Abstract

With the development of cellulose chemistry and processing technology, the applications of cellulose materials were not limited to traditional fields as engineering materials in forest originated products, paper, and textile industries, but also used for advanced functional applications in the field of biomedical and smart health care, printed electronics, and responsive wearable textiles. With the advantage of sophisticated geometry fabrication and low cost production, 3D printing technologies have been employed with many materials for a variety of applications. This critical review focuses specifically on the development and assessment of cellulose materials for 3D printing. A special focus was paid on extrusion based 3D printing. Detailed examinations of cellulose hydrogel rheology, fiber entanglement, fiber alignment, gelation, printability, shape fidelity, cell viability and processing parameters in extrusion based 3D printing are explored. Other 3D printing techniques such as inkjet 3D printing, 3D spinning, stereolithography, laminated object manufacturing and selective laser sintering are also introduced. The functionality of 3D printed constructs was designed either by cellulose surface modification or by incorporation of functional components. The properties and performances of 3D printed cellulose constructs as well as their potential applications in the fields of medical, electronics, and smart textile are discussed. Finally, perspective and current important limitations of 3D printing with cellulose materials for advanced application are provided.

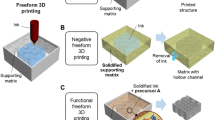

Graphical Abstract

Reprinted with permission from Gross et al. (2014)

Reprinted with permission from Gibson et al. (2015)

Reprinted from Hochleitner et al. (2015) under the Creative Commons Attribution Licence

Reprinted with permission from Wimpenny et al. (2003)

Reprinted with permission from Kariz et al. (2015)

Reprinted from Tao et al. (2017) under the Creative Commons Attribution License

Reprinted from Pitt et al. (2017) under the Creative Commons Attribution License

Reprinted with permission from Le Duigou et al. (2016)

Reprinted with permission from Siqueira et al. (2017)

Reprinted with permission from Lauri et al. (2017)

Reprinted from Leppiniemi et al. (2017) under the ACS AuthorChoice License

Reprinted with permission from Wang et al. (2018)

Reprinted from Derby (2015) under the Creative Commons Attribution License

Reprinted from Paxton et al. (2017) under Creative Commons Attribution Licence

Reprinted with permission from Gatenholm et al. (2016)

Reprinted with permission from Pattinson and Hart (2017)

Reprinted with permission from Gladman et al. (2016)

Similar content being viewed by others

References

Atila D, Keskin D, Tezcaner A (2015) Cellulose acetate based 3-dimensional electrospun scaffolds for skin tissue engineering applications. Carbohydr Polym 133:251–261. https://doi.org/10.1016/j.carbpol.2015.06.109

Ávila HM, Schwarz S, Rotter N, Gatenholm P (2016) 3d bioprinting of human chondrocyte-laden nanocellulose hydrogels for patient-specific auricular cartilage regeneration. Bioprinting 1:22–35. https://doi.org/10.1016/j.bprint.2016.08.003

Blaeser A, Duarte Campos DF, Puster U, Richtering W, Stevens MM, Fischer H (2016) Controlling shear stress in 3d bioprinting is a key factor to balance printing resolution and stem cell integrity. Adv Healthc Mater 5(3):326–333. https://doi.org/10.1002/adhm.201500677

Celzard A, Fierro V, Kerekes R (2009) Flocculation of cellulose fibres: new comparison of crowding factor with percolation and effective-medium theories. Cellulose 16(6):983–987. https://doi.org/10.1007/s10570-009-9314-0

Chai X, Chai H, Wang X, Yang J, Li J, Zhao Y, Cai W, Tao T, Xiang X (2017) Fused deposition modeling (fdm) 3d printed tablets for intragastric floating delivery of domperidone. Sci Rep 7:2829. https://doi.org/10.1038/s41598-017-03097-x

Chau M, Sriskandha SE, Pichugin D, Therien-Aubin H, Nykypanchuk D, Chauve G, Methot M, Bouchard J, Gang O, Kumacheva E (2015) Ion-mediated gelation of aqueous suspensions of cellulose nanocrystals. Biomacromol 16(8):2455–2462. https://doi.org/10.1021/acs.biomac.5b00701

Chen L, Wang Q, Hirth K, Baez C, Agarwal UP, Zhu JY (2015) Tailoring the yield and characteristics of wood cellulose nanocrystals (cnc) using concentrated acid hydrolysis. Cellulose 22(3):1753–1762. https://doi.org/10.1007/s10570-015-0615-1

Chia HN, Wu BM (2015) Recent advances in 3d printing of biomaterials. J Biol Eng 9(1):4. https://doi.org/10.1186/s13036-015-0001-4

Chimene D, Lennox KK, Kaunas RR, Gaharwar AK (2016) Advanced bioinks for 3d printing: a materials science perspective. Ann Biomed Eng 44(6):2090–2102. https://doi.org/10.1007/s10439-016-1638-y

Chung JHY, Naficy S, Yue ZL, Kapsa R, Quigley A, Moulton SE, Wallace GG (2013) Bio-ink properties and printability for extrusion printing living cells. Biomater Sci 1(7):763–773. https://doi.org/10.1039/c3bm00012e

Correa D, Papadopoulou A, Guberan C, Jhaveri N, Reichert S, Menges A, Tibbits S (2015) 3d-printed wood: programming hygroscopic material transformations. 3D Print Addit Manuf 2(3):106–116. https://doi.org/10.1089/3dp.2015.0022

