Abstract

Alternative sources for an industrial production of essential substances represent an exciting field of study for many researchers. Based on the previous research, itaconic acid and its esters were intensively studied as one of the sources. This paper relates to a determination of the basic physical–chemical properties of bis(2-methylbutyl) itaconate and bis(3-methylbutyl) itaconate that are produced from itaconic acid and 2-methylbutan-1-ol and 3-methylbutan-1-ol, respectively, from biomass. According to our best knowledge, physical–chemical properties of these substances, such as density, viscosity, and saturated vapor pressure, are not presented in the literature, and these are important for the future research of their production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The growing consumption and depletion of fossil resources force researchers to find new alternative sources to produce essential substances in the chemical industry. Itaconic acid (IA) and its esters represent an interesting bio-based and widely applicable compounds due to their molecular structure and properties. A report from the Biomass Program of the US Department of Energy [1] presents IA as one of the most promising bio-based feedstocks. A presence of a double bond in the methylene group leads to a potential polymerization, and therefore to its use in polymer chemistry. The IA polymerization was intensively studied and applied [2, 3]. Moreover, IA represents a sustainable resource for resins, polymers, and dyes production and should also be used as a super-absorbent, detergent, or bioactive substance in agriculture or the production of pharmaceuticals [4]. IA was identified as a product of the biosynthetic process of various microorganisms [4,5,6,7,8,9].

2-methylbutan-1-ol (2-MBuOH) is a natural component in fragrances of grapes, nectarines, apples, oranges or tomatoes [10]. Moreover, it is a component of fusel alcohol that is formed during the natural fermentation process that should increase a potential application in many fields due to its low toxicity [11,12,13]. In addition, fusel alcohol should be potentially used as an alternative fuel or in production of bio lubricants that are eco-safe and naturally harmless. Even 2-MBuOH, as one of the representatives of higher alcohols, should be considered as a new bio-based fuel replacing ethanol [14].

3-methylbutan-1-ol (3-MBuOH) is a main component of fusel alcohol mentioned above. 3-MBuOH is used in production of a banana oil, mainly in a cosmetic industry. The natural or synthetic esters are widely used in a food industry as flavors; for instance, banana, cherry, apricot, plum, whisky or pralines [13].

Due to the high demand for bio-based materials in academic and industrial areas, IA and its esters are currently appreciated and intensively studied for their properties. In our previous work [15, 16], we focused on physical–chemical properties of dimethyl-, diethyl-, di-n-propyl-, (bis)isopropyl-, and di-n-butyl itaconates, same as the relevant methylsuccinates that also represent an interesting bio-based compounds for a various application. Dimethyl itaconate or 4-octyl itaconate are intensively studied for their application in pharmacy, due to their immunoregulative and anti-inflammatory effects [17, 18]. Moreover, other itaconates are deeply studied in the field of cancer treatment, same as the treatment of bacterial or viral diseases. In an area of a dental hygiene, IA monoesters exhibit an excellent hardness, resistance to pressure, and they should be therefore applied as dental fillers and adhesives. In addition, itaconates; for instance, dibutyl itaconate, finds an application in adhesives, plasticizers, lubricants, anti-corrosion additives or detergent additives [19, 20]. A polymer chemistry represents an important field of itaconates uses, where mostly a synthesis of various elastomers was studied by several authors [21,22,23].

A determination of a new experimental data set of the esters’ properties is essential for future research in this field because these esters are manufactured by reactive distillation processes. For research and development of these bio-based compounds, it is necessary to know their basic physical–chemical properties. Therefore, this work is focused on the determination of the basic properties of two itaconic acid esters with the potential for commercial use, such as density, viscosity, and saturated vapor pressure.

2 Experimental

2.1 Chemicals

The chemicals used in this paper are summarized in Table 1.

