Abstract

Accurate determination of molar mass distribution for disperse cellulose samples has proved to be a challenging task. While size-exclusion chromatography coupled to multi-angle light scattering (MALS) and differential refractive index (DRI) detectors has become the most commonly used method for molar mass determination of celluloses, this technique suffers low sensitivity at the low-molar mass range. As discussed here, the universal method for accurate molar mass distribution analysis of cellulose samples not exists and thus thorough understanding on the differences of the various methodological approaches is important. In this study, the focus is in the accurate determination of the low-molar mass fraction. The results obtained by combining the two calibration strategies, MALS/DRI for polymeric region of a cellulose sample and conventional calibration for oligomeric region, was compared to the results obtained using only MALS/DRI (with extrapolation of the curve where signal-to-noise of MALS is low). For birch pulp sample, the results from the two approaches were comparable; it should be highlighted, however, that MALS/DRI slightly overestimates the molar masses at the low-molar-mass region.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Accurate knowledge on the molar mass distribution of polymeric material is often important when evaluating the material’s structure–function properties. This applies also for highly disperse biopolymers, such as polysaccharides. Molar mass determination of polysaccharides is not a straightforward task (Maina et al. 2014; Potthast et al. 2015; Striegel et al. 2009a). Variation in chain length, heterogeneous chemical composition, challenges in dissolution, and impurities complicates the molar mass determination of polysaccharides, among other factors. A good example is cellulose, the most abundant renewable material, which commonly has a broad chain length distribution from oligomeric material to ultra-high molar mass chains, and a very limited solubility in common solvents. A lot of effort has been made in order to find “a universal method” for accurate molar mass determination of cellulose (Potthast et al. 2015) but the complexity of the material makes this task mission impossible. Critical evaluation of the pros and cons of different methods deserves, however, to be thoroughly discussed.

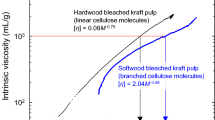

In order to obtain information on the distribution of different chain lengths, separation technique is needed to separate the fractions with different sizes. Size-exclusion chromatography (SEC) is the most common technique for determination of molar mass distribution. Basically, two different approaches are commonly used to determine the molar mass for each size-separated fraction: either the columns are calibrated using narrow dispersity molar mass standards or the light-scattering detector is employed. Since the relationship between the size and molar mass is different for structurally different polymers, the column calibration approach usually gives biased values (or the values should be given as “equivalents” of the calibrant, such as pullulan equivalents). In general, light-scattering detection (most commonly multi-angle light scattering, MALS, detection) gives more realistic molar mass values since it is independent of calibrants. Despite of the fact that MALS is nowadays the preferred method, it has some well-known limitations. MALS detection has low sensitivity in the low-molar mass region. In addition, concentration and refractive index increment (∂n/∂c) are included in the light-scattering equation (Striegel et al. 2009b). Thus, the accuracy of these parameters (for each SEC separated fraction) has direct impact on the accuracy of the molar mass values from MALS. It is often assumed that ∂n/∂c is constant for the disperse polymer sample, but it should be noted that this parameter is dependent on the chemical composition. In addition, ∂n/∂c of oligomeric material might differ from the one determined for the polymeric counterpart due to the chain ends that are more abundant in the oligomeric part of the sample (Striegel 2013). The other required parameter, concentration, is most often determined by differential refractive index detector (DRI). ∂n/∂c is also needed for determination of concentration for each SEC separated fraction. Alternatively, it can be assumed that the area under the DRI signal corresponds to the injected amount. If this latter approach is used, special care must be taken during the sample preparation.