Derby B (2010) Inkjet printing of functional and structural materials: fluid property requirements, feature stability, and resolution. Annu Rev Mater Res 40(1):395–414. https://doi.org/10.1146/annurev-matsci-070909-104502

Derby B (2015) Additive manufacture of ceramics components by inkjet printing. Engineering 1(1):113–123. https://doi.org/10.15302/J-ENG-2015014

Dong J, Li M, Zhou L, Lee S, Mei C, Xu X, Wu Q (2017) The influence of grafted cellulose nanofibers and postextrusion annealing treatment on selected properties of poly(lactic acid) filaments for 3d printing. J Polym Sci Part B Polym Phys 55(11):847–855. https://doi.org/10.1002/polb.24333

Du X, Zhang Z, Liu W, Deng Y (2017) Nanocellulose-based conductive materials and their emerging applications in energy devices—a review. Nano Energy 35:299–320. https://doi.org/10.1016/j.nanoen.2017.04.001

Dumanli AG (2017) Nanocellulose and its composites for biomedical applications. Curr Med Chem 24(5):512–528. https://doi.org/10.2174/0929867323666161014124008

Fall AB, Lindström SB, Sprakel J, Wågberg L (2013) A physical cross-linking process of cellulose nanofibril gels with shear-controlled fibril orientation. Soft Matter 9(6):1852–1863. https://doi.org/10.1039/c2sm27223g

Feng X, Yang Z, Chmely S, Wang Q, Wang S, Xie Y (2017) Lignin-coated cellulose nanocrystal filled methacrylate composites prepared via 3d stereolithography printing: mechanical reinforcement and thermal stabilization. Carbohydr Polym 169:272–281. https://doi.org/10.1016/j.carbpol.2017.04.001

Filgueira D, Holmen S, Melbø JK, Moldes D, Echtermeyer AT, Chinga-Carrasco G (2017) Enzymatic-assisted modification of thermomechanical pulp fibers to improve the interfacial adhesion with poly(lactic acid) for 3d printing. ACS Sustain Chem Eng 5(10):9338–9346. https://doi.org/10.1021/acssuschemeng.7b02351

Fu K, Yao Y, Dai J, Hu L (2017) Progress in 3d printing of carbon materials for energy-related applications. Adv Mater 29(9):1603486. https://doi.org/10.1002/adma.201603486

Gao X, Shi Z, Kuśmierczyk P, Liu C, Yang G, Sevostianov I, Silberschmidt VV (2016) Time-dependent rheological behaviour of bacterial cellulose hydrogel. Mater Sci Eng C 58:153–159. https://doi.org/10.1016/j.msec.2015.08.019

Gatenholm P, Martinez H, Karabulut E, Amoroso M, Kölby L, Markstedt K, Gatenholm E, Henriksson I (2016) Development of nanocellulose-based bioinks for 3d bioprinting of soft tissue. In: Ovsianikov A, Yoo J, Mironov V (eds) 3d printing and biofabrication. Springer, Cham, pp 1–23. https://doi.org/10.1007/978-3-319-40498-1_14-1

Gibson I, Rosen DW, Stucker B (2015) Additive manufacturing technologies. Springer, New York. https://doi.org/10.1007/978-1-4939-2113-3

Giese M, Blusch LK, Khan MK, MacLachlan MJ (2015) Functional materials from cellulose-derived liquid-crystal templates. Angew Chem Int Ed 54(10):2888–2910. https://doi.org/10.1002/anie.201407141

Gladman AS, Matsumoto EA, Nuzzo RG, Mahadevan L, Lewis JA (2016) Biomimetic 4d printing. Nat Mater 15(4):413–418. https://doi.org/10.1038/nmat4544

Goole J, Amighi K (2016) 3d printing in pharmaceutics: a new tool for designing customized drug delivery systems. Int J Pharm 499(1–2):376–394. https://doi.org/10.1016/j.ijpharm.2015.12.071

Gross BC, Erkal JL, Lockwood SY, Chen CP, Spence DM (2014) Evaluation of 3d printing and its potential impact on biotechnology and the chemical sciences. Anal Chem 86(7):3240–3253. https://doi.org/10.1021/ac403397r

Gunasekera DH, Kuek S, Hasanaj D, He Y, Tuck C, Croft AK, Wildman RD (2016) Three dimensional ink-jet printing of biomaterials using ionic liquids and co-solvents. Faraday Discuss 190:509–523. https://doi.org/10.1039/c5fd00219b

Habibi Y (2014) Key advances in the chemical modification of nanocelluloses. Chem Soc Rev 43(5):1519–1542. https://doi.org/10.1039/c3cs60204d

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110(6):3479–3500. https://doi.org/10.1021/cr900339w

Håkansson KMO (2015) Online determination of anisotropy during cellulose nanofibril assembly in a flow focusing device. RSC Adv 5(24):18601–18608. https://doi.org/10.1039/c4ra12285b

Hakansson KM, Fall AB, Lundell F, Yu S, Krywka C, Roth SV, Santoro G, Kvick M, Prahl Wittberg L, Wagberg L, Soderberg LD (2014) Hydrodynamic alignment and assembly of nanofibrils resulting in strong cellulose filaments. Nat Commun 5:4018. https://doi.org/10.1038/ncomms5018

