others.

2.2 Related Work

As is to be expected with a widely established general purpose technology, the literature base on CPS is already exceedingly comprehensive. Literature that is relevant for this research as related work in the form of reviews or systematizations on the topic of CPS can be divided into general, topic-specific, and industry-oriented perspectives.

As part of the general examination, Chen (2017b) reviewed and analyzed the theoretical foundations of CPS. In another general review on CPS, Liu et al. (2017) highlighted the system integration, architectures, and challenges associated with CPS. Using a less theoretical orientation, Hehenberger et al. (2016) introduced methods and applications for the design, modelling, simulation, and integration of CPS. Adjacent to these topics, there is a systematic review on interoperability and integration in the context of CPS by Gürdür and Asplund (2018). Besides the contributions mentioned above, which approach the subject of CPS from a broad viewpoint, there are also reviews, such as that by Muccini et al. (2016), on system self-adaptation, which examine CPS in general but exclusively with respect to one characteristic. In addition to reviews, there are also structuring works on CPS, such as that by Asare et al. (2012), who designed a CPS Concept Map with 51 items (e.g., applications, requirements, etc.) and their relations based on taxonomy developed during the 2012 NIST CPS Workshop.

Topic-specific research focuses on dedicated applications, technologies, or domains pertaining to CPS. A general overview of possible applications is given in a review by Chen (2017a). In this study, ten application areas are described and analyzed. The survey on CPS security by Humayed et al. (2017) is an example for reviews focusing on exclusively one application field. Other reviews, like those on blockchain-enabled CPS (Zhao et al., 2021) or CPS clouds (Chaâri et al., 2016), concentrate on technologies and their integrated operation with CPS. There are also dedicated reviews on CPS utilization in specific domains, such as the one by Haque et al. (2014) on healthcare.

There is also a wide range of preliminary work in the Industry 4.0 domain. For example, Dafflon et al. (2021) dealt with the general challenges, approaches, and used techniques of CPS for manufacturing in their literature review. The relevance of CPS to complementary concepts and technologies, such as internet of things (IoT), big data, and cloud computing, in the context of digitalized industrial value creation has been analyzed (Kim, 2017). The question of interoperability standards to enable interconnectivity between these technologies and the devices employing them was addressed in the review of Burns et al. (2019). Furthermore, a systematic mapping study of architectures, technologies, and challenges for CPS in Industry 4.0 was conducted by Hofer (2018). Further articles focusing on CPS architectures for manufacturing were contributed by Lee et al. (2015) and Pivoto et al. (2021), whose reviews drew specific attention to applications involving the industrial internet of things. Other reviews investigated the characteristics of CPS in the context of smart factories (Napoleone et al., 2020) and smart manufacturing (Thoben et al., 2017). The topic of smart manufacturing, in particular the control of its processes, was also examined in a literature review by Rojas and Rauch (2019). The design process of CPS for manufacturing was analyzed in the course of a literature review by Lozano and Vijayan (2020); Hermann et al. (2016) contributed design principles for Industry 4.0 scenarios. A general state of the art on the topic of Industry 4.0 with an additional outlook on future trends was provided by (Xu et al., 2018). In addition to the analytical studies and reviews cited above, there is also research on industrial CPS that present concepts that structure thematic areas in different forms. Against this backdrop, Monostori et al. (2016) offered 23 keywords, roots, expectations towards research, case studies, and R&D challenges regarding the implementation of CPS in manufacturing. Additionally, an application map for industrial CPS was introduced by Oks et al. (2017), which indicates specific CPS application fields for both production and smart products. In addition, a taxonomy consisting of nine items for techniques for approaching big data-related issues in CPS by Xu and Duan (2019), a classification of CPPS applications provided by Cardin (2019) and a concept map of CPPS research topics by Wu et al. (2020) should be mentioned in this regard. Along with that, Berger et al. (2021) provided a terminology, taxonomy, and reference model for entities in CPPS from a self-organizing systems’ perspective. Concluding, there was a trend map for cyber-physical systems research and education in 2030 introduced by Gürdür Broo et al. (2021), that provides 44 possible influencing factors in 7 categories regarding this topic.

Although the work outlined above is very extensive and contributions came from a wide variety of disciplines, there is yet no comprehensive approach to the topic of CPS in the form of a state of research nor a categorization of CPS related and relevant topics in the context of Industry 4.0 that are presented coherently in a suitable form. This work addresses this research gap through its two objectives.

3 Research Method

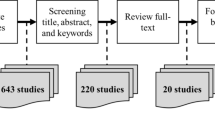

In order to address the two research objectives of this study, we chose the following research design: A comprehensive systematic literature review for data collection was conducted. The resulting data set was analyzed and transferred into a state of knowledge on CPS research and a categorization of CPS related and relevant topics in the context of Industry 4.0. Following the suggestions of vom Brocke et al. (2015) for conducting literature searches in information systems research, we defined the search scope as follows. We chose a sequential process, following the recommendations of Tranfield et al. (2003), which is described in more detail in subsequent paragraphs. Indexing services and databases were chosen as sources (cf. Fig. 2). As described in the motivation for this research, both the state of knowledge on CPS and the categorization of CPS related and relevant topics in the context of Industry 4.0 are intended to provide a comprehensive, general, and holistic overview of the subject area The coverage of our literature search, therefore, is comprehensive as well, in order to include as many relevant publications as possible (cf. vom Brocke et al., 2015). In terms of technique, we primarily applied a keyword search; the exact procedure is described below.

A systematic literature review was chosen for data collection and analysis because of its transparent, exhaustive, and heuristic qualities. In a systematic literature review, research contributions on a specific topic are localized, assessed, and interpreted. It differs from a traditional narrative review because of its methodological strategy and the detailed description of each individual process step. Furthermore, it aims at minimizing bias and increasing the reproducibility and transparency of the researchers’ approaches, decisions, and conclusions (Tranfield et al., 2003). The concrete procedure follows the recommendations of Denyer and Tranfield (2009) and Tranfield et al. (2003); it consists of five steps with sub-steps. All of these were performed manually by the research consortium of this paper, with one exception where the Citavi 6 function to detect and sort out duplicates was used. There were no fewer than five researchers involved in any step of the workflow. Table 1 explains the five main steps of the systematic literature review.

