Abstract

A multi-scale modeling framework is proposed for the prediction of the chemo-mechanical degradation of paper, with the particular aim of uncovering the key factors affecting the degradation process. Paper is represented as a two-dimensional, periodic repetition of a fibrous network unit cell, where the fibers are characterized by a moisture-dependent chemo-hygro-mechanical constitutive behavior. The degradation of paper occurs primarily as a result of the hydrolysis of cellulose, which causes a reduction of the degree of polymerization and a consequent decrease of the effective mechanical properties, ultimately leading to fiber embrittlement and a loss of material integrity. The interplay between the acidity of the paper, the ambient environmental conditions, and its chemo-mechanical degradation behaviour is a complex process. In the model, these interactions are accounted for by determining the coupled temporal evolution of the degree of polymerization, the acidity of the paper, and the moisture content, from which the time-dependent tensile strength of the paper is calculated. The internal stresses developing in the fibrous network under a change in moisture content lead to brittle fiber fracture once they reach the fiber tensile strength. The successive breakage of individual fibers results in damage development in the fibrous network, altering its effective constitutive properties. The temporal evolution of the effective hygro-mechanical properties of the fibrous network is calculated by employing asymptotic homogenization. For obtaining accurate model input, the strength and stiffness properties of individual fibers and the degree of polymerization of paper samples are measured at different ageing times by carrying out dedicated experiments. Subsequently, a series of numerical simulations is performed to analyze the chemo-mechanical degradation process of paper, highlighting the influence of the time-evolving acidity and moisture content. The numerical study further considers the effects of micro-structural features (i.e., the anisotropy of the fibrous network orientation and the fiber longitudinal elastic modulus) on the macroscopic degradation response of paper. The results of this work may help conservators of cultural heritage institutions determining optimal environmental conditions to limit or delay the time-dependent degradation of valuable historical paper artefacts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The preservation of historic paper artefacts is a major concern for cultural heritage curators, due to the vulnerability of the artefacts to acid-catalyzed hydrolysis reactions that can cause rapid chemical and mechanical degradation (Strliç and Kolar 2005). In order to mitigate or delay these degradation processes, implementing preventive conservation policies that establish specific indoor climate ranges has proven to be one of the most effective approaches (Lucchi 2018). Nonetheless, for developing optimal specifications for this policy, it is crucial to thoroughly understand and predict the consequences of chemo-mechanical degradation mechanisms on the lifespan of paper artefacts.

Paper is a composite material characterized by an intrinsic hierarchical structure consisting of cellulose fibers connected to form a discrete network (Niskanen 1998). The deterioration of paper is primarily controlled by the degradation of cellulose, which is the principal structural component of paper fibers (Zou et al. 1994; Strliç and Kolar 2005). Cellulose degradation occurs as a result of the cleavage of cellulose molecular chains caused by the breaking of glycosidic bonds (Strliç and Kolar 2005; Zou et al. 1996), which gradually reduces the average molecular weight (Zervos 2010; Pan 2015). The kinetics of the degradation process is commonly quantified in terms of the degree of polymerization, representing the average number of monomeric units in a macro-molecule (Emsley and Stevens 1994; Emsley et al. 1997; Calvini et al. 2008). Chain cleavage in cellulose is due to hydrolysis reactions, often acid-catalyzed, and non-hydrolytic reactions, such as oxidation (Nevell 1985; Whitmore and Bogaard 1994; Barański 2002; Vibert et al. 2023). The rate and extent of these chemical reactions are influenced by various internal and external factors, which include the acidity of the paper, the presence of metal ions in the ink, the environmental storage or display conditions (temperature, relative humidity, and light exposure), and the presence of air pollutants (Shahani and Harrison 2002; Calvini and Gorassini 2006; Liu et al. 2017; Alam and Sharma 2023). The cleavage of cellulose chains resulting from these reactions significantly affects the mechanical properties of the material. A decrease in molecular weight causes a reduction in effective mechanical properties, including the tensile strength and stiffness (Emsley et al. 2000; Hill et al. 1995; Tétreault et al. 2019; Vizárová et al. 2012; Zou et al. 1994). Additionally, due to the hydrophilic nature of cellulose, paper fibers are highly sensitive to fluctuations in moisture content, which can result in moisture-induced deformations (Niskanen 1998; Brandberg et al. 2020). The constrained moisture-induced deformations of individual fibers in the bonding regions result in the build-up of internal stresses in the fibrous network. If these stresses reach the tensile strength of the fibers, fiber breakage occurs, ultimately leading to embrittlement and fragmentation of the paper artefacts. These phenomena limit their physical usability, readability, and visual appearance.

In the literature, different modeling approaches have been proposed for the prediction of degradation of historic paper. The approaches commonly rely on dose-response functions that describe the time-evolution of the degree of polymerization, as affected by various degradation factors, such as the temperature, relative humidity, air pollutants, and the acidity of the paper (Strlič et al. 2015a, b, c; Pastorelli et al. 2019; Vibert et al. 2023; Tétreault et al. 2023). The dependency on these degradation factors is established by performing dedicated experiments or using existing data. The dose-response functions deduced can estimate the lifetime of individual paper artefacts by comparing the predicted damage with a critical threshold value, indicating when a paper object becomes unfit for use or display. Despite their great value, these approaches only consider the chemical aspect, neglecting the mechanical contribution and chemo-mechanical couplings in paper degradation processes. Moreover, they address the problem solely at the macroscopic sheet level, ignoring the intrinsically multi-scale nature of paper.

In our previous work (Parsa Sadr et al. 2022), a computational model has been developed within a multi-scale and multi-physics framework to predict the chemo-mechanical degradation of historical paper. In the modeling approach, the underlying paper micro-structure is simulated via a periodic unit cell representing a fibrous network with an isotropic fiber orientation distribution. The model determines the temporal evolution of paper fiber tensile strength as a function of the degree of polymerization, ambient environmental conditions, and acidity of the paper, using specific assumptions, such as a constant moisture content and paper acidity throughout the ageing process. The response of the paper fibers is characterized by a chemo-hygro-mechanical constitutive behavior, assuming moisture-independent mechanical properties. The proposed model first computes the local elastic stresses within the network, induced by changes in relative humidity. These stresses lead to brittle fiber fracture once the fiber tensile strength is reached. Accordingly, the model couples chemical degradation with the development of local damage and the redistribution of stress in the fibrous network. Ultimately, the modeling framework employs asymptotic homogenization to calculate the resulting time-decaying effective hygro-mechanical properties of the fibrous network, which quantify the extent of macroscopic degradation of historical paper.

Building upon our previous work (Parsa Sadr et al. 2022), this contribution enhances the chemo-mechanical model for paper degradation by adopting a more accurate description of the coupled chemo-hygro-mechanical interactions and the geometry of the fibrous network. As mentioned above, the degradation is influenced by the relative humidity (or moisture content) and the acidity of the paper. At the same time, the degree of degradation has a reverse effect on the paper acidity and the ability of cellulose to absorb moisture. Specifically, the cleavage of cellulose molecules reduces the ratio between the regions of amorphous cellulose and crystalline cellulose, as a result of which the overall capacity of cellulose to absorb moisture diminishes since the moisture sorption capacity of amorphous cellulose is larger than that of crystalline cellulose (Tétreault et al. 2019). Hence, the moisture sorption capacity of cellulose decreases as the degradation of paper progresses. This behavior is simulated by adopting a relationship in which the moisture content of the paper fibers decreases as the degree of polymerization decreases. Additionally, the acidity of paper increases through the absorption of volatile compounds from the surrounding environment. Because the absorption of volatile compounds leads to paper degradation (Tétreault et al. 2013), this effect is accounted for by assuming the pH level of paper to decrease under a decreasing degree of polymerization (Tétreault et al. 2019). The enhanced model formulation further uses a hygro-mechanical constitutive law that incorporates the dependency of the elastic properties of paper fibers on the moisture content (Nissan 1976; Linvill and Östlund 2014; Jajcinovic et al. 2018; Urstöger et al. 2020). It also includes a sophisticated geometrical description of the fibrous network, by accounting for an anisotropic fiber orientation distribution that may originate from the paper production process (Caulfield 1988; Strliç and Kolar 2005; Leheny et al. 2021).

Additionally, dedicated experimental measurements are performed to accurately calibrate various material parameters of the proposed chemo-hygro-mechanical model. First, the fiber longitudinal elastic modulus and fracture strength are determined by applying a recently developed experimental methodology based on in-situ tensile testing of individual fibers combined with optical profilometry (Maraghechi et al. 2023a). The experiment was performed for fibers from various paper samples that are characterized by different ageing states. Second, the degree of polymerization of the paper samples was measured using the rheometry-based experimental procedure recently proposed in Maraghechi et al. (2023b). By combining the results of the micro-tensile experiments and the degree of polymerization measurements, the fiber fracture strength is determined as a function of the degree of polymerization. With this experimental input, a set of numerical simulations is performed to demonstrate the ability of the enhanced model to predict the chemo-mechanical degradation process of paper, scrutinizing the effects of the time-dependent acidity and time-dependent moisture content. A parameter variation study explores the influence of the anisotropy of the fiber network orientation and the longitudinal elastic modulus of the fibers on the macroscopic degradation response of historical paper.

