Abstract

4-Carboxybenzaldehyde (4-CBA), a major component of purified terephthalic acid wastewater, is toxic to living organisms and required to be removed before the discharge of treated wastewater in a natural water body. In this work, the adsorptive removal of 4-CBA was studied using bagasse fly ash (BFA), a waste product from the sugar industry. The adsorption capacity of BFA was compared with the commercially available adsorbent, granular activated carbon (GAC). A 4-factorial, 5-stage central composite design (CCD) was used to optimize 4-CBA removal and adsorption uptake by BFA using response surface methodology (RSM). The variables considered for the study were pH, adsorbent dose (m), initial concentration (Co) and time (t). At the optimum treatment conditions of pH = 4, m = 9 g/L, Co = 100 mg/L and t = 7.5 h, the removal efficiency and adsorption uptake of 4-CBA on BFA were found to be 79% and 9.9 mg/g, respectively. BET surface area of BFA was determined to be 284 m2/g. A kinetic study was performed using a first- and second pseudo-order model. The adsorption equilibrium data were fitted for various adsorption models. A positive value \(\Delta H^{0}\) indicates that the adsorption process is endothermic. This study indicated that BFA is a cost-effective adsorbent for the removal of 4-CBA with high adsorption capacity and fast kinetics.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The petrochemical industry has recently experienced tremendous growth in recent times due to the high demand for value-added products and their wide applicability and ability to replace expensive and heavy materials. Terephthalic acid: a petrochemical product used in the production of polyethylene terephthalate, saw an increase in its production in the last decade (Annual Report, 2021–2022). 4-Carboxybenzaldehyde (4-CBA) is formed as a by-product or intermediate due to incomplete oxidation of p-xylene in the production of purified terephthalic acid (PTA) and is considered an impurity. 4-CBA causes problems in production due to its similarity of structure to terephthalic acid. It crystallizes with terephthalic acid and becomes trapped, making it inaccessible to complete oxidation (Tomás et al. 2013). 4-CBA causes irritation of the skin/eyes, respiratory tract and mucous membranes; it can also cause chemical conjunctivitis. Laboratory experiments have shown a mutagenic effect (Material safety data sheet 2023).

Studies on the treatment of 4-CBA-containing PTA wastewater have been conducted by numerous scientists and some of them proposed successful methods such as biological degradation (Amalorpavanathan et al. 2020), coagulation and flocculation (Verma et al. 2010; Tian et al. 2020), photocatalytic degradation (Shafaei et al. 2010), advanced oxidation processes (Chen et al. 2020; Garg and Prasad 2016), solvent extraction, nanofiltration, electrodialysis, pervaporation, supercritical water oxidation and adsorption (Anbia and Salehi 2012; Sandhwar and Prasad 2017; Verma et al. 2017).

A number of bio-recalcitrant chemical compounds can be effectively removed using the adsorption procedure. Although there are no by-products created during the adsorption process, the used adsorbents must be recycled for cyclic treatment or disposed off and handled responsibly. Due to its versatility and high removal efficiency, the adsorption process has been widely used for PTA wastewater treatment. Various adsorbents which have been used for the removal of toxic compounds from PTA wastewater are activated carbon (Sandhwar and Prasad 2017; Sandhwar et al. 2021), polyelectrolyte-modified ordered nanoporous carbon (Anbia and Salehi 2012), cationic MCM-41 (Huang et al. 2004) and mesoporous silica (FSM-16) (Tozuka et al. 2005). However, the high cost, long adsorption time and low adsorption equilibrium uptake of these adsorbents lead to the search for suitable adsorbents that can meet the above requirements.

Agricultural waste could be used as a precursor for activated carbon (Blachnio et al. 2020), but the problem with such an adsorbent is the limited surface area. After the sugarcane is juiced, the remaining waste is called bagasse and burned in a boiler to generate energy for sugar mills. The carbonaceous solid waste collected by the particulate filters connected to the flue gas line of bagasse-fired sugarcane boilers is referred to as bagasse fly ash (BFA) (Srinivas et al. 2021). Due to its low cost (almost free), short adsorption contact time and abundant availability, BFA has emerged as a highly favorable absorbent for the removal of various pollutants from wastewater. Utilization of BFA, a waste of the sugarcane industry, for the removal of 4-CBA from petrochemical wastewater has not been reported previously. The benefit of using BFA is that there is no need for regeneration since it is a waste. The spent BFA makes it a suitable raw material for making ceramic products such as insulation materials, membrane filters and structural ceramics. Spent BFA can also be added to mortar and concrete as a mineral blend (Amin et al. 2022).

In this study, the feasibility of the central composite design (CCD) method to optimize the removal of 4-CBA from an aqueous BFA solution as an adsorbent was investigated. The development of the mathematical model, the experimental design and the study of the interactive effect of the process parameters were carried out using the CCD method within the framework of the response surface methodology (RSM). The physicochemical characterization and adsorption capacities of BFA and granular activated carbon (GAC) were carried out. The thermodynamic parameters were evaluated, and the feasibility of the process was determined by checking the Gibbs free energy values and kinetics/isotherms.

Materials and methods

Characterization

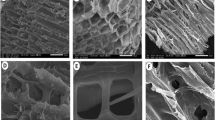

To investigate the structure of BFA, X-ray diffraction of these adsorbents was performed using an X-ray diffractometer (Bruker, Germany). The scanning angle (2θ) varied from 10º to 90º. The morphology of BFA was studied using a SEM-EDX quanta 200, Netherland. SEM microscopic images of BFA before/after adsorption are shown in Fig. 1a at different magnifications.