In the first step (1), the two research objectives were defined according to the motivation for this research: The first objective is (I) to describe and analyze the state of research on CPS, and the second is (II) to develop and graphically present a categorization of CPS related and relevant topics in the context of Industry 4.0.

The second step (2) was to identify the relevant literature needed to achieve the defined research objectives, which included screening, selecting, and assessing the search results. For the search, the online databases and library services EBSCO, Emerald Insight, Google Scholar, SAGE Journals, Science Direct, and Springer Link were selected to cover all relevant subject areas. The advanced search function was used in all databases for more comprehensive search options. The keywords were based on the term “cyber-physical systems”, considering different spellings in the existing literature. Both synonyms and plural forms were used to ensure an exhaustive search as well as comprehensive and valid results. The complete list of search terms is available in Appendix Table 3. The keywords and their synonyms were combined to search strings by using Boolean operators. The keyword “Industry 4.0” was intentionally omitted despite the thematic focus of the categorization within this context. This approach ensures that CPS sources relevant to the Industry 4.0 domain that do not explicitly contain the term Industry 4.0 in their title, keywords or abstract are also collected and considered. E.g., this becomes evident with terms such as smart factory, smart manufacturing, etc., since these tend to be used synonymously for Industry 4.0 and also for each other. Moreover, there are many papers on niche topics that only address a technical problem, phenomenon, etc., but are relevant to CPS in general, regardless of the respective application domain.

In the third step (3), the search results were screened and selected based on definite inclusion and exclusion criteria. The inclusion criteria were the containment of keywords or synonyms and relatedness to the topic. Exclusion criteria included publication languages different from English or German, inadequacy of outletFootnote 1, or the use of CPS as an abbreviation with a different meaning. Using the described concepts as search terms, the search returned 2777 publications. The procedure was as follows: The first reduction was realized in the databases EBSCO, Google Scholar and Springer Link, where the selection of the option “Source type is different from “Academic Journal”” and “Title does not contain at least one of the keywords or their synonyms” initially reduced the number of papers to be considered. Thereupon, after prior discussion, approval and sample round, it was decided for each source based on title, keywords and the abstract about the consideration based on the stated exclusion criteria. Six researchers in two-person teams performed this step of the process. After removing duplicates with the software Citavi 6 and merging the results from all databases, 2507 publications remained. In a final reduction by applying quality criteriaFootnote 2, the number of publications decreased to 2365. No exclusions were applied with regard to subject-specific selections and rankings of the research outlets, since all themes as well as new, less established research domains had to be considered to achieve a comprehensive overview. In contrast to other systematic literature reviews, a larger number of publications was explicitly considered for analysis because of the topic of CPS itself. First, CPS emerge from the combination of several hardware and software components, rely on complex architectures and multilayered communication standards, and involve miscellaneous stakeholders (Khaitan & McCalley, 2014). Second, the domain of industrial value creation, with its core of production, is interlinked with many other domains, such as logistics and energy supply, which hold many application scenarios for CPS (Oks et al., 2017). Third and last, since the research field of CPS is highly topical, findings in specific niches can have a universal validity that is relevant to other research disciplines as well.

In step four (4), the selected contributions were analyzed to extract and synthesize the relevant data, however, in different procedures for the two objectives I and II.

Analysis and synthesis for objective I: First, a data extraction form, which had been adapted to the requirements of the research objective, was applied to outline the present state of the research on CPS. The data extraction form, which is displayed below (cf. Table 2), includes both standard information, such as publication type, name of journal, authors, etc., as well as a set of specific parameters, such as dimensions and application domains. In the next step, the sources were analyzed according to the data extraction form. The allocation was performed by the research consortium while ensuring objectivity as is typical for qualitative research by applying inter-coder reliability measures and discussion of results (Mayring, 2015). Concluding, the analysis results were processed quantitatively by summation and proportion calculation.

Analysis and synthesis for objective II: For the second objective, to elaborate a holistic categorization of CPS related and relevant topics in the context of Industry 4.0. Due to this large variety, we decided to create a categorization as opposed to a classification. According to Jacob’s (2004) definition, relevant topics, technologies, concepts, and procedures cannot always be strictly delimited or assigned, and overlapping areas may exist; a classification would require stricter delimitation, hierarchies, and representations (Jacob, 2004). Given the heterogeneity within the field of CPS in Industry 4.0, this did not appear to be expedient. A classification in the form of a taxonomy was equally unsuitable for these reasons (Nickerson et al., 2013). Ontologies, as a comparable approach, focus more on relationships between different phenomena or constructs (Wand & Weber, 2004), however our categorization does not aim to represent encompassing relationships between different items. To compose the categorization, the titles, abstracts, and keywords of the contributions were analyzed for terms of interest regarding CPS in the context of Industry 4.0. These included topics, technologies, concepts, and procedures. Methodically this was conducted by the performance of a structured qualitative content analysis. For this purpose, an inductive code creation approach, following Mayring (2015), was applied. The titles, abstracts, and keywords of all 2365 papers were included in the analysis; relevant passages or words were marked in Citavi 6. A total of 313 codes were created, often by matching words exactly, but also by marking sentences or paragraphs to include content or context. The qualitative content analysis was conducted by five researchers who regularly discussed the codes to ensure a common and consistent understanding and coding procedure. Results were compared and adjusted until a common consensus was reached. Inter-coder reliability measures were also used for quality assurance opposing potential subjectivity in this qualitative research procedure (Mayring, 2015). For the development of the categorization, 288 categories were derived from the 313 codes based on their respective properties. The reduction results from the clustering of similar codes or the omission of codes that were irrelevant or incompatible with the classification system. The 288 categories were arranged into a hierarchy with sub-categories consisting of 246 fields, 32 areas, and 10 sections using Citavi 6. Each field is a specific technology, concept, or procedure. An area is superordinate to this and can be separated, for example, by architecture, value creation process or organizational structure. Sections are overarching subjects into which the areas and fields are classified.