Håkansson KM, Lundell F, Prahl-Wittberg L, Soderberg LD (2016a) Nanofibril alignment in flow focusing: measurements and calculations. J Phys Chem B 120(27):6674–6686. https://doi.org/10.1021/acs.jpcb.6b02972

Håkansson KM, Henriksson IC, de la Peña Vázquez C, Kuzmenko V, Markstedt K, Enoksson P, Gatenholm P (2016b) Solidification of 3d printed nanofibril hydrogels into functional 3d cellulose structures. Adv Mater Technol 1(7):1600096. https://doi.org/10.1002/admt.201600096

He Y, Yang F, Zhao H, Gao Q, Xia B, Fu J (2016) Research on the printability of hydrogels in 3d bioprinting. Sci Rep 6:29977. https://doi.org/10.1038/srep29977

Henke K, Treml S (2013) Wood based bulk material in 3d printing processes for applications in construction. Eur J Wood Wood Prod 71(1):139–141. https://doi.org/10.1007/s00107-012-0658-z

Henriksson I, Gatenholm P, Hägg DA (2017) Increased lipid accumulation and adipogenic gene expression of adipocytes in 3d bioprinted nanocellulose scaffolds. Biofabrication 9(1):015022. https://doi.org/10.1088/1758-5090/aa5c1c

Hochleitner G, Jüngst T, Brown TD, Hahn K, Moseke C, Jakob F, Dalton PD, Groll J (2015) Additive manufacturing of scaffolds with sub-micron filaments via melt electrospinning writing. Biofabrication 7(3):035002. https://doi.org/10.1088/1758-5090/7/3/035002

Hoeng F, Denneulin A, Bras J (2016) Use of nanocellulose in printed electronics: a review. Nanoscale 8(27):13131–13154. https://doi.org/10.1039/c6nr03054h

Holzl K, Lin S, Tytgat L, Van Vlierberghe S, Gu L, Ovsianikov A (2016) Bioink properties before, during and after 3d bioprinting. Biofabrication 8(3):032002. https://doi.org/10.1088/1758-5090/8/3/032002

Hong JK (2015) Bioactive cellulose nanocrystal reinforced 3d printable poly (epsilon-caprolactone) nanocomposite for bone tissue engineering. Doctoral thesis, Virginia Polytechnic Institute and State University

Hu L, Cui Y (2012) Energy and environmental nanotechnology in conductive paper and textiles. Energy Environ Sci 5(4):6423–6435. https://doi.org/10.1039/C2EE02414D

Hu Z, Cranston ED, Ng R, Pelton R (2014) Tuning cellulose nanocrystal gelation with polysaccharides and surfactants. Langmuir 30(10):2684–2692. https://doi.org/10.1021/la404977t

Hubbe MA, Tayeb P, Joyce M, Tyagi P, Kehoe M, Dimic-Misic K, Pal L (2017) Rheology of nanocellulose-rich aqueous suspensions: a review. BioResources 12(4):9556–9661. https://doi.org/10.15376/biores.12.4.9556-9661

Isogai A, Bergström L (2018) Preparation of cellulose nanofibers using green and sustainable chemistry. Curr Opin Green Sustain Chem 12:15–21. https://doi.org/10.1016/j.cogsc.2018.04.008

Isogai A, Saito T, Fukuzumi H (2011) Tempo-oxidized cellulose nanofibers. Nanoscale 3(1):71–85. https://doi.org/10.1039/c0nr00583e

Jia C, Bian H, Gao T, Jiang F, Kierzewski IM, Wang Y, Yao Y, Chen L, Shao Z, Zhu JY, Hu L (2017a) Thermally stable cellulose nanocrystals toward high-performance 2d and 3d nanostructures. ACS Appl Mater Interfaces 9(34):28922–28929. https://doi.org/10.1021/acsami.7b08760

Jia C, Chen L, Shao Z, Agarwal UP, Hu L, Zhu JY (2017b) Using a fully recyclable dicarboxylic acid for producing dispersible and thermally stable cellulose nanomaterials from different cellulosic sources. Cellulose 24(6):2483–2498. https://doi.org/10.1007/s10570-017-1277-y

Jungst T, Smolan W, Schacht K, Scheibel T, Groll J (2016) Strategies and molecular design criteria for 3d printable hydrogels. Chem Rev 116(3):1496–1539. https://doi.org/10.1021/acs.chemrev.5b00303

Kalsoom U, Nesterenko PN, Paull B (2016) Recent developments in 3d printable composite materials. RSC Adv 6(65):60355–60371. https://doi.org/10.1039/c6ra11334f

Kariz M, Sernek M, Kuzman MK (2015) Use of wood powder and adhesive as a mixture for 3d printing. Eur J Wood Wood Prod 74(1):123–126. https://doi.org/10.1007/s00107-015-0987-9

Kearns AJ (2017) Cotton cellulose fibers in 3d print material. Master Thesis, North Carolina State University

Kearns A, Farahbakhsh N, Venditti R, Jur J (2016) Cotton fibers in 3d printing. In: Solid Freeform Fabrication 2016: Proceedings of the 26th annual international solid freeform fabrication symposium—an additive manufacturing conference, pp 899–905

