Abstract

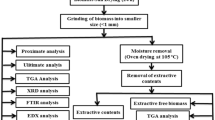

Sustainable technologies provide a route to address future energy needs by converting lignocellulosic biomass into fuels, eco-friendly substances, and chemicals. These advancements hold promise as substitutes for fossil fuels while maintaining a carbon–neutral footprint. The current research is centered around investigating the potential of biomass waste betel nut inflorescence (BNI), red lucky nut seed pod (RLP), and Cycas circinalis seed shell (CSS) for producing biofuels through thorough physiochemical analysis. Various methods were used to characterize the selected biomass waste, including proximate and ultimate analysis, TGA, FTIR spectroscopy, and XRD. Among the studied biomass types, the CSS biomass exhibited the highest calorific value, 16.36 MJ/kg. Lowest value is reported 13.50 MJ/kg for BNI. Alcoholic and phenolic functional groups, along with alkanes, alkenes, and certain aromatic compounds, were detected in all biomass samples. The XRD results indicate that all biomass exhibits an amorphous structure with low-intensity peaks indicative of cellulose presence. In each instance, the highest weight reduction occurred between 200 and 500 °C during thermal pyrolysis. To understand the kinetics of the process, model-free techniques like Kissinger–Akahira–Sunose (KAS) and Flynn–Wall–Ozawa (FWO) were employed to determine the kinetic parameters. The activation energies obtained from both the FWO and KAS models were around 274.19 kJ/mol, 161.17 kJ/mol, and 333.92 kJ/mol for CSS, BNI, and RLP biomass, respectively. The absence of sulfur and minimal nitrogen content observed in all analyzed biomass samples underscores their environmentally favorable attributes. The research findings substantiate the viability of the selected biomass feedstocks for utilization in bioenergy production.

Similar content being viewed by others

Data availability

Data sharing is not applicable—no new data generated.

References

Benny M, Suraj P, Arun P, Muraleedharan C (2023) Agglomeration behavior of lignocellulosic biomasses in fluidized bed gasification: a comprehensive review. J Therm Anal Calorim 148:9289–9308

Nandhini R, Berslin D, Sivaprakash B et al (2022) Thermochemical conversion of municipal solid waste into energy and hydrogen: a review. Environ Chem Lett 20:1645–1669

Shah S, Venkatramanan V (2019) Advances in microbial technology for upscaling sustainable biofuel production. In: New and future developments in microbial biotechnology and bioengineering. Elsevier 69–76

Chen Z, Hu M, Zhu X et al (2015) Characteristics and kinetic study on pyrolysis of five lignocellulosic biomass via thermogravimetric analysis. Bioresour Technol 192:441–450

Liu H, Zhao B, Zhang X, Zhang Y (2022) Influence of intrinsic physicochemical properties of agroforestry waste on its pyrolysis characteristics and behavior. Materials 16:222

Mishra RK, Naik SU, Chistie SM et al (2022) Pyrolysis of agricultural waste in a thermogravimetric analyzer: studies of physicochemical properties, kinetics behaviour, and gas compositions. Mater Sci Energy Technol 5:399–410

Geronà MS, Melo RC, Barros HLM et al (2020) Advances in the research of Adenanthera pavonina: from traditional use to intellectual property. J Med Plants Res 14:24–53

Lindamulage IK, Soysa P (2016) Evaluation of anticancer properties of a decoction containing Adenanthera pavonina L. and Thespesia populnea L. BMC Complement Altern Med 16:1–8

Mujahid M, Ansari VA, Sirbaiya AK et al (2016) An insight of pharmacognostic and phytopharmacology study of Adenanthera pavonina. J Chem Pharm Res 8:586–596

Dangore-Khasbage S, Bhowate RR, Khubchandani M, Bhowate R (2023) Chemical composition of areca nut and its adverse effects on human health. Cureus 15:8

Zulkarnain AS, Shahruddin AF, Aspawani NB, Abd Kadir A (2023) The use of areca nut fiber in soundproof particle board manufacturing. Multidiscip Appl Res Innov 4:10–16

Rai S, Raychaudhuri R, Kudarha R et al (2023) Bioderived cellulose fibre-guar gum grafted poly (N, N′-dimethylacrylamide) polymer network for controlled release of metformin hydrochloride. Int J Biol Macromol 253:126882