The utilization of software or AI applications was not an option for the development of the categorization either, since it was not a deductive procedure in which all category titles would already have been known, but an inductive one in which the categories first had to be developed from the literature.

In the fifth (5) and final step of the research process, the presentation of the findings is performed.

Presentation and interpretation of findings for objective I: The summed and proportional findings were then converted into bar graphs showing them into proportional, numerical form.

Presentation and interpretation of findings for objective II: The resulting categorization was transferred to a graphical representation for a clearer overview and a more descriptive presentation. In addition, an interactive web tool was created to make the data even more accessible (cf. Appendix Fig. 18). The underlying literature for each category is provided and linked, and the fields and areas can be marked and annotated. Furthermore, a search function has been implemented to enable the direct retrieval of terms and properties. The web tool features a selection of languages, including English and German.

Complementing the graphical representations, the findings in form of the state of research and the categorization are extensively described in Section 4 and discussed in Section 5. The detailed process of the review steps is outlined in Fig. 2.

4 Findings

In the following, the results of the literature review and analysis are presented in two subchapters. First, in Section 4.1, a state of research on CPS is given, which is determined based on the characteristics of the analyzed publications. Second, in Section 4.2, a categorization of CPS related and relevant topics in the context of Industry 4.0 is provided, which organizes them in 10 sections, 32 areas, and 246 fields in detail.

4.1 State of Research on Cyber-Physical Systems

The state of research on cyber-physical systems with regard to the distribution of publications by type is predominantly divided into contributions to edited volumes and conference proceedings (1499) and journal articles (810). The other types, including books, dissertations, and reports, on the other hand, account for a minor proportion of the total, as can be seen in Fig. 3.

In terms of the distribution of the publications according to different scientific disciplines, three are the most prominent. These are computer science (856), computer engineering (808), and engineering (625). Business studies (36), mathematics and physics (26), and medicine (15) also deal with the subject matter, though there are a significantly lower number of publications in these disciplines.

Concerning the distribution of publications according to the disciplines specified in Figs. 4 and 5 shows that, in terms of the dimension of CPS introduced by Oks et al. (2017), the technical is notably the largest, with 2030 contributions. Given the 130 publications in the organizational and 44 in the socio-technical disciplines, it is evident that the topic of CPS has so far been examined primarily from technical and systems design perspectives, while organizational application and systems integration of humans has been of minor interest to date.

When considering the distribution of publications that can be allocated to a specific application domain (an explicit application is described in relation to singularly one domain), as displayed in Fig. 6, a greater variety becomes apparent. The four domains that account for more than 10% of all domain-specific publications (593) are mobility (135), manufacturing (109), energy (104), and healthcare (73). With a cumulative total of 313 contributions focusing on manufacturing, energy, logistics, robotics, safety and hazard defense, maintenance, smart products and coal, oil and gas industry, more than half of domain-specific contributions are relevant to industrial utilization.

A precise examination of the 109 contributions of the application domain manufacturing shows the various utilization potentials of CPS in this context; specific topics and the distribution of the related literature are illustrated in Fig. 7.

4.2 Categorization of Cyber-Physical Systems Related and Relevant Topics in the Context of Industry 4.0

The categorization arranges the CPS related and relevant topics in the context of Industry 4.0 in a structured way. To this end, the findings from the literature are categorized into 10 sections. These include the characteristics and the overall context of industrial CPS as well as the potentials/opportunities and challenges/issues associated with their application. The requirements of industrial CPS, concepts and technologies by which they are accompanied, and their functionality as socio-technical systems are presented. Besides, the architecture of industrial CPS is outlined, and its influence on industrial value creation is characterized. Finally, the potentials of industrial CPS with respect to trans-organizational integration and alliance formation are addressed.

To enhance the readability of this sub-section, the categories are marked in italics. Exemplary underlying literature can be found in the Appendix in Table 4. The table is sorted chronologically by occurrence of the categories in the text and contains sample citations of existing research on the respective topics.

The fundamental characteristics of CPS apply to the industrial application in the same way that they do to other domains, and are divided into general and the self-characteristics as presented in Fig. 8. General characteristics include connectivity and modularity; they highlight the comprehensive adaptability of industrial CPS, which can be designed to respond to varying situations and tasks by means of universal interfaces and modular construction. Real-time capability and traceability ensure that system adaptations can be both performed ad hoc and verifiable in this context. The high degree of autonomy of CPS is reflected in the self-characteristics, which describe the abilities of CPS to react autonomously to internal and external influences and control the system state by at least maintaining the system, if not optimizing it by anticipation without external intervention. CPS, therefore, have a high degree of resilience.

The overall context in which the systems are situated is what characterizes them specifically as industrial CPS. In the literature, this is widely referred to as Industry 4.0, as shown in Fig. 9. Originating from the title of a German governmental funding initiative, Industry 4.0 has become a catchphrase for digitized and interconnected industrial value creation. The firm anchorage of industrial CPS in this context highlights the innovation potential inherent in and relevance of this concept.