This contribution is organized as follows. Section “Time-dependent chemo-mechanical degradation model” presents the main features of the enhanced model for chemo-mechanical degradation of paper. Section “Multi-scale model” outlines the multi-scale methodology employed for upscaling the degradation response from the fibrous network level to the macroscopic sheet scale, and subsequently presents the adopted numerical solution strategy. Section “Model input” discusses the parameter values used as input for the numerical simulations, which are determined from dedicated experiments and experimental results reported in the literature. The numerical results are treated in Sect. “Numerical results”, where specific features of the enhanced model and the micro-structural characteristics of the fibrous network are analyzed with respect to the degradation development of paper. Finally, the main conclusions of the work are summarized in Sect. “Conclusions”.

Time-dependent chemo-mechanical degradation model

Chemical degradation of paper fibers

Degradation of paper is governed by a complex combination of chemical and mechanical processes interacting across multiple length scales. Paper fibers consist of cellulose micro-fibrils that are embedded in a matrix of hemicellulose and lignin. Since cellulose is the major structural component of paper fibers (Borodulina et al. 2015), it is reasonable to assume that the chemo-mechanical degradation response of paper fibers is controlled by the degradation of cellulose and the influence of the hemicellulose and lignin phases may be neglected (Malachowska et al. 2020, 2021). The degradation of cellulose molecules is caused by the cleavage of the long cellulose molecular chains, a process that is governed by the breakage of glycosidic bonds. Cleavage results in a gradual reduction of the average molecular length, and thus in a decrease in average molecular weight (Zervos 2010; Pan 2015). The reduction of average molecular weight eventually leads to the degradation of the intrinsic mechanical properties of fibers. In this work, the chemical degradation process is considered to occur uniformly across the various length scales. Consequently, the molecular scale, the fiber scale, the fibrous network scale, and the macroscopic sheet scale are characterized by the same extent of chemical degradation.

The model selected for simulating cellulose degradation is based on the well-known Ekenstam equation (Montroll 1941; Ekenstam 1936), which is a first-order kinetic equation in which the degree of polymerization represents the number of monomer units in the polymer, i.e.,

where \(\textrm{DP}_0\) and \(\textrm{DP}\) are the degrees of polymerization of cellulose at the initial time \(t_0\) and the current time t (in years), respectively. The parameter k (with units year\(^{-1}\)) describes the reaction rate of polymer cleavage, which may depend on both extrinsic (temperature, relative humidity, light exposure, and pollution) and intrinsic (acidity, presence of additives or ink) parameters (Shahani and Harrison 2002; Calvini and Gorassini 2006; Liu et al. 2017). Following Zou et al. (1996), it is assumed that the three most relevant factors controlling the rate of paper degradation are the temperature, the relative humidity, and the acidity of the paper. Accordingly, Strlič et al. (2015c) proposed an experimentally calibrated relation to explicitly describe the dependence of the reaction rate k on these three factors, considering Ekenstam’s model—Eq. (1)—as the reference model for cellulose degradation. They used data from 121 degradation experiments on paper subjected to a set of different environmental conditions (temperature, relative humidity) and pH levels. When formulating the reaction rate parameter k in terms of the equilibrium moisture content \({m}\) of paper (instead of the ambient relative humidity), this relation is given by (Strlič et al. 2015c)Footnote 1

where the temperature T is measured in \(^\circ\)C and “\(\ln\)” represents the natural logarithmic function. The equilibrium moisture content \({m}\) depends on the relative humidity \(\textrm{RH}\) and the temperature T of the ambient environment. Additionally, the capacity for moisture uptake of paper is closely related to its degradation state, which is quantified by the degree of polymerization. Specifically, as the degradation process of paper advances, the cellulose molecules undergo cleavages, resulting in a decrease in the ratio between the regions of amorphous cellulose and crystalline cellulose. Since the moisture sorption capacity of amorphous cellulose is larger than that of crystalline cellulose, the overall ability of cellulose to absorb moisture diminishes. Hence, the moisture sorption capacity of cellulose decreases as the degradation of paper develops. From these considerations the moisture content \({m}\) can be expressed as (Tétreault et al. 2019):

Here, the function \(f(\textrm{RH},\textrm{T})\) describes the dependency of the moisture content on the relative humidity and temperature, which can be calibrated from the results of moisture sorption experiments. In Tétreault et al. (2019), the expression for \(f(\textrm{RH},\textrm{T})\) was determined in accordance with the Guggenheim-Anderson-de Boer sorption equation (Parker et al. 2006; Timmermann 2003). However, following Strlič et al. (2015c) and our previous work (Parsa Sadr et al. 2022), the sorption isotherm function experimentally deduced in Paltakari and Karlsson (1996) is used here instead, i.e.,

in which the relative humidity RH is defined as a ratio (instead of a percentage). Further, in Tétreault et al. (2019) the function \(g(\textrm{DP})\) is calibrated from the experiments reported in Tétreault et al. (2013) as

in which the reference moisture content \({m}_{ref,0}\) is the moisture content of paper under the initial conditions at time \(t_0\). The initial conditions correspond to an initial degree of polymerization DP\(_0\), and a reference temperature T\(_0\) = 20 \(^\circ\)C and reference relative humidity RH\(_0=0.5\) (= 50%) that are representative of the conditions in the experiments presented in Sect. “Experiments and material parameters”. Inserting these conditions in Eqs. (4) and (5) respectively leads to \(f(\textrm{RH}_0,\textrm{T}_0)=0.073\) and \(g(\textrm{DP}_0)=1\). From Eq. (3) the value of the reference moisture content is then obtained as \({m}_{ref,0}=0.073\). This value will be used in the experimental calibration procedure presented in Sect. “Experiments and material parameters”.

The pH level in Eq. (2) is determined by endogenous sources, such as the hydrogen ions naturally present in the paper constituents, and exogenous sources, such as pollutants and volatile compounds that are provided by the surrounding environment and may be absorbed by the paper during its lifespan (Tétreault et al. 2019). The absorption of volatile compounds, which are considered to be a degradation factor and thereby decrease the degree of polymerization, results in an increase of the acidity of paper. By analyzing the experimental data on acidic paper presented in Tétreault et al. (2013), this coupling effect is modeled in Tétreault et al. (2019) via the following relation between \(\textrm{DP}\) and pH:

where “log" refers to the common logarithmic function. The above relation is adopted in the present work and holds for acidic paper with a pH of 3.5 or higher (Tétreault et al. 2019).

Chemo-hygro-mechanical response of paper fibers

Since paper fibers are predominantly oriented in the in-plane direction of a paper sheet, the numerical studies are performed using a two-dimensional plane-stress formulation. It is assumed that the fibers are characterized by a hygro-elastic, brittle material behavior, where the fracture strength depends on the degree of chemical degradation. The deformation response of paper fibers is susceptible to moisture content variations (Niskanen 1998; Brandberg et al. 2020; Simon 2021). Accordingly, the constrained moisture-induced deformations of individual fibers in bonding regions result in a build-up of internal stresses in the fibrous network. In the elastic regime, the development of fiber stresses is simulated with a hygro-mechanical model, in which the material properties are considered to be transversely isotropic with respect to the longitudinal fiber direction. Accordingly, the fourth-order elastic tensor \(^4\textbf{C}\) is defined by four independent constants, namely the elastic moduli \(E_t\) and \(E_\ell\) in the (isotropic) transverse plane and longitudinal direction of the fiber, the in-plane Poisson’s ratio \(\nu _{\ell t}\) and the in-plane shear modulus \(G_{\ell t}\), where \(\ell\) and t respectively denote the longitudinal and transverse material axes of the fiber. Additionally, the second-order hygro-expansion tensor \(\varvec{\beta }\) is defined by the coefficients \(\beta _\ell\) and \(\beta _t\) in the longitudinal and transverse directions of the fiber. The contribution of temperature-induced deformations on the mechanical fiber response is ignored, since it is typically considerably smaller than that caused by moisture-induced deformations (Niskanen 1998).