While the challenges in the accurate determination of molar mass for ultra high-molar-mass polysaccharides has been in the focus during the recent years (Isenberg et al. 2010; Maina et al. 2014), the challenges related to the accurate mass characterization of low-molar-mass fraction of the polysaccharides has gained less attention (Striegel and Alward 2002; Striegel 2013). Depending on the application, the accurate knowledge on the lower range of the molar mass distribution might be significant. One good example is spinning of man-made cellulosic fibers for textiles and clothing. It has been shown that spinnability largely depends on the amount of the high molar mass fraction (degree of polymerization, DP > 2000) as well as the amount of the low-molar mass fraction (DP < 100) of cellulose sample and thus, accurate quantitation of both ends of the molar mass distribution is highly important (Michud et al. 2015). In case of cellulose, an attempt was made to solve the problem associated with the MALS/DRI approach or column calibration with structurally different standard compounds by preparing cello-oligomeric standards up to the degree of polymerization (DP) of 21 (Oberlerchner et al. 2016; Zweckmair et al. 2016). This is the best approach for accurate characterization of low-molar mass celluloses but preparation, purification, and mass characterization of the cello-oligosaccharides (by mass spectrometry) is quite time-consuming. In addition, another method for fractions with higher molar mass chains is still needed. In case of cellulose, correction factors for calibration between the two structurally different calibrants (i.e. cello-oligosaccharides and commercially available narrow dispersity calibrants) (Oberlerchner et al. 2016) or calibrant and MALS/DRI calibration curve (Berggren et al. 2003) has also been established. By using correction factors, error in the column calibration approach can be significantly reduced especially at the high molar mass region.

In this work we compared different SEC calibration approaches for the determination and quantitation of the low molar mass fraction from a disperse cellulose sample. Differences between the results obtained by these methods were critically evaluated and the problems related to both MALS/DRI detection and conventional calibration were comprehensively discussed.

Experimental

Materials

Pre-hydrolyzed kraft birch pulp sample was from Stora Enso (Enocell mill, Finland). Pullulans and polystyrenes were from Polymer Standards Service (Mainz, Germany) and cello-oligosaccharides (cellobiose, cellotriose, cellotetraose, and cellopentaose) and linear xylo-oligosaccharides (xylobiose, xylotriose, xylotetraose) from Megazyme (Wicklow, Ireland). Dextrans with nominal molar masses of 1000 and 5000 g/mol were from Sigma-Aldrich (Buchs, Switzerland). Pullulans (nominal molar masses of 342, 1080, 6100, and 107,000 g/mol) were from Polymer Standards Service (Mainz, Germany). Microcrystalline cellulose (MCC) and lithium chloride (LiCl) were from Merck (Darmstadt, Germany) and HPLC grade N,N-dimethylacetamide (DMAc) from VWR Prolabo Chemicals (Radnor, USA).

Size-exclusion chromatography

The instrument consisted of Dionex Ultimate 3000 HPLC module (Thermo Fisher Scientific Inc., Waltham, US), Shodex DRI (RI-101) detector (Showa Denko, Ogimachi, Japan), and Viscotek/Malvern SEC/MALS 20 multi-angle light-scattering (MALS) detector (Malvern Panalytical Ltd., Malvern, UK). The set of four PLgel MIXED-A columns (Agilent Technologies Inc., Palo Alto, US) were used for separation with the flow rate of 0.75 ml/min. The samples were dissolved in the eluent (0.9% LiCl in DMAc) using solvent exchange procedure (water/acetone/DMAc) (Potthast et al. 2002). The injection volume was 100 µl. Detector constants (MALS and DRI) were determined using narrow polystyrene sample (Mw = 96,000 g/mol, Đ = 1.04, refractive index increment, ∂n/∂c, 0.146 ml/g) dissolved directly in 0.9% LiCl in DMAc. Broad polystyrene sample (Mw = 248,000 g/mol, Đ = 1.73) was used for checking the detector calibration. The ∂n/∂c value of 0.136 ml/g was used for celluloses in 0.9% LiCl in DMAc (Schelosky et al. 1999; Potthast et al. 2015). The ∂n/∂c values are known to be wavelength dependent and the value commonly increases with decreasing wavelength. Similar behavior has been observed for cellulose (Ono et al. 2016) but since the effect of wavelength in case of cellulose seems to be quite insignificant, the generally accepted value of 0.136 ml/g measured at 488 nm was used. Cello-oligosaccharides (DP 3–6) were analyzed to construct conventional calibration curve for low-molar mass region. The ∂n/∂c for cello-oligosaccharides, dextrans (nominal molar masses 1000 and 5000) pullulans (nominal molar masses 342, 1080, and 21,100) and xylo-oligosaccharides (DP 2–4) in 0.9% LiCl in DMAc were determined from the online SEC/DRI experiment assuming 100% recovery.

