Abstract

This publication presents the results of the fundamental research on the interaction of laser radiation and lignocellulosic fibres with respect to the melting of the fibre main components cellulose, hemicellulose and lignin. In the first part, hand sheets made of different lignocellulosic fibres were irradiated with laser radiation from a carbon monoxide laser. Fluence-dependent interaction regimes, the dynamics of flash pyrolysis and chemical changes due to irradiation are discussed. Using a high-speed camera, an intermediate liquid state could be observed as a result of the irradiation. This is decomposed into gaseous reaction products by a highly dynamic boiling process. In addition to the time-resolved investigations, extensive FTIR studies were carried out. The second part is intended to further investigate former work on melting of cellulose. The basic idea is to combine laser radiation and mechanical pressure by compressing the sample between two steel bolts and simultaneously irradiating the joint. The processed samples show some visual indications of intermediate melting, such as increased transparency or flow behaviour. However, these can be traced back to effects that do not require a melting state.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cellulose is the most abundant polymer on earth (O’Sullivan 1997) and the main component of paper and paper products. Packaging in particular is one of the largest sales markets for this natural material type. Unfortunately in comparison to other packaging materials like plastics or metals, the shaping as well as joining behavior is limited due to lack of material immanent thermoplasticity (Klemm et al. 2005; Hon and Shiraishi 1991). Therefore in addition to various form-fit joining processes, joints are mainly achieved by adhesive bonding. In view of the growing environmental awareness, the importance of good recyclability of packaging is constantly increasing. Many established adhesives make this process more difficult, as they cause deposits on machine parts and holes as well as dirt specks in papers and thus lead to paper machine downtimes and increased waste formation (Delagoutte 2015; Hamann 2015). A separation of larger particles is technologically possible to about 70–95%. However, smaller adhesive residues often have to be passivated and fixed to the pulp by the increased use of process chemicals. This is usually only incompletely successful. The joining of paper materials by melting and welding would be an excellent alternative, because no additional material has to be added.

Besides the industrial motivation to melt cellulose, there is also the scientific motivation, since it is not yet possible due to the lack of a suitable temperature range between melting and pyrolytic decomposition. The first investigations on the melting of cellulose were carried out in the 1970s by Back and Nordin (Nordin et al. 1974; Back et al. 1974; Back 1973). Back predicted melting by rapid heating to 450 °C and subsequent cooling in tenths of a millisecond. The melting temperature of 450 °C was not measured, but calculated from the glass transition temperature and a correlation generally valid for linear polymers (Boyer 1963). Experimentally, this was realized by a carbon dioxid (CO2) laser with 0.1 ms pulses and a stream of liquid nitrogen. A decrease of the fibrous structure, the formation of bubble-like structures and an increase of the amorphous phase could be observed. The resulting reaction products have been studied by Suzuki et al. (1983), Kwon et al. (2006) and Teixeira et al. (2011) and have been uniformly identified as mainly mono- and oligosaccharides. These are short-chain sugars consisting of a maximum of three monomers and are formed by chain splitting of the cellulose molecule and other transformative reactions. The existence of an intermediate liquid state during the decomposition of cellulose was already described in the Broido-Shafizadeh model by Shafizadeh et al. (1979) at the end of the 1970s. A visual observation of the so-called active cellulose was carried out by Boutin et al.(1998, 2002) with a high-speed camera due to its short lifetime. They observed the passage of a liquid intermediate phase before the final decomposition into gaseous components.

The investigations of Schröter and Felix (2005) followed a different approach than Back and Nordin had done 30 years earlier. Since a direct excitation of the intermolecular hydrogen bonds by laser radiation is technically difficult to realize due to the low resonance frequency, they pursue the theory that by applying mechanical pressure to the cellulose, a shift of the bonding energy or resonance frequency in the direction of the wavelength of the carbon dioxide laser radiation occurs.

The last two approaches are directly linked to our own investigations. The irradiation experiments with pulsed carbon monoxide laser radiation were not only examined microscopically and IR-spectroscopically afterwards, but also during irradiation with a high-speed camera. The assessment of whether the papers were melted or decomposed is mainly carried out by infrared (IR) spectroscopy. The investigations of Schröter and Felix were reproduced and further developed. The generated samples were subjected to a detailed IR-spectroscopic analysis to interpret the transformation reactions.

Materials and methods

Materials

Four different paper materials with varying composition were investigated as sample substrates. The first paper was made of cotton linters and is therefore called linters in the following. The second paper is made of elemental chlorine free bleached pine and spruce pulp and is called sulphate pulp due to the used sulphate production process. The third paper is called sulphite pulp and is made from beech by the sulphite process and is elemental chlorine free bleached as well. The last paper is chemithermomechanical pulp from spruce and will be referred to as CTMP in the following. In Table 1 the main components and some paper related key characteristics are listed. DP is the degree of polymerization. Lignin describes the percentage of lignin in the paper. S5 and S18 indicate the solubility in 5% and 18% caustic soda lye respectively. S5 indicates the amount of low molecular weight compounds from 5-fold sugars, S18 indicates the amount of all hemicelluloses. Ashes describe all inorganic compounds in the paper. CI is the crystallinity index according to Segal et al. (1959). D is the mean thickness of the papers.