Due to the hydrophilic nature of paper fibers, their elastic constants depend on the actual value of the moisture content (Nissan 1976; Linvill and Östlund 2014). Following Nissan’s theory on hydrogen bond dissociation in hydrogen bond dominated solids (Nissan 1976), it is assumed that the elastic response of paper fibers softens with increasing moisture content, due to the reduction of the number of effective hydrogen bonds within cellulose molecules. Consequently, the longitudinal elastic modulus of a fiber is related to its moisture content as (Nissan 1976):

Here, \(E_{\ell ,\textrm{dry}}\) represents the longitudinal elastic modulus at zero moisture content, and \({m}_{c}\) denotes the specific moisture content marking the transition between the two regimes distinguished in Eq. (7). In the first regime, which is characterized by \(0 \le {m}< {m}_c\), hydrogen bonds progressively dissociate, resulting in a gradual decrease of the elastic modulus with respect to the moisture content \({m}\). In the second regime, specified by \({m}\ge {m}_{c}\), clusters of hydrogen bonds simultaneously break, leading to a substantially higher degradation rate of the elastic modulus. Figure 1 illustrates the dependency of the normalized value \({E_\ell }/E_{\ell ,\textrm{dry}}\) of the longitudinal elastic modulus on the moisture content \({m}\), where the value selected in Eq. (7) for \({m}_c\) is 0.05, which is based on the experimental results reported in Nissan (1976). This value is also used in the experimental calibrations and numerical simulations presented in the current work. Since in the literature the transverse elastic modulus and the shear modulus of paper fibers are commonly expressed as functions of the longitudinal elastic modulus via \(E_{t}= c_1 \textrm{E}_{\ell }\) and \(\textrm{G}_{\ell \mathfrak { t }} = c_2 \textrm{E}_{\ell }\), respectively, the influence of the moisture content on these moduli can be directly accounted for through relation (7) by specifying the values of \(c_1\) and \(c_2\). The Poisson’s ratio \(\nu _{\ell t}\) is considered to be independent of the moisture content.

Influence of the moisture content \({m}\) of paper fibers on the longitudinal elastic modulus \(E_{\ell }\) (normalized with respect to its value \(E_{\ell ,\textrm{dry}}\) in the dry state) (Nissan 1976). The transition between the two regimes distinguished in Eq. (7) occurs at the moisture content \(m= {m}_{c} = 0.05\)

The fracture response of paper fibers is characterized as ideally brittle, i.e., a fiber abruptly breaks once the maximum principal stress in the fiber reaches the fiber fracture strength. It is assumed that the fiber failure criterion governing this behavior is isotropic, where the fracture strength \(\sigma _{\textrm{u}}\) of the fibers depends on the chemical degradation process through the degree of polymerization \(\textrm{DP}\) of cellulose, in accordance with (Tétreault et al. 2019; Parsa Sadr et al. 2022):

where \(\sigma _{\textrm{u},0}\) represents the initial fracture strength at the initial degree of polymerization \(\textrm{DP}_0\), and \(\gamma\) is a coefficient that quantifies the decrease in fracture strength under a decreasing degree of polymerization. The values of \(\sigma _{\textrm{u},0}\) and \(\gamma\) are calibrated from micro-tensile tests on individual fibers extracted from samples subjected to accelerated ageing, as described in Sect. “Experiments and material parameters”. Various studies have demonstrated that paper degradation caused by ageing primarily is controlled by a decrease in fiber tensile strength rather than a decrease in fiber bond strength (Emsley et al. 2000; Seth and Page 1988; Zou et al. 1994). Hence, in the present model, the fracture behaviour at the fiber scale is assumed to be solely determined by the time-dependent tensile strength of individual fibers, as described via Eq. (8), while the specific strength of the inter-fiber bonds is considered not to be critical and therefore not accounted for. It is emphasized, however, that failure in the fibrous network typically occurs at fiber locations close to inter-fiber bonds, where the constrained moisture-induced deformations of individual fibers lead to the largest internal tensile stresses.

Multi-scale model

Fibrous network model and asymptotic homogenization

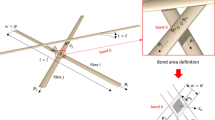

The multi-scale degradation behavior of paper is analyzed by determining the time decay of the effective material properties according to the modeling framework developed in Parsa Sadr et al. (2022), which is summarized below. The framework is based on asymptotic homogenization (Bakhvalov and Panasenko 1989), which is a multi-scale method that enables to calculate the effective response of heterogeneous materials with a periodic micro-structure. Accordingly, the micro-structural fibrous network is described as a periodic repetition of two-dimensional unit cells. Although paper micro-structures are generally not periodic, the unit cell reflects a representative volume element that is sufficiently large to contain enough micro-structural information to represent a real stochastic fibrous network (Drugan and Willis 1996; Kloppenburg et al. 2023). The network unit cell Q is modeled as a square domain with edges of length L. The individual fibers in the network have a rectangular shape with length l and width w, and a rectangular cross-section wh where h is the fiber thickness. Following the procedure described in Bosco et al. (2018), the network is generated by depositing each individual fiber in the region Q, with the location of the geometrical center of the fiber determined by a uniform random point field. The orientation of the fibers in the fibrous network follows a wrapped Cauchy orientation distribution (Cox 1952):

where \(\theta \in [-\pi /2, \pi /2 \!>\) is the angle between the longitudinal fiber axis and the in-plane, horizontal direction \(\theta =0\), and \(q \in [0,1]\) is the network anisotropy parameter. Figure 2a shows the orientation distribution function for four values of the parameter q, i.e., \(q = [0, 0.25, 0.5, 0.75]\). For \(q = 0\), the function \(f(\theta )\) represents a uniform distribution, i.e., an isotropic fibrous network. As the value of q grows to unity, the fibers become increasingly oriented towards the in-plane, horizontal direction \(\theta =0\).

Fibrous network model. a Fiber orientation distribution function depicted for different values of the parameter q, which quantifies the anisotropy of the fibrous network orientation. b Example of a micro-scale unit cell. Fibrous network configuration with an isotropic distribution of fiber orientations, \(q = 0\), and coverage \(\bar{c} = 5\), composed of fibers with an aspect ratio \(l/w=50\). The different colours denote different fiber orientations

To ensure geometrical periodicity, the fiber parts that extend outside a specific boundary of the square domain Q are trimmed and copied inside the domain at the opposite boundary. In the fibrous network, the number of fibers across the thickness and their orientations are specified at each material point. The fibers that overlap in a given material point are assumed to be perfectly bonded. The average thickness of the network is quantified by the areal coverage \(\bar{c}\), which represents the average number of fiber layers within the fibrous network. The coverage \(\bar{c}\) is computed as the ratio between the total area of the fibers and the area of the unit cell, \(\bar{c} = n_f wl / Q\), with \(n_f\) the total number of fibers in the network. Figure 2b shows an example of a network of fibers with an aspect ratio of \(l/w = 50\), where different colours denote different fiber orientations. The network coverage is \(\bar{c} = 5\), which is representative of a realistic paper micro-structure, such as the historic paper analyzed in Sect. “Numerical results”.

The constitutive behaviour of individual paper fibers is described by the chemo-hygro-mechanical model presented in Sect. “Chemo-hygro-mechanical response of paper fibers”. To compute the local stiffness tensor \({^4\textbf{C}(\textbf{x})}\) and the hygro-expansion tensor \({\varvec{\beta }(\textbf{x})}\) in the material points of the fibrous network, the constitutive contributions from the fibers passing through a specific material point are summed up and divided by the local thickness of the network. Once the network geometry and constitutive properties are defined, the asymptotic homogenization method is applied. The method departs from expressing the displacement field as an asymptotic expansion in terms of the microscopic and macroscopic spatial variables and inserting it into the mechanical equilibrium equation. At the micro-scale, this results in the formulation of specific boundary value problems, known as the “cell problems". These cell problems are defined for representative network geometries and are solved numerically using the finite element method. The solution of the cell problems provides the influence functions \({^3\textbf{N}^1(\textbf{x})}\) and \({\textbf{b}^1(\textbf{x})}\), which describe the periodic micro-fluctuations of the displacement field of the network in response to variations of the average macroscopic strain and moisture content, respectively. The influence functions can be further used to compute:

-

The effective properties of the network. The effective stiffness tensor \({^4\overline{\textbf{C}}}\) and the effective hygro-expansion tensor \({\overline{\varvec{\beta }}}\) are defined by (Bosco et al. 2017b, a; Parsa Sadr et al. 2022):

$$\begin{aligned} \begin{array}{lcl} {^4\overline{\textbf{C}}}&{} = &{} \displaystyle { \frac{1}{\vert Q \vert }\int _Q{{^4\textbf{C}(\textbf{x})}:(\varvec{\nabla }({^3\textbf{N}^1(\textbf{x})}) + {^4\textbf{I}^S})}\textrm{d}Q , }\\ {\overline{\varvec{\beta }}}&{} = &{} \displaystyle { \frac{1}{\vert Q \vert }{^4\overline{\textbf{C}}}^{-1}:\int _Q{{^4\textbf{C}(\textbf{x})}: ({\varvec{\beta }(\textbf{x})}- \varvec{\nabla }{\textbf{b}^1(\textbf{x})}) }\textrm{d}Q} , \end{array} \end{aligned}$$(10)where the symbol \(\varvec{\nabla }\) is the gradient operator. Furthermore, \({^4\textbf{I}^S}\) is the fourth-order symmetric identity tensor, with components \(I^S_{ijkl} = (\delta _{il}\delta _{jk} + \delta _{ik}\delta _{jl} )/2\), where \(\delta _{ij}\) is the Kronecker delta symbol.

