Abstract

The effect of surface roughness on the interfacial contact resistance (ICR) and the corrosion behavior of 446 stainless steel in simulated anode environments for proton exchange membrane fuel cell (PEMFC) (i.e., 0.5 mol L−1 H2SO4 + 2 ppm F− and 5 × 10−4 mol L−1 H2SO4 + 0.1 ppm F− bubbled with hydrogen gas at 80 °C) was investigated by means of atomic force microscopy, potentiodynamic polarization, electrochemical impedance spectroscopy and ICR test. The surface roughness (Ra) produced by mechanical grinding increases noticeably with the decrease of sandpaper grit size from 1000# to 240#. 446 stainless steel shows the active state under free corrosion conditions in the two test solutions and the passive state at the typical anode working potential of PEMFC after the activation-passivation transition. The corrosion resistance decreases with the increase of roughness in both solutions. The corrosion product films formed in the solution with lower acidity are more protective, leading to the appearance of the diffusion process. The enlargement of surface roughness results in the gradual reduction of ICR, but the acceleration of active and passive dissolutions.

Similar content being viewed by others

References

Silva RF, Franchi D, Leone A, Pilloni L, Masci A, Pozio A (2006) Surface conductivity and stability of metallic bipolar plate materials for polymer electrolyte fuel cells. Electrochim Acta 51:3592–3598

Oh MH, Yoon YS, Park SG (2004) The electrical and physical properties of alternative material bipolar plate for PEM fuel cell system. Electrochim Acta 50:777–780

Wang X, Luo H, Luo J (2019) Effects of hydrogen and stress on the electrochemical and passivation behaviour of 304 stainless steel in simulated PEMFC environment. Electrochim Acta 293:60–77

Asri NF, Husaini T, Sulong A, Majlan EH, Daud WRW (2017) Coating of stainless steel and titanium bipolar plates for anticorrosion in PEMFC: A review. Int J Hydrogen Energy 42:9135–9148

Saadat N, Jaffer S, Tjong J, Oksman K, Sain M (2023) Enhancing performance of advanced fuel cell design with functional energy materials and process. J Mater Res Technol 26:1723–1735

Tawfik H, Hung Y, Mahajan D (2007) Metal bipolar plates for PEM fuel cell—a review. J Power Sources 163:755–767

André J, Antoni L, Petit J-P (2010) Corrosion resistance of stainless steel bipolar plates in a PEFC environment: a comprehensive study. Int J Hydrogen Energy 35:3684–3697

Joseph S, McClure J, Chianelli R, Pich P, Sebastian P (2005) Conducting polymer-coated stainless steel bipolar plates for proton exchange membrane fuel cells (PEMFC). Int J Hydrogen Energy 30:1339–1344

Feng K, Shen Y, Sun H, Liu D, An Q, Cai X, Chu PK (2009) Conductive amorphous carbon-coated 316L stainless steel as bipolar plates in polymer electrolyte membrane fuel cells. Int J Hydrogen Energy 34:6771–6777

Wang H, Sweikart MA, Turner JA (2003) Stainless steel as bipolar plate material for polymer electrolyte membrane fuel cells. J Power Sources 115:243–251

Cheng H, Luo H, Wang X, Pan Z, Zhao Q, Dong C, Li X (2023) Improving the performance of titanium bipolar plate in proton exchange membrane water electrolysis environment by nitrogen-chromium composite cathode plasma electrolytic deposition. Int J Hydrogen Energy 48:38557–38568

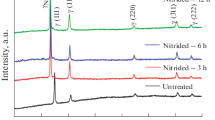

Lee K, Lee S, Kim J, Lee Y, Kim Y, Kim M, Wee D (2009) Effects of thermal oxi-nitridation on the corrosion resistance and electrical conductivity of 446M stainless steel for PEMFC bipolar plates. Int J Hydrogen Energy 34:1515–1521

Antunes RA, Oliveira MCL, Ett G, Ett V (2010) Corrosion of metal bipolar plates for PEM fuel cells: a review. Int J Hydrogen Energy 35:3632–3647

Makkus RC, Janssen AH, de Bruijn FA, Mallant RK (2000) Use of stainless steel for cost competitive bipolar plates in the SPFC. J Power Sources 86:274–282

Wind J, Späh R, Kaiser W, Böhm G (2002) Metallic bipolar plates for PEM fuel cells. J Power Sources 105:256–260