Kempin W, Franz C, Koster L-C, Schneider F, Bogdahn M, Weitschies W, Seidlitz A (2017) Assessment of different polymers and drug loads for fused deposition modeling of drug loaded implants. Eur J Pharm Biopharm 115(Supplement C):84–93. https://doi.org/10.1016/j.ejpb.2017.02.014

Khaled SA, Burley JC, Alexander MR, Yang J, Roberts CJ (2015) 3d printing of five-in-one dose combination polypill with defined immediate and sustained release profiles. J Control Release 217(Supplement C):308–314. https://doi.org/10.1016/j.jconrel.2015.09.028

Kirchmajer DM, Gorkin R III, In het Panhuis M (2015) An overview of the suitability of hydrogel-forming polymers for extrusion-based 3d-printing. J Mater Chem B 3(20):4105–4117. https://doi.org/10.1039/c5tb00393h

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed Engl 44(22):3358–3393. https://doi.org/10.1002/anie.200460587

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50(24):5438–5466. https://doi.org/10.1002/anie.201001273

Kumar S, Hofmann M, Steinmann B, Foster EJ, Weder C (2012) Reinforcement of stereolithographic resins for rapid prototyping with cellulose nanocrystals. ACS Appl Mater Interfaces 4(10):5399–5407. https://doi.org/10.1021/am301321v

Kyle S, Jessop ZM, Al-Sabah A, Whitaker IS (2017) ‘Printability’ of candidate biomaterials for extrusion based 3d printing: state-of-the-art. Adv Healthc Mater 6(16):1700264. https://doi.org/10.1002/adhm.201700264

Lauri J, Koponen A, Haavisto S, Czajkowski J, Fabritius T (2017) Analysis of rheology and wall depletion of microfibrillated cellulose suspension using optical coherence tomography. Cellulose 24(11):4715–4728. https://doi.org/10.1007/s10570-017-1493-5

Le Duigou A, Castro M, Bevan R, Martin N (2016) 3d printing of wood fibre biocomposites: from mechanical to actuation functionality. Mater Des 96:106–114. https://doi.org/10.1016/j.matdes.2016.02.018

Lee M, Kim H-Y (2014) Toward nanoscale three-dimensional printing: nanowalls built of electrospun nanofibers. Langmuir 30(5):1210–1214. https://doi.org/10.1021/la404704z

Leppiniemi J, Lahtinen P, Paajanen A, Mahlberg R, Metsä-Kortelainen S, Pinomaa T, Pajari H, Vikholm-Lundin I, Pursula P, Hytönen VP (2017) 3d-printable bioactivated nanocellulose–alginate hydrogels. ACS Appl Mater Interfaces 9(26):21959–21970. https://doi.org/10.1021/acsami.7b02756

Li Y, Zhu H, Shen F, Wan J, Han X, Dai J, Dai H, Hu L (2014) Highly conductive microfiber of graphene oxide templated carbonization of nanofibrillated cellulose. Adv Funct Mater 24(46):7366–7372. https://doi.org/10.1002/adfm.201402129

Li T, Aspler J, Grenon J, Manfred T, Cormier LM, Zou X (2016a) Printed electronics and 3d printing as new manufacturing technologies-new opportunities for bio-based materials. In: NIP & digital fabrication conference. Society for imaging science and technology, pp 435–441

Li T, Aspler J, Kingsland A, Cormier LM, Zou X (2016b) 3d printing–a review of technologies, markets, and opportunities for the forest industry. J Sci Technol For Prod Process 5(2):30–37

Li H, Tan YJ, Leong KF, Li L (2017a) 3d bioprinting of highly thixotropic alginate/methylcellulose hydrogel with strong interface bonding. ACS Appl Mater Interfaces 9(23):20086–20097. https://doi.org/10.1021/acsami.7b04216

Li VC-F, Dunn CK, Zhang Z, Deng Y, Qi HJ (2017b) Direct ink write (diw) 3d printed cellulose nanocrystal aerogel structures. Sci Rep 7:8018. https://doi.org/10.1038/s41598-017-07771-y

Li Y, Zhu H, Wang Y, Ray U, Zhu S, Dai J, Chen C, Fu K, Jang SH, Henderson D (2017c) Cellulose-nanofiber-enabled 3d printing of a carbon-nanotube microfiber network. Small Methods 1(10):1700222. https://doi.org/10.1002/smtd.201700222

Li L, Zhu Y, Yang J (2018a) 3d bioprinting of cellulose with controlled porous structures from nmmo. Mater Lett 210:136–138. https://doi.org/10.1016/j.matlet.2017.09.015

Li VCF, Mulyadi A, Dunn CK, Deng Y, Qi HJ (2018b) Direct ink write 3d printed cellulose nanofiber aerogel structures with highly deformable, shape recoverable, and functionalizable properties. ACS Sustain Chem Eng. https://doi.org/10.1021/acssuschemeng.7b03439

Ligon SC, Liska R, Stampfl J, Gurr M, Mulhaupt R (2017) Polymers for 3d printing and customized additive manufacturing. Chem Rev 117(15):10212–10290. https://doi.org/10.1021/acs.chemrev.7b00074

Lille M, Nurmela A, Nordlund E, Metsä-Kortelainen S, Sozer N (2018) Applicability of protein and fiber-rich food materials in extrusion-based 3d printing. J Food Eng 220:20–27. https://doi.org/10.1016/j.jfoodeng.2017.04.034