Farma R, Winalda B, Apriyani I (2023) The self-adhesive properties of carbon activated-like shape coin derived from Palmae plant waste and used as high-performance supercapacitor electrodes. J Electrochem Energy Convers Storage 20:020902

Das N, Srivastava V, Goswami R, Kumar A (2023) Development of low-cost filters for the treatment of water polluted with food waste leachate. Holist Approach Environ 13:32–39

Subran N, Ajit K, Krishnan H et al (2023) Synthesis and performance of a cathode catalyst derived from areca nut husk in microbial fuel cell. Chemosphere 312:137303

Ravi A, Hemapriya J, Sudha PN, Revathi S, Sasirekha R, Vijayanand S (2023) Nanobiomaterials in bioremediation In: Nanobiomaterials. CRC Press 283–313

Vanisree GS, Aparna K (2022) Thermochemical characterization of Cycas circinalis seed shell to evaluate their potential as biofuel source. IOP Conf Ser: Mater Sci Eng 1221:012016

Noora B, Sudheesh C, Sangeetha N, Sunooj KV (2019) Effect of isolation methods on the crystalline, pasting, thermal properties and antioxidant activity of starch from queen sago (Cycas circinalis) seed. J Food Meas Charact 13:2147–2156

Taylor GW (2008) Save Our Sagos TM A Pesticide Spray Additive that enhances the effectiveness of pesticides used to combat armored scale insects (ie Cycad Asian Scale (CAS))

Yao Z, Cai D, Chen X et al (2024) Thermal behavior and kinetic study on the co-pyrolysis of biomass with polymer waste. Biomass Convers Biorefinery 14:1651–1662

Seah CC, Tan CH, Arifin N et al (2023) Co-pyrolysis of biomass and plastic: circularity of wastes and comprehensive review of synergistic mechanism. Results Eng 17:100989

Hamzah HT, Veluru S, Hasan HM et al (2023) Microwave assisted pyrolysis of biomass feedstock fundamentals and the effect of process parameters-a review. J Phys: Conf Ser 2550:012003

Polat S, Sayan P (2023) Assessment of the thermal pyrolysis characteristics and kinetic parameters of spent coffee waste: a TGA-MS study. Energy Sources Part Recover Util Environ Eff 45:74–87

Kaur R, Kumar A, Biswas B et al (2024) Py-GC/MS and pyrolysis studies of eucalyptus, mentha, and palmarosa biomass. Biomass Convers Biorefinery 14:5319–5330

Cai W, Liu Q, Shen D, Wang J (2019) Py-GC/MS analysis on product distribution of two-staged biomass pyrolysis. J Anal Appl Pyrolysis 138:62–69

Tsuge S, Ohtani H (1997) Structural characterization of polymeric materials by pyrolysis—GC/MS. Polym Degrad Stab 58:109–130

Bensidhom G, Arabiourrutia M, Trabelsi ABH et al (2021) Fast pyrolysis of date palm biomass using Py-GCMS. J Energy Inst 99:229–239

Olatunji OO, Akinlabi S, Madushele N et al (2021) Geospatial investigation of physicochemical properties and thermodynamic parameters of biomass residue for energy generation. Biomass Convers Biorefinery 11:2813–2827

Kaur R, Gera P, Jha MK, Bhaskar T (2018) Pyrolysis kinetics and thermodynamic parameters of castor (Ricinus communis) residue using thermogravimetric analysis. Bioresour Technol 250:422–428

Narnaware SL, Panwar N (2022) Kinetic study on pyrolysis of mustard stalk using thermogravimetric analysis. Bioresour Technol Rep 17:100942

Ahmad MS, Mehmood MA, Al Ayed OS et al (2017) Kinetic analyses and pyrolytic behavior of Para grass (Urochloa mutica) for its bioenergy potential. Bioresour Technol 224:708–713

Flynn JH, Wall LA (1966) A quick, direct method for the determination of activation energy from thermogravimetric data. J Polym Sci [B] 4:323–328

de Paiva EM, Mattos ALA, da Silva JCG et al (2024) Pyrolysis of cashew nutshell residues for bioenergy and renewable chemicals: kinetics, thermodynamics, and volatile products. J Anal Appl Pyrolysis 177:106303