Characterization

Morphology and threshold fluence

The visual appearance as well as the morphology was observed by light microscopy (VHX 5000, Keyence).

To evaluate the threshold fluence (Hthr), the average effect diameter was determined from several measurements. By regression of the measured values in a semi-logarithmic plot of the squared effect diameter over the peak fluence the threshold fluence could be determined (Liu 1982).

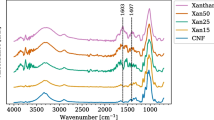

Differentiation of cellulose configurations

The spectrum of cellulose and the assignment of the peaks will not be part of this paper, as it is described in detail elsewhere (Fan et al., Maréchal and Chanzy 2000, Ivanova et al. 1989, Liang and Marchessault 1959). The scope of this section is the differentiation of the cellulose configurations I and II and their relevance. All spectral data was recorded by fourier transform infrared (FTIR) -attenuated total reflection (ATR) -spectroscopy (Tensor 27, Bruker). The storage and measurement of the samples took place at room temperature and room humidity.

Naturally occurring cellulose contains predominantly the cellulose I configuration (O’Sullivan 1997). If it is treated chemically, thermally or mechanically in such a way that some of the hydrogen bonds are broken, then the cellulose will orientate itself according to the Cellulose II configuration when recombined again, since this is thermodynamically more stable and thus more sensible in terms of energy (Nelson and O´Connor 1964a). A conversion from cellulose I to cellulose II can therefore also be expected during melting and resolidification. The main differences between cellulose I and II occur in the fingerprint region, between 850 cm−1 and 1450 cm−1 (Fig. 1). The sharply defined peaks of Cellulose I reduce in intensity or are combined to form broad peaks (Nelson and O´Connor 1964a). Furthermore, a shift to lower wave numbers can be observed. It should also be emphasized that the spectra of crystalline cellulose II and amorphous cellulose are very similar. Amorphous cellulose is often produced by mechanical processes, during which crystalline subareas including the system of hydrogen bonds are destroyed. Subsequently, the energetically sensible network of Cellulose II is formed.

Determination of crystallinity index

Another possibility to prove a structural transformation in cellulose is the crystallinity index CI. In IR spectroscopy, CI corresponds to the ratio of two peaks, one correlating with the proportion of the crystalline phase and one with the proportion of the amorphous phase. In comparison to other methods, IR spectroscopy can only detect a change in the ratio and no absolute measurements can be made (Kasprzyk and Wichlacz 2004). In this work the total crystallinity index CItot is used, because in contrast to the lateral crystallinity index CIlat this index is still valid during the conversion of cellulose I to II (Nelson and O´Connor 1964b; Hurtubise and Krassig 1960). A disadvantage is the large distance between the compared maxima, which are therefore based on different absorption coefficients of the material due to the dispersion.

\({CI}_{\text{t}\text{o}\text{t}}=\frac{{I}_{1370 {\text{c}\text{m}}^{-1}}}{{I}_{2899 {\text{c}\text{m}}^{-1}}}\) 1

The peak at a wavenumber of around 1370 cm−1 is correlated to the amount of the amorphous phase (Nelson and O´Connor 1964b). Its intensity is determined from a tilted base line through the local minima at 1290 cm−1 and 1400 cm−1 (Fig. 2). The peak at a wavenumber of around 2899 cm−1 is correlated to the amount of the crystalline phase and its intensity is measured from a horizontal base line through the local minima at 3000 cm−1 (Kasprzyk and Wichlacz 2004) (Fig. 3).

Dynamic of flash pyrolysis

The dynamic of the flash pyrolysis was investigated with a high-speed camera (Fastcam SA-X2, Photron Limited) and usually recorded at 12,500 or 30,000 frames per second. The high speed recordings allow a general description of the flash pyrolysis as well as the division into four characteristic time ranges according to objective visual characteristics. The duration of the time ranges can be quantified depending on the acting laser fluence (H) and the irradiated paper. Thus, a comparison of the papers and, with regard to their composition, an interpretation of the differences is possible.

Systems and devices

Laser systems

The irradiation experiments were carried out with a carbon monoxide (CO) laser (TruFlow 1500 (CO), Trumpf), as its photon energy at a wavelength of 5.6 μm is close to the binding energy of the hydrogen bonds. The laser was usually operated in pulsed mode or for the recordings of the high-speed camera in single pulse mode. Due to the high pulse energies, the irradiation was performed in a strongly defocused state, usually about 100 mm from the focus. This ensures sufficiently low fluences and a suitable ablation diameter for the examination.

In the investigations on the combination of laser radiation and mechanical pressure, a pulsed CO2 laser system (SC x20, Rofin) was used for the best possible reproduction of the results. The irradiation was also strongly defocused in accordance with the published results, resulting in low fluences and large beam diameters. In Table 2 some more additional parameters of the used laser systems are displayed.