Netwall CJ, Gould BD, Rodgers JA, Nasello NJ, Swider-Lyons KE (2013) Decreasing contact resistance in proton-exchange membrane fuel cells with metal bipolar plates. J Power Sources 227:137–144

Alizadeh E, Ghadimi M, Barzegari MM, Momenifar M, Saadat SHM (2017) Development of contact pressure distribution of PEM fuel cell’s MEA using novel clamping mechanism. Energy 131:92–97

Liu R, Jia Q, Zhang B, Lai Z, Chen L (2022) Protective coatings for metal bipolar plates of fuel cells: a review. Int J Hydrogen Energy 47:22915–22937

Lin C-H (2013) Surface roughness effect on the metallic bipolar plates of a proton exchange membrane fuel cell. Appl Energy 104:898–904

Qiu D, Peng L, Yi P, Lai X (2017) A micro contact model for electrical contact resistance prediction between roughness surface and carbon fiber paper. Int J Mech Sci 124–125:37–47

Barber M, Sun TS, Petrach E, Wang X, Zou Q (2008) Contact mechanics approach to determine contact surface area between bipolar plates and current collector in proton exchange membrane fuel cells. J Power Sources 185:1252–1256

Kraytsberg A, Auinat M, Ein-Eli Y (2007) Reduced contact resistance of PEM fuel cell’s bipolar plates via surface texturing. J Power Sources 164:697–703

André J, Antoni L, Petit J-P, De Vito E, Montani A (2009) Electrical contact resistance between stainless steel bipolar plate and carbon felt in PEFC: A comprehensive study. Int J Hydrogen Energy 34:3125–3133

Kim KM, Kim SN, Kim JH, Lee YY, Kim KY (2012) Study on surface topography of 446M stainless steel as a bipolar plate on interfacial contact resistance of polymer electrolyte membrane fuel cell. J Power Sources 220:42–46

Avasarala B, Haldar P (2009) Effect of surface roughness of composite bipolar plates on the contact resistance of a proton exchange membrane fuel cell. J Power Sources 188:225–229

Lee SJ, Lee CY, Yang KT, Lee YM, Chang YJ, Ho CL (2013) The surface morphology effects of a metallic bipolar plate on the interfacial contact resistance of a proton exchange membrane fuel cell. Int J Green Energy 10:739–753

Rajasekar S, Chetty R, Neelakantan L (2015) Low-nickel austenitic stainless steel as an alternative to 316L bipolar plate for proton exchange membrane fuel cells. Int J Hydrogen Energy 40:12413–12423

Li DG, Wang JD, Chen DR, Liang P (2015) Molybdenum addition enhancing the corrosion behaviors of 316 L stainless steel in the simulated cathodic environment of proton exchange membrane fuel cell. Int J Hydrogen Energy 40:5947–5957

Feng K, Li Z, Cai X, Chu PK (2011) Silver implanted 316L stainless steel as bipolar plates in polymer electrolyte membrane fuel cells. Mater Chem Phys 126:6–11

Feng K, Shen Y, Mai J, Liu D, Cai X (2008) An investigation into nickel implanted 316L stainless steel as a bipolar plate for PEM fuel cell. J Power Sources 182:145–152

Jin J, Tian X, Tao Y, Kou X, Mi Y, Xu X, Yang H (2023) Effect of carbon doping on corrosion resistance and conductivity of CrMoN-coated 316L stainless steel bipolar plates. J Solid State Electrochem 27:2309–2321

Wang H, Turner JA (2004) Ferritic stainless steels as bipolar plate material for polymer electrolyte membrane fuel cells. J Power Sources 128:193–200

Kim KM, Park JH, Kim JH, Kim KY (2011) Effect of chemical and heat treatment on the interfacial contact resistance and corrosion resistance of 446M ferritic stainless steel as a bipolar plate for polymer electrolyte membrane fuel cells. Int J Hydrogen Energy 36:9926–9935

Burstein G, Pistorius P (1995) Surface roughness and the metastable pitting of stainless steel in chloride solutions. Corrosion 51:380–385

Hong T, Nagumo M (1997) Effect of surface roughness on early stages of pitting corrosion of type 301 stainless steel. Corros Sci 39:1665–1672

Barmatov E, Hughes T, Eskin D (2016) Effect of surface roughness on corrosion behaviour of low carbon steel in inhibited 4 M hydrochloric acid under laminar and turbulent flow conditions. Corros Sci 103:196–205