-

The local strain and stress fields in the network. Specifically, under hygroscopic loading conditions the strain field \(\varvec{\varepsilon }(\textbf{x})\) in the micro-structure is determined as (Parsa Sadr et al. 2022)

$$\begin{aligned} \varvec{\varepsilon }(\textbf{x})= \left( {\overline{\varvec{\beta }}}+ \varvec{\nabla }({^3\textbf{N}^1(\textbf{x})}):{\overline{\varvec{\beta }}}+ \varvec{\nabla }{\textbf{b}^1(\textbf{x})}\right) \Delta {m}, \end{aligned}$$(11)where \(\Delta {m}= {m}-{m}_0\) is the difference between the current moisture content \({m}\) and the reference moisture content \({m}_0\). The local moisture-induced self-stress \(\varvec{\sigma }(\textbf{x})\) in the fibrous network is next calculated by inserting Eq. (11) in the hygro-mechanical constitutive relation:

$$\begin{aligned} \varvec{\sigma }(\textbf{x})= ~^4\textbf{C}(\textbf{x}): \left( \varvec{\varepsilon }(\textbf{x}) - \varvec{\beta }(\textbf{x}) \Delta {m}\right) ~. \end{aligned}$$(12)From the stress \(\varvec{\sigma }(\textbf{x})\), the maximum principal stress \({\sigma }_I(\textbf{x})\) is computed. By comparing \({\sigma }_I(\textbf{x})\) to the time-dependent tensile strength \(\sigma _{\textrm{u}}\) of the fibers, defined by Eq. (8), it is determined whether brittle fracture takes place or not.

For details on the solution of the cell problems, the computation of the effective properties and local fields, and the numerical implementation, the reader is referred to Bosco et al. (2017b); Parsa Sadr et al. (2022).

Numerical solution procedure

The multi-scale chemo-hygro-mechanical model for paper degradation is implemented in a finite element method framework developed in MATLAB. The incremental update scheme is schematically presented in Table 1. The solution procedure departs from the generation of the fibrous network unit cell and the discretization of its geometry into a finite element mesh. At the onset of a simulation, the necessary input parameters for the numerical analysis are assigned to the network model. The chemical properties of the network are defined through the initial value of the degree of polymerization \(\textrm{DP}_0\). The mechanical properties include the reference values of the longitudinal elastic modulus \(E_{\ell ,\textrm{dry}}\), the transverse elastic modulus \(E_{t,\textrm{dry}}= c_1 E_{\ell ,\textrm{dry}}\), the shear modulus \(G_{\ell t}= c_2 E_{\ell ,\textrm{dry}}\) and the fracture strength \(\sigma _{u,0}\). Additionally, the Poisson’s ratio \(\nu _{\ell t}\), the hygro-expansion coefficients \(\beta _\ell , \beta _t\), and the fracture strength coefficient \(\gamma\) are specified. The mechanical model is completed through the application of periodic boundary conditions on the micro-scale fibrous network. The environmental conditions experienced by the paper sheet during the time of display or storage are next prescribed in terms of the temperature T and the relative humidity RH, along with their reference values T\(_0\) and \(\textrm{RH}_0\).

The numerical solution procedure starts with solving the chemical problem. Note that in Eq. (1) the reaction rate k for chemical degradation of paper depends on the moisture content \({m}\), the paper pH, and the temperature T (which remains constant during the process), as represented by Eq. (2). The moisture content and paper pH are functions of the degree of polymerization, as defined via Eqs. (3) and (6), respectively. Correspondingly, Eqs. (1), (2), (3), and (6) are solved in a coupled fashion, resulting in the time evolutions of the degree of polymerization \(\textrm{DP}(t)\), the reaction rate k(t), the paper pH(t), and the moisture content \({m}(t)\) of the paper. From the time dependency of the degree of polymerization DP(t), the time evolution of the fiber tensile strength \(\sigma _u(t)\) is next calculated via Eq. (8). Together with the initial value of the moisture content \({m}_0\), the time-dependent tensile strength \(\sigma _u(t)\), and time-dependent moisture content \({m}(t)\) in the fibrous network serve as input for the mechanical analysis.

The mechanical simulation is based on an incremental time-stepping procedure. At the beginning of each time increment \(t_j\), the stiffness parameters of the paper fibers that correspond to the current value of the moisture content \({m}\) are calculated using Eq. (7). The effective mechanical stiffness \({^4\overline{\textbf{C}}}\) and the hygro-expansion coefficient \({\overline{\varvec{\beta }}}\) are computed through asymptotic homogenization following Eq. (10). Subsequently, the strain \(\varvec{\varepsilon }(\textbf{x})\) and stress \(\varvec{\sigma }(\textbf{x})\) are determined in each finite element integration point of the fibrous network from Eqs. (11) and (12). From the stress \(\varvec{\sigma }\) computed at the integration points of a finite element, the corresponding maximum principal stress values \({\sigma }_I\) are calculated and averaged over the element. The element-averaged maximum principal stress \(\bar{\sigma }_I^e\) is compared against the current value of the fiber tensile strength \(\sigma _u(t_j)\). If this maximum principal stress reaches or (slightly) exceeds the fiber strength, \(\bar{\sigma }_I^e \ge \sigma _u(t_j)\), the corresponding finite element is considered fully damaged and thus is removed from the fibrous network geometry. Subsequently, the finite element mesh of the fibrous network is consistently updated, and the mechanical analysis is repeated for the next time increment \(t_{j+1}\). The incremental time-stepping procedure continues until the fibrous network has lost its structural integrity, by which the degradation of the paper sheet is complete.

Model input

Experiments and material parameters

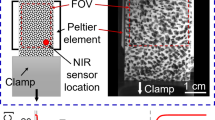

The values of the longitudinal elastic modulus and fracture strength of the fibers were determined from an experimental methodology that combines in-situ tensile testing of individual fibers with optical profilometry, as recently proposed in Maraghechi et al. (2023a). The fibers were extracted from Whatman No. 1 filter paper samples. Four samples were subjected to hygro-thermal ageing, and one unaged sample was used as a reference sample. The accelerated ageing process was performed using Lab-Line hybridization tubes (144 ml), following the standard Technical Association of the Pulp and Paper Industry (2009). The four test samples were subjected to a temperature of \(90~^{\circ }\)C for periods of 6, 12, 20, and 35 days. For each ageing time (including the unaged condition), three fibers were extracted from the samples and subsequently tested. The experiments were performed under climate conditions that are typical of the display/storage conditions maintained in large international museums, i.e., RH \(= 50 \%\) and T \(= 20~^\circ\)C (Michalski 2007; Verticchio et al. 2021). Since the temperature and relative humidity are constant during the experiments, these values correspond to the reference values RH\(_0\) and T\(_0\).

In the experimental procedure, optical profilometry was performed at the top and bottom surfaces of the fiber specimen to accurately measure the fiber cross-sectional area. The local stress was incrementally determined at specific fiber locations along the fiber length from the force recorded during the tensile test and the local cross-sectional area measured. By determining the height profiles during the micro-tensile testing and applying global digital height correlation, a rigorous measurement of the local strain at multiple locations along the fiber length was obtained. This procedure typically results in 10 to 20 stress–strain curves per fiber (Maraghechi et al. 2023a). From these local stress–strain curves, the local longitudinal elastic moduli of the fibers were deduced, from which the overall, average elastic modulus was computed. In addition, the ultimate tensile strength of each fiber was determined from the maximum force registered during the tensile test and the minimum cross-sectional area of the fiber. More details on the experimental procedure are provided in Maraghechi et al. (2023a).

The degree of polymerization of the (aged and unaged) paper samples was measured using the rheometry-based method recently proposed in Maraghechi et al. (2023b). Accordingly, a dilute cellulose solution was prepared by dissolving the cellulose paper samples in a solvent. The dynamic viscosity of the cellulose solutions was measured via rotational rheometry, which is based on the application of a rotational shear flow to a thin film of the considered fluid (Morrison 2001). After converting the dynamic viscosity to the intrinsic viscosity, the viscosity-average degree of polymerization (\(\textrm{DP}_{v}\)) was deduced by applying the Mark-Houwink-Sakurada relation (Maraghechi et al. 2023b). From each paper sample of a specific age, three specimens were extracted and tested, and the average \(\textrm{DP}_{v}\) value was determined for each ageing time. Finally, these \(\textrm{DP}_{v}\) values were converted to \(\textrm{DP}\) values that represent the average number of monomeric units in the cellulose molecules, using the relation (Tétreault et al. 2019):

Combining the results of the micro-tensile experiments and DP measurements, a relationship between the fiber fracture strength \(\sigma _u\) and the degree of polymerization \(\textrm{DP}\) of the paper sheet is established. The chemical degradation process is assumed to occur uniformly across the various length scales, so that the degree of polymerization measured at the macroscopic sheet scale is the same at the fiber scale. This assumption enables to directly use the sheet scale DP measurements for calibration of the fiber fracture strength via Eq. (8).