Analytical measurement

The 4-CBA concentration in the aqueous solution was estimated by a UV-spectrophotometer (Shimadzu). A standard solution of 4-CBA was scanned, and it was found that the maximum absorbance occurred at a wavelength of 257 nm (Web reference 1, https://pubchem.ncbi.nlm.nih.gov/compound/4-Formylbenzoic-acid#section=UV-VIS-Spectra). At this fixed wavelength, the absorbance corresponding to different concentrations of the 4-CBA solution was measured. The calibration curve was linear (absorbance = 1.77) with a correlation coefficient (R2) = 0.997 for the 4-CBA concentration range of 1 to 18 mg/L. If the absorbance of the sample was higher than 1.8 during the experiment, the sample was diluted accordingly to keep the 4-CBA absorbance within the calibration range.

Adsorption tests

The effect of pH, m, Co and t on the adsorptive removal of 4-CBA was investigated in batch experiments. Each experimental run was performed according to Tables 1 and 2. 100 ml solution of 4-CBA was placed in a 250 ml stoppered conical flask at a stirring speed (Shaker, Remi Instruments, Mumbai) of 150 rpm. The temperature of the incubation shaker was maintained at 30 ºC. To eliminate the effect of leaching of the adsorbent into the solution, blank experiments were performed simultaneously under similar conditions by adding 0.5 g of adsorbent to 100 mL of distilled water. The calculation of percent 4-CBA removal and adsorption equilibrium was performed as follows:

Equilibrium adsorption uptake

where Ct is 4-CBA concentration (mg/L) at time t, Co is initial 4-CBA concentration (mg/L), m is the mass of adsorbent g, qt is adsorption uptake (mg/g) and V is the volume of solution.

Adsorbents and adsorbate

The low-cost adsorbent BFA was purchased from Uttam Sugar Mills, Roorkee (India), and sieved using standard sieves (IS 437–1979) to remove the fine particles. No further treatment was carried out, and a mass fraction between 0 to 1 mm and 450 µm was used as an adsorbent to remove 4-CBA. Laboratory-grade GAC was provided by GSE Chemical Testing Laboratory, New Delhi, and used as adsorbent as it was procured. Physicochemical characterization was carried out according to a standard procedure to obtain essential properties of the adsorbents. 4-CBA, a petrochemical compound, was used as adsorbate and was manufactured by HiMedia Laboratories Pvt. Ltd. Mumbai, India, with a minimum content of 96%. 4-CBA is also known as P-carboxybenzaldehyde, 4-formylbenzoic acid and terephthalaldehydic acid. Due to its low solubility at normal temperature, 4-CBA was dissolved in distilled water and heated to the appropriate temperature to prepare the stock solution (200 mg/L).

The bulk density of BFA and GAC was determined using a bulk density meter supplied by Macro Scientific Works, Delhi. The textural properties of BFA and GAC were determined using an automated Micromeritics Chemisorb 2720 and the N2 adsorption isotherm at 77.15 K. During the experiment, degassing was first performed to avoid errors in surface area measurements. The textural properties of both adsorbents were determined using the Brunauer–Emmett–Teller method (BET) (Brunauer et al. 1938). Mesopore distribution for BFA and GAC was calculated using the BJH method (Barret et al. 1951). The functional groups in BFA before/after adsorption of CBA were determined by FTIR Thermo Nicolet, Magna 7600.

RSM and CCD

RSM mainly consists of three steps: (i) selection of parameters and design of experiments, (ii) modeling of the reaction surface by regression, and (iii) optimization of the reaction (Kütahyali et al. 2012; Jaouachi et al. 2007). Box Behnken, CCD statistical experimental design and two-step full factorial experimental design are used to optimize the considered parameters in the framework of RSM.

CCD was originally introduced by Box and Wilson (1951). CCD is preferred over the full factorial experimental design because it provides comparable results while reducing the number of experimental runs required. Statistical models provided by CCD are useful for understanding the interaction between the optimized parameters. In CCD, all effective factors are optimized simultaneously. The central point for each factor is assumed to be 0, and the experimental design is considered symmetric about the central point (Brereton 2003).

For the statistical calculation, the following relationship is established between the coded value (xi) and the real value (Xi)

Here ΔX is a step change and X0 is the real value at the midpoint. Since the input parameters interact in a linear-to-linear and linear-to-quadratic manner, the system behavior considering all interactions can be described as follows:

where β0 is constant coefficient, ε is the residual error, i and j are linear, quadratic coefficients; n is a number of parameters (here n = 4), βi is slop or linear effect of input factor xi, βii is the quadratic effect on input factor xi and βij is the linear interaction effect between input factors xi and xj (Benyounis et al. 2005).

In the adsorption process, various parameters such as m, pH solution, t, Co, and operating temperature, as well as adsorbent surface area, play an important role, but among these parameters: m (X2), pH (X1), Co (X3), and t (X4) primarily affect the adsorption process, and in this study, these factors are used for optimization. CCD with Design-Expert software was used to design the experiments (Trial version 6.0.8).

In this study, a five-level (− α, − 1, 0, + 1, + α) four-parameter CCD was used to investigate and validate the adsorption process affecting 4-CBA removal and adsorption capacity. Levels + 1 and − 1 are higher and lower levels, respectively, 0 is the midpoint, while + 2 and -2 represent star points (α). The percent of 4-CBA removal and adsorption uptake at equilibrium were considered as the response of the system. pH (pH: 2–10), m (1–9 g/L), Co (20–100 mg/L) and t (0.5–7.5 h) were variable input parameters, while the temperature of 30 ℃ was kept as a constant input parameter. The variables and levels of the CCD are listed in Table 3. The total number of experiments that needed to be performed to optimize the parameters was determined using the following formula.

where n is the number of parameters to be optimized and Nc is no of central points. For four parameters, total number of experimental runs (30) will consist of three parts.

-

(a)

24 = 16 experimental runs corresponding to factorial points.

-

(b)

2 × 4 = 8 experimental runs corresponding to axial points, fixed according to the rotatability condition at a distance α.

-

(c)

Nc = 6 Series of experiments with repetition of midpoints to determine the experimental error and reproducibility of data.