Lundahl MJ, Klar V, Wang L, Ago M, Rojas OJ (2017) Spinning of cellulose nanofibrils into filaments: a review. Ind Eng Chem Res 56(1):8–19. https://doi.org/10.1021/acs.iecr.6b04010

Malda J, Visser J, Melchels FP, Jungst T, Hennink WE, Dhert WJ, Groll J, Hutmacher DW (2013) 25th anniversary article: engineering hydrogels for biofabrication. Adv Mater 25(36):5011–5028. https://doi.org/10.1002/adma.201302042

Markstedt K, Sundberg J, Gatenholm P (2014) 3d bioprinting of cellulose structures from an ionic liquid. 3D Print Addit Manuf 1(3):115–121. https://doi.org/10.1089/3dp.2014.0004

Markstedt K, Mantas A, Tournier I, Avila HM, Hagg D, Gatenholm P (2015) 3d bioprinting human chondrocytes with nanocellulose-alginate bioink for cartilage tissue engineering applications. Biomacromol 16(5):1489–1496. https://doi.org/10.1021/acs.biomac.5b00188

Markstedt K, Escalante A, Toriz G, Gatenholm P (2017) Biomimetic inks based on cellulose nanofibrils and cross-linkable xylans for 3d printing. ACS Appl Mater Interfaces 9(46):40878–40886. https://doi.org/10.1021/acsami.7b13400

Martinez D, Kiiskinen H, Ahlman A-K, Kerekes R (2003) On the mobility of flowing papermaking suspensions and its relationship to formation. J Pulp Pap Sci 29(10):341–347

Mendoza L, Batchelor W, Tabor RF, Garnier G (2018) Gelation mechanism of cellulose nanofibre gels: a colloids and interfacial perspective. J Colloid Interface Sci 509(Supplement C):39–46. https://doi.org/10.1016/j.jcis.2017.08.101

Mertaniemi H, Escobedo-Lucea C, Sanz-Garcia A, Gandía C, Mäkitie A, Partanen J, Ikkala O, Yliperttula M (2016) Human stem cell decorated nanocellulose threads for biomedical applications. Biomaterials 82:208–220. https://doi.org/10.1016/j.biomaterials.2015.12.020

Montalvo Navarrete JI, Hidalgo-Salazar MA, Escobarnunez E, Rojas Arciniegas AJ (2017) Thermal and mechanical behavior of biocomposites using additive manufacturing. Int J Interact Des Manuf (IJIDeM). https://doi.org/10.1007/s12008-017-0411-2

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40(7):3941–3994. https://doi.org/10.1039/c0cs00108b

Müller M, Öztürk E, Arlov Ø, Gatenholm P, Zenobi-Wong M (2017) Alginate sulfate–nanocellulose bioinks for cartilage bioprinting applications. Ann Biomed Eng 45(1):210–223. https://doi.org/10.1007/s10439-016-1704-5

Murphy SV, Atala A (2014) 3d bioprinting of tissues and organs. Nat Biotechnol 32(8):773–785. https://doi.org/10.1038/nbt.2958

Murphy CA, Collins MN (2016) Microcrystalline cellulose reinforced polylactic acid biocomposite filaments for 3d printing. Polym Compos. https://doi.org/10.1002/pc.24069

Murphy SV, Skardal A, Atala A (2013) Evaluation of hydrogels for bio-printing applications. J Biomed Mater Res A 101(1):272–284. https://doi.org/10.1002/jbm.a.34326

Nechyporchuk O, Belgacem MN, Pignon F (2014) Rheological properties of micro-/nanofibrillated cellulose suspensions: wall-slip and shear banding phenomena. Carbohydr Polym 112:432–439. https://doi.org/10.1016/j.carbpol.2014.05.092

Nechyporchuk O, Belgacem MN, Pignon F (2016) Current progress in rheology of cellulose nanofibril suspensions. Biomacromol 17(7):2311–2320. https://doi.org/10.1021/acs.biomac.6b00668

Nechyporchuk O, Yu J, Nierstrasz VA, Bordes R (2017) Cellulose nanofibril-based coatings of woven cotton fabrics for improved inkjet printing with a potential in e-textile manufacturing. ACS Sustain Chem Eng 5(6):4793–4801. https://doi.org/10.1021/acssuschemeng.7b00200

Nguyen D, Hägg DA, Forsman A, Ekholm J, Nimkingratana P, Brantsing C, Kalogeropoulos T, Zaunz S, Concaro S, Brittberg M (2017) Cartilage tissue engineering by the 3d bioprinting of ips cells in a nanocellulose/alginate bioink. Sci Rep 7:658

Oksman K, Aitomäki Y, Mathew AP, Siqueira G, Zhou Q, Butylina S, Tanpichai S, Zhou X, Hooshmand S (2016) Review of the recent developments in cellulose nanocomposite processing. Compos A Appl Sci Manuf 83:2–18. https://doi.org/10.1016/j.compositesa.2015.10.041

Oropallo W, Piegl LA (2015) Ten challenges in 3d printing. Eng Comput-Ger 32(1):135–148. https://doi.org/10.1007/s00366-015-0407-0