Figure 3 shows for each ageing time the experimental strength values of paper fibers versus the corresponding DP value. The data at the initial degree of polymerization, \(\textrm{DP}_0 = 2452\), were obtained from the DP measurements on the unaged paper samples. The experimental data points exhibit significant scatter; this is due to the fact that the local fiber cross-sectional area used for calculating the fiber tensile strength varies substantially across different fibers, as a result of the irregular shape typical of organically formed paper fibers (Maraghechi et al. 2023a). Nonetheless, the trend of a decreasing tensile strength under a decreasing degree of polymerization is consistent with other sources in the literature, e.g., Tétreault et al. (2019). The black solid line represents the best fit of the average experimental strength values using Eq. (8), with the initial tensile strength \(\sigma _{u,0}\) and the coefficient \(\gamma\) equal to \(\sigma _{u,0} = 636.3\) MPa and \(\gamma = 0.0719\), respectively.

In addition to the tensile strength, the micro-tensile experiments provided the longitudinal elastic modulus \(E_{\ell }\) of individual fibers. The longitudinal elastic modulus depends on the moisture content \({m}\) via Eq. (7), which, in turn, depends on the degree of polymerization \(\textrm{DP}\) via Eqs. (3) and (5). The parameter value of \(E_{\ell }\) is determined at DP\(_0\) from the experimental measurements on the three fibers extracted from the unaged paper sample, which resulted in \(E_{\ell }=6.5\) GPa. It is worth noting that the value of \(E_{\ell }\) falls within the range of values of 5 to 43 GPa following from other experimental works on paper fibers (Lorbach et al. 2014; Kouko et al. 2019; Maraghechi et al. 2023a). As mentioned, the environmental conditions during the experiments correspond to RH =RH\(_0= 50~\%\) and T = T\(_0= 20 ~^\circ\)C, which, together with DP=DP\(_0\) (representing the unaged paper sample), via Eqs. (3)–(5) leads to \(m=m_{ref,0}=0.073\). Inserting this value for the moisture content in Eq. (7)\(_2\) (using \(m_c=0.05\)) leads to \(E_{\ell ,\textrm{dry}} = 7.9\) GPa. The transverse elastic modulus and the shear modulus of cellulose fibers under dry conditions can be subsequently computed based on the stiffness ratios \(c_1 = E_{\ell ,\textrm{dry}}/E_{t,\textrm{dry}}\) = 6 and \(c_2 = {E}_{\ell ,\textrm{dry}}/\textrm{G}_{\ell \mathfrak { t }, \textrm{dry}}\) = 10 (Schulgasser and Page 1988; Bergander and Salmén 2002), which results in \(E_{t,\textrm{dry}}\) = 1.3 GPa and \(\textrm{G}_{\ell \mathfrak { t }, \textrm{dry}}\) = 0.8 GPa. From these stiffness values and the values of \(c_1\) and \(c_2\), the variations of \(E_t\) and \(G_{\ell t}\) as a function of the moisture content can be determined from Eq. (7). The remaining material parameters follow from the literature, with the Poisson’s ratio of the fibers selected as \(\nu _{\ell t}\) = 0.3 (Schulgasser and Page 1988), and the hygro-expansion coefficients in the longitudinal and transverse directions respectively taken as \(\beta _\ell\) = 0.013 and \(\beta _{\mathfrak { t }}= 20\beta _\ell\) = 0.260 (Niskanen 1998). Table 2 summarizes the chemical and hygro-mechanical material parameters of the model.

Fiber tensile strength versus the degree of polymerization \(\textrm{DP}\) of the corresponding paper sheets. The blue dots represent experimental data, and the black curve reflects the best fit of the average values of the experimental fiber tensile strength using Eq. (8)

Geometrical properties of the fibrous network

The geometrical parameters adopted for constructing the network geometry are selected from different sources in the literature and summarized in Table 3. Initially, a network of cellulose fibers with a uniform fiber orientation distribution (i.e., \(q = 0\), see Eq. (9)) is considered. The fiber width is taken as w = 35 \(\mu\)m (Jajcinovic et al. 2016), and the average fiber length is calculated using an aspect ratio of l/w = 50 (Niskanen 1998), resulting in l = 1.75 mm. The coverage is taken as \(\bar{c}\) = 5, which is a representative value for paper sheets (Niskanen 1998). The size L of the micro-scale unit cell is selected as \(L = 2l = 3.5\) mm. This value has been determined from a convergence study in which the effective hygro-mechanical material properties have reached constant values within a predefined tolerance (Bosco et al. 2017b). Accordingly, the periodic fibrous unit cell incorporates sufficient micro-structural information to be considered statistically representative of a real, stochastic fibrous network.

The generation of an appropriate finite element mesh for the fibrous network geometry is a challenging task, particularly at the inter-fiber bonding regions where overlapping fibers with different orientations need to be accurately represented by the local mesh densities of individual fibers (Samantray et al. 2020). In this work, a simplified yet robust meshing strategy is adopted, which employs a mesh consisting of a regular grid of square-shaped, bilinear quadrilateral finite elements, equipped with a four-point Gauss quadrature. The element edge length is defined as \(l_e = w/\zeta\), where \(\zeta \ge 1\) is an integer. The parameter \(\zeta\) is set to 5, resulting in an element size of \(l_e = w/\zeta = 7\) \(\mu\)m. Accordingly, the unit cell is discretized by a regular grid of 500\(\times\)500 elements, see also Parsa Sadr et al. (2022). Additional simulations not presented here have confirmed that this spatial discretization is sufficiently fine to achieve mesh-independent computational results within a small, predefined tolerance.

Initial and boundary conditions

In the numerical simulations, the thermal and hygroscopic boundary conditions are selected following the climate specifications commonly used in museums and libraries for the display and storage of paper artefacts, i.e., T = 20 \(^\circ\)C and \(\textrm{RH}= 50 \%\) (Michalski 2007; Verticchio et al. 2021). The initial reference value of the relative humidity \(\textrm{RH}_0\), with respect to which self-stresses build up in the fibers, is defined by the water content during the paper production process. In the production process the dry pulp is dispersed into water to form a slush (Bajpaj 2015), so that it can be assumed that \(\textrm{RH}_0 = 100\%\). The thermal strains in paper are typically negligible compared to the hygroscopic strains (Niskanen 1998). Hence, the reference value of the temperature T\(_0\) is only employed to determine the reference value of the moisture content \(m_0\) using Eqs. (3) and (4). For simplicity, T\(_0\) is set equal to the temperature at storage/display conditions, T\(_0\) (= T) = 20 \(^\circ\)C. As mentioned in Sect. “Numerical solution procedure”, in the mechanical analysis the boundary conditions of the unit cell are taken as periodic. The total duration of the simulated paper degradation process is discretized into 500 equal time increments. It has been verified that this time discretization simulates the time course of the degradation process at sufficiently high accuracy.

Numerical results

In this section, the results of the numerical simulations are analyzed and discussed. Section “Reference simulation” presents the outcome of the reference simulation based on the parameter sets listed in Tables 2 and 3. Section “Influence of time-dependent acidity and moisture content” assesses the influence of the time-dependency of the acidity and moisture content on the chemo-mechanical degradation response of paper. Finally, in Sect. “Influence of micro-structural features” the influence on the degradation process by underlying micro-structural features is investigated, by performing a parameter variation study on the fiber orientation distribution and the fiber longitudinal elastic modulus.

Reference simulation

The chemo-mechanical degradation of paper is discussed with reference to the environmental conditions presented in Sect. “Initial and boundary conditions”, which correspond to a temperature T = \(20 \, ^\circ\)C and a relative humidity \(\textrm{RH}= 50 \%\). Figure 4a shows the time evolution of the degree of polymerization of the cellulose fibers, which starts at the initial value \(\textrm{DP}_0 = 2452\) and gradually decreases in value with time. Figure 4b illustrates that the process of depolymerization of cellulose decreases the pH of the paper, see also Eq. (6). Specifically, the pH starts at an initial value of 6.50 (determined at \(\textrm{DP}_0\)) and reduces towards a value of 4.95 upon completion of the degradation process. Figure 4c displays the relation between the degree of polymerization and the moisture content; it can be observed that from the initial value \(m=m_{ref,0}=0.073\) at DP\(_0 = 2452\) the moisture content mildly decreases to a value of \(m=0.07\) at \(\textrm{DP}= 500\), followed by a relatively strong decrease to \(m=0.062\) as the degree of polymerization further reduces to a final value of \(\textrm{DP}= 165\).