Mechanical device

The device for simultaneous application of laser radiation and mechanical pressure was inspired by Schröter and Felix (2005). It consists out of two steel bolts with a diameter of 3.5 mm which are pressed together with a pneumatic cylinder. Applying the force through a cylinder instead of e.g. a screw ensures a constant pressure, even if parts of the paper substrate are pressed out between the bolts. The axial force was monitored with a pressure load cell (AEP transducers) and a standard deviation of less than 3.7 N between several measurements in the relevant range below 1.3 kN was achieved. After processing, the samples were examined by light microscopy and IR spectroscopy.

The varied process parameters are the press force, the type of paper and the laser power. The billet temperature was monitored with a thermal imaging camera (ImageIR 8375 S, InfraTec) on both sides of the paper and on the top and bottom of the billets.

Results and discussion

Threshold fluences and fluence regimes

When paper is irradiated with CO laser radiation, a browning of the fibers occurs from a material-specific threshold fluence onwards without any removal of matter (Fig. 4 lefthand). This indicates the beginning of chemical decomposition in the form of a hydrolysis or splitting off of hydroxyl groups (Shimazu and Sterling 1966). The amount of energy introduced per unit area is not sufficient to completely decompose the cellulose fibres. Thus a partial chemical transformation follows, mainly in the amorphous areas of the cellulose (Kolar et al. 2000). With a further increase of the laser fluence a second threshold fluence is reached, from which ablation and pyrolytic decomposition of the fibres takes place (Fig. 4 righthand). After irradiation, solidified bubbles and circular residues with a diameter of several 10 μm can be observed in the ablation area. These indicate the presence of a temporarily liquid phase as a result of the irradiation, since liquids under the influence of surface tension strive to minimize their surface area. The formation of bubbles is a consequence of coexistence with gaseous reaction products.

In the case of sulphate and sulphite substrate, the vesicles occur more frequently comparing to the linters substrate, which can be explained by the high share of hemicellulose and inorganic components (Fig. 5). Hemicellulose, in particular, decomposes into mono- and oligosaccharides at temperatures as low as 230 to 330 °C (Yeo et al. 2019; Yang et al. 2007; Shimazu and Sterling 1966), which have been identified as the main components of solid, soluble residues after irradiation.

The CTMP substrate does not show any blistering, but accumulations of high carbon compounds are present. These are the result of the high lignin content, which has the highest percentage by weight of carbonaceous residues after decomposition compared to the other main paper components (Yang et al. 2007).

A comparison with the paper technical parameters shows a negative correlation of the threshold fluences with lignin, S5, S18 and ash content (compare Tables 1 and 3). These characterize the purity of the paper and the proportion of non-cellulose and inorganic additives. This indicates that a major part of the radiation is not absorbed by the cellulose but by other paper components and then is transferred to the cellulose fibres in the form of heat. A positive correlation exists between threshold fluences and crystallinity index. A low CI corresponds to a high volume fraction of amorphous cellulose. Chemical conversion processes preferably take place in these areas (Kolar et al. 2000) which results in an increased ablation. However, since the CI is influenced by the presence of hemicellulose and lignin in the direction of an increase in the amorphous portion, this interpretation is possibly synonymous with the former. No provable explanation can be formulated for a correlation between the degree of polymerization and the material removal behavior.

Spectroscopic analysis

General description

The laser-irradiated samples were examined by IR spectroscopy, once directly after irradiation and once after extraction of water-soluble pyrolysis products and subsequent air drying at room temperature. The change of the spectrum in the wavenumber range significant for the conversion into cellulose II is described exemplarily by means of the linters substrate in dependence of the laser fluence.

The spectra without aqueous extraction (Fig. 6 top) show a decrease in peak intensities with increasing fluence, in particular, the peaks at 1030 cm− 1, 1055 cm− 1, 1110 cm− 1, 1160 cm− 1, 1335 cm− 1 and 1425 cm− 1 can be mentioned here. The decrease becomes clear from a fluence of 2.1 J cm− 2 onwards, which is due to the exceeding of the threshold fluence for ablation (1.03 J cm− 2). With lower fluences (browning regime) only slight changes in the spectra can be observed. The decrease in peak intensities indicates a conversion to cellulose II or amorphous cellulose. However after extraction of all water-soluble pyrolysis products, the peaks between 1030 cm− 1 and 1425 cm− 1 reappear. The substances that have changed the spectrum towards the cellulose II-like spectrum are water soluble and therefore can not be assigned to cellulose macromolecules. The remaining low intensity of the band at 1110 cm− 1 is due to non-water-soluble reaction products. A spectrum similar to that of cellulose II is achieved by these molecules, as they have a similar basic structure as cellulose and therefore similar vibrational frequencies. However, as they are disordered and have a lower degree of polymerization on average, a reduction of spatially separated peaks can be observed as in amorphous cellulose.