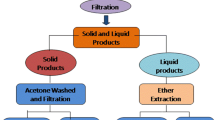

2.2 Methodology of Synthesis of Itaconic Acid Esters

Before measuring physical and chemical properties, itaconic acid esters were laboratory synthesized by a reactive distillation process. The apparatus for the diesters’ synthesis is shown in Fig. 1. For the synthesis, the bottom of the distillation column represents the reaction section. IA and relevant alcohol (initial molar ratio 1:3) were placed into the three-necked flask together with p-toluenesulfonic acid as the catalyst (1 wt %), phenothiazine, 4-methoxyphenol and hydroquinone (100 ppm total) as the polymerization inhibitors. The condensed two-phase azeotropic mixture containing water and alcohol was separated, the organic phase was recycled, and the aqueous phase was removed from the system. The chemical equilibrium is being shifted towards the esterification products, leading to the total conversion of IA after water removal out of the reaction system. As a result, mono- and diesters are formed, while diester is preferably formed at higher IA conversion. The reactive distillation was carried out at the maximum boiling point of the reaction mixture 383 K, kept by controlling the pressure. A higher boiling temperature of the reaction mixture is not desirable due to the higher level of IA and esters’ polymerization. The produced relevant diester contains about 1 % to 5 % of alcohol, 1 % to 2 % of monoester, and the catalyst. Therefore, the diester has to be purified by an extraction process (five cycles) with water (volume ratio diester/water 1/7) to separate the catalyst and finally distilled (column with ten theoretical plates) under lower pressure. The final product was achieved with the final concentration higher than 99.5 mol % that was verified by GC–MS (GC: Shimadzu GC2010 Ultra, MS: Shimadzu GCMSQP2010) with DB-5MS column (35 m × 0.33 mm × 0.2 μm) and the temperature program of initial temperature 80 °C and hold time 1 min, temperature ramp 10 °C·min−1 up to 280 °C and hold time 4 min. Helium was used as a carrier gas. The parameters of the used MS were: ion source temperature 280 °C, interface temperature 250 °C, detector voltage 900 V, start m/z 10, end m/z 250. The water content in the final product was lower than 0.01 %, the content of p-toluenesulfonic acid was under the detection limit.

The apparatus for diesters’ synthesis: (1) a magnetic stirrer and heater; (2) a three-necked flask with the reaction mixture; (3) a PT100 probe; (4) a sample taking capillary; (5) a distillation column; (6) a cooler; (7) a separator of a two-phase azeotropic mixture; (8) a flask for the aqueous phase removal

2.3 Determination of Density

The pycnometric determination of the tested esters’ density was performed. The calibration of the pycnometer (50 cm3) was performed with demineralized and degassed water at all temperatures, calculation of water density at relevant temperature was obtained from [24]. Five independent pycnometers were used to avoid a systematic error, and the volume of each pycnometer was determined ten times (uncertainty of the pycnometer volume is 0.022 cm3 as a combination of mass balance deviation and measurement reproducibility). The dilatation of the pycnometer was negligible, and it is involved in the value of the standard uncertainty of density. In total, the uncertainty of density was calculated as a combination of mass balance deviation, pycnometers’ volume uncertainty and dilatation, and measurements reproducibility. Water (producer UCT Prague) was passed through the reverse osmosis (apparatus: Goro Aqua 65), and a conductivity of 1.621 μS·cm−1 was measured at 293.15 K (apparatus: Thermo Scientific Orion Star A 212). Impurities were controlled by gas chromatography with a thermal-conductivity detector (GC-TCD). The experimental determination of esters’ density was performed in the temperature range from 303 K to 353 K. The pycnometers were tempered at the requested temperature for 60 min. The final value of the presented density for various esters is an average of ten independent measurements. The quality of the experimental data was evaluated by a mean absolute deviation (MAD), calculated as follows:

The relation between the density and thermodynamic temperature was evaluated in Aspen Plus (V12.1) simulation software by the DIPPR equation (Eq. 2), which coefficients were obtained from the experimental data of pure components.

where \(\rho\) is density of a pure component, Ai are adjustable constants, and T is thermodynamic temperature.

The quality of the experimental data fitting by the DIPPR equation was evaluated based on calculated average absolute deviation (AAD) values for temperature and density specified by the following equations:

where \({T}^{\text{exp}}\) is experimental temperature, \({T}^{\text{cal}}\) is calculated temperature by the model, \({\rho }^{\text{exp}}\) is experimental density, \({\rho }^{\text{cal}}\) is calculated density by the model.