Time-dependent behavior of paper displayed/stored at a temperature \(\textrm{T} = 20 \, ^\circ \textrm{C}\) and a relative humidity \(\textrm{RH}= 50 \%\). a Degree of polymerization \(\textrm{DP}\) as a function of time t. b pH of paper as a function of the degree of polymerization \(\textrm{DP}\). c Moisture content m of paper as a function of the degree of polymerization \(\textrm{DP}\)

Figures 5a, b depict the time evolution of the effective stiffness \(\bar{C}_{xxxx}\) and the effective hygroscopic expansion \(\bar{\beta }_{xx}\) in \(x-\)direction, respectively. The values of these parameters have been computed by averaging at each time step the responses of five different realizations of the micro-structural fibrous network.

Time-dependent effective constitutive properties of paper exposed to a temperature \(\textrm{T} = 20 \, ^\circ\)C and a relative humidity \(\textrm{RH}= 50 \%\). Time-evolution of a the effective stiffness component \(\bar{C}_{xxxx}\) (GPa) and b the effective hygro-expansion coefficient \(\bar{\beta }_{xx}\)

Since the distribution of fibers is isotropic (\(q = 0\)), the effective properties in the \(y-\) direction are virtually equal to those in the \(x-\)direction, and therefore are omitted here. Furthermore, although not illustrated here, the time-dependent response of the remaining components of the stiffness tensor and hygroscopic expansion tensor are similar to those of \(\bar{C}_{xxxx}\) and \(\bar{\beta }_{xx}\), respectively. Figure 5a reveals that during an initial period of approximately 1100 years the effective stiffness \(\bar{C}_{xxxx}\) of the paper mildly increases. This increase is due to the drop in the moisture absorption capacity of the fibers as the degree of polymerization decreases (with increasing time), see Fig. 4c, which causes an increase in the elastic modulus of the fibers, see Fig. 1, and thus results in a slight growth of the effective stiffness of the paper. This typical feature is confirmed by experimental investigations on the degradation of biodegradable polymers, which indicate that the value measured for the effective stiffness initially either remains constant or slightly increases (Zou et al. 1994; Lam et al. 1994; Duek et al. 1999; Yuan et al. 2002; Tsuji and Suzuyoshi 2002; Saha and Tsuji 2006). As the aging time increases, however, the reduction in fiber tensile strength under a decreasing degree of polymerization - as governed by Eq. (8) - starts to dominate the mechanical response of the paper sheet. The internal stresses in the fibrous network locally reach the reduced fiber tensile strength after the paper has aged for more than 1100 years. Consequently, damage progressively develops at several locations in the fibrous network, leading to a fast decrease in the effective stiffness of the paper. The effective stiffness vanishes at around 1250 years, corresponding to a complete loss of the integrity of the paper sheet. Figure 5b illustrates that the effective hygroscopic expansion coefficient \(\bar{\beta }_{xx}\) initially remains constant, but starts to strongly decrease after about 1100 years, more or less simultaneously with the strong reduction in effective stiffness shown in Fig. 5a. In contrast to the stiffness, the hygro-expansivity maintains a finite value when the paper is fully damaged. This can be explained by the fact that the numerous damaged fiber parts characterizing the loss of integrity of the fibrous network are no longer able to transfer stresses (in correspondence with a vanishing elastic deformation), but do experience some hygroscopic deformation. Note finally that the specific trend of the time-decay of the effective hygro-elastic properties depends on the combined influence of the time evolution of the tensile strength - governed by Eq. (8)—and the longitudinal elastic modulus of the fibers. The relatively low elastic modulus (\(E_{\ell ,dry} = 7.9\) GPa) used in the reference simulation results in the abrupt degradation process observed in Fig. 5. Conversely, for stiffer fibers, the degradation process will occur more gradually, as discussed in Sect. “Effect of fiber longitudinal elastic modulus”.

The sudden and significant decrease in the stiffness and hygro-expansion coefficients of paper depicted in Fig. 5 implies that degradation processes can manifest rather unexpectedly within a relatively short time, emphasizing the need for proactive monitoring and preservation strategies. When translating these results to a degradation risk assessment, it is recalled that the lifetime of historic paper is typically defined as the expected time at which an artefact reaches a threshold state beyond which it becomes unfit for use or display. There are several criteria to quantify this fitness threshold, which may be based on changes in mechanical, physical, chemical, and/or visual properties (Strlič et al. 2015b). Adopting the criterion established in our previous work (Parsa Sadr et al. 2022), a loss of 20% of paper stiffness relative to its initial value indicates that the paper is no longer fit for use. When applying this criterion to the results shown in Fig. 5a, the expected lifetime of the paper samples becomes approximately 1210 years, which is only slightly shorter than the 1250 years at which the paper has lost its effective stiffness and disintegrates.

Influence of time-dependent acidity and moisture content

In the reference simulation discussed in Sect. “Reference simulation” above, the moisture content and the acidity of the paper evolve as a function of the degree of polymerization (and thus time), as described via Eqs. (3) and (6), respectively. To assess the influence of these two evolution laws on the paper ageing behaviour, in this section the results of the reference simulation are compared to simulation results in which the acidity and the moisture content consecutively are taken as constant in time. The remaining model parameters and the environmental conditions adopted in these simulations are the same as for the reference simulation. Similar to the reference simulation, the computational results are presented through the average response calculated from five micro-structural realizations.

Effect of time-dependency of paper acidity

Figures 6a, b show the time evolutions of, respectively, the effective stiffness component \(\bar{C}_{xxxx}\) and the effective hygro-expansion coefficient \(\bar{\beta }_{xx}\) under a constant pH level (blue dashed line) and a time-dependent pH level (black solid line). The result for the time-dependent pH level refers to the reference simulation and is taken from Fig. 5. The numerical simulation with a constant acidity considers a pH value of 6.50, which corresponds to the initial pH value in the reference simulation, see Fig. 4b. It can be observed that the stiffness and the hygro-expansivity of paper under the time-dependent pH level degrade significantly faster than under the constant pH level. In specific, the lifetime of 3000 years calculated for a constant pH value of 6.50 is 2.4 times longer than the 1250-year lifetime following from the reference simulation, in which the pH value monotonically drops from 6.50 to 4.95 with decreasing degree of polymerization, see Fig. 4b. This result emphasizes the importance of accounting for the evolution in acidity as a function of the degree of polymerization in the analysis of paper ageing, since its neglect may lead to a significant overestimation of the paper's lifetime. It further shows that it is useful to explore the effectiveness of deacidification techniques for extending the lifetime of paper artefacts, see Baty et al. (2010) for more details.

Effect of the time-dependency of the paper acidity on the effective constitutive properties. Time evolutions of a the effective stiffness component \(\bar{C}_{xxxx}\), and b the effective hygro-expansion coefficient \(\bar{\beta }_{xx}\). The numerical result of the reference simulation that considers a time-dependent acidity profile is represented by the black solid line and is taken from Fig. 5 and the result for a constant acidity with a pH of 6.50 is represented by the blue dashed line

Effect of time-dependency of moisture content

Figures 7a, b show the time evolutions of, respectively, the effective stiffness component \(\bar{C}_{xxxx}\) and the effective hygro-expansion coefficient \(\bar{\beta }_{xx}\) under a constant moisture content m (red dash-dotted line) and a time-dependent moisture content m (black solid line).

Effect of the time-dependency of the moisture content of paper on the effective constitutive properties. Time evolutions of a the effective stiffness component \(\bar{C}_{xxxx}\), and b the effective hygro-expansion coefficient \(\bar{\beta }_{xx}\). The numerical result of the reference simulation that considers a time-dependent moisture content m is represented by the black solid line and is taken from Fig. 5 and the result for a constant moisture content with \(m=0.073\) is represented by the red dash-dotted line

The result for the time-dependent moisture content corresponds to the reference simulation and is taken from Fig. 5. The numerical simulation with a constant moisture content uses a value of \({m}= 0.073\), which agrees with the initial moisture content in the reference simulation where the moisture content monotonically decreases from \({m}= 0.073\) to \({m}= 0.062\) under a decreasing DP value, see Fig. 4c. Figure 7a shows that, under a constant moisture content, the initial stiffness increase in time has vanished; instead, the effective stiffness remains constant over a large time due to the fact that the elastic modulus of the fibers does not change, in agreement with Eq. (7). Further, the onset of rapid degradation starts earlier than under a varying moisture content, i.e., at about 800 years, as illustrated by the steep drop in the time evolution of both the stiffness \(\bar{C}_{xxxx}\) and the hygro-expansivity \(\bar{\beta }_{xx}\). Correspondingly, the loss of integrity of the paper sample under a constant moisture content is approximately \((1-835/1250)\)=0.33 times shorter than under a varying moisture content. The longer lifetime at varying moisture content is mainly due to the gradual decrease of the reaction rate k when the moisture content reduces to its final value \({m}= 0.062\), as described by Eq. (2).