Results and discussion

Challenges of using MALS detection for low-molar mass celluloses

As already pointed out in Introduction, light scattering detection has challenges in the detection of low-molar-mass analytes. Approximation of well-known Rayleigh–Gans–Debye equation (Wyatt 1993; Striegel et al. 2009a, b) yields:

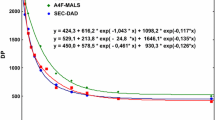

where LS is light scattering detector response, Mw is weight-average molar mass, c is concentration, and ∂n/∂c is refractive index increment. From this approximation we can see that light scattering detector response is directly proportional to the weight-average molar mass which explains the low sensitivity of this detection technique in the low-molar mass region. Since the LS detector response is also proportional to concentration, increasing the concentration of an oligomeric SEC sample yields better signal-to-noise of light scattering signal, but this approach cannot be used for high dispersity samples such as cellulose which also contains ultra-high molar mass chains (risk of entanglement formation and saturation of light scattering detector signals). Thus, commonly the way to obtain molar mass for oligomeric region of disperse analyte by static light scattering technique is to extrapolate the molar mass calibration curve. This was also done in this study for the birch pulp sample. As can be seen in Fig. 1, the extrapolated part (MALS/DRI curves without any noise) starts around retention volume of 29 ml. In this case, with the instrumentation used and with sample concentration of ~ 1 mg/ml, extrapolated curve for molar masses below ~ 38,000 g/mol was used.

Comparison of MALS/DRI and conventional calibration for low-molar-mass region

In addition to constructing the calibration curve for standard pulp sample by MALS/DRI approach, conventional calibration curve was constructed using commercially available low-molar-mass (DP 3–6) cello-oligosaccharides. Since these oligosaccharides cover very narrow molar mass range (504–991 g/mol), MCC with molar mass of 23,900 g/mol (determined by SEC-MALS/DRI) was also used in order to draw a calibration curve for the low-molar-mass region where MALS/DRI calibration curve is extrapolated. For better comparison between MALS/DRI and conventional calibration curves, conventional calibration curve was extrapolated to cover the whole molar mass region of the pulp peak (Fig. 1). As can be seen in Fig. 1, both calibration curves overlay in the molar mass region which covers the most abundant fractions of the pulp sample (measured molar mass values from MALS/DRI and extrapolated values from conventional calibration curve). The two calibration lines, however, deviate from each other at the high and the low-molar mass region. It seems that at the high molar mass region the extrapolated conventional calibration gives higher molar mass values than MALS/DRI curve whereas the situation is opposite at the low-molar mass region. Similar behavior has been reported for kraft pulp cellulose except that the conventional calibration curve was constructed using narrow dispersity pullulan standards (Berggren et al. 2003). Since the molar masses of the early eluting (high-molar-mass) species can be measured by MALS/DRI, these “absolute” molar mass values can be considered reliable. As already pointed out, MALS/DRI curve is extrapolated at the low-molar mass region and thus it is very likely that the accuracy of the conventional calibration curve is better for low molar masses than the MALS/DRI curve. Thus, it can be assumed that the MALS/DRI method combined with the separation technique, which is generally considered to be the most accurate method for determining the molar mass distribution of disperse homopolymers, overestimates the molar mass of low-molar mass cellulose and cello-oligosaccharides. An overestimation of the molar mass of oligomeric region can affect the number-average molar mass calculated from the distribution. The effect on the weight-average molar mass of disperse cellulose sample is less pronounced as will be discussed later.