Batch experimentation

To check the stability of the adsorbate, 100 mL of the adsorbate solution was stirred without adding any adsorbent under similar conditions. No difference was found in the concentration before and after stirring, confirming the stability of the adsorbate. The pH of the solution was adjusted by adding 0.1 N NaOH/HCl solution accordingly. After removing the samples from the shaker, it was found that some BFA particles were in suspended form. To settle them completely, all samples were centrifuged by Remi Scientific int. at 5000 rpm for 5 min. The centrifuged samples were collected, filtered and diluted if necessary, and the concentration was measured. A kinetic study was performed by evaluating the adsorption equilibrium uptake of CBA at different time intervals from an aqueous solution for a fixed initial adsorbate concentration. An adsorption isotherm study was performed by stirring initial aqueous solutions of various CBA concentrations with a fixed amount of adsorbent until equilibrium was reached.

Results and discussion

Adsorbents characterization

The bulk densities of BFA and GAC were found to be 119.5 and 613 kg/m3, respectively. The percent solid carbon, ash, volatile matter, and moisture content of BFA and GAC were determined according to Bureau of Indian Standards (BIS) specifications (IS 1984, 1985). The result of the proximate analysis is given in Table S1. The results show that BFA has a higher fixed carbon content than GAC.

SEM as shown in Fig. 1a and b demonstrates the porous nature and surface texture of BFA. In Fig. 1a, SEM image of BFA shows a lamellar structure with large but shallow pore size and strands in each fold, while Fig. 1b shows the spent BFA. Elemental analysis of BFA was performed by energy-dispersive X-ray spectroscopy (EDX), and it was found that blank BFA contains 74.4% carbon, 18.9% oxygen, 3.2% silicon and 1.8% potassium. After adsorption, the percentage of carbon was increased by 5%.

The pore size distribution of BFA and GAC was performed using the BJH method. Classification of micropores, mesopores and macropores was done per the IUPAC (IUPAC 1982). Particles with a pore diameter of less than 20 Ǻ are classified as micropores, while 20 Ǻ, 500 Ǻ are referred to as mesopores. BJH adsorption area shows that BFA and GAC have 27.3 and 35% micropore area and mesopore area 72.7%, respectively. According to the desorption pore distribution, mesopores accounted for 67 and 63% of the total pore area of BFA and GAC, respectively. Thus, BFA was found to have a larger mesopore area than GAC, and both adsorbents had a more significant proportion of mesopores and a smaller proportion of micropores. The XRD of BFA showed large bumps indicating the presence of silica. The absence of a sharp peak confirms the amorphous nature of BFA.

The FTIR spectra displayed in Fig. 1c demonstrate the presence of multiple functional groups on the surface of BFA. The broad band observed between 3200 and 3600 cm−1 signifies the existence of both free and hydrogen bonded OH groups, which suggests the presence of water and silanol (SiOH) groups on the BFA surface. The weak bands observed at 2924 and 2800 cm−1 correspond to the asymmetric and symmetric C-H stretching of methylene groups, respectively. The presence of a band at 1376 cm−1 indicates the existence of carboxyl-carbonate structures. The strong band observed around 1047 cm−1 suggests the presence of inorganic silicates. Additionally, the presence of inorganic SO42− ion is indicated by the band observed in the 605-cm−1 region (3300–3600 cm−1) (Patel 2020) (Ricordel et al. 2001).

Removal of 4-CBA by BFA

Evaluating the effect of dose, pH, time, removal concentration and adsorption capacity in the presence of matrix compounds is shown in Table 2. Lower-order interactions mainly influence a system with many variables. However, higher-order interactions can be neglected due to their small size compared to lower-order interactions (Kalengyo et al. 2022). A regression equation was developed by fitting the experimental data into different models. The following tests were performed to select the appropriate model to explain the adsorption of 4-CBA on BFA. The tests for the sum of squares of the sequential model and the summary statistics of the model are sufficient to test the adequacy. This study and the results are shown in Tables S2 and S3. The cubic model was not selected because it exhibits aliasing.

From the table of the sum of squares of the sequential model, comparing the values of the probability factor 'p' for different models, it can be seen that the value of p for the linear model is less than 0.01 in the case of 4-CBA, while p for the quadratic model is less than 0.01 in the case of adsorption capacity. In the table of summary statistics of the models, the values of "R-squared" and "adjusted R-squared" for the linear model were closer to unity in the case of 4-CBA removal, while these values were close to unity for the quadratic model in the case of adsorption capacity. Considering the p-value, the "R-squared" and "adjusted R-squared," we can conclude that the linear and the quadratic models are the best fitting model for 4-CBA removal and adsorption capacity, respectively. Figure 2 illustrates the Pareto chart and the corresponding p-value of the variable to check the significance of the regression coefficients of the model. As shown, the largest effect on 4-CBA adsorption was a linear term of adsorption dosage, concentration and time (X2, X3 and X4) which implied a higher t-value (11.65, 9.69 and 5.02, respectively) and the lowest p-value (0.00, 0.00 and 0.01, respectively).

Polynomial equation fitting

Analysis of variance 'ANOVA' of the data was performed to test the significance of the model, and the predicted results are shown in Table 3 and Eqs. S4 and S5. The significant Fisher's F-test value (9.24) and the corresponding low p-value (p < 0.0001) indicate that the regression is highly statistically significant. The reliability and accuracy of the performed experiments were checked by the value of the coefficient of variation (C.V.). A low-value C.V. = 12.05% indicates that the performed experiments were precise and reliable. The correlation coefficient (R2) and the adjusted R2 value are used to check the model's fit. A relatively moderate value of R2 = 0.8739 and adjusted-R2 = 0.7794 indicates the best relation between observed and predicted values.