Influence of micro-structural features

The impact of underlying micro-structural features on the time-dependent degradation of paper is investigated through a parameter variation study. For this purpose, the parameter q defining the anisotropy of the fiber network orientation and the longitudinal elastic modulus \(E_{\ell ,\textrm{dry}}\) of the fibers at zero moisture content are varied within ranges representative of realistic micro-structures of paper materials. The influence of these two parameters on the degradation behaviour of the paper is discussed in Sects. “Effect of fiber orientation distribution” and “Effect of fiber longitudinal elastic modulus”, respectively. The remaining parameters and the prescribed environmental conditions used in these simulations are the same as those of the reference simulation. The computational results are presented through the average response obtained from five micro-structural realizations.

Effect of fiber orientation distribution

The influence of the fiber orientation distribution on the degradation of paper is analyzed by considering four different values for the network anisotropy parameter, namely q = [0, 0.25, 0.5, 0.75], see Fig. 8, with \(q = 0\) corresponding to the isotropic network considered in the reference simulation presented in Sect. “Reference simulation”. Figures 8a, b show the time evolutions of the effective stiffness components \(\bar{C}_{xxxx}\) and \(\bar{C}_{yyyy}\), respectively.

Effect of the fiber orientation distribution on the time-dependent effective constitutive properties of paper. Time evolutions of a the effective stiffness component \(\bar{C}_{xxxx}\), b the effective stiffness component \(\bar{C}_{yyyy}\), c the effective hygro-expansion coefficient \(\bar{\beta }_{xx}\), and d the effective hygro-expansion coefficient \(\bar{\beta }_{yy}\), for four values of the network anisotropy parameter, q = [0, 0.25, 0.5, 0.75]. The black solid line denotes the result of the reference simulation

A higher value of the network anisotropy parameter q corresponds to a stronger preferential alignment of the fibers along the x-direction. This respectively increases and decreases the initial effective stiffness in x- and y-directions, since the fiber stiffness \(E_{\ell ,\textrm{dry}}\) in the longitudinal fiber direction is approximately 6 times larger than the fiber stiffness \(E_{t,\textrm{dry}}\) in the transversal direction, see Table 2. Hence, for the largest value of the network anisotropy parameter, \(q=0.75\), the initial effective stiffness in x-direction is \(5.5/1.5 = 3.7\) times larger than in y-direction. Figure 8c, d illustrate that the hygro-expansion coefficient components \(\bar{\beta }_{xx}\) and \(\bar{\beta }_{yy}\) show the opposite trend, where for the maximum value of the network anisotropy \(q=0.75\) the effective hygro-expansivity \(\bar{\beta }_{xx}\) in x-direction is about 10 times smaller than the value \(\bar{\beta }_{yy}\) in y-direction. This is due to the fact that the fiber hygro-expansivity \(\beta _{\ell }\) in the longitudinal direction is 20 times smaller than the value \(\beta _t\) in the transversal direction, see Table 2. Finally, it is observed that the degree of network anisotropy hardly influences the time-dependent degradation behavior and lifetime of the paper.

Effect of fiber longitudinal elastic modulus

The influence of the longitudinal elastic modulus of the fibers on paper degradation is analyzed by selecting three different values, namely \(E_{\ell ,\textrm{dry}}\) = [7.9 GPa, 25.4 GPa, 42.8 GPa]. The lowest value \(E_{\ell ,\textrm{dry}}\) = 7.9 GPa relates to the reference simulation discussed in Sect. “Reference simulation”, and has been determined from the micro-scale tensile tests described in Sect. “Experiments and material parameters”. The other two values reflect the parameter spread representative of the experimental data reported in other works on cellulose fibers (Lorbach et al. 2014; Kouko et al. 2019; Maraghechi et al. 2023a). Figure 9a, b respectively show the normalized effective stiffness component \({\tilde{C}}_{xxxx} = {\bar{C}_{xxxx}}/{\bar{C}^0_{xxxx}}\) and the normalized effective hygro-expansion coefficient \({\tilde{\beta }}_{xx}\) = \(\bar{\beta }_{xx}/\bar{\beta }^0_{xx}\), with \(\bar{C}^0_{xxxx}\) and \(\beta ^0_{xx}\) the initial values at \(t=0\). It is seen that the decrease in effective properties initiates earlier if the fibers are stiffer. This is, since at a specific deformation a higher fiber elastic modulus results in higher tensile stresses in the fibrous network. Further, the value of the fiber elastic modulus does not significantly influence the instant at which the integrity of the paper is completely lost. Nevertheless, using the criterion proposed in Parsa Sadr et al. (2022), for which the fitness threshold corresponds to a loss of 20% of paper stiffness relative to its initial value, for the highest value of the longitudinal elastic modulus, \(E_{\ell ,\textrm{dry}}\) = 42.8 GPa, the expected lifetime of the paper is approximately 245 years shorter than that computed for the lowest elastic modulus, \(E_{\ell ,\textrm{dry}}\) = 7.9 GPa. This indicates the importance of accurately measuring the fiber elastic modulus in paper degradation studies, highlighting the great value and potential of the micro-scale tensile testing methodology proposed in Maraghechi et al. (2023a).

Effect of the fiber longitudinal elastic modulus on the time-dependent effective constitutive properties of paper. Time evolutions of a the normalized effective stiffness component \({\tilde{C}}_{xxxx}\), and b the normalized effective hygro-expansion coefficient \({\tilde{\beta }}_{xx}\), for three values of the fiber elastic modulus, \(E_{\ell ,\textrm{dry}}\) = [7.9 GPa, 25.4 GPa, 42.8 GPa]. The black solid line denotes the result of the reference simulation

Conclusions

An advanced multi-scale modeling framework is proposed for the prediction of chemo-mechanical degradation of historical paper, with the particular aim of uncovering the key factors affecting the degradation process. The primary mechanism driving paper degradation is the hydrolysis of cellulose, which is influenced by environmental parameters, i.e., temperature and relative humidity, and the acidity of the paper. The proposed model accounts for the temporal evolution of the degree of polymerization, acidity, and moisture content in a paper fibrous network, from which the time-dependent tensile strength of the paper fibers is derived. The constitutive behaviour of the fibers is simulated by a chemo-hygro-mechanical model, which incorporates moisture-dependent mechanical properties. Fluctuations in relative humidity induce internal stresses in the fibrous network, which may lead to brittle fiber fracture once the fiber tensile strength is reached. Since the tensile strength depends on the extent of chemical degradation, in the fibrous network the fiber fractures gradually develop over time, from which the consequent reduction in the effective properties of the fibrous network is calculated through asymptotic homogenization.

The calibration of various material parameters in the chemo-mechanical model is achieved through dedicated experimental measurements. The fiber longitudinal elastic modulus and fracture strength are determined through a recently developed experimental methodology based on in-situ tensile testing of individual fibers combined with optical profilometry (Maraghechi et al. 2023a). The experiment was repeated for fibers from various paper samples characterized by different ageing states. The degree of polymerization is measured using a rheometry-based experimental procedure (Maraghechi et al. 2023b). By combining the results of the micro-tensile experiments and the degree of polymerization measurements, the fiber fracture strength is determined as a function of the degree of polymerization.

Numerical simulations are carried out to predict the chemo-mechanical degradation behaviour of paper, taking into account the time-dependent evolutions of the paper acidity and moisture content. Under a time-dependent increase of the acidity, the paper stiffness and hygro-expansion coefficients deteriorate more rapidly than under a constant acidity. This emphasizes the importance of managing and controlling acidity levels for the preservation of paper artefacts. The simulations also reveal that a time-dependent decrease in moisture content results in an initial stiffening of the paper material, which is consistent with findings from other degradation studies. The numerical simulations further consider the influence of micro-structural features (i.e., the fiber network anisotropy and the fiber longitudinal elastic modulus) on the effective degradation response of paper. The fiber network anisotropy has a minimal influence on the paper degradation behavior and its lifetime. In contrast, the longitudinal elastic modulus of cellulose paper fibers does not affect the time at which the integrity of paper is completely lost, but does influence its expected lifetime based on the specific fitness threshold criterion applied. Accordingly, papers composed of fibers with a higher elastic modulus have a shorter expected lifetime. This suggests that accurately measuring the elastic modulus of individual paper fibers is crucial for performing high-quality paper degradation studies, highlighting the significance of the advanced micro-scale tensile testing methodology applied in this study. The outcome of the proposed model provides valuable insights into the time-dependent degradation behaviour and the corresponding lifespan of historical paper artefacts under indoor climate conditions typically maintained in museums, archives, and libraries. Therefore, the results of this work can help conservators of cultural heritage institutions determining optimal environmental conditions and conservation procedures for protecting their valuable historical paper artefacts.

Data availibility

Data will be available upon reasonable request.

Notes

It is noted that the factor of 0.244 in the right-hand side of Eq. (2) is accidentally misprinted as 2.44 in equation (4) of our previous work (Parsa Sadr et al. 2022). Nevertheless, for the computation of the numerical results presented in Parsa Sadr et al. (2022), the correct value of 0.244 was used.