The dilemma of obtaining reliable molar masses for oligomeric celluloses/cello-oligosaccharides has been discussed by Oberlerchner et al. (2016). They prepared monodisperse cello-oligosaccharides up to DP 21 by acetolysis and preparative chromatographic separation, constructed the SEC calibration curve using the in-house prepared cello-oligosaccharides, and compared the calibration curve to the ones obtained by commercial narrow dispersity standards namely, pullulan, polystyrene, PMMA, and dextran. While the calibration curves constructed using synthetic polymers polystyrene and PMMA deviated significantly from the cello-oligosaccharide curve, low-molar-mass dextran and pullulan showed similar retention behavior to cello-oligosaccharides (similar elution behavior of cello-oligosaccharides and low-molar-mass pullulans was observed in this study; results not shown). Even though it is a known fact that, in general, pullulan calibration overestimates the molar mass data of (1 → 4)-linked polysaccharides (Oberlerchner et al. 2016; Pitkänen et al. 2017), it seems that this is not the case for the low-molar-mass region. Oberlerchner et al. (2016) also compared the cello-oligosaccharide calibration curve to the extrapolated MALS/DRI curve of Avicel cellulose. Similarly to the observations made in this study, the extrapolated MALS/DRI curve gave overestimated molar mass values.

Since MALS detector is not always available and because pullulan calibration curve is known to overestimate the molar masses of celluloses (mid and high chain lengths), correction factors have been determined between MALS/DRI calibration curves and conventional calibration curves in order to obtain MALS/DRI equivalent molar masses for celluloses using conventional calibration (Berggren et al. 2003). The molar mass results obtained from conventional pullulan calibration are more realistic if correction factors have been used but it should be kept in mind, however, that molar mass of low-molar mass region is still overestimated (because MALS/DRI overestimate the masses in the low-molar-mass region). In addition, the correction factors are sensitive to experimental setup, such as concentration of the LiCl in DMAc (LiCl has huge impact on the refractive index of the solvent; see the discussion later for further details) and SEC separation.

Effect of calibration on the quantitation of cellulose low-molar-mass fraction

As already discussed in Introduction, the accurate quantitation of low-molar-mass fraction of cellulose is important for certain applications, such as when evaluating the spinnability of pulp for production of man-made cellulose fibers. As discussed in the previous chapter, molar mass obtained by MALS/DRI method for each SEC separated low-molar mass fraction is inaccurate (overestimate) and that the cello-oligosaccharide calibration curve gives more realistic molar masses for the low-molar mass cellulose chains. In principle, the elution volume of each sample fraction in relation to calibrants determines the molar mass and the DRI peak height the relative concentration if the conventional calibration is used for determination of molar mass distribution. The effect of calibration curve on the molar mass distribution of pulp sample is presented in Fig. 2. As can be seen in Fig. 2, when conventional calibration is used, low-molar-mass analytes with molar masses ranging from 800 to 2000 g/mol is present. These fractions are not quantified when MALS/DRI method is used.

Molar mass distribution of a birch pulp sample determined using MALS/DRI method and calibration where cello-oligosaccharides have been used for low-molar mass region (M ≤ ~ 39,000 g/mol; the point in which the two calibration lines intersect in Fig. 1)

Even though the calibration method for the low-molar mass region have clear effect on the molar mass distribution, only small effect on the distribution averages can be observed (Table 1). Weight-average molar mass (Mw) is practically not affected at all which is expected due to the emphasis of this average on the mass of the chains. Number-average molar mass (Mn) is more affected; Mn obtained when two calibration methods are combined, conventional calibration for low-molar mass region and MALS/DRI for the masses ≥ 39,000 g/mol, is 25% lower compared to the value which was obtained using only the MALS/DRI calibration. The change in Mn value also affect the dispersity. Due to the quantitation of lower molar masses by conventional calibration, the proportion of chains having molar mass lower than DP 100 (16,200 g/mol) is larger (7.4%) compared to case where this value is calculated from the data obtained solely by MALS/DRI (6.4%). DP < 100 is important parameter describing the spinnability of the cellulose fibers. It has been reported that high-molar-mass chains combined with a low amount of short-chain fraction (DP < 100) favors the formation of high strength cellulosic fibers (Michud et al. 2015). The significance of the differences in the data obtained with different calibration curves obviously depend on the application but for the pulp sample used in this study as a model cellulose sample, the differences cannot be considered very significant.