2.4 Determination of Dynamic Viscosity

Standard capillary Ubbelohde type viscometers were used to determine esters’ viscosity. The viscometer was placed in the water bath tempered at the requested temperature. A difference of 0.1 K to 0.2 K was observed between the set bath temperature and the liquid temperature in the viscometer. Therefore, the bath temperature was set up higher to keep the requested temperature of the liquid in the viscometer. For the viscosity measurements, the liquid is placed in the viscometers’ reservoir and then sucked through the capillary and measuring bulb. The measurement is based on the efflux time needed for the liquid to pass through two marking lines (efflux time for all measurements was at least 120 s), and the kinematic viscosity is subsequently calculated from Hagen–Poiseuille law. The relation between kinematic and dynamic viscosity is expressed by Eq. 5, where the density at the relevant temperature was calculated from the previous pycnometric measurements. The viscometer calibration was performed with demineralized and degassed water at all relevant temperatures. As a result, the dynamic viscosity could be determined from Eq. 6.

where η represents dynamic viscosity of the relevant ester, \({\eta }_{\text{ref}}\) represents dynamic viscosity of water under relevant temperature calculated from [24], \(\tau\) is time of the ester flow through the viscometer, \({\tau }_{\text{ref}}\) is time of the water flow through the viscometer, and it represents a mean absolute value of ten independent measurements, \(\rho\) is density of measured ester, \({\rho }_{\text{ref}}\) is density of water at relevant temperature calculated from [24], ν represents kinematic viscosity. The final presented value of esters’ dynamic viscosity is an average of ten independent measurements. The absolute value of the standard uncertainty of dynamic viscosity is the combination of calibration uncertainty and measurements reproducibility. The quality of the experimental viscosity data was evaluated by MAD calculated by Eq. 1.

The relation between the dynamic viscosity and thermodynamic temperature was evaluated by the Andrade equation (Eq. 7) in Aspen Plus simulation software, which coefficients were obtained from the experimental data of pure components.

where \(\eta\) is dynamic viscosity of a pure component, Bi are adjustable constants, and T is thermodynamic temperature.

The quality of the experimental data fitting by the Andrade equation was evaluated based on the calculated AAD values. For temperature, AAD values are expressed by Eq. 3; for viscosity, these are specified by the following equation:

where \({\eta }^{\text{exp}}\) is experimentally determined dynamic viscosity and \({\eta }^{\text{cal}}\) is dynamic viscosity calculated by the model.

2.5 Determination of Saturated Vapor Pressure

Achieving the equilibrium between the liquid and vapor phases of a pure component is the essential condition for determining saturated vapor pressure. The determination of saturated vapor pressure was conducted in the apparatus shown in our previous paper [15]. Vapor pressure of the system was measured by a pre-calibrated manometer Fluke 700GA4 (a standard uncertainty ± 0.06 kPa). The temperature measurements were performed by ETI reference thermometer with PT100 probe with a standard uncertainty ± 0.07 K and resolution 0.01, UKAS certified. The calibration of the experimental procedure was performed on pure sulfolane, while the reference extended Antoine model was taken from the Aspen Plus (V12.1) simulation software. The comparison between the reference model and the experimental calibration data are shown in Fig. S1 in the Supplementary information file.

The relation between the saturated vapor pressure and thermodynamic temperature was evaluated in Aspen Plus simulation software by the Antoine equation (Eq. 9), which coefficients were obtained from the experimental data of pure components.

where \({p}_{\text{L}}\) is the saturated vapor pressure of a pure component, Ci are adjustable constants, and T is thermodynamic temperature.

The quality of experimental data fitting by the Antoine equation was evaluated based on calculated AAD values for temperature (Eq. 3) and saturated vapor pressure that is specified by the following equation:

where \({p}_{\text{L}}^{\text{exp}}\) is experimentally determined saturated vapor pressure and \({p}_{\text{L}}^{\text{cal}}\) is saturated vapor pressure calculated by the Antoine model.