Qiao YX, Zheng YG, Okafor PC, Ke W (2009) Electrochemical behaviour of high nitrogen bearing stainless steel in acidic chloride solution: effects of oxygen, acid concentration and surface roughness. Electrochim Acta 54:2298–2304

Li W, Li DY (2006) Influence of surface morphology on corrosion and electronic behavior. Acta Mater 54:445–452

Saito S, Takeda K, Soumura T, Tani T, Maeda T (1994) Effects of surface roughness and patches on the work function of cobalt. Phys Status Solidi A 142:K29–K32

Tan Z, Xu R, Bi H, Zhang Z, Li M (2023) Effects of potential on corrosion behavior and contact resistance of 446 stainless steel in simulated proton exchange membrane fuel cell cathode environment. J Solid State Electrochem 27:13–2003

Jiang L, Syed JA, Gao Y, Zhang Q, Zhao J, Lu H, Meng X (2017) Electropolymerization of camphorsulfonic acid doped conductive polypyrrole anti-corrosive coating for 304SS bipolar plates. Appl Surf Sci 426:87–98

Papadias DD, Ahluwalia RK, Thomson JK, Meyer HM, Brady MP, Wang H, Turner JA, Mukundan R, Borup R (2015) Degradation of SS316L bipolar plates in simulated fuel cell environment: corrosion rate, barrier film formation kinetics and contact resistance. J Power Sources 273:1237–1249

Ghosh A, Goswami P, Mahanta P, Verma A (2014) Effect of carbon fiber length and graphene on carbon-polymer composite bipolar plate for PEMFC. J Solid State Electrochem 18:3427–3436

Yoon W, Huang X, Fazzino P, Reifsnider KL, Akkaoui MA (2008) Evaluation of coated metallic bipolar plates for polymer electrolyte membrane fuel cells. J Power Sources 179:265–273

Feng K, Wu G, Li Z, Cai X, Chu PK (2011) Corrosion behavior of SS316L in simulated and accelerated PEMFC environments. Int J Hydrogen Energy 36:13032–13042

Lædre S, Kongstein OE, Oedegaard A, Seland F, Karoliussen H (2012) The effect of pH and halides on the corrosion process of stainless steel bipolar plates for proton exchange membrane fuel cells. Int J Hydrogen Energy 37:18537–18546

Li DG, Wang JD, Chen DR (2014) Influence of pH value on the structure and electronic property of the passive film on 316L SS in the simulated cathodic environment of proton exchange membrane fuel cell (PEMFC). Int J Hydrogen Energy 39:20105–20115

Li DG, Wang JD, Chen DR, Liang P (2014) Influences of pH value, temperature, chloride ions and sulfide ions on the corrosion behaviors of 316L stainless steel in the simulated cathodic environment of proton exchange membrane fuel cell. J Power Sources 272:448–456

Agneaux A, Plouzennec MH, Antoni L, Garnier J (2006) Corrosion behaviour of stainless steel plates in PEMFC working conditions. Fuel Cells 6:47–53

Leng Y, Ming P, Yang D, Zhang C (2020) Stainless steel bipolar plates for proton exchange membrane fuel cells: materials, flow channel design and forming processes. J Power Sources 451:227783

Kumagai M, Myung S-T, Ichikawa T, Yashiro H (2010) Applicability of extra low interstitials ferritic stainless steels for bipolar plates of proton exchange membrane fuel cells. J Power Sources 195:7181–7186

Kumagai M, Myung S-T, Kuwata S, Asaishi R, Yashiro H (2008) Corrosion behavior of austenitic stainless steels as a function of pH for use as bipolar plates in polymer electrolyte membrane fuel cells. Electrochim Acta 53:4205–4212

Luo H, Su H, Dong C, Xiao K, Li X (2016) Influence of pH on the passivation behaviour of 904L stainless steel bipolar plates for proton exchange membrane fuel cells. J Alloys Compd 686:216–226

Jiao K, Xuan J, Du Q, Bao Z, Xie B, Wang B, Zhao Y, Fan L, Wang H, Hou Z, Huo S, Brandon NP, Yin Y, Guiver MD (2021) Designing the next generation of proton-exchange membrane fuel cells. Nature 595:361–369

Hermas AA, Morad MS (2008) A comparative study on the corrosion behaviour of 304 austenitic stainless steel in sulfamic and sulfuric acid solutions. Corros Sci 50:2710–2717