Refractive index increment (∂n/∂c) values for oligosaccharides

The lowest molar masses which can be determined by MALS/DRI method (without extrapolation) greatly depend on the sensitivity of the MALS detector and also the concentration of the analyte. As an example, good MALS signal-to-noise has been reported for styrene monomer (M = 104 g/mol) when 10 mg of sample was injected (Striegel and Alward 2002) (it should be noted that the common injected mass is around 0.05–0.1 mg for celluloses). As can be seen from the Eq. (1), the concentration for each eluted SEC fraction is crucial in order to obtain the molar mass from the MALS detector. Thus, the concentration sensitive detection such as DRI is commonly used together with light scattering detector. The response of the DRI detector is proportional to both c and ∂n/∂c:

In practice, if the ∂n/∂c is known, the concentration can be determined with DRI detector. The ∂n/∂c values for certain polymer/solvent combinations can be found from the literature (Theisen et al. 2000) or those can be measured with refractomer using either online or offline approach. In general, it is assumed that ∂n/∂c is constant for certain sample and no molar mass dependence occurs. However, the ∂n/∂c values for low molar mass analytes may no longer be constant due to a larger number of chain ends (Striegel 2013).

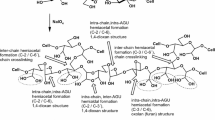

The determination of ∂n/∂c for cellulose has proved to be a challenging task. In order to measure ∂n/∂c accurately, sample concentration needs to be known precisely. Poor solubility of cellulose complicates this task. Direct dissolution of cellulose samples to DMAc containing 8–9% LiCl (after activation steps with water, acetone and neat DMAc) has become a standard sample preparation procedure for SEC (Sjöholm et al. 1999; Matsumoto et al. 2001; Potthast et al. 2015). The samples are commonly diluted before the SEC analysis with neat DMAc to obtain a final LiCl concentration of 0.5–0.9% and the same composition is used as mobile phase in SEC analysis. Even though DMAc/LiCl dissolves cellulose well, LiCl salt complicates further the determination of ∂n/∂c. The ∂n/∂c value of 0.324 ml/g has been reported for LiCl dissolved in DMAc (Berggren et al. 2003). This value is significantly higher than the values reported for cellulose (values for cellulose range from around 0.100 ml/g to 0.140 ml/g depending on the concentration of LiCl; the higher the LiCl concentration, the higher the ∂n/∂c). Also, LiCl is known to interact with the hydroxyl groups of polysaccharides and thus the distribution of LiCl is not even in the solutions (Striegel 1998; Ono et al. 2016). Due to this phenomenon, online measurement of ∂n/∂c (separation of a fully dissolved sample with SEC columns and detection of a sample with known concentration by DRI detector) has proved to be more reliable than the off-line measurements (in which series of samples with various concentration is directly injected to the DRI detector cell). It has been speculated that the LiCl is more evenly distributed in the cellulose solution when the cellulose concentration is low (as is the case in SEC for each eluted fraction) than when it is higher (as is the case when the ∂n/∂c value is determined off-line); LiCl concentration in the vicinity of the cellulose chains is higher as compared to the solvent which is located further away from the cellulose (Ono et al. 2016). Due to this effect, the ∂n/∂c values obtained using off-line method are too low. Cellulose forms stable structures with LiCl leading to structurally heterogeneous solutions. Despite of the challenges in determining ∂n/∂c for celluloses, reliable data on ∂n/∂c are available in the literature (Schelosky et al. 1999; Potthast et al. 2015; Ono et al. 2016). To our knowledge, however, ∂n/∂c for oligomeric carbohydrates is less studied.