The reason for this is apparent due to the potentials/opportunities that industrial CPS offer for value creation processes. From an organizational perspective, they cover both production engineering and management aspects while also providing benefits for the users of products and services. In general, processes can be further automated and autonomized, particularly to the previously discussed characteristics of industrial CPS. Through the continuous monitoring of physical and digital processes and the resulting homogenization, an improved system-wide level of information is achieved, which allows for increases in efficiency for both management activities and process execution. Among other things, this enables batch/lot size one production at costs approaching those of mass production, which means that market demand for product individualization can be anticipated. Due to universal interfaces and increasing location independence, as well as less hierarchical system architectures, industrial CPS can be set up in decentralized structures. Decentralization, in combination with an improved level of information within the overall system, also allows for complex event processing with increasing flexibility. For example, production and logistics processes can be coordinated with a significantly shorter planning horizon facilitated by lead time reductions. The sensor-aided improvement of the level of information regarding the condition of system components allows fault/failure scenarios to be detected earlier or even predictive, which leads to quality improvements for both production facilities and products. The continuous and extensive backflow of status information from smart products reinforces this trend even further. Among other things, the general rapid increase in the availability of data allows for the development of new, data-driven business models. Alongside this, potentials for market penetration strategies arise in the form of product portfolio enlargements and time-to-market reductions. An overview of the potentials/opportunities offered by industrial CPS is provided in Fig. 10.

In addition to the vast potentials/opportunities, the implementation of industrial CPS also brings challenges/issues with it, including increased system complexity resulting from far-reaching changes in system size and structure. In that way, the number of system components (technological, organizational, inter-organizational) can increase significantly due to the connection and interaction of formerly independent and self-sufficient systems as well as the dissolving of system boundaries towards ad-hoc systems of systems. Additionally, system architectures become more multilayered and overall system diversity increases. Alongside the changes in system architectures, industrial CPS also lead to an increase in complexity in the organizational landscape. Linear value creation processes dissolve towards holistic value networks which become increasingly inter-organizational. Also, further organizational units and stakeholder groups are involved with and affected by industrial CPS than before. This complexity is intensified by time-related factors, as, for example, production management becomes more real-time-critical and product life cycles are shortening. Advancing inter-organizational integration in particular can lead to reduced transparency concerning system structures, synchronization problems, and new challenges for risk and uncertainty management. Due to the integration of numerous system components, the continuous monitoring of conditions, and the thereof resulting data throughput rates and volumes, and the inherent real-time feedback loops between sensors and actuators in industrial CPS, communication problems, such as delays or jitter, pose a severe threat to system functionality. As with many digitization matters, the implementation of industrial CPS occasionally arouses concerns and reservations among employees due to notions that working conditions might change and certain professions might become obsolete. High implementation efforts are an additional challenge/issue. With regard to the acquisition of new production plants or the retrofitting of existing ones to integrate them into industrial CPS and the, in many cases, high capital requirement resulting from this, a conclusive cost-benefit calculation is often rather difficult in advance. Particularly in the case of industrial CPS which have trans-organizational structures or are used to facilitate hybrid value creation networks, juridical matters arise because responsibilities and liability issues in the event of system failures or manufacturing defects that lead to malfunctioning products cannot always be unequivocally clarified.

Two further challenges/issues that are discussed in detail in the literature on industrial CPS are safety and security. The field of safety is divided into hazard defense and state. In hazard defense, strategies are described to prevent system failures through environmental monitoring or, in the case of such failures, to facilitate emergency management. System state control, which attempts to detect fault/failure situations before they become safety issues, is closely related. While safety deals with the operational integrity of systems, i.e., the protection of people and the environment from physical damage, security addresses data and information protection within a system. In the context of industrial CPS, this concerns the defense against threats and vulnerabilities like (cyber-) attacks and the securing of privacy, e.g., via preventing data abuse. Additionally, practical measures are presented for attack detection, information flow control, and access and control message protection (cryptography, digital signatures, and steganography). In summary and relation, the challenges/issues associated with industrial CPS are illustrated in Fig. 11.

Industrial CPS are subject to various requirements, as listed in Fig. 12, that are necessary or advantageous for their functionality and operation. These include autonomy, which ensures the functioning of systems within the defined functional objectives, especially if they cannot be operated from outside in either a planned or unplanned capacity. To this end, systems must be designed in order to be context-aware and sensitive so that changes in state and status are not only sensed but can also be considered in the superordinate application context and operate according to predefined algorithms. This ensures a high degree of dependability and reliability with regard to system availability and behavior as well as the value creation processes based on it. This dependable and reliable system availability is particularly necessary because, especially in the context of large-scale interconnected systems, (sub-)system failures can have serious consequences, including the collapse of entire systems of systems. Availability is also of utmost importance whenever safety-relevant processes are monitored and controlled by the system. In the context of maintaining system functionality under adverse conditions and in critical situations, robustness and resilience are also essential for industrial CPS. To a certain extent, the systems should be able to cope with environmental changes; their configuration should be able to robustly sustain these conditions. If the environmental changes are so severe that they cannot be handled by robustness, the systems should be so resilient that they adjust and adapt their configurations accordingly. The system state must be observable, with a high degree of reliability, and the information output on the state and control processes must be trustworthy so that fact-based decisions by administrators are possible at all times. In this context of system monitoring and control, it is also vital to have the most accurate predictability of expected system behavior in different situations so that the controllability of the system is given, despite its complexity and high degree of automation and autonomy.

In order to react to changes and new requirements in industrial CPS-based value creation processes, such as short-term capacity fluctuations or long-term market, production or product-related trends, it is a further requirement of industrial CPS that they are scalable, which can be executed briefly. Furthermore, since, as previously mentioned, value creation activities are becoming increasingly interactive and networked both intra- and inter-organizationally, the interoperability of individual industrial CPS is also of great interest.

All the requirements mentioned above should be met under the premise of sustainability in order to achieve efficiency and effectiveness in economic, ecological, and social dimensions.

