Abstract

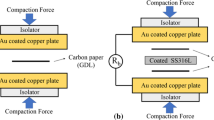

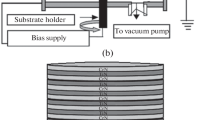

CrMoCN coatings with different carbon contents are prepared on 316L stainless steel substrates by closed-field unbalanced magnetron sputtering. The microstructure, phase composition, bonding state, corrosion properties, interfacial conductivity, and hydrophobicity of the coatings are investigated. The structural analysis shows that the nitride coating gradually changes to the coexistence of nitride phase, carbide phase, and amorphous carbon with increasing carbon content. As the phase structure transition, the CrMoCN-14 coating possesses the lowest corrosion current density of 6.28 × 10−8 A cm−2 after potentiodynamic polarization in the simulated cathodic environment. The electrochemical impedance spectroscopy also proved that the CrMoCN-14 sample has the best chemical stability. Furthermore, the CrMoCN-14 coating has a very low interfacial contact resistance value of 7.54 mΩ cm2 compared to the SS316L substrate. The analysis results demonstrated that the CrMoCN coating has excellent anti-corrosion performance and interfacial conductivity and is a potential material for bipolar plates.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at the time as the data also forms part of an ongoing study.

References

He RY, Jiang J (2020) Anti-corrosion and conductivity of titanium diboride coating on metallic bipolar plates. Corros Sci 170

Yan W, Zhao Y (2022) Corrosion-resistant and interfacial conductive AlTiVCrMo high-entropy alloy and (AlTiVCrMo)Nx high-entropy ceramics coatings for surface modification of bipolar plates in proton exchange membrane fuel cells. J Power Sources 527

Tan Q,Wang Y (2022) Preparation and properties of conductive Ti4O7 surface coating for Ti bipolar plates of proton exchange membrane fuel cells. J Alloys Compd 911

Wang X-Z, Ye C-P (2021) Potential polarization accelerated degradation of interfacial electrical conductivity for Au/TiN coated 316L SS bipolar plates used in polymer electrolyte membrane fuel cells. Corros Sci 189

Hu B, He G (2022) Low filler and highly conductive composite bipolar plates with synergistic segregated structure for enhanced proton exchange membrane fuel cell performance. Energy 251

Yan P, Ying T (2022) Investigation of anodized Ta/Ag coating on magnesium bipolar plate for lightweight proton exchange membrane fuel cells. Corros Sci 197

Zhang P, Hao C (2020) Electrochemical behavior and surface conductivity of NbC modified Ti bipolar plate for proton exchange membrane fuel cell. Surf Coat Technol 397

Alaefour I, Shahgaldi S (2021) Synthesis and ex-situ characterizations of diamond-like carbon coatings for metallic bipolar plates in PEM fuel cells. Int J Hydrog Energ 46:11059–11070

Liu Q, Wang X (2022) Mechanical properties, corrosion resistance, and rubber pad forming of cold differential speed-rolled pure titanium for bipolar plates of proton-exchange membrane fuel cells. Int J Hydrog Energ 47:17737–17748

Kuan Y-D, Ciou C-W (2021) Bipolar plate design and fabrication using graphite reinforced composite laminate for proton exchange membrane fuel cells. Int J Hydrog Energ 46:16801–16814

Jannat S, Rashtchi H (2019) Preparation and performance of nanometric Ti/TiN multi-layer physical vapor deposited coating on 316L stainless steel as bipolar plate for proton exchange membrane fuel cells. J Power Sources 435

Dong Z, Zhou T (2019) Performance of surface chromizing layer on 316L stainless steel for proton exchange membrane fuel cell bipolar plates. Int J Hydrog Energ 44:22110–22121

Peng S, Xu J (2022) Titanium bipolar plates augmented by nanocrystalline TiZrHfMoW coatings for application in proton exchange membrane fuel cells. App Surf Sci 591

Xu J, Huang HJ (2016) Corrosion behavior of a ZrCN coated Ti alloy with potential application as a bipolar plate for proton exchange membrane fuel cell. J Alloy Compd 663:718–730