As already stated, reliability of the MALS/DRI data for oligomeric region greatly depend on the sensitivity of the MALS detector. If good MALS signal-to-noise can be achieved, correct molar mass data can be obtained if the ∂n/∂c is known. In this study, the ∂n/∂c for cello-oligosaccharides with different DP was measured online (in DMAc with 0.9% of LiCl) to find out the possible effect of DP on the ∂n/∂c value (Table 2). The ∂n/∂c values of other glucose containing oligo- and polysaccharides, namely dextran and pullulan were measured for reference. Hardwood pulp samples commonly contain a small amount of hemicelluloses (mainly xylans; this particular pulp sample contains 5.2% of xylan) which are known to have lower molar mass compared to cellulose. Since xylans might elute as part of a low-molar mass fraction, the ∂n/∂c value for xylo-oligosaccharides was measured in order to see if there was any difference between the ∂n/∂c value of hexo-oligosaccharides (glucose-based oligosaccharides) and pento-oligosaccharides (xylose-based oligosaccharides). The ∂n/∂c value for the lowest molar mass hexo-oligosaccharides (both cello-oligosaccharides and pullulans) was around 0.15 ml/g (Table 2), which is higher compared to value of 0.136 ml/g which is commonly used for cellulose (Potthast et al. 2015). Oligosaccharides contain higher number of free hydroxyl groups compared to the corresponding polymers due to the abundance of chains ends. As discussed in the previous paragraph, LiCl interacts with free hydroxyl groups, which in turn increases the ∂n/∂c. The ∂n/∂c was significantly lower for oligosaccharides with somewhat higher molar mass (molar mass of ~ 1000 g/mol and above), being around 0.13 ml/g (in case of pullulan, the oligosaccharide having molar mass of 1080 had ∂n/∂c close to 0.15 ml/g, but sample with molar mass of 6100 has lower ∂n/∂c of 0.132 ml/g). Thus, it seems that these higher-molar-mass oligosaccharides behave optically the same way as the corresponding polysaccharides. Pento-oligosaccharides had quite low ∂n/∂c compared to hexo-oligosaccharides. The ∂n/∂c values for xylo-oligosaccharides (DP 2–4) varied between 0.115 and 0.123 ml/g. The difference in the ∂n/∂c values between the pento-oligosaccharides and hexo-oligosaccharides can be explained by the different amount of free hydroxyl groups in the structures. Cello-oligosaccharides have higher number of free hydroxyl groups in their structure than the xylose-containing structures due to free hydroxyl group at position of C6 which is absent in xylose (since both of the structures are (1 → 4)-linked, free hydroxyl groups exists at the positions C2 and C3). It is likely that higher amount of LiCl is bound to the cello-oligosaccharides than to the xylo-oligosaccharides due to the higher number of free hydroxyl groups in the former. Similar behavior applies to low-molar mass dextrans and pullulans as for cello-oligosaccharides. Dextrans are (1 → 6)-linked glucose polymers and thus this structure has free hydroxyl groups at the positions of C2, C3, and C4. Pullulan has α-(1 → 4)- and α-(1 → 6)-linkages in its structure and contains free hydroxyl groups at the positions C2, C3 and C4 or C6.