Nguyen TQ, Breitkopf C (2018) Determination of diffusion coefficients using impedance spectroscopy data. J Electrochem Soc 165:E826–E831

Bhosale AC, Rengaswamy R (2019) Interfacial contact resistance in polymer electrolyte membrane fuel cells: recent developments and challenges. Renew Sust Energ Rev 115:109351

Urquidi-Macdonald M, Real S, Macdonald DD (1990) Applications of Kramers—Kronig transforms in the analysis of electrochemical impedance data—III. Stability and linearity. Electrochim Acta 35:1559–1566

Boissy C, Alemany-Dumont C, Normand B (2013) EIS evaluation of steady-state characteristic of 316L stainless steel passive film grown in acidic solution. Electrochem Commun 26:10–12

Xuan J, Xin Y, Xu L, Guo M, Huang L, Zhang Y, Zhao Y, Liu Y, Li L, Xue L, Li L (2023) Effects of fluoride ions on corrosion performance and surface properties of SS304 in simulated PEMFC cathodic environments. Renew Energy 212:769–778

Li MC, Zeng CL, Luo SZ, Shen JN, Lin HC, Cao CN (2003) Electrochemical corrosion characteristics of type 316 stainless steel in simulated anode environment for PEMFC. Electrochim Acta 48:1735–1741

Xiao L, Liu Q, Wang J, Chen N, Chen J, Song J, Zhang X, Xiao K (2023) Study on corrosion mechanism of Al–Zn coatings in the simulated polluted marine atmosphere. J Mater Res Technol 25:6446–6458

Hu S, Liu R, Liu L, Cui Y, Wang F (2021) Influence of temperature and hydrostatic pressure on the galvanic corrosion between 90/10 Cu–Ni and AISI 316L stainless steel. J Mater Res Technol 13:1402–1415

Li MC, Jiang LL, Zhang WQ, Qian YH, Luo SZ, Shen JN (2007) Electrochemical corrosion behavior of nanocrystalline zinc coatings in 3.5% NaCl solutions. J Solid State Electrochem 11:1319–1325

Zeng H, Yang Y, Zeng M, Li M (2021) Effect of dissolved oxygen on electrochemical corrosion behavior of 2205 duplex stainless steel in hot concentrated seawater. J Mater Sci Technol 66:177–185

Yang GM, Du YF, Chen SY, Ren YS, Ma YL (2021) Effect of secondary passivation on corrosion behavior and semiconducting properties of passive film of 2205 duplex stainless steel. J Mater Res Technol 15:6828–6840

Xuan J, Liu Y, Xu L, Bai S, Xin Y, Wang L, Zhang G, Su Y, Xue L, Li L (2022) Investigation of acidity on corrosion behavior and surface properties of SS304 in simulated PEMFC cathode environments. Int J Hydrogen Energy 47:22938–22951

Li R, Fu B-g, Dong T-s, Li G-l, Li J-k, Zhao X-b, Liu J-h (2022) Effect of annealing treatment on microstructure, mechanical property and anti-corrosion behavior of X2CrNi12 ferritic stainless steel. J Mater Res Technol 18:448–460

Zeng H, Yang Y, Liu L, Li M (2021) Pitting and crevice corrosion evolution characteristics of 2205 duplex stainless steel in hot concentrated seawater. J Solid State Electrochem 25:1555–1565

Wei L, Liu Y, Li Q, Cheng YF (2019) Effect of roughness on general corrosion and pitting of (FeCoCrNi)0.89(WC)0.11 high-entropy alloy composite in 3.5 wt.% NaCl solution. Corros Sci 146:44–57

Seo MJ, Shim H-S, Kim KM, Hong S-I, Hur DH (2014) Influence of surface roughness on the corrosion behavior of Alloy 690TT in PWR primary water. Nucl Eng Des 280:62–68

Zhang Z, Wang J, Han E-H, Ke W (2012) Characterization of different surface states and its effects on the oxidation behaviours of Alloy 690TT. J Mater Sci Technol 28:353–361

Li W, Li DY (2005) Variations of work function and corrosion behaviors of deformed copper surfaces. Appl Surf Sci 240:388–395

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, R., Jin, X., Bi, H. et al. Effect of surface roughness on contact resistance and electrochemical corrosion behavior of 446 stainless steel in simulated anode environments for proton exchange membrane fuel cell. J Solid State Electrochem (2024). https://doi.org/10.1007/s10008-024-05864-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10008-024-05864-z