Oskui SM, Diamante G, Liao C, Shi W, Gan J, Schlenk D, Grover WH (2015) Assessing and reducing the toxicity of 3d-printed parts. Environ Sci Technol Lett 3(1):1–6. https://doi.org/10.1021/acs.estlett.5b00249

Ouyang L, Yao R, Zhao Y, Sun W (2016) Effect of bioink properties on printability and cell viability for 3d bioplotting of embryonic stem cells. Biofabrication 8(3):035020. https://doi.org/10.1088/1758-5090/8/3/035020

Pakkanen J, Manfredi D, Minetola P, Iuliano L (2017) About the use of recycled or biodegradable filaments for sustainability of 3d printing. In: International conference on sustainable design and manufacturing. Springer, pp 776–785

Palaganas NB, Mangadlao JD, de Leon ACC, Palaganas JO, Pangilinan KD, Lee YJ, Advincula RC (2017) 3d printing of photocurable cellulose nanocrystal composite for fabrication of complex architectures via stereolithography. ACS Appl Mater Interfaces 9(39):34314–34324. https://doi.org/10.1021/acsami.7b09223

Parandoush P, Lin D (2017) A review on additive manufacturing of polymer-fiber composites. Compos Struct 182(Supplement C):36–53. https://doi.org/10.1016/j.compstruct.2017.08.088

Park JS, Kim T, Kim WS (2017) Conductive cellulose composites with low percolation threshold for 3d printed electronics. Sci Rep 7:3246. https://doi.org/10.1038/s41598-017-03365-w

Pattinson SW, Hart AJ (2017) Additive manufacturing of cellulosic materials with robust mechanics and antimicrobial functionality. Adv Mater Technol 2(4):1600084. https://doi.org/10.1002/admt.201600084

Paxton N, Smolan W, Bock T, Melchels F, Groll J, Jungst T (2017) Proposal to assess printability of bioinks for extrusion-based bioprinting and evaluation of rheological properties governing bioprintability. Biofabrication 9(4):044107. https://doi.org/10.1088/1758-5090/aa8dd8

Penttilä A, Sievänen J, Torvinen K, Ojanperä K, Ketoja J (2013) Filler-nanocellulose substrate for printed electronics: experiments and model approach to structure and conductivity. Cellulose 20(3):1413–1424. https://doi.org/10.1007/s10570-013-9883-9

Piras CC, Fernandez-Prieto S, De Borggraeve WM (2017) Nanocellulosic materials as bioinks for 3d bioprinting. Biomater Sci 5(10):1988–1992. https://doi.org/10.1039/c7bm00510e

Pitt K, Lopez-Botello O, Lafferty AD, Todd I, Mumtaz K (2017) Investigation into the material properties of wooden composite structures with in situ fibre reinforcement using additive manufacturing. Compos Sci Technol 138(Supplement C):32–39. https://doi.org/10.1016/j.compscitech.2016.11.008

Puisto A, Illa X, Mohtaschemi M, Alava M (2012) Modeling the rheology of nanocellulose suspensions. Nord Pulp Pap Res J 27(2):277–281. https://doi.org/10.3183/NPPRJ-2012-27-02-p277-281

Rees A, Powell LC, Chinga-Carrasco G, Gethin DT, Syverud K, Hill KE, Thomas DW (2015) 3d bioprinting of carboxymethylated-periodate oxidized nanocellulose constructs for wound dressing applications. Biomed Res Int 2015:925757. https://doi.org/10.1155/2015/925757

Rejeski D, Zhao F, Huang Y (2018) Research needs and recommendations on environmental implications of additive manufacturing. Addit Manuf 19:21–28. https://doi.org/10.1016/j.addma.2017.10.019

Ribeiro A, Blokzijl MM, Levato R, Visser CW, Castilho M, Hennink WE, Vermonden T, Malda J (2017) Assessing bioink shape fidelity to aid material development in 3d bioprinting. Biofabrication 10(1):014102. https://doi.org/10.1088/1758-5090/aa90e2

Rigotti D, Nguyen VDH, Cataldi A, Pegoretti A (2017) Polyvinyl alcohol reinforced crystalline nanocellulose in 3d printing application. In: The 21st International conference on composites materials. Xi’an, China, pp 1–8

Rosenthal M, Henneberger C, Gutkes A, Bues C-T (2017) Liquid deposition modeling: a promising approach for 3d printing of wood. Eur J Wood Wood Prod 76(2):797–799. https://doi.org/10.1007/s00107-017-1274-8

Rymansaib Z (2016) Printing materials and processes for electrochemical applications. University of Bath

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by tempo-mediated oxidation of native cellulose. Biomacromol 8(8):2485–2491. https://doi.org/10.1021/bm0703970

Salmoria GV, Klauss P, Paggi RA, Kanis LA, Lago A (2009) Structure and mechanical properties of cellulose based scaffolds fabricated by selective laser sintering. Polym Test 28(6):648–652. https://doi.org/10.1016/j.polymertesting.2009.05.008

Schutz K, Placht AM, Paul B, Bruggemeier S, Gelinsky M, Lode A (2017) Three-dimensional plotting of a cell-laden alginate/methylcellulose blend: towards biofabrication of tissue engineering constructs with clinically relevant dimensions. J Tissue Eng Regen Med 11(5):1574–1587. https://doi.org/10.1002/term.2058