Bolouri A, Kang CG (2014) Study on dimensional and corrosion properties of thixoformed A356 and AA7075 aluminum bipolar plates for proton exchange membrane fuel cells. Renew Energ 71:616–628

Chanda UK, Padhee SP (2020) Electrodeposited Ni–Mo–Cr–P coatings for AISI 1020 steel bipolar plates. Int J Hydrog Energ 45:21892–21904

Li T, Yan Z (2021) Surface microstructure and performance of TiN monolayer film on titanium bipolar plate for PEMFC. Int J Hydrog Energ 46:31382–31390

Karacan K, Celik S (2020) Investigation of formability of metallic bipolar plates via stamping for light-weight PEM fuel cells. Int J Hydrog Energ 45:35149–35161

Lee W-J, Yun E-Y (2020) Ultrathin effective TiN protective films prepared by plasma-enhanced atomic layer deposition for high performance metallic bipolar plates of polymer electrolyte membrane fuel cells. App Surf Sci 519

Leng Y, Ming P (2020) Stainless steel bipolar plates for proton exchange membrane fuel cells: materials, flow channel design and forming processes. J Power Sources 451

Bi J, Yang J (2021) Development and evaluation of nitride coated titanium bipolar plates for PEM fuel cells. Int J Hydrog Energ 46:1144–1154

Wang X-Z, Zhang M-M (2022) Long-term polarization accelerated degradation of nano-thin C/Ti coated SS316L bipolar plates used in polymer electrolyte membrane fuel cells. Int J Hydrog Energ 47:8974–8992

Li H, Guo P (2020) Interface-induced degradation of amorphous carbon films/stainless steel bipolar plates in proton exchange membrane fuel cells. J Power Sources 469

Jin J, Hu M (2020) Investigation of incorporating oxygen into TiN coating to resist high potential effects on PEMFC bipolar plates in vehicle applications. Int J Hydrog Energ 45:23310–23326

Müller M-V, Giorgio M (2022) Investigation of the effect of carbon post- vs pre-coated metallic bipolar plates for PEMFCs – start-up and shut-down. Int J Hydrog Energ 47:8532–8548

Tian R (2011) Chromium nitride/Cr coated 316L stainless steel as bipolar plate for proton exchange membrane fuel cell. J Power Sources 196:1258–1263

Wang L, Sun J (2012) Molybdenum nitride modified AISI 304 stainless steel bipolar plate for proton exchange membrane fuel cell. Int J Hydrog Energ 37:5876–5883

Pan TJ, Dai YJ (2022) Anti-corrosion performance of the conductive bilayer CrC/CrN coated 304SS bipolar plate in acidic environment. Corros Sci 206:110495

Feng K, Li Z (2013) C/CrN multilayer coating for polymer electrolyte membrane fuel cell metallic bipolar plates. J Power Sources 222:351–358

Bi F, Yi P (2015) Effects of Al incorporation on the interfacial conductivity and corrosion resistance of CrN film on SS316L as bipolar plates for proton exchange membrane fuel cells. Int J Hydrog Energ 40:9790–9802

Ma G, Yuan J (2022) Balancing the corrosion resistance and conductivity of Cr-Al-C coatings via annealing treatment for metal bipolar plates. App Surf Sci 597

Wang H (2003) Stainless steel as bipolar plate material for polymer electrolyte membrane fuel cells. J Power Sources 115:243–251

Jin J, He Z (2020) Formation of a protective TiN layer by liquid phase plasma electrolytic nitridation on Ti–6Al–4V bipolar plates for PEMFC. Int J Hydrog Energ 45:12489–12500

Xu X, Sun J (2021) Microstructure, electrochemical and tribocorrosion behaviors of CrCN nanocomposite coating with various carbon content. Surf Coat Technol 411

Wang T, Zhang G (2017) Effect of nitrogen flow rate on structure and properties of MoNx coatings deposited by facing target sputtering. J Alloy Compd 701:1–8