IR spectra for irradiated (top) as well as irradiated and water-extracted (bottom) linters substrate in dependency of the laser fluence, from bottom to top: 0.0 J cm-2, 0.3 J cm-2, 0.5 J cm-2, 2.1 J cm-2, 5.2 J cm-2, 13.7 J cm-2. Vertical lines indicate peak positions at 1030 cm−1, 1055 cm−1, 1110 cm−1, 1160 cm−1, 1335 cm−1 and 1425 cm−1

Sulphate, sulphite and CTMP substrate show similar changes. The intensity of some peaks are reduced, with the largest change again occurring between 0.5 J cm− 2 and 2.1 J cm− 2. In this range are the ablation threshold fluences of the sulphate and the sulphite substrate (0.85 J cm− 2 and 0.69 J cm− 2, respectively). The CTMP substrate shows a greater change already at a fluence of 0.5 J cm− 2, which is in good agreement with the ablation threshold fluence of 0.47 J cm− 2. After the aqueous extraction the majority of the bands is observed again.

Crystallinity index

Figure 7 shows the crystallinity indices of the paper substrates as a function of the laser fluence for irradiated (crosses and solid lines) and irradiated and water-extracted (circles and dashed lines) samples. The straight lines are first-degree sectionwise polynomial regressions and are used for clarity and to illustrate the general course. The vertical lines between 0 J cm− 2 and 2 J cm− 2 represent the threshold fluences of the ablation regime of the respective substrate.

The CI of the samples before extraction show a decrease with increasing fluence at fluences below the ablation threshold. This decrease is due to chemical conversion reactions, which are also responsible for browning, since in this fluence range no molten states exist. Above the threshold fluence the course flattens out and the CI remains more or less unchanged. The transition between the two ranges is particularly evident for the sulphate, sulphite and CTMP substrate. A strong decrease seems to correlate with the amount of hemicellulose and inorganic additives (sulphate and sulphite) or of lignin (CTMP). Less solidified pyrolysis products were observed when irradiating linters. These may also be responsible for a decrease in the CI due to a lack of order.

After aqueous extraction, the CI at low fluences (H < Hthr.) shows fluctuations around the values without extraction, which indicates that no water-soluble products are produced in this fluence range. Above the threshold fluence stagnation is observed again. The CI of CTMP decreases with increasing laser fluence, because of the high lignin content. Lignin has, in comparison to cellulose and hemicellulose, the highest percentage by weight of non-water-soluble, amorphous carbon residues after decomposition (Yang et al. 2007). With increasing fluence more carbon compounds are produced and the CI is decreasing. Nevertheless CI is generally above the values of the unirradiated substrates, which can be interpreted in an increase of the crystalline material proportion. Since the papers sulphate, sulphite and CTMP have a higher crystallinity index after aqueous extraction, even without irradiation, it can be assumed that the material contains water-soluble compounds that reduce the CI. As a result of laser irradiation, these substances could vaporize or be bound between other pyrolysis products and would thus be easier to extract. The result is a purification of the cellulose from amorphous constituents. However, this explanation is only reliable for sulphate and sulphite, due to their high hemicellulose content.

Change of peak intensities

Figure 8 shows the maximum intensities of the OH stretching vibration peak at around 3300 cm− 1 and of the OH bending vibration peak at around 1645 cm− 1. The OH stretching vibration was chosen because the OH group is close to the hydrogen bond and reflects changes in this bond. Since this band contains vibrations not only of the cellulose molecule but also of adsorbed water in the paper web, the intensity of the OH bending vibration is used for verification. This band is formed exclusively by water molecules and is therefore an indication of the amount of adsorbed water. The spectra of CTMP allow no clear identification of this band because it is overlaid by vibrations of the lignin molecules.

Peak intensities of the OH stretching vibration band (≈ 3330 cm−1, blue) and of the OH bending vibration band of adsorbed water (≈ 1645 cm−1, red) of an irradiated (crosses and solid lines) as well as an irradiated and water-extracted sulphate substrate (circles and dashed lines) as a function of the laser fluence

Before the aqueous extraction (crosses and solid lines) and above the ablation threshold (H ≥ 2 J cm− 2) an increase of the intensities of the stretching and the bending vibration peak can be observed. A simultaneous increase indicates adsorbed water as the cause for the intensity increase. This correlates with the reduced crystallinity index, since water molecules from the ambient air are mainly adsorbed in the amorphous subregions. As in the case of the crystallinity index, a change of the slope in the range of the threshold fluences, between 0.5 J cm− 2 and 2 J cm− 2, can be observed. After the aqueous extraction (circles and dashed lines) an inverse behaviour is noticeable, both peak intensities decrease with increasing fluence, again with a change of slope in the range of the threshold fluence. In particular, the amplitude of the stretching vibration peak decreases with increasing fluence. When the threshold fluence is exceeded, an almost constant intensity occurs.

The change of the bending vibration peak is much less pronounced and lies in the range of measurement fluctuations. This means that after aqueous extraction the adsorption of water is almost similar when irradiated with fluences above and below the ablation threshold. The greatly reduced intensity of the stretching vibration thus indicates a change in the OH bond or binding environment.