3 Results and Discussion

3.1 Determination of Density

The experimental data of the density of 2-MBuITA and 3-MBuITA at various temperatures are presented in Table 2. These data are not present in the literature so far, and this paper is the first one to do so. The quality of the experimental data is presented in Fig. S2 in the Supplementary information by a column graph, where MAD values for each experimental point are shown. The experimental data were fitted in Aspen Plus simulation software by the DIPPR equation. The obtained parameters of the DIPPR model are listed in Table 3. The parameters of the model are in K and mol·l−1-units. Therefore, the results should be multiplied by the relevant esters’ molecular mass to recalculate the values into kg·m−3-units. Values of AAD expressing the conformity of the experimental and calculated data for temperature and density are also summarized in Table 3. According to these values, the chosen models fit the experimental data with high precision, and these models should be used for a data prediction in a wide range of temperatures. The graphical expression of the experimental data fitting by the DIPPR model is shown in Fig. 2.

3.2 Determination of Viscosity

The experimental data of dynamic viscosity and calculated values of kinematic viscosity of 2-MBuITA and 3-MBuITA at various temperatures are presented in Table 4. According to our best knowledge, the literature does not offer any relevant kinematic or dynamic viscosity data, same as the density data. The quality of the experimental data is presented in Fig. S3 in the Supplementary information file by a column graph, where MAD values for each experimental point are shown. The experimental data were fitted by the Andrade equation in Aspen Plus simulation software. The obtained constants of the Andrade model are presented in Table 5 together with AAD values for temperature and dynamic viscosity characterizing the conformity of the model and the experimental data. According to these values, the chosen models fit the experimental data with high precision, and it could be used to predict viscosity at various conditions. The graphical expression of the experimental data fitting by the Andrade model is listed in Fig. 3.

3.3 Determination of Saturated Vapor Pressure

The experimental data of the saturated vapor pressures of the studied 2-MBuITA and 3-MBuITA are presented in Table 6. The data were fitted by the Antoine equation in Aspen Plus simulation software, and the calculated parameters are presented in Table 7 together with the values of AAD for temperature and saturated vapor pressure characterizing the conformity of the calculated Antoine model and the experimental data. According to the values, the Antoine models fit the experimental data with high precision for both studied esters. The graphical expressions of the Antoine model and the experimental data conformity for both itaconates’ saturated vapor pressures are presented in Fig. 4.

4 Conclusions

This paper provides a new comprehensive experimental data set of fundamental properties of bis(2-methylbutyl) itaconate and bis(3-methylbutyl) itaconate. These bio-based itaconates represent an exciting alternative for replacing esters performed from fossil resources in many industrial areas. The ultimate contribution of this work is the basic knowledge about the physical–chemical properties of these esters, such as density, viscosity, and saturated vapor pressure. These properties are essential for a future research in itaconates’ production. According to our best knowledge, no complete data sets of these fundamental properties are published in the literature. The experimental data were evaluated and subsequently fitted in Aspen Plus simulation software by relevant models for each property. The quality of the data fitting was verified by AAD values. The results show that chosen models fit the experimental data with high precision, and they should be used for further process simulations.

Data Availability

All data generated or analyzed during this study are included in this article and Supplementary Information file.

Abbreviations

- IA:

-

Itaconic acid

- 2-MBuOH:

-

2-methylbutan-1-ol

- 3-MBuOH:

-

3-methylbutan-1-ol

- 2-MBuITA:

-

bis(2-methylbutyl) itaconate

- 3-MBuITA:

-

bis(3-methylbutyl) itaconate

- GC–MS:

-

Gas chromatography-mass spectrometry

- GC-TCD:

-

Gas chromatography with a thermal-conductivity detector

- MAD:

-

Mean absolute deviation

- AAD:

-

Average absolute deviation

References

T. Werpy, G. Petersen, Top value added chemicals from biomass (the pacific northwest national library and the national renewable energy laboratory, 2004), https://www.nrel.gov/docs/fy04osti/35523.pdf. Accessed 12 June 2024

B. Cornils, P. Lappe, Updated by Staff in Ullmann’s Encyclopedia of Industrial Chemistry (Wiley-VCH, Weinheim, 2014), pp.1–18

J.T. Trotta, A. Watts, A.R. Wong, A.M. LaPointe, M.A. Hillmyer, B.P. Fors, A.C.S. Sustain, Chem. Eng. 7, 2691 (2019)

B.C. Saha, G.J. Kennedy, N. Qureshi, M.J. Bowman, Biotechnol. Prog. 33, 1059 (2017)