The significance of pH, m, concentration and time for the adsorption process was determined using the sum of squares, F value and p-value in Table 3. The model terms are significant at p < 0.05, while the terms are not considered significant at p > 0.1. From the regression Eq. (6), we can see that m and time have a positive coefficient, which means that 4-CBA removal increases when these factors are changed from low to high, while the negative coefficient of pH and concentration means that 4-CBA removal decreases when the values of these factors are increased. "Adeq precision" measures the signal-to-noise ratio, and a ratio > 4 is desirable (Muniz et al. 2020). The value of 11.608 indicates that the model has been used to navigate.

Effect of initial pH and m on 4-CBA removal and adsorption capacity

The initial pH of the solution is an essential parameter in the adsorption process and affects the degree of ionization speciation and the surface charge of the adsorbent of various pollutants. Different functional groups dissociate at different pH values; therefore, the adsorption capacity of the adsorbent changes at different pH values, leading to a shift in the equilibrium properties. The cationic/anionic species adsorb on the adsorbent surface depending on the competitive adsorption of OH and H + ions with adsorbates. It was generally observed that anions are preferentially adsorbed on the surface of the adsorbent when the pH is < pHpzc, while at a higher pH the surface is active for the adsorption of cations due to the availability of OH− ions. Due to the presence of carboxyl and aldehyde groups in 4-CBA, the aqueous solution of 4-CBA is acidic; therefore, the pH values are below pHpzc (8.5, not shown here), i.e., the BFA surface in an aqueous solution of 4-CBA is positively charged. Thus, the interactions expected in the adsorption of 4-CBA are electrostatic attraction and dispersion interactions. The dependence of 4-CBA removal on initial pH and m is shown in Fig. 3a. From Fig. 3a, it can be seen that the adsorption fraction increases with the decrease in initial pH and 4-CBA concentration. At a lower pH (2–4), the surface of BFA is positively charged; therefore, in this pH range, the electrostatic attraction between the positively charged active groups of BFA and the negatively charged molecules of 4-CBA is maximum, resulting in increased adsorption of 4-CBA. With a further increase in pH, the adsorption on BFA decreases because, with an increase in pH, the positive surface charge on BFA decreases, resulting in a lower electrostatic attraction between BFA and 4-CBA molecules (Tukaram Bai et al. 2020). The natural pH of the 4-CBA solution without any pH adjustment by NaOH/H2SO4 was about 4 in this study; therefore, pH0 = 4 was chosen as the optimal pH for additional experiments. The effect of pH on adsorption capacity is shown in Fig. 3c. The pH affects the adsorption capacity of the adsorbents similarly to the percentage removal of 4-CBA.

The cost of the adsorption process depends strongly on the adsorbent, so it is necessary to determine the optimal m. Figure 3a clearly shows that for a fixed pH, with an increase in m, the 4-CBA removal initially increases, but this increase in adsorbate removal becomes almost constant for a given adsorbent. As m increases, the surface area for adsorption increases, as does the availability of adsorption sites, and this increase leads to higher adsorption of 4-CBA. At m > 8.5 g/L, sufficient adsorption has occurred at this condition, 4-CBA concentration in the solution comes into equilibrium with each other therefore the additional 4-CBA removal becomes very small. At about m = 9 g/L, the removal efficiency becomes constant (84%). When m was further increased, no significant improvement in 4-CBA removal was observed because the adsorbate has to travel a longer distance and there was no driving force due to the equilibrium of the adsorbate in both phases. Therefore, the m value of 9 g/L for BFA was chosen as the mopt value for further studies.

The effect of m on adsorption capacity is shown in Fig. 3d. The adsorption capacity of the adsorbent decreases with increasing dose, since the availability of a large number of adsorption sites decreases the probability that the adsorbate was adsorbed at a particular site.

Effect of Co and t on 4-CBA removal and adsorption capacity

The effect of contact time and initial adsorbate concentration is shown in Fig. 3b. The figure shows that at a fixed time for 4-CBA adsorption, a significant decrease in the 4-CBA removal was observed when the 4-CBA concentration was increased from 20 to 90 mg/L. At a lower 4-CBA concentration, the % removal is high because the number of adsorbates competing for the same number of adsorption sites is less than at a higher 4-CBA concentration, where a large number of adsorbates compete for the same number of sites. Therefore, the residual concentration is high in the case of a higher initial concentration, resulting in low removal at a high concentration. When the 4-CBA concentration was further increased from 90 to 100 mg/L, the adsorption of 4-CBA did not change significantly.

The increase in the amount of 4-CBA adsorbed per unit mass of BFA with increasing concentration is shown in Fig. 3c. The main driving force for the adsorption capacity is the concentration difference of 4-CBA between the aqueous/solid phases. As the initial concentration increases, the driving force increases and can overcome the mass transfer resistance, increasing adsorption capacity. Higher initial concentration facilitates more interaction between 4-CBA and free BFA sites and functional groups.

The effect of contact time on 4-CBA removal by BFA under different experimental conditions is given in Table 2 and shown in Fig. 3b. The figure shows that the percentage removal of adsorbate increases with increasing time for a given 4-CBA concentration. Due to the longer contact time, the adsorbate can diffuse over longer distances and overcome resistances until equilibrium is no longer reached. The adsorption rate is higher in the initial phase of adsorption because larger free surfaces are available for adsorption. About 40% of 4-CBA adsorption occurs within 30 min. The initial high removal rate indicates surface-bound sorption, and after some time, the low removal rate can be attributed to the remote diffusion of the adsorbate into the internal pores of the adsorbent (Cardoso et al. 2021). After a sufficient time, the 4-CBA concentration in the aqueous phase and on the adsorbent surface comes into equilibrium, and adsorption can no longer be observed.

Removal of 4-CBA by GAC

Preliminary experiments were performed to investigate the optimal pH for removing 4-CBA by GAC. It was found that the trend and optimal pH in the case of GAC for removing 4-CBA was similar to that of BFA. However, the optimal dose of GAC was determined and was 20 g/L, as shown in Fig. 4.