References

Alam I, Sharma C (2023) Degradation of paper products due to volatile organic compounds. Sci Rep 13(1):6426

Bajpaj P (2015) Green chemistry and sustainability in pulp and paper industry. Springer, Switzerland

Bakhvalov NS, Panasenko G (1989) Homogenisation: averaging processes in periodic media. Mathematical Problems in the Mechanics of Composite Materials. Kluwer, Dordrecht

Barański A (2002) Ageing kinetics of cellulose and paper. Restaurat Int J Preserv Lib Arch Mater 23(2):77–88

Baty JW, Maitland CL, Minter W et al (2010) Deacidification for the conservation and preservation of paper-based works: a review. BioResources 5(3):1955–2023

Bergander A, Salmén L (2002) Cell wall properties and their effects on the mechanical properties of fibers. J Mater Sci 37(1):151–156

Borodulina S, Kulachenko A, Tjahjanto DD (2015) Constitutive modeling of a paper fiber in cyclic loading applications. Comput Mater Sci 110:227–240

Bosco E, Peerlings RH, Geers MGD (2017) Hygro-mechanical properties of paper fibrous networks through asymptotic homogenization and comparison with idealized models. Mech Mater 108:11–20

Bosco E, Peerlings RHJ, Geers MGD (2017) Asymptotic homogenization of hygro-thermo-mechanical properties of fibrous networks. Int J Solids Struct 115–116:180–189

Bosco E, Peerlings RHJ, Lomans BAG et al (2018) On the role of moisture in triggering out-of-plane displacement in paper: from the network level to the macroscopic scale. Int J Solids Struct 154:66–77

Brandberg A, Motamedian HR, Kulachenko A et al (2020) The role of the fiber and the bond in the hygroexpansion and curl of thin freely dried paper sheets. Int J Solids Struct 193–194:302–313

Calvini P, Gorassini A (2006) On the rate of paper degradation: lessons from the past. Restaurat Int J Preserv Lib Arch Mater 27(4):275–290

Calvini P, Gorassini A, Merlani AL (2008) On the kinetics of cellulose degradation: looking beyond the pseudo zero order rate equation. Cellulose 15(2):193–203

Caulfield DF (1988) Dimensional stability of paper: papermaking methods and stabilization of cell walls. In: Suchsland O (ed) Stabilization of the wood cell wall. Michigan State University Press, Michigan, pp 87–98

Cox HL (1952) The elasticity and strength of paper and other fibrous materials. Br J Appl Phys 3(3):72

Drugan WJ, Willis JR (1996) A micromechanics-based nonlocal constitutive equation and estimates of representative volume element size for elastic composites. J Mech Phys Solids 44(4):497–524

Duek EAR, Zavaglia CAC, Belangero WD (1999) In vitro study of poly(lactic acid) pin degradation. Polymer 40(23):6465–6473

Ekenstam A (1936) The behaviour of cellulose in mineral acid solutions: kinetic study of the decomposition of cellulose in acid solution. Berichte der Deutchen Chemischen Gesellschaft 69:553

Emsley AM, Stevens GC (1994) Kinetics and mechanisms of the low-temperature degradation of cellulose. Cellulose 1(1):26–56

Emsley AM, Heywood RJ, Ali M et al (1997) On the kinetics of degradation of cellulose. Cellulose 4:1–5

Emsley AM, Heywood RJ, Ali M et al (2000) Degradation of cellulosic insulation in power transformers. Part 4: Effects of ageing on the tensile strength of paper. IEE Proc-Sci Measur Technol 147(6):285–290

Hill DJT, Le TT, Darveniza M et al (1995) A study of degradation of cellulosic insulation materials in a power transformer, Part 1. Molecular weight study of cellulose insulation paper. Polym Degrad Stabil 48(1):79–87

Jajcinovic M, Fischer WJ, Hirn U et al (2016) Strength of individual hardwood fibres and fibre to fibre joints. Cellulose 23(3):2049–2060

Jajcinovic M, Fischer WJ, Mautner A et al (2018) Influence of relative humidity on the strength of hardwood and softwood pulp fibres and fibre to fibre joints. Cellulose 25(4):2681–2690

Kloppenburg G, Walther E, Holthusen H et al (2023) Using numerical homogenization to determine the representative volume element size of paper. Proc Appl Math Mech (PAMM) 22(1):1

Kouko J, Jajcinovic M, Fischer W et al (2019) Effect of mechanically induced micro deformations on extensibility and strength of individual softwood pulp fibers and sheets. Cellulose 26(3):1995–2012

Lam KH, Nieuwenhuis P, Molenaar I et al (1994) Biodegradation of porous versus non-porous poly (L-lactic acid) films. J Mater Sci - Mater Med 5(4):181–189

Leheny S, Robbins TC, Robbins CK et al (2021) Directional dependence of the mechanical properties of aged paper. Mech Mater 162:104–036

Linvill E, Östlund S (2014) The combined effects of moisture and temperature on the mechanical response of paper. Exp Mech 54(8):1329–1341

Liu Y, Kralj Cigié I, Strliç M (2017) Kinetics of accelerated degradation of historic iron gall ink-containing paper. Polym Degrad Stab 142:255–262

Lorbach C, Fischer WJ, Gregorova A et al (2014) Pulp fiber bending stiffness in wet and dry state measured from moment of inertia and modulus of elasticity. BioResources 9(3):5511–5528

Lucchi E (2018) Review of preventive conservation in museum buildings. J Cult Herit 29:180–193

Malachowska E, Dubowik M, Boruszewski P et al (2020) Influence of lignin content in cellulose pulp on paper durability. Sci Rep 10(1):1–12

Malachowska E, Dubowik M, Boruszewski P et al (2021) Accelerated ageing of paper: effect of lignin content and humidity on tensile properties. Herit Sci 9(1):1–8

Maraghechi S, Bosco E, Suiker ASJ et al (2023a) Experimental characterisation of the local mechanical behaviour of cellulose fibres: an in-situ micro-profilometry approach. Cellulose 30:4225–4245

Maraghechi S, Dupont AL, Cardinaels R et al (2023b) Assessing rheometry for measuring the viscosity-average degree of polymerisation of cellulose in paper degradation studies. Herit Sci 11(15):1–9

Michalski SW (2007) The ideal climate, risk management, the ASHRAE chapter, proofed fluctuations, and toward a full risk analysis model. In: Experts roundtable on sustainable climate management strategies, pp 1–19

Montroll E (1941) Molecular size distributions and depolymerization reactions in polydisperse systems. J Am Chem Soc 63(5):1215–1220

Morrison F (2001) Understanding rheology, vol 1. Oxford University Press, New York

Nevell TP (1985) Degradation of cellulose by acids, alkalis, and mechanical means (chapter 9). In: Nevell TP, Zeronian H (eds) Cellulose chemistry and its applications. Ellis Horwood Limited, Chichester, West Sussex, pp 223–242

Niskanen K (ed) (1998) Paper physics. Book 16. Fapet Oy, Helsinki

Nissan AH (1976) H-bond dissociation in hydrogen bond dominated solids. Macromolecules 9(5):840–850

Paltakari J, Karlsson M (1996) Determination of specific heat for dry fibre material. In: CPPA 82nd Annual Meeting-Technical Section, Canadian Pulp and Paper Association, pp B117–B120

Pan J (2015) Modelling degradation of bioresorbable polymeric medical devices. Woodhead Publishing, Elsevier, Cambridge

Parker ME, Bronlund JE, Mawson AJ (2006) Moisture sorption isotherms for paper and paperboard in food chain conditions. Packag Technol Sci Int J 19(4):193–209

Parsa Sadr A, Bosco E, Suiker ASJ (2022) Multi-scale model for time-dependent degradation of historic paper artefacts. Int J Solids Struct 248:111–609

Pastorelli G, Cao S, Cigić IK et al (2019) Development of dose-response functions for historic paper degradation using exposure to natural conditions and multivariate regression. Polym Degrad Stab 168:108–944

Saha SK, Tsuji H (2006) Effects of rapid crystallization on hydrolytic degradation and mechanical properties of poly(L-lactide-co-ε-caprolactone). React Funct Polym 66(11):1362–1372

Samantray P, Peerlings RHJ, Bosco E et al (2020) Level set-based extended finite element modeling of the response of fibrous networks under hygroscopic swelling. J Appl Mech 87(10):101–005

Schulgasser K, Page DH (1988) The influence of tranverse fibre properties on the in-plane elastic behaviour of paper. Compos Sci Technol 32(4):279–292

Seth RS, Page DH (1988) Fiber properties and tearing resistance. Tappi J 71(2):103–107

Shahani CJ, Harrison G (2002) Spontaneous formation of acids in the natural aging of paper. Stud Conserv 47(Supplement 3):189–192

Simon JW (2021) A review of recent trends and challenges in computational modeling of paper and paperboard at different scales. Arch Comput Methods Eng 28(4):2409–2428