In light of the far-reaching and holistic digitization of industrial value creation, a wide range of complementing concepts and technologies are being applied. In this, industrial CPS often serve as a linking element that systematically integrates these concepts and technologies in a goal-oriented and application-specific manner. Big data analyses are one of these concepts. Based on the widespread utilization of sensor technology in production and in products as such, industrial CPS often generate extensive data (5 Vs: volume, velocity, variety, value, veracity), which can be transferred by algorithm-based analyses such as pattern detection/recognition in smart data for general optimization purposes, as well as data-driven services and business models (data as a service). As often distributed and decentralized systems, industrial CPS use cloud, edge and ubiquitous computing to perform data processing and system control detached from the conventional automation pyramid. In many application scenarios of industrial CPS, the use of artificial intelligence (AI), e.g., as a foundation for the self-characteristics described previously, is suitable. Conventional methods to this end include reasoning or machine learning. As previously indicated, industrial CPS can be connected ad hoc to systems of systems according to context and task. To ensure integrity in the exchange of data and resources, distributed ledger technologies, such as blockchain, offer an adequate solution. Another concept that is compatible with industrial CPS is additive manufacturing. On the one hand, topics as resource efficiency, availability of spare parts, rapid prototyping, etc. can be addressed via this concept. On the other hand, production processes itself can apply technologies such as 3D printing.

Another concept that goes hand in hand with the digitization of industrial processes is work 4.0/future of work, which describes the elaboration of innovative working methods that are either possible or necessary due to technological changes. This may concern the general conditions of work in the industrial sector, which can even allow execution of work independent of time and location and in virtual teams/crowd working. Additionally, the introduction of industrial CPS is often accompanied by extensive changes in job requirements and professional training. Thus, the need for interdisciplinary competencies arises due to increasing system complexity, which is also reflected in a progressive linking and overlapping of disciplines relevant to value creation. Furthermore, the increasing automation associated with industrial CPS in particular leads to a reduction of low-wage-sector and unskilled jobs demand. Role changes become, therefore, necessary, which often require extensive training measures.

The spectrum of concepts and technologies that complement industrial CPS is shown Fig. 13.

In addition to the primary technical consideration of industrial CPS, the literature also examines the integration of humans in the form of socio-technical systems. In the field of production-supporting activities, this affects work execution. Due to increasing availability of information and new forms of HCI, information can be provided through various decision support systems, e.g., by means of action guidelines in maintenance. In addition, media discontinuities are being reduced due to increasing document/content digitization. The topic of knowledge in relation to industrial CPS is also covered by the literature. Additionally, due to new methods of system-integrated education and qualification, the integration of implicit knowledge can be achieved, making previously person-bound knowledge increasingly available to a wider circle of personnel (e.g., by the creation of action guidelines for machine repairs and further maintenance activities). The socio-technical systems integration of industrial CPS is presented in Fig. 14.

CPS have a common architecture with individual specifications depending on the application domain. The architecture of industrial CPS, which is described hereafter, serves as the underlying principle and scheme for the definition of concrete system features and configurations from design alternatives, depending on functional and non-functional requirements, and for the selection of suitable system components. Thereby, industrial CPS are allocated to the superordinate domain of information technology (IT), respectively, information and communication technology (ICT). From this domain, industrial CPS combine technologies and concepts of the (industrial) internet of things ((I)IoT) or web of things (WoT), which can be partitioned into a cyber sphere and a physical sphere according to the underlying logic of CPS. Software architecture and the data processing of industrial CPS are situated within the cyber sphere while hardware architecture and human-computer interaction (HCI) exist within the physical sphere. Network architecture serves as a connective link between the two spheres.

In the area software architecture, industrial CPS literature covers the following topics: Adequate operating systems for the respective system components are analyzed, the design of these systems from a programming standpoint with the subfields algorithms and programming languages as well as software agents with further subfields mobile agents and multi-agents. Further topics are sufficient middleware in the form of data distribution services (DDS) and workflow engines. Beyond that, concepts are presented that allow dynamic software updating (DSU) for CPS.

Concerning data in the context of industrial CPS, the following focal points receive particular attention in the literature. First, the data acquisition by sensors is discussed. This data can then be aggregated with existing data or fused with data from external sources. The resulting data sets are analyzed and evaluated by processing. The literature also examines how data traffic, in the form of dissemination, exchange, and transmission, can be performed both within a system but in exchange with other systems. With regard to the qualitative aspects of data, their quality and reliability are considered. Further topics are data recovery and the concept of supervisory control and data acquisition (SCADA).

The domain of hardware architecture contains the components that physically constitute industrial CPS. These are mainly embedded systems that are extended by sensors that continuously record physical environmental conditions. The resulting data is processed by processors and field programmable gate arrays (FPGA). The subsequent operation of actuators, which, in turn, affect the physical environment, is carried out by controllers. Identifiers ensure the individual identifiability of each system component. Furthermore, passive components can be integrated into industrial CPS via radio-frequency identification (RFID) technologies, such as near field communication (NFC). In addition, the field of robotics is receiving a considerable amount of attention in the context of industrial CPS.

In the area of HCI, the integration of humans in industrial CPS is addressed. Against this backdrop, the literature deals, among other things, with the support of humans in the performance of physical work. E.g., cobots or collaborative robotics are used to enable humans and machines to carry out tasks jointly in order to integrate the respective superior skills optimally. Technology can also be worn on the human body as wearables; these wearables can provide physical support, as seen with (powered) exoskeletons, or can be used to provide information in the form of augmented reality (AR) and virtual reality (VR) devices. In the field of user interfaces of industrial CPS, the literature deals with different forms of human-machine-interfaces (HMI) and graphical user interfaces (GUI), which can be operated via gesture control or voice control. In the overall context of HCI, unrestrained human-machine collaboration combined with the highest standards of workplace safety is of particular importance.