Adsorption kinetics and effect of contact time for BFA and GAC

The experiments were performed to investigate the contact time effect and compare the equilibrium adsorption uptake of BFA with GAC. The results are shown in Fig. 5a and b. The adsorption rate was relatively high in the initial phase of adsorption (3 h) for both adsorbents, which may be attributed to the availability of many free sites, but as time increases, the adsorption rate decreases. The decrease in adsorption rate can be attributed to the unavailability of the external surface for adsorption and the resistance the adsorbed molecule offers to the new molecules. From Fig. 5a and b, it can be seen that there is no significant change in the adsorption rate after 4 h. Because of this, t = 4 h was chosen as the equilibrium time. The initial rapid uptake showed surface-bound sorption, and the slow second phase was due to the adsorbate's remote diffusion into the adsorbent's internal pores (Onawumi et al. 2020).

The kinetic study helps develop and optimize batch reactor processes to treat industrial wastewater. Pseudo-first-order equation is represented in mathematical form as follows

where qe is adsorption capacity at equilibrium (mg/g), qt is the amount of adsorbate adsorbed at time t (mg/g), kf pseudo-first-order constant, and t is the contact time between adsorbate and adsorbent (min). The value of the constant, along with the best-fit values, MPSD, and coefficient correlation (R2) values for both adsorbents, is shown in Table 4.

Pseudo-second-order equations were represented in the following form (Ho and McKay 1999):

Here, ks is the second-order pseudo-rate constant (g/mg min), and qt and qe were defined as before. If we integrate and rearrange the above equation with the initial condition qt = 0 at t = 0, we obtain

where h (mg/g min) = ksqe2 is the initial sorption rate.

The adequacy and accuracy of the fit of the kinetic model to the experimental data and the most appropriate model were determined using Marquardt's percent standard deviation error function (MPSD) (Marquardt 1963). MPSD was given as:

In the above equation, 'exp' represents the values obtained from experimental data, while 'pred' refers to the values obtained by fitting a particular model, n is the number of measurements made, and p is the number of parameters in the model.

Values of qe and ks, along with MPSD and correlation coefficient, are given in Table 4. qe,exp are values obtained from the experiment, while qe,pred values are predicted by curve fitting using the solver add-in function available in Microsoft Excel. From Table 4, the value of adsorption capacity increases and the rate constant decreases with an increase in concentration for second-order kinetics for both adsorbents.

Comparing the values of R2 and MPSD from Table 4, we find that the values of R2 for the pseudo-second-order model are close to one and the values of MPSD are minimal in the case of the pseudo-second-order model. Thus, it can be concluded that the adsorption kinetics data for the adsorption of 4-CBA on BFA and GAC best fit the pseudo-second-order model.

Intra rate-controlling step/particle diffusion model

The adsorption mechanism of 4-CBA on BFA and GAC was studied using the intraparticle diffusion mechanism (Weber and Morris 1963), according to which the uptake is directly proportional to t1/2, as indicated below

Here Kid is defined as the constant of the intraparticle diffusion rate (mg/g min1/2), while I is a constant given by the intercept of the diagram qe versus t0.5, which gives an idea of the thickness of the boundary layer, i.e., the more significant the intercept, the larger the boundary layer effect and the slower the corresponding step.

In the adsorption process, the movement of the adsorbate from the primary phase to the adsorbent occurs in the following steps: (a) movement of the adsorbate from the primary solution into the outer film surrounding the adsorbent, (b) mass transfer of the adsorbate from the boundary layer to the surface of the adsorbent, (c) movement of the adsorbate molecule in the pores of the adsorbent either by a pore diffusion process or by a solid surface diffusion mechanism, (d) adsorption at the surface site. The slowest of these steps is the rate-limiting step and controls the sorption process. External transport cannot be a rate-limiting step because sufficient agitation is provided during the sorption process, reducing the resistance to film diffusion and causing adsorption to occur faster. Site adsorption was also considered extremely fast, preventing it from being the slowest step (dos Santos et al. 2022).

Figure 6a and b shows a plot between qt and time0.5 at different concentrations of 4-CBA for both adsorbents. The lines in Fig. 6a and b do not pass through the origin, suggesting a difference between the initial and final adsorption rates. It can be seen from the figure that the curve is multi-linear over the entire time0.5 range. The first sharper section connecting the origin to the first point of each line (line not shown in Fig. 6a and b) corresponds to boundary layer diffusion, and the other two linear sections represent diffusion within the particles. The first linear section shown in the figure, where adsorption occurs immediately, represents macropore or surface diffusion and can be attributed to the gradual equilibrium stage where intraparticle diffusion dominates. The second linear part represents the mesopore diffusion, and in this part, the intraparticle diffusion starts to slow down due to the low residual concentration of the adsorbate in the solution). The multi-linear character of the curve indicates that the mechanism was controlled by intraparticle diffusion and surface diffusion (Ofomaja et al. 2020).

The values of I1, I2, Kid,1 and Kid,2 are given in Table 4. From the table, it can be seen that the value of Kid for the first linear section is about 6 times higher than that of the second section, implying a higher initial adsorption rate. Due to the more significant value of the axial section for the second line, the resistance is more significant, resulting in a slower absorption rate. Table 4 shows that as the concentration increases, the value of Kid increases and therefore does the uptake rate.

Adsorption isotherm study

The operating temperature in the adsorption process affects different capacities. Figure 7a and b show a plot of qe versus Ce for the systems 4-CBA-BFA and 4-CBA-GAC at different temperatures (15, 30, 45 ºC). Usually, the adsorption process is considered exothermic and the adsorption capacity should decrease with increasing temperature. However, our study showed that, contrary to the usual observation, adsorption increases with increasing temperature for both absorbents. The increase in adsorption capacity can be attributed to the activation of new sites by an increase in temperature, an increase in the mobility of the adsorbate ions at high temperatures and a decrease in the retardation force. Diffusivity is positively affected by temperature and contributes to the adsorption capacity of the adsorbate with an increase in temperature, provided that the adsorption process was controlled by the diffusion process (intraparticle diffusion). In addition to intraparticle diffusion, adsorption was also controlled by diffusion resistance and surface diffusion can be neglected if the process continues for a sufficient contact time. Therefore, the increase in adsorption equilibrium uptake of 4-CBA on adsorbents is due to chemisorption (Verma et al. 2017).