Shafeiei-Sabet S, Hamad WY, Hatzikiriakos SG (2013) Influence of degree of sulfation on the rheology of cellulose nanocrystal suspensions. Rheol Acta 52:741–751. https://doi.org/10.1007/s00397-013-0722-6

Shao Y, Chaussy D, Grosseau P, Beneventi D (2015) Use of microfibrillated cellulose/lignosulfonate blends as carbon precursors: impact of hydrogel rheology on 3d printing. Ind Eng Chem Res 54(43):10575–10582. https://doi.org/10.1021/acs.iecr.5b02763

Shatkin JA, Wegner TH, Bilek ET, Cowie J (2014) Market projections of cellulose nanomaterial-enabled products-part 1: applications. Tappi J 13(5):9–16

Shen X, Shamshina JL, Berton P, Gurau G, Rogers RD (2016) Hydrogels based on cellulose and chitin: fabrication, properties, and applications. Green Chem 18(1):53–75. https://doi.org/10.1039/c5gc02396c

Shin S, Hyun J (2017) Matrix-assisted three-dimensional printing of cellulose nanofibers for paper microfluidics. ACS Appl Mater Interfaces 9(31):26438–26446. https://doi.org/10.1021/acsami.7b07609

Shin D-G, Kim T-H, Kim D-E (2017) Review of 4d printing materials and their properties. Int J Precis Eng Manuf-Green Technol 4(3):349–357. https://doi.org/10.1007/s40684-017-0040-z

Siqueira G, Kokkinis D, Libanori R, Hausmann MK, Gladman AS, Neels A, Tingaut P, Zimmermann T, Lewis JA, Studart AR (2017) Cellulose nanocrystal inks for 3d printing of textured cellular architectures. Adv Funct Mater 27(12):1604619. https://doi.org/10.1002/adfm.201604619

Studart AR (2016) Additive manufacturing of biologically-inspired materials. Chem Soc Rev 45(2):359–376. https://doi.org/10.1039/c5cs00836k

Sultan S, Siqueira G, Zimmermann T, Mathew AP (2017) 3d printing of nano-cellulosic biomaterials for medical applications. Curr Opin Biomed Eng 2(Supplement C):29–34. https://doi.org/10.1016/j.cobme.2017.06.002

Tang A, Liu Y, Wang Q, Chen R, Liu W, Fang Z, Wang L (2016) A new photoelectric ink based on nanocellulose/cds quantum dots for screen-printing. Carbohydr Polym 148:29–35. https://doi.org/10.1016/j.carbpol.2016.04.034

Tao Y, Wang H, Li Z, Li P, Shi SQ (2017) Development and application of wood flour-filled polylactic acid composite filament for 3d printing. Materials 10(4):339. https://doi.org/10.3390/ma10040339

Tenhunen T-M, Moslemian O, Kammiovirta K, Harlin A, Kääriäinen P, Österberg M, Tammelin T, Orelma H (2018) Surface tailoring and design-driven prototyping of fabrics with 3d-printing: an all-cellulose approach. Mater Des 140:409–419. https://doi.org/10.1016/j.matdes.2017.12.012

Torres-Rendon JG, Köpf M, Gehlen D, Blaeser A, Fischer H, Laporte LD, Walther A (2016) Cellulose nanofibril hydrogel tubes as sacrificial templates for freestanding tubular cell constructs. Biomacromol 17(3):905–913. https://doi.org/10.1021/acs.biomac.5b01593

Tran TN, Bayer IS, Heredia-Guerrero JA, Frugone M, Lagomarsino M, Maggio F, Athanassiou A (2017) Cocoa shell waste biofilaments for 3d printing applications. Macromol Mater Eng 302(11):1700219. https://doi.org/10.1002/mame.201700219

Ursan ID, Chiu L, Pierce A (2013) Three-dimensional drug printing: a structured review. J Am Pharm Assoc 53(2):136–144. https://doi.org/10.1331/JAPhA.2013.12217

Wang Q, Zhu J (2015) Facile preparation of nanofiller-paper using mixed office paper without deinking. Tappi J 14(3):167–174

Wang Q, Zhu J (2016) Effects of mechanical fibrillation time by disk grinding on the properties of cellulose nanofibrils. Tappi J 15(6):419–423

Wang QQ, Zhu JY, Gleisner R, Kuster TA, Baxa U, McNeil SE (2012a) Morphological development of cellulose fibrils of a bleached eucalyptus pulp by mechanical fibrillation. Cellulose 19(5):1631–1643. https://doi.org/10.1007/s10570-012-9745-x

Wang QQ, Zhu JY, Reiner RS, Verrill SP, Baxa U, McNeil SE (2012b) Approaching zero cellulose loss in cellulose nanocrystal (cnc) production: recovery and characterization of cellulosic solid residues (csr) and cnc. Cellulose 19(6):2033–2047. https://doi.org/10.1007/s10570-012-9765-6

Wang QQ, Zhu JY, Considine JM (2013) Strong and optically transparent films prepared using cellulosic solid residue recovered from cellulose nanocrystals production waste stream. ACS Appl Mater Interfaces 5(7):2527–2534. https://doi.org/10.1021/am302967m

Wang Q, Zhao X, Zhu JY (2014a) Kinetics of strong acid hydrolysis of a bleached kraft pulp for producing cellulose nanocrystals (cncs). Ind Eng Chem Res 53(27):11007–11014. https://doi.org/10.1021/ie501672m