The network architecture of industrial CPS draws on a variety of established technologies and concepts and adapts them to the specifics inherent in industrial CPS as needed. In general, the network architecture provides the link between the cyber sphere and the physical sphere and enables the transfer of signals and data. The literature on industrial CPS deals extensively with the subject of how network architectures can be designed in these systems and what requirements they have to meet, and a great deal of attention is paid to the networks themselves. Different types of networks and their suitability for a variety of applications due to differences in transmission power, range, and data transfer rates are considered. The first worth mentioning are sensor networks (SN), which can be divided into mobile actuator/sensor networks (MASN), wireless sensor networks (WSN) and wireless sensor and actuator networks (WSAN). These network types are used to link sensors and actuators and to ensure the transfer of measured environmental values and coordinated actuator behavior. Controller area networks (CAN) are used as a serial bus system and are particularly useful in safety-relevant areas. For short-distance applications, wireless personal area networks (WPAN), such as Bluetooth or wireless personal body networks (WPBN), offer the advantage that interference with other networks can be reduced and that there is a low power requirement for transmitting units. For large-scale coverage, the pervasive wireless local area networks (WLAN) are used. For the integration of geographically remote system units, wide area networks (WAN) are used in form of long range wide area networks (LoRaWAN) and low power wide area networks (LPWAN), which offer high energy efficiency. Cellular networks with LTE and 5G standards are also used for interconnecting widely separated system units, especially if those are mobile. Depending on the type of network and application, different protocols are used to determine the communication syntax. In the context of industrial CPS, IP, MAC, message queue telemetry transport (MQTT), TCP, and TCP/IP are mentioned in the literature. Dynamic spectrum access for the optimization of frequency spectra of connections and routing for the coordination of message streams are also being considered, as they can help to handle increased data volumes in a system-efficient manner. The subject of plant networking is also receiving a large amount of interest; therefore, plug-and-produce and (standardized) interfaces that enable the interoperability of diverse production plants with minimal setup effort are of great importance in the process of industrial CPS development. In this context of machine-to-machine communication (M2M), the OPC Unified Architecture (OPC UA) provides a platform-independent, service-oriented architecture (SOA) for the exchange of machine data.

Figure 15 provides a holistic visualization of the architecture underlying industrial CPS.

Within the realization of the already described potentials through the application of CPS they transform industrial value creation. This applies to all sequential stages and organizational levels in value chains and value networks; they can be broken down into the pre-production stage, production stage, and product in use stage.

Already in the pre-production stage, the monitoring of raw, auxiliary, and operating materials, as well as of supplier parts and construction groups intended for later production begins. Through the continuous collection and consolidation of data on smart (raw)materials/components, information regarding condition, processing, and transport becomes available in form of digital twins, already in the earliest stages of the value chain and is manipulation-proof passed on across organizational boundaries. This applies both to newly extracted raw materials and to reprocessed and renewed materials and components within the scope of lifecycle management.

In the production stage, the transformation of industrial value creation is discussed in the context of the holistic concepts, digital factory, smart factory, and smart manufacturing. Manufacturing systems that use CPS in their processes are referred to as cyber-physical production systems (CPPS). In the literature, CPPS are examined from different focal points; specifically, production system development, production execution, and production support can be clustered.

Production system development describes all activities and procedures on the way to a CPS-based production system. In the subarea design, the planning and development of the production processes takes place. Within the design space exploration, the options and alternatives for the future system configuration are discussed and structured. The subsequent IT design process can be carried out with different system level design methodologies. With component-based development, the aim is to design standardized components that can be used several times in different applications of modular systems with the same or related requirements, minimizing the amount of effort required. Contract-based development is particularly important when a large number of modules from various providers are combined into a single system. Hereby, the definition of formal contracts for the use of standardized interfaces ensures compatibility. Model-based design and development is used in particular when the intended system has a high degree of complexity. By using predefined models with advanced functional characteristics, systems can be simulated and tested in detail, even before physical engineering. Due to the previously discussed challenges associated with CPS, such as complexity, method-combining procedures are feasible. If these are participative, co-creative, or open, the term co-design is used.

Simulation is used to determine the behavior and performance, as well as the safety and security, of CPPS before they are constructed and launched. In this process, modeling is used to create a physical or digital representation of the system or its individual parts. Deliberate reductions and omissions lead to an individual abstraction of the original. Depending on the application purpose, models can take the form of formal descriptions, physical objects or computer-based virtualizations. In co-simulation, different simulation tools that use different models, each of which represents subsystems, are interconnected to enable a holistic system simulation. This procedure is particularly suitable for CPPS since components and systems from different (technical) disciplines are combined in this process. Due to the ongoing digitization and increasing automation of production through the establishment of CPS, production control continues to receive a great deal of attention in the literature. For programmable logic controllers (PLC), which are used to control systems, robots, and actuators, hardware-in-the-loop simulation is applied to make them operational before they are directly connected to the hardware to be controlled.

For the subsequent engineering of CPPS, two initial situations can be distinguished: Greenfield, when a completely new production system is designed, and brownfield/retrofit, when an existing production system is upgraded to a CPPS. In the literature, the following activities are described for both cases with the specifics that the respective initial situation entails. In requirements engineering, the first step is to define the characteristics and general parameters that the system should fulfill. One of the factors that affect the requirements for CPPS is product line engineering, which, therefore, should be considered in close connection with production line engineering. Depending on the selection of the hardware to be utilized, software engineering should be adjusted accordingly. For the combination and iterative adaptation of CPPS hardware and software, it is advantageous to prototype them before integrating them into a consistent CPPS.

In the production execution stage, the plants are operated. Manufacturing is an essential part of this. In this area, the literature deals with the effects of implementing industrial CPS on production management with the subfields process control and process management. It is also described how the application of industrial CPS enables advanced manufacturing, which refers to the execution of particularly complex production processes for the manufacturing of equally complex products, both of which are only possible through the use of digital technologies and concepts. Moreover, cloud manufacturing, which describes a less organization- and location-bound value creation through flexible, virtual production networks, benefits from the utilization of industrial CPS. Another topic that receives attention in the context of CPS-based manufacturing is industrial services. This includes service composition, which is concerned with the arrangement and orchestration of service bundles, often from various providers, that are combined to form integrated service systems. One service to be highlighted in this field is maintenance. Due to the many degrees of freedom regarding potential events and their resolution, processes related to maintenance are difficult to optimize. However, based on live sensor data and results of big data analytics, condition-based and predictive maintenance procedures can increasingly be implemented in CPPS with great optimization potential.