As a summary, knowledge on the ∂n/∂c of cello-oligosaccharides is crucial if accurate molar mass data for low-molar mass celluloses want to be obtained by MALS (i.e., the concentration of the analytes are sufficient and/or the sensitivity of the detector is high enough for good signal-to-noise ratio of the light scattering signals). Pulps often contain small amounts of hemicelluloses such as xylans which have lower molar mass than celluloses and thus elute in SEC at higher retention volumes together with low-molar mass celluloses. It was showed in this study that cello-oligosaccharides have higher ∂n/∂c values than the xylo-oligosaccharides due to the higher number of the free hydroxyl groups which interact with LiCl in the solution. If the sample contains both cello-oligosaccharides and xylo-oligosaccharides, the average ∂n/∂c likely falls somewhere close to the value which is used for cellulose (0.136 ml/g) and this difference between the ∂n/∂c values of the two oligosaccharide classes likely has only very insignificant impact on the accuracy of the molar mass results. Even though it was not investigated in this study, it is very likely that polymeric xylan has somewhat lower ∂n/∂c value in DMAc/LiCl than (polymeric) cellulose. Methyl glucuronoxylan in hardwood contains methylglucuronic acid side groups and high number of xyloses in the xylose backbone carry acetyl groups at the position of C2 and/or C3 (Timell 1967; Jacobs et al. 2001) which decrease further the number of free hydroxyl groups. Thus, in the case of a mixture of cellulose and xylan, the molar masses obtained by MALS/DRI could slightly be underestimated if the ∂n/∂c value for cellulose is used. Other hemicellulose fraction which can be found in softwood pulp, galactoglucomannan, consists of hexoses and, most likely, behave optically the same way as cellulose even though, similarly to methyl glucuronoxylan, some of the hydroxyl groups of mannose and glucose units carry an acetyl group at the position of C2 or C3 (Timell 1967; Willför et al. 2008).

Conclusions

Molar mass determination of cellulose is often a challenging task due to the broad mass range from several millions grams per mole to low-molar-mass (oligomeric) region. Due to the broad molar mass range of cellulose, different chain lengths need to be separated from each other before determination of their molar mass. Separation is commonly done by size-exclusion chromatography (SEC). Coupling of SEC to multi-angle light scattering (MALS) and differential refractive index detectors (DRI) allows the molar mass determination without calibrants but the sensitivity of the light scattering detector at the low-molar mass region is often too low for accurate determination of molar mass and in these cases, molar mass for oligomeric region is obtained by extrapolation of the MALS/DRI curve. More accuracy to the low-molar mass region can be obtained by using the cello-oligo standards and constructing the conventional calibration curve. Commercial cello-oligo standards are, however, available only up to DP 6 and preparation of standards with higher chain lengths is a tedious task. Thus, it is impossible to find the universal method for determination of molar mass distribution for highly disperse cellulose samples.

In this study, we combined the two calibration methods, MALS/DRI for molar masses higher than ~ 39,000 g/mol and conventional calibration curve for the region with molar masses below this number, for molar mass distribution characterization of birch pulp sample. When the data from this combined method was compared with the data obtained solely by MALS/DRI (with extrapolation at the low-molar-mass region), it was clear that the molar mass of the low-molar-mass region was overestimated by MALS/DRI method. The molar mass averages were, however, quite comparable with each other. Number-average molar mass was somewhat lower when conventional calibration was used for low-molar-mass region. All in all, it can be concluded that MALS/DRI can be considered the method of choice if the small errors in the low-molar mass region can be accepted. For samples containing only low-molar-mass celluloses (e.g., degraded celluloses), high sample concentration is required for obtaining adequate MALS signal-to-noise. If molar mass data for oligomeric celluloses is determined with MALS/DRI, the change in the ∂n/∂c value compared to the polymeric cellulose should be taken into consideration.

References

Berggren R, Berthold F, Sjöholm E, Lindström M (2003) Improved methods for evaluating the molar mass distributions of cellulose in kraft pulp. J Appl Polym Sci 88:1170–1179

Isenberg SL, Brewer AK, Côté GL, Striegel AM (2010) Hydrodynamic versus size exclusion chromatography characterization of alternan and comparison to off-line MALS. Biomacromolecules 11:2505–2511

Jacobs A, Larsson PT, Dahlman O (2001) Distribution of uronic acids in xylans from various species of soft- and hardwood as determined by MALDI mass spectrometry. Biomacromolecules 2:979–990

Maina NH, Pitkänen L, Heikkinen S, Tuomainen P, Virkki L, Tenkanen M (2014) Challenges in analysis of high-molar mass dextrans: comparison of HPSEC, AsFlFFF and DOSY NMR spectroscopy. Carbohydr Polym 99:199–207

Matsumoto T, Tatsumi D, Tamai N, Takaki T (2001) Solution properties of celluloses from different biological origins in LiCl · DMAc. Cellulose 8:275–282

