Abstract

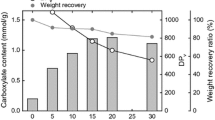

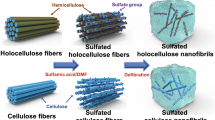

Hemp bast holocellulose fiber (Cannabis sativa L. Subsp. Sativa) was oxidized by TEMPO (2,2,6,6-tetramethylpiperidine-1-oxyl radical)-mediated oxidation at various NaClO addition levels in water at pH 10. When carboxylate contents of the oxidized products were 1.5–1.7 mmol/g, TEMPO-oxidized cellulose nanofibrils almost completely dispersed at the individual nanofibril were obtained by mechanical disintegration of the TEMPO-oxidized hemp bast holocelluloses in water, where the nanofibrillation yields were 98–100 %. The sugar composition analysis revealed that most of hemicelluloses originally present in the hemp bast holocellulose were degraded and removed from the solid oxidized products, providing almost pure TEMPO-oxidized celluloses. X-ray diffraction patterns of all TEMPO-oxidized hemp bast holocelluloses had the same cellulose I crystal structure and similar crystallinity indices and crystal widths, indicating that carboxylate groups formed by the oxidation were selectively present on the crystalline cellulose microfibril surfaces in the holocellulose. However, the weight recovery ratios and viscosity-average degrees of polymerization of the TEMPO-oxidized hemp bast holocelluloses decreased to 69–59 % and 470–380, respectively, when their carboxylate contents increased to 1.5–1.7 mmol/g by the TEMPO-mediated oxidation. Atomic force microscopy height images showed that the nanofibril widths were 2.7–2.9 nm, and the average nanofibril lengths decreased from 590 to 400 nm as the NaClO addition level was increased from 7.5 to 12.5 mmol/g in the TEMPO-mediated oxidation.

Similar content being viewed by others

References

Klemm D, Heubletin B, Fink HP, Bohn A (2005) Angew Chem Int Ed 44:3358

Pérez S, Samain D (2010) Adv Carbohydr Chem Bi 64:25

Sakurada I, Nukushina Y, Ito T (1962) J Polym Sci 57:651

Samir MASA, Alloin F, Dufresne A (2005) Biomacromolecules 6:612

Siró I, Plackett D (2010) Cellulose 17:459

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Angew Chem Int Ed 50:5438

Isogai A, Saito T, Fukuzumi H (2011) Nanoscale 3:71

Iwamoto S, Abe K, Yano H (2008) Biomacromolecules 9:1022

Abe K, Yano H (2009) Cellulose 16:1017

Chen W, Yu H, Liu Y (2011) Carbohydr Polym 86:453

Abe K, Yano H (2010) Cellulose 17:271

Alemdar A, Sain M (2008) Bioresour Technol 99:1664

de Morais Teixeira E, Corrêa A, Manzoli A, de Lima Leite F, de Oliveira C, Mattoso L (2010) Cellulose 17:595

Wang B, Sain M, Oksman K (2007) Appl Compos Mater 14:89

Moran JI, Alvarez VA, Cyras VP, Vazquez A (2008) Cellulose 15:149

Cherian BM, Leão AL, de Souza SF, Thomas S, Pothan LA, Kottaisamy M (2010) Carbohydr Polym 81:720

Rosa MF, Medeiros ES, Malmonge JA, Gregorski KS, Wood DF, Matoso LHC (2010) Carbohydr Polym 81:83

Zuluaga R, Putaux JL, Cruz J, Velez J, Mondragon I, Gãnan P (2009) Carbohydr Polym 76:51

Mandal A, Chakrabarty D (2011) Carbohydr Polym 86:1291

Dinand E, Chanzy H, Vignon RM (1999) Food Hydrocolloid 13:275

Dufresne A, Cavaille JY, Vignon MR (1997) J Appl Polym Sci 64:1185

Saito T, Nishiyama Y, Putaux JL, Vignon M, Isogai A (2006) Biomacromolecules 7:1687

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Biomacromolecules 8:2485

Saito T, Hirota M, Tamura N, Kimura S, Fukuzumi H, Heux L (2009) Biomacromolecules 10:1992

Iwamoto S, Kai W, Isogai A, Iwata T (2009) Biomacromolecules 10:2571

Gümüşkaya E, Usta M, Balaban M (2006) Bioresour Technol 98:491

Wang HM, Postle R, Kessler RW, Kessler W (2003) Text Res J 73:664

Kostic M, Pejic B, Skundric P (2008) Bioresour Technol 99:94

Sbiai A, Kaddami H, Sautereau H, Maazouz A, Fleury E (2011) Carbohydr Polym 86:1445

Milanovic J, Kostic M, Milanovic P, Skundric P (2012) Ind Eng Chem Res 51:9750

Wise LE, Marphy M, D’Adieco A (1946) Paper Trade J 122:35

Shinoda R, Saito T, Okita Y, Isogai A (2012) Biomacromolecules 13:842

Tappi Text Method T 249 cm-00 (2009)

Yamamoto M, Kuramae R, Yanagisawa M, Ishii D, Isogai A (2011) Biomacromolecules 12:3982

Okita Y, Saito T, Isogai A (2009) Holzforschung 63:529

Testing method for dissolving pulp. JIS P8101 (1994)

Saito T, Isogai A (2004) Biomacromolecules 5:1983

Isogai T, Saito T, Isogai A (2011) Cellulose 18:421

Alexander LE (1979) X-ray diffraction methods in polymer science. Krieger, New York

Okita Y, Saito T, Isogai A (2010) Biomacromolecules 11:1696

Fujisawa S, Isogai T, Isogai A (2010) Cellulose 17:607

Acknowledgments

The authors wish to thank Suphat Kamthai of Chaing Mai University and Queen Sirikit Botanic Garden, Thailand, who kindly provided the hemp bast sample. This research was supported by Grant-in-Aids for Scientific Research S (21228007) from the Japan Society for the Promotion of Science (JSPS). Buapan Puangsin is a recipient of the Monbu-Kagakusho Scholarship for foreign students.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Puangsin, B., Fujisawa, S., Kuramae, R. et al. TEMPO-Mediated Oxidation of Hemp Bast Holocellulose to Prepare Cellulose Nanofibrils Dispersed in Water. J Polym Environ 21, 555–563 (2013). https://doi.org/10.1007/s10924-012-0548-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-012-0548-9