Ye Y, Wang Y (2015) Influences of bias voltage on the microstructures and tribological performances of Cr–C–N coatings in seawater. Surf Coat Technol 270:305–313

Wang Y, Zhang J (2020) Improvement in the tribocorrosion performance of CrCN coating by multilayered design for marine protective application. App Surf Sci 528

Zhao D, Jiang X (2018) Microstructure evolution, wear and corrosion resistance of Cr C nanocomposite coatings in seawater. Appl Surf Sci 457:914–924

Wang L, Tao Y (2019) Molybdenum carbide coated 316L stainless steel for bipolar plates of proton exchange membrane fuel cells. Int J Hydrog Energ 44:4940–4950

Ye Y, Wang Y (2015) An analysis on tribological performance of CrCN coatings with different carbon contents in seawater. Tribol Int 91:131–139

Fu Y, Zhou F (2020) Electrochemical and tribocorrosion performances of CrMoSiCN coating on Ti-6Al-4V titanium alloy in artificial seawater. Corros Sci 165

Qian J, Li S (2019) Effect of heat treatment on structure and properties of molybdenum nitride and molybdenum carbonitride films prepared by magnetron sputtering. Surf Coat Technol 374:725–735

Zhang M, Zhou F (2019) Structural and tribological properties of CrMoCN coatings with various Mo contents in artificial seawater. Appl Surf Sci 493:485–496

Fu Y, Zhou F (2020) Structural, mechanical and tribocorrosion performances of CrMoSiN coatings with various Mo contents in artificial seawater. App Surf Sci 525

Jiang R, Chen C (2010) The non-linear fitting method to analyze the measured M-S plots of bipolar passive films. Electrochim Acta 55:2498–2504

Barranco J, Barreras F (2010) Cr and Zr/Cr nitride CAE-PVD coated aluminum bipolar plates for polymer electrolyte membrane fuel cells. Int J Hydrog Energ 35:11489–11498

Oje AM, Ogwu AA (2019) Effect of temperature variation on the corrosion behaviour and semiconducting properties of the passive film formed on chromium oxide coatings exposed to saline solution. Corros Sci 154:28–35

Wang Z, Feng Z (2020) Effect of high temperature on the corrosion behavior and passive film composition of 316 L stainless steel in high H2S-containing environments. Corros Sci 174

Ding J, Zhang L (2014) The electrochemical behaviour of 316L austenitic stainless steel in Cl− containing environment under different H2S partial pressures. Appl Surf Sci 289:33–41

Zhang Y, Yu J (2022) Passive behavior of laser directed energy deposited Inconel 718 after homogenization and aging heat treatment. Corros Sci 205

Man C, Dong C (2018) A comparative study of primary and secondary passive films formed on AM355 stainless steel in 0.1 M NaOH. Appl Surf Sci 427:763–773

Wang Z, Jin J (2022) Effect of temperature on the passive film structure and corrosion performance of CoCrFeMoNi high-entropy alloy. Corros Sci 208:110661

Latu-Romain L, Parsa Y (2017) Towards the growth of stoichiometric chromia on pure chromium by the control of temperature and oxygen partial pressure. Corros Sci 126:238–246

Feng K, Li Z (2014) Corrosion resistance and electrical properties of carbon/chromium–titanium–nitride multilayer coatings on stainless steel. J Power Sources 249:299–305

Li Y C, Zhang W W (2022) Effect of spray powder particle size on the bionic hydrophobic structures and corrosion performance of Fe-based amorphous metallic coatings. Surf Coat Technol 437

Funding

This work was supported by the Zhejiang Province “Jianbing” Project of China [grant number: 2022C01014].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jin, J., Tian, X., Tao, Y. et al. Effect of carbon doping on corrosion resistance and conductivity of CrMoN-coated 316L stainless steel bipolar plates. J Solid State Electrochem 27, 2309–2321 (2023). https://doi.org/10.1007/s10008-023-05513-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-023-05513-x