Equilibrium adsorptions isotherms at different temperatures for (a) 4-CBA-loaded BFA system, t = 4 h, Co = 20–200 mg/L; m = 9 g/L. lines predicted by Sips model (b) 4-CBA-loaded GAC system, t = 4 h, Co = 20–200 mg/L; m = 20 g/L. The lines are predicted by Redlich–Peterson. In both figures, experimental data points are given by symbols

The adsorption isotherm describes the relationship between the adsorbent and the concentration of the dissolved adsorbate as well as the amount of adsorbed materials. This distribution of the adsorbate is based on the homogeneity/heterogeneity of the adsorbent, the nature of coverage, and the interaction between adsorbate and adsorbent (dos Santos et al. 2022). In the Langmuir isotherm, adsorption occurs in a single layer with homogeneous surface energy and no solute transmigration. The constant 'b' value is used to describe how strongly the adsorbate is adsorbed onto the adsorbent. The Freundlich isotherm is used in the case of a heterogeneous surface. Each site has a different binding energy and the sites with the stronger binding energy are occupied first. The values of 1/n are used to measure the adsorption intensity or heterogeneity of the surface. When 1/n is less than 1, chemisorption occurs and when 1/n is greater than 1, cooperative adsorption occurs. The Redlich–Peterson (R-P) isotherm exhibits both the Langmuir and Freundlich isotherms. It approaches the Freundlich isotherm at high concentration (when g approaches zero) and the Langmuir isotherm at low concentration (when g approaches 1). The sips isotherms represent a combined form of the Freundlich and Langmuir isotherms derived for the evaluation of heterogeneous systems (Üzek et al. 2022).

The values of the parameters for different isothermal models, such as Langmuir, Freundlich, R-P, Hills, Sips, Toth, and Temkin, along with the sum of squared errors (SSE) and correlation coefficient (R2) at different temperatures, were evaluated using MS Excel for Windows and are tabulated in Table 5. For the Langmuir isotherm, the increase in the values of Q0 and b with increasing temperature confirms the endothermic process. The values of 1/n for the Freundlich isotherm are less than 1 for both adsorbents; therefore, the adsorption of 4-CBA is favorable for both adsorbents (Table 5). Table 5 shows that the value of g is between 0 and 1 for the R-P isotherm (except for GAC at 318 K); therefore, adsorption is favorable at all temperatures.

It was found that the optimal adsorption capacity of BFA is greater than that of GAC. GAC has a larger surface area than BFA, but the higher adsorption capacity of BFA suggests that the available surface area of BFA for adsorption is greater than that of GAC. This could also be due to the greater affinity of 4-CBA for BFA. It is also evident from Fig. 7a and b that the adsorption rate is higher at lower adsorbate concentrations than at high adsorbate concentrations. To find the best isotherm, the values of R2 and SSE were compared for all isotherms. From Table 5, considering the closeness of R2 to unity, it can be concluded that the R-P isotherm best fits for the 4-CBA-GAC system, while Sips model best fits for the 4-CBA-BFA system for adsorption equilibrium data.

Thermodynamic parameters study

Thermodynamic parameters were calculated with the help of the following mathematical equation:

where R is the universal gas constant (8.314 J/mol K), \(\Delta G_{{{\text{ads}}}}^{0}\) the change in free energy (kJ/mol), T is the absolute temperature (K), \(K_{{{\text{ads}}}}\) the equilibrium constant of the interaction between the adsorbate and the surface of the adsorbent, \(\Delta H^{0}\) the change in enthalpy (kJ/mol), and the change in entropy (kJ/mol K). \(K_{{{\text{ads}}}}\) is determined from the intersection of ln(qe/Ce) versus qe (Raghav and Kumar 2018). The values of all parameters are shown in Table 6. A positive value confirms both adsorbents' overall endothermic nature of the adsorption process. The liquid/solid adsorption process proceeds in two steps: In the first step, the previously adsorbed water molecule (solvent) is desorbed, and in the second step, the adsorbate adsorbs onto the adsorbent. The complete process requires the displacement of water molecules by 4-CBA molecules. Energy is required to complete the process, making this process endothermic. As the temperature increases, the randomness of the interface between the solid and the solution increases, causing structural changes in the adsorbate and the adsorption system for the adsorption process. An increase in randomness means an increase in the entropy of the system.

Conclusions

In the present study, the main process variables affecting the adsorption of 4-CBA on BFA were optimized using CCD. The optimized condition for the experiment was pH = 4, initial concentration of 4-CBA = 100 mg/L, time of 4 h and adsorbent dose = 9 g/L. Under the optimized conditions, the removal efficiency and adsorption uptake of 4-CBA on BFA were 79% and 9.9 mg/g, respectively. The adsorbent dose and contact time had a synergistic effect, while pH and initial sorbate concentration had an antagonistic effect on the percent removal of 4-CBA. A reasonably good R2 value (0.87 for percent removal of 4 CAB and 0.90 for adsorption uptake) from the analysis of ANOVA ensures a satisfactory fit of the regression model data. The pseudo-second-order model provided the best fit to the kinetic data of adsorption of 4 CAB on BFA and GAC. The adsorption capacity of BFA was compared with that of GAC, and the results show that BFA has a better adsorption capacity for the removal of 4-CBA. Different isotherm models were investigated to study the equilibrium isotherm. The Redlich–Peterson and Sips models best fitted the isothermal equilibrium data for BFA and GAC, respectively. The effects of temperature and process feasibility were determined by evaluating the thermodynamic parameters.