Wang Q, Zhu Q, Xu J, Sun J (2014b) Combined mechanical destruction and alkaline pretreatment of wheat straw for enhanced enzymatic saccharification. BioResources 9(4):6841–6850. https://doi.org/10.15376/biores.9.4.6841-6850

Wang Q, Wei W, Chang F, Sun J, Xie S, Zhu Q (2016) Controlling the size and film strength of individualized cellulose nanofibrils prepared by combined enzymatic pretreatment and high pressure microfluidization. BioResources 11(1):2536–2547. https://doi.org/10.15376/biores.11.1.2536-2547

Wang R, Chen L, Zhu J, Yang R (2017a) Tailored and integrated production of carboxylated cellulose nanocrystals (cnc) with nanofibrils (cnf) through maleic acid hydrolysis. ChemNanoMat 3(5):328–335. https://doi.org/10.1002/cnma.201700015

Wang X, Jiang M, Zhou Z, Gou J, Hui D (2017b) 3d printing of polymer matrix composites: a review and prospective. Compos B Eng 110:442–458. https://doi.org/10.1016/j.compositesb.2016.11.034

Wang Z, Xu J, Lu Y, Hu L, Fan Y, Ma J, Zhou X (2017c) Preparation of 3d printable micro/nanocellulose-polylactic acid (MNC/PLA) composite wire rods with high mnc constitution. Ind Crop Prod 109(Supplement C):889–896. https://doi.org/10.1016/j.indcrop.2017.09.061

Wang J, Chiappone A, Roppolo I, Shao F, Fantino E, Lorusso M, Rentsch D, Dietliker K, Pirri CF, Grutzmacher H (2018) All-in-one cellulose nanocrystals for 3d printing of nanocomposite hydrogels. Angew Chem Int Ed Engl. https://doi.org/10.1002/anie.201710951

Wimpenny DI, Bryden B, Pashby IR (2003) Rapid laminated tooling. J Mater Process Technol 138(1–3):214–218. https://doi.org/10.1016/s0924-0136(03)00074-8

Wu ZY, Li C, Liang HW, Chen JF, Yu SH (2013) Ultralight, flexible, and fire-resistant carbon nanofiber aerogels from bacterial cellulose. Angew Chem 125(10):2997–3001. https://doi.org/10.1002/anie.201209676

Wu Y, Lin ZY, Wenger AC, Tam KC, Tang X (2018) 3d bioprinting of liver-mimetic construct with alginate/cellulose nanocrystal hybrid bioink. Bioprinting 9:1–6. https://doi.org/10.1016/j.bprint.2017.12.001

Xu H-N, Tang Y-Y, Ouyang X-K (2017) Shear-induced breakup of cellulose nanocrystal aggregates. Langmuir 33(1):235–242. https://doi.org/10.1021/acs.langmuir.6b03807

Yang G, Li X, He Y, Ma J, Ni G, Zhou S (2018) From nano to micro to macro: electrospun hierarchically structured polymeric fibers for biomedical applications. Prog Polym Sci 81:80–113. https://doi.org/10.1016/j.progpolymsci.2017.12.003

Yu DG, Branford-White C, Ma ZH, Zhu LM, Li XY, Yang XL (2009) Novel drug delivery devices for providing linear release profiles fabricated by 3dp. Int J Pharm 370(1–2):160–166. https://doi.org/10.1016/j.ijpharm.2008.12.008

Zander NE, Dong H, Steele J, Grant JT (2014) Metal cation cross-linked nanocellulose hydrogels as tissue engineering substrates. ACS Appl Mater Interfaces 6(21):18502–18510. https://doi.org/10.1021/am506007z

Zhang F, Wei M, Viswanathan VV, Swart B, Shao Y, Wu G, Zhou C (2017) 3d printing technologies for electrochemical energy storage. Nano Energy 40:418–431. https://doi.org/10.1016/j.nanoen.2017.08.037

Zhao Y, Li Y, Mao S, Sun W, Yao R (2015) The influence of printing parameters on cell survival rate and printability in microextrusion-based 3d cell printing technology. Biofabrication 7(4):045002. https://doi.org/10.1088/1758-5090/7/4/045002

Zhu H, Luo W, Ciesielski PN, Fang Z, Zhu JY, Henriksson G, Himmel ME, Hu L (2016) Wood-derived materials for green electronics, biological devices, and energy applications. Chem Rev 116(16):9305–9374. https://doi.org/10.1021/acs.chemrev.6b00225

Acknowledgments

This study was supported by the National Natural Science Foundation of China (31300493), China Postdoctoral Science Foundation (2016T90423, 2015M581740), Young Scholar Award Program of Jiangsu University, and open funding from the State Key Laboratory of Pulp and Paper Engineering, South China University of Technology (201527), Key Laboratory of Biomass Energy and Material of Jiangsu Province, Institute of Chemical Industry of Forest Products, Chinese Academy of Forestry (JSBEM201605) and the Priority Academic Program Development of Jiangsu Higher Education Institution (PAPD). We thank Rana Muhammad Yousaf Saeed for proofreading.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Q., Sun, J., Yao, Q. et al. 3D printing with cellulose materials. Cellulose 25, 4275–4301 (2018). https://doi.org/10.1007/s10570-018-1888-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-1888-y