Short time melting and flash pyrolysis

Time ranges

For a better understanding, please refer to online resource 1 of this publication.

The general discussion of the interaction of laser radiation with paper and the following processes is based on the irradiation of a linters substrate, as this is the purest paper with the least amount of non-cellulosic components, at a peak fluence of 2.20 J cm− 2 (H > Hthr.,abl). The pyrolytic decomposition was divided into four time periods based on objective visual characteristics.

Time domain 1

In the first milliseconds after the first exposure to the laser radiation (Fig. 9 “+0.00 ms“) a slight movement takes place in the fibres which propagates from the center of the irradiation. This is the only observable change when irradiated with fluences in the browning regime (Hthr,br. < H < Hthr,abl.). Since it also occurs during irradiation of paper with reduced moisture content, the heating and evaporation of the adsorbed water is only one possible explanation. Likewise, the decomposition of the cellulose in the amorphous subregions as well as the discharge of internal tensions can be seen here. From about 4 ms onwards, a further, stronger movement takes place in the center. This indicates the onset of the melt-like state.

Time domain 2

For fluences above the ablation threshold the second phase starts after a few milliseconds (Fig. 9 “+7.84 ms”). Due to the high fluences, the formation of a melt-like state begins in the centre of the laser beam and spreads outwards (Fig. 9 “+9.12 ms” and “+12.00 ms”) until a constant diameter is reached (Fig. 9 “+24.80 ms”). The simultaneous presence of liquid and gaseous reaction products and the sudden expansion of the latter results in highly dynamic boiling during the irradiation, also called reactive boiling. Furthermore, the liquid products are completely permeated by the gaseous ones, resulting in the formation of a kind of foam from a multitude of bubbles. According to the Broido-Shafizadeh model, the removal of matter takes place by transformation into the liquid state and then into volatile gaseous products. In addition, the boiling ejection of larger melt-like particles is possible, especially at higher fluences. For the duration of the laser pulse there is a constant energy input and thus conversion and ablation.

Time domain 3

At the end of the irradiation (Fig. 9 “+29.36 ms”), the third phase of decomposition begins, which is referred to in the following as the primary lifetime (of the liquid substances after single energy input). Without further energy input the conversion into gaseous products decreases and the decay of the foam-like accumulations begins (Fig. 9 “+38.72 ms” and “+43.12 ms”). In this process, smaller bubbles join together to form larger ones, which burst or collapse from a critical size.

Time domain 4

After the larger bubbles have decayed, the fourth and last phase begins, which is referred to in the following as secondary lifetime (of the liquid substances after single energy input). In this phase, which can last several 10 ms, the decomposition is largely completed. However, a certain movement can still be observed in the irradiated area, which can probably be traced back to solidification processes of the liquid decomposition products (Fig. 9 “+53.28 ms” and “+120.00 ms”).

Comparison of the papers

The decomposition of the sulphate substrate is very similar to that of the linters substrate. Due to the high hemicellulose content, more dark decomposition products accumulate in the center. The sulphite substrate shows a stronger blackening during as well as after the irradiation. The high proportion of carbonyl groups is a decisive material property here, since these show a resonant absorption band in the region of the CO wavelength (Calvini and Gorassini 2002), which leads to an increase in the absorbed energy.

The CTMP substrate has the biggest difference to the other papers. During irradiation there is no highly dynamic boiling, but a browning with slight bubble formation, which is due to the high lignin content. In contrast to the abrupt decomposition of cellulose and hemicellulose, lignin shows a very uniform mass decrease with increasing temperature (Yang et al. 2007).

In addition, accumulations of highly concentrated carbonaceous compounds are formed, again caused by lignin. Since in the case of lignin the proportion of compounds that cannot be further decomposed at the end of the pyrolysis clearly outweighs the corresponding proportion in the case of cellulose and hemicellulose.

In Fig. 10 the durations of the time periods as a function of the laser fluence (crosses) and for better differentiation a second-order polynomial regression (solid lines) is shown. Time domains 3 and 4 could not be determined for the CTMP substrate because it does not exhibit reactive boiling.

Duration of the different time domains as a function of the laser peak fluence: time domain 1: t = 0 until first formation of melt-like state, time domain 3: primary lifetime, time domain 4: secondary lifetime, time domain 3 + 4: total lifetime. Crosses indicate measured values, solid lines are second-degree polynomial regressions to illustrate the general trend. Linters: black, sulphate: red, sulphite: blue, CTMP: green