J.C. De Carvalho, A.I. Magalhaes Jr., C.R. Soccol, Chim. Oggi 36, 56 (2018)

T. Klement, J. Buechs, Bioresour. Technol. 135, 422 (2013)

A. Kuenz, Y. Gallenmueller, T. Willke, K.-D. Vorlop, Appl. Microbiol. Biotechnol. 96, 1209 (2012)

W.E. Levinson, C.P. Kurtzman, T.M. Kuo, Enzyme Microb. Technol. 39, 824 (2006)

N. Maassen, M. Panakova, N. Wierckx, E. Geiser, M. Zimmermann, M. Boelker, U. Klinner, L.M. Blank, Eng. Life Sci. 14, 129 (2014)

P. H. Howard, Handbook of Environmental Fate and Exposure Data for Organic Chemicals, vol. IV, 1st edn. (CRC Press., New York, 1993), pp. 392–397

M. Bandres, P. De Caro, S. Thiebaud-Roux, M.E. Borredon, C. R. Chimie. 14, 636 (2011)

National Center for Biotechnology Information. "PubChem Compound Summary for CID 31260, Isoamyl alcohol" PubChem, https://pubchem.ncbi.nlm.nih.gov/compound/Isoamyl-alcohol. Accessed 12 June 2024

Ataman Kimya. Product list ISOAMYL ALCOHOL, https://atamankimya.com/sayfalar.asp?LanguageID=2&cid=3&id=13&id2=10409. Accessed 12 June 2024

Y.J. Choi, J. Lee, Y.S. Jang, S.Y. Lee, MBio 5, e01524 (2014)

J. Trejbal, M. Zapletal, A. Obuchov, T. Sommer, Int. J. Therm. 43, 51 (2022)

M. Zapletal, J. Pokorný, J. Trejbal, T. Sommer, Int. J. Therm. 43, 120 (2022)

J. Lin, J. Ren, D.S. Gao, Y. Dai, L. Yu, Front. Chem. 9, 669308 (2021)

D. Olagnier, E. Farahani, J. Thyrsted et al., Nat. Commun. 11, 4938 (2020)

T. Willke, K.D. Vorlop, App. Microbiol. Biotechnol. 56, 289 (2001)

Y. Yu, S. Wang, Z. Yang, F. Wang, L. Deng, J. Chem. Technol. Biot. 95, 2879 (2020)

H. Ji, H. Yang, X. Zhou, C. Sun, L. Li, S. Zhao, J. Yu, S. Li, R. Wang, L. Zhang, Compos. B Eng. 248, 110383 (2023)

Y. Shou, S.B. Campbell, A. Lam, A.J. Lausch, J.P. Santerre, M. Radisic, L. Davenport Huyer, ACS App. Polym. Mater. 3, 1943 (2021)

R. Wang, J. Ma, X. Zhou, Z. Wang, H. Kang, L. Zhang, K.C. Hua, J. Kulig, Macromolecules 45, 6830 (2012)

Design Institute for Physical Properties, DIPPR Project 801 Sponsored by AIChE, https://app.knovel.com/kn/resources/kt0139HQD2/kpDIPPRPF7/html?cid=kt0139HQD2&curve_ids=kr0DKKY2G1&page=1&rcid=kpDIPPRPF7. Accessed 12 June 2024

Funding

Open access publishing supported by the National Technical Library in Prague. Authors declare that no funding has been received for the research reported in this manuscript.

Author information

Authors and Affiliations

Contributions

Martin Zapletal - conceptualization, experimental determination 2-MBuITA and 3-MBuITA dynamic viscosity; Tomáš Dlugoš - experimental determination of 3-MBuITA density; Marek Plachý - experimental determination of 2-MBuITA density; Tomáš Sommer - experimental determination of saturated vapor pressure, data fitting, manuscript writing; Jiří Trejbal - conceptualization, data fitting, supervising.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zapletal, M., Dlugoš, T., Plachý, M. et al. Determination of Various Physical–Chemical Properties of bis(2-Methylbutyl) Itaconate and bis(3-Methylbutyl) Itaconate from Bio-Based Resources. Int J Thermophys 45, 110 (2024). https://doi.org/10.1007/s10765-024-03402-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-024-03402-7