Bakhattar I, Asbik M, Koukouch A, Aadnan I, Zegaoui O, Belandria V, Sarh B (2023) Physicochemical characterization, thermal analysis and pyrolysis kinetics of lignocellulosic biomasses. Biofuels 14:1015–1026

Kavimani V, Divakaran D, Sriariyanun M, Suganya Priyadharshini G, Gopal PM, Suyambulingam I, Siengchin S (2023) Facile exfoliation and physicochemical characterization of biomass-based cellulose derived from Pandanus tectorius leaves for sustainable environment. Biomass Conv Bioref 25:1–12

Poyilil S, Palatel A, Chandrasekharan M (2021) Physico-chemical characterization study of coffee husk for feasibility assessment in fluidized bed gasification process. Environ Sci Pollut Res 29:51041–51053

He J, Strezov V, Kumar R et al (2019) Pyrolysis of heavy metal contaminated Avicennia marina biomass from phytoremediation: characterisation of biomass and pyrolysis products. J Clean Prod 234:1235–1245

Oliveira ÉR, Carvalho GR, Santos PR, Queiroz F (2020) Green coffee (Coffea arabica) and its residual biomass: characterization for the industrial approach. Curr Nutr Food Sci 16:1072–1087

Lu H, Zhang L, Liu C et al (2018) A novel method to prepare lignocellulose nanofibrils directly from bamboo chips. Cellulose 25:7043–7051

Tiwari AK, Prasad N, Jana SK et al (2022) Waste biomass valorisation of Bambusa vulgaris dust and Delonix regia pods: characterization and kinetic study. Sustain Energy Technol Assess 53:102590

Siddiqi H, Bal M, Kumari U, Meikap B (2020) In-depth physiochemical characterization and detailed thermo-kinetic study of biomass wastes to analyze its energy potential. Renew Energy 148:756–771

Prasad BR, Suman P, Ghosh G, Padhi RK (2023) Physicochemical characterisation of lignocellulosic biomass for the identification of potential candidacy towards alternative renewable energy. International Conference on Power, Instrumentation, Energy and Control (PIECON) IEEE, pp 1–5

Ondachi P, Ozigis II, Zarmai MT (2023) Physicochemical characterisation of Abuja’s municipal solid wastes as a renewable energy resource. ABUAD J Eng Res Dev 6:38–43

Ali RM, El Katory M, Hassaan M et al (2020) Highly crystalline heterogeneous catalyst synthesis from industrial waste for sustainable biodiesel production. Egypt J Chem 63:1161–1178

Cheah CB, Ramli M (2011) The implementation of wood waste ash as a partial cement replacement material in the production of structural grade concrete and mortar: an overview. Resour Conserv Recycl 55:669–685

Lozano DCP, Jones HE, Reina TR et al (2021) Unlocking the potential of biofuels via reaction pathways in van Krevelen diagrams. Green Chem 23:8949–8963

Prins MJ, Ptasinski KJ, Janssen FJ (2007) From coal to biomass gasification: comparison of thermodynamic efficiency. Energy 32:1248–1259

Garba K, Mohammed IY, Isa YM et al (2023) Pyrolysis of Canarium schweinfurthii hard-shell: thermochemical characterisation and pyrolytic kinetics studies. Heliyon 9:13234

Barzegar R, Yozgatligil A, Olgun H, Atimtay AT (2020) TGA and kinetic study of different torrefaction conditions of wood biomass under air and oxy-fuel combustion atmospheres. J Energy Inst 93:889–898

Gajera B, Panwar N (2023) Pyrolysis and kinetic behaviour of black gram straw using thermogravimetric analysis. Energy Sources Part Recover Util Environ Eff 45:2371–2384

Suresh Kumar P, Edwin M, Bensam Raj J (2023) Pyrolysis characteristics and kinetic analysis of Indian almond fruit biomass by thermogravimetric analysis for the potential source of bioenergy. Proc Inst Mech Eng Part E J Process Mech Eng 237:290–299