The decrease of domain 1 with increasing fluence is due to the fact that the laser radiation only raises to the intensity required for decomposition after a certain time. At higher pulse energies this rising edge of the pulse is steeper and the decomposition intensity is reached faster. Differences between the papers can not be observed. The decrease of the primary lifetime (time domain 3) with increasing fluence is attributed to the increased amount of energy introduced. At higher fluences and thus more energy in the system after irradiation, the matter can be heated faster from the liquid to the gaseous phase. Thus the last step of the decomposition is completed faster. The fluence dependence is most pronounced for the sulphate substrate (from 43 ms to 19 ms) and hardly pronounced for the linters substrate (from 28 ms to 25 ms). One reason for this could be the different compositions, since the hemicellulose content increases from linters via sulphite to sulphate. This explanation is also supported by the fact, that the secondary lifetime (time domain 4) shows a similar but inverse dependence. For the linters substrate it remains almost the same with increasing fluence (from 43 ms to 52 ms) and for the sulphate and the sulphite substrate it increases considerably (from 23 ms to 51 ms and from 19 ms to 46 ms, respectively). The increase of the secondary lifetime with increasing fluence can also be attributed to the increased amount of energy in the material. At higher fluences, more residual heat remains in the material after boiling and more time is needed to complete the final conversion reactions and to distribute the heat. The decrease of the primary and the increase of the secondary lifetime with increasing fluence largely compensate each other, so that the total lifetime (sum of the first two) remains approximately the same for linters, sulphate and CTMP substrate. Exclusively for the sulphite substrate, a larger increase can be observed (from 51 ms to 69 ms). The Linters substrate consistently has the longest and the CTMP substrate consistently the shortest overall lifetime. This can again be explained by the purity of the linters substrate and the increased absorption of the lignin in the CTMP and the hemicellulose in the sulphate and the sulphite substrate, as less energy is available for cellulose decomposition.

Combination of laser radiation and mechanical pressure

General considerations

In a first step the experimental parameters of Schröter and Felix (2005) were recreated to reproduce the results. In order to guarantee sufficiently low fluences, the irradiation was carried out at a distance of 100 mm from the laser beam focus. However, the defocusing caused the beam diameter to increase to about 6.7 mm and no longer only hit the gap or the pressed paper. This makes it difficult to distinguish whether the effects observed are a consequence of the interaction between laser radiation and paper or caused by the heating of the contact bolts. Two different irradiation strategies were used to investigate this. On the one hand, a line was scanned directly on the gap, thus irradiating the paper directly. On the other hand, two lines were scanned onto the bolts at a distance of 2 mm from the gap were the paper was heated indirectly. Since the fluence plays a minor role here, the distance to the focus was reduced to about 50 mm. The beam with a resulting radius of 1.7 mm is not in contact with the paper. The directly irradiated sample (Fig. 11 left) is browned in the upper area, with the discoloration decreasing with reduced distance to the center. This is due to the direct contact with the laser radiation, which also burns the majority of the paper outside the bolts. This is also slightly noticeable with indirect heating and should be avoided by a different process design (less defocusing, inductive heating, etc.). The sample produced by direct irradiation has a similar visual appearance with increased transparency. For conversion over the entire cross-section, the laser radiation would have to pass through the paper sample with sufficient intensity (Fig. 12).

The Lambert–Beer law

describes, starting from the original intensity I0, the decrease in the intensity when passing through an absorbing medium of thickness d. An absorption coefficient of at least 10.8 mm− 1 can be calculated from measurements of the total radiation balance. After passing through the paper sample over a distance of 3.5 mm (bolt diameter), the intensity has thus fallen to around 3.3 ∙ 10− 15% of the incident intensity. Even without taking into account other effects such as scattering, which lead to a decrease in power density, a conversion over the entire thickness of the paper can be excluded.

The processing of paper products under pressure and heat is similar to a process established in the paper industry called sealing or hot pressing (Blechschmidt 2010; Bleisch et al. 2014). The connection during sealing of paper substrates is made by an additional thermoplastic layer, as there is no suitable temperature range for melting. Since the processed samples show some characteristics of a melt and there is a lack of information on the chemical and physical processes in heat-sealing without a thermoplastic layer, investigations are carried out with indirect heating by irradiating the bolts. Advantageous compared to direct irradiation is the more homogenous transformation of the paper as well as less burnt or decomposed material areas.

Influence of process parameters

When processing the paper samples, the transparency in the contact area usually increases as compression reduces the thickness and thus the light scattering. At medium bolt temperatures (approx. 240 °C), the transparency increases with increasing pressure, which is not only due to the reduced thickness, but also to a transformation of the fibre structure. If the fibres are still clearly visible at low forces, they disappear at higher forces and the grinding marks of the contact bolts are imprinted in the surface. At elevated pressure and room temperature the fibres remain intact. With increasing temperature, the transparency increases further until a nearly transparent sample is produced at a bolt temperature of 321 °C. The darker areas in the dark-field microscopy images indicate areas of the specimen where either directional reflection or directional transmission occurs. An uncompressed fibre web in combination with the relatively transparent cellulose fibres has a highly scattering appearance due to the many interfaces between fibres. This is reinforced by the polycrystalline structure within the cellulose fibre. Areas of increased transparency are thus the result of a compression of the fibre web. The number of interfaces is reduced and the surface and volume scattering decreases. In addition, some of the crystalline areas are destroyed by the mechanical influence. Amorphous areas have a more transparent appearance than polycrystalline areas due to the lower refractive index fluctuations. From 1299 bar upwards, the pressures in combination with the bolt temperature are sufficient to induce a certain flow behavior and displace material from between the bolts. After the exit follows the partial decomposition due to the interaction with the laser radiation.