Overall, i.e., beyond the maintenance application, industrial CPS, with their sensors and actuators, offer vast potentials for reforming monitoring/control in production. Condition monitoring enables a meaningful and comprehensive status overview to be obtained in real-time for all equipped system components, including both production infrastructure and production parts. Event processing is focused on the continuity and real-time capability through the application of industrial CPS. This enables a reliable event-triggered control, in which events are reacted to mostly automatically with adequate measures when they occur. To prevent adverse events, predictive control uses the ability to recognize trends and patterns in data and take countermeasures before critical values are reached. Also, for the field of fuzzy control, industrial CPS offer implications for the definition of control variables as well as for the already known SCADA.

In addition to the usage of monitoring/control, the exorbitant increase in status information, and data sets generated by industrial CPS, sensor technology can also be exploited for analysis. Testing is carried out, among other activities in this area, all of which can be largely automated by model-based testing with optimized testbed conditions. These test activities can examine hardware and software as well as processes in production plants and production output. Additionally, the literature deals with validation and verification as a means for requirements fulfilment with the subfields model checking and runtime verification. In supplement to this, eigen analysis is explicitly mentioned.

The third and last subject area concerning CPPS is constituted by production support, including the area logistics. Here, the whole context of material handling within an organization but also beyond its borders is examined. Especially for warehouse systems, industrial CPS offer far-reaching application potentials, which allow for optimizations in warehouse volumes and processes through increased transparency. In addition to warehousing, internal logistics also benefit in the form of automated guided vehicles (AGV), which ensure highly automated, event-based, and system-integrated flows of materials into production. With the establishment of intelligent transportation systems (ITS), industrial CPS are also applied in logistics between geographically dispersed production sites of an organization or different organizations in a value chain, which results in supply chain optimization, including the delivery of final products to vendors and end-users.

Another area involved in production support is the smart grid integration of plants. The integration of industrial CPS in the power supply of production facilities affects the general energy efficiency of these facilities by better incorporating energy requirements, availability, and costs into production planning and execution. In addition, methods such as energy harvesting from physical processes of industrial CPS and battery management in less grid-dependent production processes offer opportunities to improve energy balances.

In the third stage, the product in use stage, industrial CPS are used to feed back relevant information regarding product performance into the CPPS. In particular, smart products, which, due to their integrated sensor and actuator technology, enable information and data generation similar to that of the production systems that manufacture them, allow monitoring throughout the entire product life cycle (product usage data). This continuously collected information regarding the condition and usage of the products is a highly valuable source for the evaluation and possible adjustment of product planning and production execution parameters.

By the holistic approach of lifecycle management, recycling or downcycling is applied at the end of product use, in the course of which the data collected over the entire product lifecycle in the form of a digital twin is, at best, reintroduced into the reprocessing or renewal in the new pre-production stage.

Apart from the subjects that can be clearly assigned to the individual stages, there are also those that are relevant across company/organization boundaries throughout the entire value chain. These include the digital twin, which combines the industrial CPS-based information of the entire lifecycles of both production plants and products. The integrated supply chain, which merges inter-organizational logistics processes due to increased transparency from industrial CPS, is another example of an activity that takes place across company/organization boundaries throughout the entire value chain. In this, procedures such as ad-hoc connectivity increase the interoperability of production systems, facilities, and services, which expands the potential realization of industrial CPS. In this context, the increasing establishment of platform ecosystems, which enable the linking of heterogeneous services and hardware to industrial CPS in the form of systems of systems, is particularly noteworthy.

A general overview of how CPS transform industrial value creation is shown in Fig. 16.

The application potentials of industrial CPS across company/organizational boundaries offer opportunities for horizontal and vertical integration/operational and strategic alliances. The horizontal integration can either be performed within a company/organization between production sites, departments, manufacturing sectors, etc., which previously operated largely independently, or along the value chain/within the value network across organizational boundaries, both upstream and downstream.

The cooperation between companies/organizations or their organizational units can be performed at the operational or strategic level (vertical integration). While integration at the operational level is mostly about technical and procedural cooperation, which coordinate the execution of value creation activities, sometimes automated, ad-hoc and for short periods of time, those at the strategic level represent rather long-term alliances between two or more partners, which closely interconnect their industrial CPS and related processes.

The schematics of these integrations and alliances are shown in Fig. 17.

5 Discussion and Outlook

In the final Section of this study, the results are discussed, contributions to extant research, highlighted and limitations pointed out. Finally, a concluding and prospective outlook is given.

5.1 Contributions

The contribution of this study is twofold. First, it provides insight into the existing literature on CPS by organizing 2365 publications according to discipline, CPS dimension, and application field. Second, the resulting data set was analyzed and transferred into a categorization of CPS related and relevant topics in the context of Industry 4.0. Thereby, this study contributes by complementing the existing topic-specific reviews and categorizations. In addition to the general category formation, the industrial CPS architecture by incorporating technological, data-driven, and socio-technical views as well as the overview of value creation on the basis of this concept, are particularly noteworthy. Thus, our results enhance the CPS concept map of Asare et al. (2012), whose overview comes the closest to the scope of this work, significantly and set the focus on industrial CPS.

Both contributions thus provide new knowledge to the research on CPS in the context of Industry 4.0. The state of research first provides insights into the distributions of publications by discipline (cf. Figs. 4 and 5). Most originate from computer science, computer engineering, and engineering, meaning that the subject area has so far been considered from a highly technical perspective. The business, value creation, and information systems perspectives have therefore been somewhat neglected, which implicates great potential for future research in these areas. It is not surprising that research was initially conducted from a technical perspective, as technological developments for specific problems are developed first and then other application scenarios or generalization potentials are considered. At this point, we are at a frontier of information systems research, which can be more involved here to contextualize the technical developments in a larger context, e.g., business, socio-technical, development with the user/stakeholder, and value creation. This is also reflected in the state of research on CPS dimensions (cf. Fig. 5). So far, there have been primarily technical studies and only a few from the organizational and human/social disciplines.