El-Sayed SA, Khass TM, Mostafa ME (2023) Thermal degradation behaviour and chemical kinetic characteristics of biomass pyrolysis using TG/DTG/DTA techniques. Biomass Conv Bioref 25:1–25

Yang Y, Jiang C-Y, Niu M, Tsai Y-T (2023) Experimental study on combustion and explosion characteristics of different biomass powders. J Therm Anal Calorim 148:4769–4777

Shah MA, Hayder G, Kumar R et al (2023) Development of sustainable biomass residues for biofuels applications. Sci Rep 13:14248

Alabi AO, Sambo AS (2023) Comparative bio-energy potential of De-oiled coconut pulp and coconut shell: insights from physicochemical characterization, pyrolysis kinetics and thermodynamic studies. Fuel Process Technol 243:107658

Jitumoni B, Dixit SA, Pradeep P et al (2023) Study of thermal cracking kinetics and co-processing of biocrude in thermal residual upgradation unit for converting ‘waste to energy.’ J Therm Anal Calorim 148:3439–3456

Pattanayak S, Loha C (2023) Investigation of kinetic triplets and thermodynamic parameters of different species of bamboo-biomass from North-East India. Int J Chem Kinet 55:335–349

Rajamohan S, Le TT (2023) Insight into the thermodynamic and kinetic analysis of Tamarindus indica shell using thermogravimetric analysis. Energy Sources Part Recover Util Environ Eff 45:8737–8750

Mishra A, Nanda S, Parida MR et al (2023) A comparative study on pyrolysis kinetics and thermodynamic parameters of little millet and sunflower stems biomass using thermogravimetric analysis. Bioresour Technol 367:128231

Pinzi S, Buratti C, Bartocci P et al (2020) A simplified method for kinetic modeling of coffee silver skin pyrolysis by coupling pseudo-components peaks deconvolution analysis and model free-isoconversional methods. Fuel 278:118260

Yuan X, He T, Cao H, Yuan Q (2017) Cattle manure pyrolysis process: kinetic and thermodynamic analysis with isoconversional methods. Renew Energy 107:489–496

Clemente-Castro S, Palma A, Ruiz-Montoya M et al (2022) Pyrolysis kinetic, thermodynamic and product analysis of different leguminous biomasses by Kissinger-Akahira-Sunose and pyrolysis-gas chromatography-mass spectrometry. J Anal Appl Pyrolysis 162:105457

Pawar A, Panwar N, Jain S et al (2023) Thermal degradation of coconut husk waste biomass under non-isothermal condition. Biomass Convers Biorefinery 13:7613–7622

Choudhury ND, Bhuyan N, Bordoloi N et al (2021) Production of bio-oil from coir pith via pyrolysis: kinetics, thermodynamics, and optimization using response surface methodology. Biomass Convers Biorefinery 11:2881–2898

Ivanovski M, Petrovic A, Ban I et al (2021) Determination of the kinetics and thermodynamic parameters of lignocellulosic biomass subjected to the torrefaction process. Materials 14:7877

Tiwari M, Dirbeba MJ, Lehmusto J et al (2024) Analytical and applied pyrolysis of challenging biomass feedstocks: effect of pyrolysis conditions on product yield and composition. J Anal Appl Pyrolysis 177:106355

Acknowledgements

The authors would like to extend their heartfelt appreciation to the Department of Chemical Engineering at the National Institute of Technology Calicut (NITC) for generously providing the essential research facilities. Furthermore, the authors would like to convey their thanks to the Department of School of Material Science and Engineering at NITC for their kind assistance in conducting characterization. The authors are also indebted to STIC–CUSAT for their expertise and support in performing CHNS elemental analysis.

Funding

The authors wish to express their sincere gratitude for the invaluable financial support received from the Ministry of Education (India).

Author information

Authors and Affiliations

Contributions

Vanisree GS: conceptualization, methodology, formal analysis, experimentation validation, and writing a manuscript. Akash M Chandran: plotting, analysis, review, and editing. Aparna K: guidance, review, and proofreading.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vanisree, G.S., Chandran, A.M. & Aparna, K. Investigation on thermochemical characteristics and pyrolysis kinetics of lignocellulosic biomass for biofuel production feasibility. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05657-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05657-4