Abstract

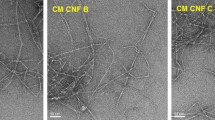

The rheological properties of a carboxymethylated (D.S. ≈ 0.1) nanofibrillated cellulose (NFC) were investigated at different solid contents. The critical overlap concentration was determined to be in the range between 0.04 and 0.07 % (w/w) using shear stress versus shear rate measurements. From the critical overlap concentration using the simple Mason excluded volume formalism, the apparent aspect ratio was estimated to be 75 [at a critical overlap concentration of 0.04 % (w/w)]. The aspect ratio of the NFC system was also estimated by using the Einstein–Simha equation together with the intrinsic viscosity value of the system (corrected for the electroviscous effects). The obtained value was found to be around 80, which is in good agreement with the value obtained from the excluded volume calculation. Further, by combining oscillatory measurements and the equation of Shankar et al. the apparent fibril length was determined to be 4 µm. As the production of NFC through homogenization occurs at concentrations far above the critical overlap concentration an NFC-gel is constituted by a severely entangled structure. The disentanglement of the fibrils is therefore difficult and the employed dilution method was found not to lead to fully liberated nanofibrils, which was also indicated by atomic force microscopy-imaging.

Similar content being viewed by others

Notes

The strain value was measured to be within the linear viscoelastic region of the systems; results not shown.

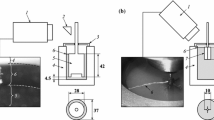

The turbidity of the samples was measured by a 2100P Portable Turbidimeter (Hach, USA).

Serial coupled Z-shaped interaction chambers with the diameters of 200 and 100 µm were used.

Assuming AR ≈ 100 and using Eq. 2, a c 0 value in the order of 0.01 % (w/w) is obtained.

References

Abdul Khalil HPS, Bhat AH, Ireana Yusra AF (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohydr Polym 87(2):963–979. doi:10.1016/j.carbpol.2011.08.078

Agoda-Tandjawa G, Durand S, Berot S, Blassel C, Gaillard C, Garnier C, Doublier JL (2010) Rheological characterization of microfibrillated cellulose suspensions after freezing. Carbohydr Polym 80(3):677–686. doi:10.1016/j.carbpol.2009.11.045

Booth F (1950) The electroviscous effect for suspensions of solid spherical particles. Proc R Soc Lond A 203(1075):533–551. doi:10.1098/rspa.1950.0155

De Gennes PG (1979) Scaling concepts in polymer physics. Cornell Univ Press, New York

Doi M, Edwards SF (1978) Dynamics of concentrated polymer systems. Part 3—The constitutive equation. J Chem Soc Faraday Trans 2 74:1818–1832. doi:10.1039/f29787401818

Eichhorn SJ, Dufresne A, Aranguren M, Marcovich NE, Capadona JR, Rowan SJ, Weder C, Thielemens W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogio M, Nakagaito AN, Mangalam A, Simonsen J, Benight AS, Bismarck A, Berglund LA, Peijs T (2010) Review: Current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45(1):1–33

Fall AB, Lindström SB, Sundman O, Ödberg L, Wågberg L (2011) Colloidal stability of aqueous nanofibrillated cellulose dispersions. Langmuir 27:11332–11338. doi:10.1021/la201947x

Fall AB, Lindström SB, Sprakel J, Wågberg L (2013) A physical cross-linking process of cellulose nanofibril gels with shear-controlled fibril orientation. Soft Matter 9:1852–1863. doi:10.1039/c2sm27223g

Fujisawa S, Saito T, Isogai A (2012) Nano-dispersion of TEMPO-oxidized cellulose/aliphatic amine salts in isopropyl alcohol. Cellulose 19:459–466. doi:10.1007/s10570-011-9648-2

Fujisawa S, Saito T, Kimura S, Iwata T, Isogai A (2013) Surface engineering of ultrafine cellulose nanofibrils toward polymer nanocomposite materials. Biomacromolecules 14:1541–1546. doi:10.1021/bm400178m