The application domains for CPS are wide ranging (cf. Fig. 6). It can therefore be confirmed that CPS are a general purpose technology. Nevertheless, it is noteworthy that many applications are in the domain of smart manufacturing. Here, a distinction can be made between discrete and process manufacturing (Ning et al., 2017; Zhang et al., 2020). There have been and are several public funding programs and initiatives in these areas due to the feasible potential. This can also be linked to fact that the application of CPS is easier to realize in an organization (on meso level) than in an overarching system.

Furthermore, the manufacturing domain was examined in more detail (cf. Fig. 7). There, as well, the application fields for CPS are wide ranging, and there are a large number of applications in industry in general. Related work by Monostori et al. (2016) also highlights the relevance of CPS in manufacturing. The literature thus suggests that we can assume far-reaching changes that qualify for an industrial revolution.

In addition to the state of research, the categorization of industrial CPS also provides several new insights for research on CPS in the context of Industry 4.0. As compared to existing taxonomies, reviews, and categorizations (cf. Section 2), our study is much more comprehensive and provides a detailed categorization and analysis of industrial CPS. We arrange our findings into 10 sections, the key conclusions of which are summarized below.

With regard to the characteristics of industrial CPS, it is apparent that CPS are a further development of systems that are oriented toward autonomous operation and independent action (cf. Fig. 8). This aspect is supported by Berger et al. (2021), who examined CPPS from a self-organizing systems’ perspective. Our results also show that CPS are clearly an enabler for Industry 4.0. Figure 10 shows that CPS have far-reaching potential that is relevant for industry, consumers, and the common good, in terms of sustainability, for example. There is also a large number of challenges to be overcome, particularly in the areas of safety and security, which is not surprising given the increased openness and interaction of entities and systems (cf. Fig. 11). Our results also contribute to an extension of the works of Liu et al. (2017) and Hofer (2018). For CPS to function properly, numerous requirements must be fulfilled (cf. Fig. 12). This point was also taken up by other authors, e.g., Asare et al. (2012), who also mentioned a few requirements in their concept map. In addition, CPS are a concept that can be seen as a hub of various complementary concepts and technologies of the digital age. CPS can only unfold their potential through interaction with these concepts and technologies (cf. Fig. 13). The relevance of CPS to complementary concepts in the context of digitalized industrial value creation has also been stated by (Kim, 2017). As shown in Fig. 14, CPS integrate humans in the form of socio-technical systems that require a user- and stakeholder-centric consideration. The architecture of CPS can be characterized as highly complex, which is also supported by other authors who described CPS architectures (Hofer, 2018; Lee et al., 2015; Pivoto et al., 2021). The architecture suggested by this study integrates software, hardware, network, data processing, and HCI components (cf. Fig. 15). CPS also offer application potential for the entire industrial value creation network (cf. Fig. 16). The interconnectivity and general network character of CPS generates potential for operational and strategic alliances with other organizations and entities (cf. Fig. 17).

The categorization of CPS related and relevant topics in the context of Industry 4.0 described above offers a variety of possible applications in practice. First, it provides an overview of the existing state of concepts and technologies in the area of industrial CPS. Thus, the categorization also serves as means of analyzing potential by documenting and evaluating existing technologies and systems and performing compatibility checks. In addition, it can be used for strategy development. Thus, organization-specific potentials and limitations regarding digitization and Industry 4.0 can be narrowed down. It can also help develop retrofit or greenfield digitization strategies. Furthermore, the categorization enables CPS design by facilitating the selection of system-relevant technologies and concepts as well as the definition of interfaces and standards. Finally, it can be used in education and training, for example through user-centered formats for knowledge transfer, in the context of system implementations, and digitization activities.

The architecture in Fig. 15 and the value creation based on industrial CPS in Fig. 16 go far beyond existing categorizations and can also be used as a design tool; a fully functional web tool was developed to that end. The web tool enables users to better comprehend industrial CPS and capture their architecture and use across the entire industrial value chain. Specifically, the tool can be applied within established methods or in the form of a canvas in workshops.

5.2 Future Work

The planned continuation of the research work is threefold: First, the state of knowledge and the categorization shall be updated by periodic repetitions of the review. On the one hand, this will allow new research foci, concepts, technologies, etc. to be observed in order to integrate them into the existing findings. On the other hand, trends, changes in thematic emphases, etc. can be identified over time, which allows statements to be made about the development of the research landscape and the implementation and application state of CPS in the context of Industry 4.0.

In addition to the scientific literature, funding projects and best practices from industry related to industrial CPS will be systematically analyzed. These can then underpin the individual topics in the categorization, particularly in the artifact Industry 4.0 Compendium, which is a functional web tool of the categorization (cf. Appendix Fig. 18), as a supplement to the scientific literature, and increase the added value for users from practice. Thus, this extension contributes to the managerial contribution. The respective systematic search and analysis process of funding projects and best practices has already started.

Furthermore, the extensive literature dataset provides an opportunity to undertake deductive—including software-assisted—analyses in order to elaborate quantitative measures and weighted links of the identified categories. In this way, the present qualitative findings of the study could be supplemented by quantitative ones, which would facilitate a more comprehensive interpretation.

5.3 Limitations

The limitations of our study are primarily determined by the subject area and the methodology. With industrial CPS, we are exploring a still relatively young and dynamic field of research. As a result, findings are constantly increasing as new developments and studies are being undertaken and published. Thus, the data presented here is only a snapshot representing the state of research and categorization of industrial CPS at one point in time. New findings and developments may have emerged in the meantime that would affect the results of this study.

The systematic literature review is influenced by the selection of literature databases and search engines. We aimed to make a selection that is as comprehensive as possible, including different disciplines and leading publishers. Search strings also influence the results of literature searches; we therefore attempted to search for publications on CPS as broadly and comprehensively as possible by using a wide variety of spellings.

The third limitation of our study results from the exclusive consideration of title, keywords, and abstract for the structured qualitative content analysis. In our opinion, this has no impact on the categorization, but it cannot be guaranteed that our approach did not necessarily exploit the complete amount of information.

5.4 Outlook