The range of the spectrum between 800 cm− 1 and 1600 cm− 1, which is significant for the conversion of cellulose I into II, does not show any characteristic changes in peak positions or intensities (Fig. 13). Only the intensity of the band at 1110 cm− 1 decreases slightly. This indicates that the cellulose I configuration continues to predominate. Melting is therefore unlikely.

IR-spectra of the linters substrate. Top: at a bolt temperature of 240 °C and as a function of pressure (from bottom to top: 260 bar, 520 bar, 780 bar, 1039 bar, 1299 bar, 1455 bar), bottom: at a pressure of 1455 bar and as a function of bolt temperature (from bottom to top: room temperature (Figs. 14, 15), 142 °C, 198 °C, 219 °C, 240 °C, 253 °C, 321 °C). Vertical line indicates peak position at 1110 cm−1

With the total crystallinity index, a decrease can be observed with increasing pressing force or increasing temperature. This dependence can be attributed to the progressive mechanical destruction of the crystalline subregions at higher pressures, which is intensified by higher temperatures due to a reduction in viscosity. This leads to an increase in the amorphous subregions and a decrease in the crystalline subregions. This is also a reason for the increasing transparency, since amorphous areas scatter less than polycrystalline areas.

With increasing pressure an increase of the peak intensities of the OH stretching as well as the OH bending vibration band is observed. This speaks for an increasing adsorption of water from the ambient air and against a change of the binding network and thus against melting. The course correlates negatively with the degree of crystallinity, since water is mainly adsorbed in the amorphous regions.

Conclusions

The aim of the investigations was to gain fundamental insights into the interaction of CO laser irradiation with paper materials by means of IR spectroscopy and high-speed videography. A few milliseconds after the start and up to a few 10 milliseconds after the end of irradiation, a liquid state was observed, which was identified as an intermediate step of a highly dynamic pyrolytic decomposition. The lifetime of the intermediate liquid state is about 40 to 80 ms. After irradiation, an increase in the amorphous material regions was confirmed by IR spectroscopy. The resolidified matter was found to be water soluble what argues for decomposition into short-chain saccharides and against melting of the cellulose.

Furthermore, investigations were carried out on the simultaneous effect of laser radiation and mechanical pressure on paper substrates. After processing, the samples exhibit increased transparency, a reduction in fiber structure and a reduced crystallinity index. However, all these changes can be explained by thermal or mechanical influences, which leads to the conclusion, in contrast to the state of the art, that melting of cellulose is not likely by laser irradiation.

References

Back EL (1973) Cellulose bei hohen Temperaturen: Selbstvernetzung, Glasumwandlung und Schmelzen unter Einwirkung von Laserstrahlen. Papier 27:475–483

Back EL, Nordin SB, Nyrén J (1974) An Indication of molten cellulose produced in a laser beam - additional informations. TEXT RES J

Blechschmidt J (2010) Taschenbuch der Papiertechnik, 1st edn. Carl Hanser Fachbuchverlag, Leipzig

Bleisch G, Langowski H-C, Majschak J-P (2014) Lexikon Verpackungstechnik, 2nd edn. Behr, Hamburg

Boutin O, Ferrer M, Lédé J (1998) Radiant flash pyrolysis of cellulose—evidence for the formation of short life time intermediate liquid species. J Anal Appl Pyrol 47:13–31. https://doi.org/10.1016/S0165-2370(98)00088-6

Boutin O, Ferrer M, Lédé J (2002) Flash pyrolysis ofcellulose pellets submitted to a concentrated radiation: experiments and modelling. Chem Eng Sci 57:15–25. https://doi.org/10.1016/S0009-2509(01)00360-8

Boyer RF (1963) The relation of transition temperatures to chemical structure in high polymers. Rubber Chem Technol 36:1303–1421. https://doi.org/10.5254/1.3539649

Calvini P, Gorassini A (2002) FTIR – deconvolution spectra of paper documents. Restaurator:48–66. https://doi.org/10.1515/REST.2002.48

Delagoutte T (2015) Contaminants impact and management in recycled pulps. In: Avanced training course on “deinking and recycling”

Fan M, Dai D, Huang B Fourier transform infrared spectroscopy for natural fibres. https://doi.org/10.5772/35482

Hamann L (2015) Stickies: definition, origin and characterization. In: Avanced training course on “deinking and recycling”

Hon DN-S, Shiraishi N (1991) Wood and cellulosic chemistry. https://doi.org/10.1021/ja015237p

Hurtubise FG, Krassig H (1960) Classification of fine structural characteristics in cellulose by infrared spectroscopy. Anal Chem 32(2):177–181. https://doi.org/10.1021/ac60158a010