Data availability

Enquiries about data availability should be directed to the authors.

Abbreviations

- 4-CBA:

-

4-Carboxybenzaldehyde

- BFA:

-

Bagasse fly ash

- GAC:

-

Granular activated carbon

- RSM:

-

Response surface methodology

- CCD:

-

Central composite design

- C 0 :

-

Initial 4-CBA concentration (mg/L)

- C t :

-

4-CBA concentration (mg/L) at time t

- m :

-

Mass of adsorbent g

- t :

-

Time

- q t :

-

Adsorption uptake (mg/g)

- V :

-

Volume of solution

- SEM:

-

Scanning electron microscope

- FTIR:

-

Fourier transform infrared spectroscopy

- \(\Delta H^{0}\) :

-

Standard enthalpy of adsorption process

- PTA:

-

Purified terephthalic acid

- q e :

-

Adsorption capacity at equilibrium

- k f :

-

Pseudo-first-order constant

- R 2 :

-

Correlation coefficient

- SSE:

-

Sum of squared errors

- T :

-

Absolute temperature

- C.V.:

-

Coefficient of variation

- BIS:

-

Bureau of Indian Standards

- XRD:

-

X-ray crystallography

- EDX:

-

Energy-dispersive X-ray spectroscopy

- IUPAC:

-

International Union of Pure and Applied Chemistry

- MPSD:

-

Marquardt's percent standard deviation error function

- \(\Delta G_{{{\text{ads}}}}^{0}\) :

-

Free energy

- \(K_{{{\text{ads}}}}\) :

-

Change in free energy

- ANOVA:

-

Analysis of variance

- AOP:

-

Advanced oxidation processes

References

Amalorpavanathan JAS, Shah Y, Gocher C, Soni S, Gopalakrishnan K, Jasra R (2020) Biodegradation of purified terephthalic acid manufacturing effluent from a petrochemical industry. Int J Environ Waste Manage 25(4):409–429

Amin M, Attia MM, Agwa IS, Elsakhawy Y, Abu El-hassan K, Abdelsalam BA (2022) Effects of sugarcane bagasse ash and nano eggshell powder on high-strength concrete properties. Case Stud Constr Mater 17:e01528

Anbia M, Salehi S (2012) Synthesis of polyelectrolyte-modified ordered nanoporous carbon for removal of aromatic organic acids from purified terephthalic acid wastewater. Chem Eng Res Des 90:975–983

Andreozzi R, Caprio V, Insola A, Marotta R (1999) Advance oxidation processes (AOP) for water purification and recovery. Catal Today 53:51–59

Barret EP, Joyer LG, Halenda PP (1951) The determination of pore volume and area distributions in porous substances: 1. Computations from nitrogen isotherms. J Am Chem Soc 73:373–380

Benyounis KY, Olabi AG, Hashmi MSJ (2005) Effect of laser welding parameters on the heat input and weld-bead profile. J Mat Process Technol 164(165):978–985

Blachnio M, Derylo-Marczewska A, Charmas B, Zienkiewicz-Strzalka M, Bogatyrov V, Galaburda M (2020) Activated carbon from agricultural wastes for adsorption of organic pollutants. Molecules 25(21):5105

Box GEP, Wilson KB (1951) On the experimental attainment of optimum conditions. J R Stat Soc B Stat Methodol 13:1–45

Brereton RG (2003) Chemometrics: data analysis for the laboratory and chemical plant. Wiley, New York, pp 76–84.

Brunauer S, Emmet PH, Teller F (1938) Adsorption of gases in multi-molecular layers. J Am Chem Soc 60(2):309–319

Cardoso CKM, Mattedi S, Lobato AKDCL, Moreira ÍTA (2021) Remediation of petroleum-contaminated saline water using value-added adsorbents derived from waste coconut fibres. Chemosphere 279:130562

Chen X, Huang ZH, Ji ZY, Guo XF, Zhao LM, Yuan JS (2020) Efficient treatment of pure terephthalic acid wastewater with Na2S2O8 based on thermal activation. Environ Technol Innov 19:100897

Garg KK, Prasad B (2016) Treatment of multicomponent aqueous solution of purified terephthalic acid wastewater by electrocoagulation process: optimization of process and analysis of sludge. J Taiwan Inst Chem Eng 60:383–393

Giraldo L, Moreno-Piraján JC (2008) Pb2+ adsorption from aqueous solutions on activated carbons obtained from lignocellulosic residues. Braz J Chem Eng 25:143–151

Ho YS, McKay G (1999) Pseudo-second order model for adsorption processes. Process Biochem 34:451–465

Huang L, Xiao H, Ni Y (2004) Cationic MCM-41: synthesis, characterization and sorption behavior towards aromatic compounds. Colloids and Surf A 247:129–136

Jaouachi B, Hassen MB, Sakli F (2007) Strengh of wet spliced denim yarns after sizing using a central composite design. Autex Res J 7:159–165

Kalengyo BR, Ibrahim MG, Fujii M, Nasr M, (2022) Synthesis of carbonized bagasse and orange peel wastes as adsorbents for dye removal from aqueous solution: a sustainable approach. In Sustainable Development of Water and Environment (pp. 153–163). Springer, Cham.

Kütahyali C, Çetinkaya B, Acar MB, Işık NO, Cireli I (2012) Investigation of strontium sorption onto Kula volcanics using Central Composite Design. J Hazard Mat 201(202):115–124

IUPAC Manual of Symbols and Terminology of Colloid Surface, Butterworths, London, (1982) 1.

Marquardt DW (1963) An algorithm for least-squares estimation of nonlinear parameters. J Soc Ind Appl Math 11:431–441

Material safety data sheet. http://fscimage.fishersci.com/msds/76480.htm. Accessed on 15.01. 2023).