Michud A, Hummel M, Sixta H (2015) Influence of molar mass distribution on the final properties of fibers regenerated from cellulose dissolved in ionic liquid by dry-jet wet spinning. Polymer 75:1–9

Oberlerchner JT, Vejdovszky P, Zweckmair T, Kindler A, Koch S, Rosenau T, Potthast A (2016) Filling the gap: calibration of the low molar-mass range of cellulose in size exclusion chromatography with cello-oligomers. J Chromatogr A 1471:87–93

Ono Y, Ishida T, Soeta H, Saito T, Isogai A (2016) Reliable dn/dc values of cellulose, chitin, and cellulose triacetate dissolved in LiCl/N,N-dimethylacetamide for molecular mass analysis. Biomacromolecules 17:192–199

Pitkänen L, Aseyev V, Laine C, Tuomainen P, Tenkanen M (2017) Size-exclusion chromatography of xylan derivatives -the critical evaluation of macromolecular data. Anal Bioanal Chem 409:4811–4817

Potthast A, Rosenau T, Buchner R, Röder T, Ebner G, Bruglachner H, Sixta H, Kosma P (2002) The cellulose solvent system N, N-dimethylacetamide/lithium chloride revisited: the effect of water on physicochemical properties and chemical stability. Cellulose 9:41–53

Potthast A, Radosta S, Saake B, Lebioda S, Heinze T, Henniges U, Isogai A, Koschella A, Kosma P, Rosenau T, Schiehser S, Sixta H, Strlič M, Strobin G, Vorwerg W, Wetzel H (2015) Comparison testing of methods for gel permeation chromatography of cellulose: coming closer to a standard protocol. Cellulose 22:1591–1613

Schelosky N, Röder T, Baldinger T (1999) Molecular mass distribution of cellulosic products by size exclusion chromatography in DMAc/LiCl. Das Papier 53:728–738

Sjöholm E, Gustafsson K, Eriksson B, Brown W, Colmsjö A (1999) Aggregation of cellulose in lithium chloride/N, N-dimethylacetamide. Carbohydr Polym 41:153–161

Striegel AM (1998) Theory and applications of DMAc/LiCl in the analysis of polysaccharides. Carbohydr Polym 34:267–274

Striegel AM (2013) There´s plenty of gloom at the bottom: the many challenges of accurate quantitation in size-based oligomeric separations. Anal Bioanal Chem 405:8959–8967

Striegel AM, Alward DB (2002) Studying abnormal viscosity behavior in dilute oligomer solutions by SEC and rheology. J Liq Chromatogr Rel Technol 25:2003–2022

Striegel AM, Isenberg SL, Côté GL (2009a) An SEC/MALS study of alternan degradation during size-exclusion chromatographic analysis. Anal Bioanal Chem 394:1887–1893

Striegel AM, Yau WW, Kirkland JJ, Bly DD (2009b) Modern size-exclusion liquid chromatography. Wiley, New Jersey

Theisen A, Johann C, Deacon MP, Harding SE (2000) Refractive increment data-book. Nottingham University Press, Nottingham

Timell TE (1967) Recent progress in the chemistry of wood hemicelluloses. Wood Sci Technol 1:45–70

Willför S, Sundberg K, Tenkanen M, Holmbom B (2008) Spruce-derived mannans: a potential raw material for hydrocolloids and novel advanced natural materials. Carbohydr Polym 72:197–210

Wyatt PJ (1993) Light scattering and the absolute characterization of macromolecules. Anal Chim Acta 272:1–40

Zweckmair T, Oberlerchner JT, Böhmdorfer S, Bacher M, Sauerland V, Rosenau T, Potthast A (2016) Preparation and analytical characterisation of pure fractions of cellooligosaccharides. J Chromatogr A 1431:47–54

Funding

Open access funding provided by Aalto University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pitkänen, L., Sixta, H. Size-exclusion chromatography of cellulose: observations on the low-molar-mass fraction. Cellulose 27, 9217–9225 (2020). https://doi.org/10.1007/s10570-020-03419-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03419-9