Ivanova NV, Korolenko EA, Korolik EV, Zhbankov RG (1989) IR spectrum of cellulose. J Appl Spectrosc 51:847–851. https://doi.org/10.1007/BF00659967

Kasprzyk H, Wichlacz K (2004) Some aspects of estimation of the crystallinity of gamma radiation wood cellulose by FTIR spectroscopy and X-ray diffraction techniques. Acta Sci Pol 3:73–84

Klemm D, Heublein B, Fink H-P, Bohn A (2005) Fascinating biopolymer and sustainable raw material. Angew Chem Int Edit 1173358–3393. https://doi.org/10.1002/anie.200460587

Kolar J, Strlic M, Pentzien S, Kautek W (2000) Near-UV, visible and IR pulsed laser light interaction with cellulose. Appl Phys A-Mater 71:87–90. https://doi.org/10.1007/PL00021097

Kwon G, Kuga S, Hori K, Yatagai M, Ando K, Hattori N (2006) Saccharification of cellulose by dry pyrolysis. J Wood Sci 52(5):461–465. https://doi.org/10.1007/s10086-005-0784-x

Liang CY, Marchessault RH (1959) Infrared spectra of crystalline polysaccharides. II. Native celluloses in the region from 640 to 1700 cm−1. J Polym Sci 39:269–278. https://doi.org/10.1002/pol.1959.1203913521

Liu JM (1982) Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt Lett 7:196–198. https://doi.org/10.1364/OL.7.000196

Maréchal Y, Chanzy H (2000) The hydrogen bond network in Ib cellulose as observed by infrared spectrometry. J Mol Struct 523:183–196. https://doi.org/10.1016/S0022-2860(99)00389-0

Nelson ML, O´Connor RT (1964a) Relation of certain infrared bands to cellulose crystallinity and crystal lattice type. Part II. A new infrared ratio for estimation of crystallinity in celluloses I and II. J Appl Polym Sci 8:1325–1341. https://doi.org/10.1002/app.1964.070080323

Nelson ML, O´Connor RT (1964b) Relation of certain infrared bands to cellulose crystallinity and crystal latticed type. Part I. Spectra of lattice types I, II, III and of amorphous cellulose. J Appl Polym Sci 8:1311–1324. https://doi.org/10.1002/app.1964.070080322

Nordin SB, Nyren JO, Back EL (1974) An indication of molten cellulose produced in a laser beam. Text Res J. https://doi.org/10.1177/004051757404400211

O’Sullivan AC (1997) Cellulose: the structure slowly unravels. Cellulose 4:173–207. https://doi.org/10.1023/A:1018431705579

Schröter J, Felix F (2005) Melting cellulose. Cellulose 12(2):159–165. https://doi.org/10.1007/s10570-004-0344-3

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-Ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Shafizadeh F, Furneaux RH, Cochran TG, Scholl JP, Sakai Y (1979) Production of levoglucosan and glucose from pyrolysis of cellulosic materials. J Appl Polym Sci 23:3525–3539. https://doi.org/10.1002/app.1979.070231209

Shimazu F, Sterling C (1966) Effect of wet and dry heat on structure of cellulose. J Food Sci 31:548–551. https://doi.org/10.1111/j.1365-2621.1966.tb01902.x

Suzuki J, Azuma J-I, Koshijima T, Okamura K, Okamoto H (1983) Characterization of mono- and oligosaccarides produced by CO2 laser irradiation an cellulose. Chem Lett 481–484. https://doi.org/10.1246/cl.1983.481

Teixeira AR, Mooney KG, Kruger JS, Williams CL, Suszynski WJ, Schmidt LD, Schmidt DP, Dauenhauer PJ (2011) Aerosol generation by reactive boiling ejection of molten cellulose. Energ Environ Sci 4(10):4306. https://doi.org/10.1039/C1EE01876K

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86(12–13):1781–1788. https://doi.org/10.1016/j.fuel.2006.12.013

Yeo JY, Chin BLF, Tan JK, Loh YS (2019) Comparative studies on the pyrolysis of cellulose, hemicellulose, and lignin based on combined kinetics. J Energy Inst 92(1):27–37. https://doi.org/10.1016/j.joei.2017.12.003

Funding

Open Access funding enabled and organized by Projekt DEAL. This work was funded by IGF project 20487 BR via AiF as part of the program for the promotion of joint industrial research (IGF) by the German Federal Ministry for Economic Affairs and Energy based on a resolution of the German Bundestag.

Author information

Authors and Affiliations

Contributions

FL, MZ and MP planned the study. FL carried out all of the laser experiments and the corresponding data collection and analysis. Paper sample preparation, their characterization as well as the extraction and FTIR investigations were carried out by MZ and TS. All authors were involved in the interpretation of the results. Florian Lull took the lead in writing the manuscript with help from the other authors according to the mentioned order. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary Material 1

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lull, F., Zahel, M., Panzner, M. et al. Fundamental investigations on the laser-melting of lignocellulosic fibres. Cellulose 29, 7587–7601 (2022). https://doi.org/10.1007/s10570-022-04702-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-022-04702-7