Muniz GL, da Silva TCF, Borges AC (2020) Assessment and optimization of the use of a novel natural coagulant (Guazuma ulmifolia) for dairy wastewater treatment. Sci Total Environ 744:140864

Ofomaja AE, Naidoo EB, Pholosi A (2020) Intraparticle diffusion of Cr (VI) through biomass and magnetite coated biomass: A comparative kinetic and diffusion study. S Afr J Chem Eng 32(1):39–55

Onawumi OO, Bello OS, Amoo FA (2020) Treatment of pharmaceutical wastewater using groundnut shells. In: Environmental Research Literacy: Classroom, Laboratory, and Beyond (pp. 131–140). American Chemical Society.

Patel H (2020) Environmental valorisation of bagasse fly ash: a review. RSC Adv 10(52):31611–31621

Raghav S, Kumar D (2018) Adsorption equilibrium, kinetics, and thermodynamic studies of fluoride adsorbed by tetrametallic oxide adsorbent. J Chem Eng Data 63(5):1682–1697

Annual Report (2021–2022) Ministry of Chemical and Petrochemical. https://chemicals.gov.in/sites/default/files/Reports/Annual_Report_2021-22.pdf)as. Accessed on 7.05.2013.

Ricordel S, Taha S, Cisse I, Dorange G (2001) Heavy metals removal by adsorption onto peanut husks carbon: characterization, kinetic study and modeling. Sep Purif Technol 24:389–401

Sandhwar VK, Prasad B (2017) Comparison of phthalic acid removal from aqueous solution by electrochemical methods: Optimization, kinetic and sludge study. J Environ Manage 203:476–488

Sandhwar VK, Saxena D, Verma S, Garg KK, Prasad B (2021) Comparison of COD removal from petrochemical wastewater by electro-Fenton and electro oxidation processes: optimization and kinetic analyses. Sep Sci Technol 56(13):2300–2309

dos Santos JMN, Lima É, Dotto GL (2022) Basic fundamentals of adsorption modeling for removal of pesticides from water and wastewater. In Pesticides Remediation Technologies from Water and Wastewater (pp. 159–188). Elsevier, Amsterdam.

Shafaei A, Nikazar M, Arami M (2010) Photocatalytic degradation of terephthalic acid using titania and zinc oxide photocatalysts: Comparative study. Desalination 252:8–16

Shaik O, Kavitha J, Varma MH, Chittibabu N (2020) Biosorption of eosin yellow dye from aqueous solution using sugarcane bagasse: Equillibrium, kinetics and thermodynamics. Mater Today Proc 26:842–849

Srinivas T, Chandana S, Rao NR (2021) Studies on effect of sugarcane bagasse fibre on mechanical properties and workability of low calcium fly ash and slag based geopolymer concrete. In: E3S Web of Conferences (Vol. 309). EDP Sciences.

Srivastava VC, Mall ID, Mishra IM (2007) Adsorption thermodynamics and isosteric heat of adsorption of toxic metal ions onto bagasse fly ash (BFA) and rice husk ash (RHA). Chem Eng J 132(1–3):267–278

Tian X, Song Y, Shen Z, Zhou Y, Wang K, Jin X, Liu HZ (2020) A comprehensive review on toxic petrochemical wastewater pretreatment and advanced treatment. J Clean Prod 245:118692

Tomás RA, Bordado JC, Gomes JF (2013) p-Xylene oxidation to terephthalic acid: a literature review oriented toward process optimization and development. Chem Rev 113(10):7421–7469

Tozuka Y, Sasaoka S, Nagae A, Moribe K, Oguchi T, Yamamoto K (2005) Rapid adsorption and entrapment of benzoic acid molecules onto mesoporous silica (FSM-16). J Colloid Interface Sci 291:471–476

Tukaram Bai M, Shaik O, Kavitha J, Hemanth Varma MS, Chittibabu N (2020) Biosorption of eosin yellow dye from aqueous solution using sugarcane bagasse: equillibrium, kinetics and thermodynamics. Mater Today Proc 26:842–849

Üzek R, Şenel S, Denizli A (2022) Investigation of thermodynamic, kinetic, and isothermal parameters for the selective adsorption of bisphenol A. ACS Omega 7(22):18940–18952

Verma S, Prasad B, Mishra IM (2010) Pretreatment of petrochemical wastewater by coagulation and flocculation and the sludge characteristics. J Hazard Mat 178:1055–1064

Verma S, Prasad B, Mishra IM (2017) Treatment of purified terephthalic acid wastewater using a bio-waste-adsorbent bagasse fly ash (BFA). Environ Sci Pollut Res 24(2):1953–1966

Weber WJ Jr, Morris JC (1963) Kinetics of adsorption on carbon from solution. J Sanit Eng Div Am Soc Civ Eng 89:31–59

Yıldız N, Gonulsen R, Koyuncu H, Calımlı A (2005) Adsorption of benzoic acid and hydroquinone by organically modified bentonites. Colloids Surf A 260:87–94

Funding

This work was supported by Slovenian Research Agency through the Research Programme (P1-0134) “Chemistry for Sustainable Development” and the Ministry of Education, Science and Sport, Slovenia (European Regional Development Grant C3330-19-952015) and research project N2-0188.

Author information

Authors and Affiliations

Contributions

MN took part in conceptualization, investigation, data curation, writing—original draft. PK took part in formal analysis, validation, methodology, visualization, writing—review & editing. VCS involved in supervision, writing—review & editing. SV involved in resources, writing—review & editing. RK took part in data curation, writing—review & editing. IDM involved in supervision, writing—review & editing. ULŠ took part in resources, writing—review & editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nasir, M., Kumar, P., Srivastava, V.C. et al. Synthesis of bio-based materials from agricultural residues for treatment of petrochemical wastewater. Clean Techn Environ Policy 25, 2287–2303 (2023). https://doi.org/10.1007/s10098-023-02504-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-023-02504-4