Fukuzumi H, Saito T, Iwata T, Kumamoto Y, Isogai A (2009) Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 10(1):162–165. doi:10.1021/bm801065u

Fukuzumi H, Saito T, Isogai A (2013) Influence of TEMPO-oxidized cellulose nanofibril length on film properties. Carbohydr Polym 93:172–177. doi:10.1016/j.carbpol.2012.04.069

Herrick FW, Casebier RL, Hamilton JK, Sandberg KR (1983) Microfibrillated cellulose: morphology and accessibility. J Appl Polym Sci Appl Polym Symp 37:797–813

Ishii D, Saito T, Isogai A (2011) Viscoelastic evaluation of average length of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 12(3):548–550. doi:10.1021/bm1013876

Ishii D, Saito T, Isogai A (2012) Correction to viscoelastic evaluation of average length of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 13(5):1706. doi:10.1021/bm300482w

Isogai A (2013) Wood nanocelluloses: fundamentals and applications as new bio-based nanomaterials. J Wood Sci 59(6):449–459. doi:10.1007/s10086-013-1365-z

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3(1):71–85. doi:10.1039/c0nr00583e

Iwamoto S, Kai W, Isogai A, Iwata T (2009) Elastic modulus of single cellulose microfibrils from tunicate measured by atomic force microscopy. Biomacromolecules 10(9):2571–2576

Iwamoto S, Lee S-H, Endo T (2014) Relationship between aspect ratio and suspension viscosity of wood cellulose nanofibers. Polym J 46(1):73–76. doi:10.1038/pj.2013.64

Junka K, Filpponen I, Lindström T, Laine J (2013) Titrimetric methods for the determination of surface and total charge of functionalized nanofibrillated/microfibrillated cellulose (NFC/MFC). Cellulose 1–9. doi:10.1007/s10570-013-0043-z

Klemm D, Heublein B, Fink H-P, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393. doi:10.1002/anie.200460587

Klemm D, Schumann D, Kramer F, Hessler N, Hornung M, Schmauder H-P, Marsch S (2006) Nanocelluloses as innovative polymers in research and application. Adv Polym Sci 205:49–96. doi:10.1007/12_097

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50(24):5438–5466. doi:10.1002/anie.201001273

Kloser E, Gray DG (2010) Surface grafting of cellulose nanocrystals with poly(ethylene oxide) in aqueous media. Langmuir 26(16):13450–13456. doi:10.1021/la101795s

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose-its barrier properties and applications in cellulosic materials: A review. Carbohydr Polym 90:735–764

Mason SG (1950) The flocculation of pulp suspensions and the formation of paper. Pulp Pap Mag Can 51:94–98

Metzger TG (2002) The rheology handbook: for users of rotational and oscillatory rheometers. Vincentz Curt R. Verlag, Hannover

Mihranyan A (2010) Cellulose from cladophorales green algae: from environmental problem to high-tech composite materials. J Appl Polym Sci 119:2449–2460

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994. doi:10.1039/c0cs00108b

Naderi A, Lindström T, Sundström J (2014) Carboxymethylated nanofibrillated cellulose: rheological studies. Cellulose 21(3):1561–1571. doi:10.1007/s10570-014-0192-8

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8(6):1934–1941. doi:10.1021/bm061215p

Pan Z, Ge J, Li W, Peng J, Qiu F (2012) Transition from polythiophene-based one-dimensional nanofibers to spherical clusters in ultrafiltration. Soft Matter 8(39):9981–9984. doi:10.1039/c2sm26523k

Puangsin B, Fujisawa S, Kuramae R, Saito T, Isogai A (2013) TEMPO-mediated oxidation of hemp bast holocellulose to prepare cellulose nanofibrils dispersed in water. J Polym Environ 21(2):555–563. doi:10.1007/s10924-012-0548-9

Rezayati CP, Dehghani-Firouzabadi M, Afra E, Shakeri A (2013) Rheological characterization of high concentrated MFC gel from kenaf unbleached pulp. Cellulose 20:727–740. doi:10.1007/s10570-013-9862-1

Saastamoinen P, Mattinen M-L, Hippi U, Nousiainen P, Sipila J, Lille M, Suurnakki A, Pere J (2012) Laccase aided modification of nanofibrillated cellulose with dodecyl gallate. BioResources 7:5749–5770

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8(8):2485–2491. doi:10.1021/bm0703970

Saito T, Uematsu T, Kimura S, Enomae T, Isogai A (2011) Self-aligned integration of native cellulose nanofibrils towards producing diverse bulk materials. Soft Matter 7(19):8804–8809. doi:10.1039/c1sm06050c

Shankar V, Pasquali M, Morse DC (2002) Theory of linear viscoelasticity of semiflexible rods in dilute solution. J Rheol 46(5):1111–1154

Shinoda R, Saito T, Okita Y, Isogai A (2012) Relationship between length and degree of polymerization of TEMPO-oxidized cellulose nanofibrils. Biomacromolecules 13(3):842–849. doi:10.1021/bm2017542

Shogren RL, Peterson SC, Evans KO, Kenar JA (2011) Preparation and characterization of cellulose gels from corn cobs. Carbohydr Polym 86:1351–1357. doi:10.1016/j.carbpol.2011.06.035

Simha R (1940) The influence of Brownian movement on the viscosity of solutions. J Phys Chem 44:25–34

Siro I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494. doi:10.1007/s10570-010-9405-y

Tanaka A, Seppanen V, Houni J, Sneck A, Pirkonen P (2012) Nanocellulose characterization with mechanical fractionation. Nord Pulp Pap Res J 27:689–694. doi:10.3183/NPPRJ-2012-27-04-p689-694

Tanaka R, Saito T, Ishii D, Isogai A (2014) Determination of nanocellulose fibril length by shear viscosity measurement. Cellulose 1–9. doi:10.1007/s10570-014-0196-4

Tatsumi D, Ishioka S, Matsumoto T (2002) Effect of fiber concentration and axial ratio on the rheological properties of cellulose fiber suspensions. J Soc Rheol Jpn 30:27–32

Turbak AF, Snyder FW, Sandberg KR (1983) Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci Appl Polym Symp 37:815–827 (Proceedings of 9th Cellulose conference, 1982, part 2)

Varanasi S, He R, Batchelor W (2013) Estimation of cellulose nanofibre aspect ratio from measurements of fibre suspension gel point. Cellulose 1–12. doi:10.1007/s10570-013-9972-9

Wågberg L, Winter L, Ödberg L, Lindström T (1987) On the charge stoichiometry upon adsorption of a cationic polyelectrolyte on cellulosic materials. Colloids Surf 27:163–173

Wågberg L, Decher G, Norgren M, Lindström T, Ankerfors M, Axnäs K (2008) The build-up of polyelectrolyte multilayers of microfibrillated cellulose and cationic polyelectrolytes. Langmuir 24(3):784–795. doi:10.1021/la702481v

Zhu H, Helander M, Moser C, Ståhlkranz A, Söderberg D, Henriksson G, Lindström M (2012) A novel nano cellulose preparation method and size fraction by cross flow ultra-filtration. Curr Org Chem 16(16):1871–1875. doi:10.2174/138527212802651197

Acknowledgments

Ann-Marie Runebjörk, Åsa Blademo, and Åsa Engström are thanked for their competent supporting work. Billerud-Korsnäs, Borregaard, De la Rue, Hansol, Holmen, Kemira, Korsnäs, Metsä Group, Stora Enso, Södra, UPM, and Evergreen Packaging are acknowledged for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naderi, A., Lindström, T. & Pettersson, T. The state of carboxymethylated nanofibrils after homogenization-aided dilution from concentrated suspensions: a rheological perspective. Cellulose 21, 2357–2368 (2014). https://doi.org/10.1007/s10570-014-0329-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0329-9