Abstract

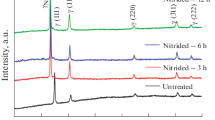

The corrosion behavior and surface conductivity of type 446 stainless steel were investigated in the simulated cathode environment of proton exchange membrane fuel cell with 0.0005 M H2SO4 + 0.1 ppm F− solution at 80 °C under different polarization potentials by using electrochemical measurement methods, X-ray photoelectron spectroscopy (XPS) and inductively coupled plasma optical emission spectroscopy (ICP-OES). The 446 stainless steel passivates spontaneously in the simulated environment. The current density and interface contact resistance (ICR) enlarge slightly with increasing the anodic polarization potential in the passive region. As the potential changes from 0.7 to 1.5 V vs. SCE, the current density and ICR increase markedly due to the occurrence of transpassivation, secondary passivation, and oxygen evolution. The ICR values are larger by about 24 mΩ cm2 after the polarization above 0.7 V vs. SCE. The polarization potential shifts from the passive region to oxygen evolution region, resulting in higher oxidized Fe and Mo contents in the product film on specimen surface and relatively more release of alloying constituents (especially Cr and Mo) into the solution. These are mainly responsible for the degradation of corrosion and surface conductivity properties.

Similar content being viewed by others

References

Mehdizadeh P, Jamdar M, Mahdi MA (2023) Rapid microwave fabrication of new nanocomposites based on Tb-Co-O nanostructures and their application as photocatalysts under UV/visible light for removal of organic pollutants in water. Arab J Chem 16:104579

Yousefi SR, Sobhani A, Alshamsi HA (2021) Green sonochemical synthesis of BaDy2 NiO5/Dy2O3 and BaDy2NiO5/NiO nanocomposites in the presence of core almond as a capping agent and their application as photocatalysts for the removal of organic dyes in water. RSC adv 11(19):11500–11512

Yousefi SR, Ghanbari M, Amiri O (2021) Dy2BaCuO5/Ba4DyCu3O9.09S‐scheme heterojunction nanocomposite with enhanced photocatalytic and antibacterial activities. J Am Ceram Soc 104(7):2952–2965

Yousefi SR, Alshamsi HA, Amiri O (2021) Synthesis, characterization and application of Co/Co3O4 nanocomposites as an effective photocatalyst for discoloration of organic dye contaminants in wastewater and antibacterial properties. J Mol Liq 337:116405

Yousefi SR, Ghanbari D, Salavati-Niasari M (2016) Photo-degradation of organic dyes: simple chemical synthesis of Ni (OH) 2 nanoparticles, Ni/Ni(OH)2 and Ni/NiO magnetic nanocomposites. J Mater Sci-Mater El 27:1244–1253

Yousefi S, Ghanbari D, Salavati NM (2016) Hydrothermal synthesis of nickel hydroxide nanostructures and flame retardant poly vinyl alcohol and cellulose acetate nanocomposites. J Nanostruct 6(1):77–82

Mahdi MA, Yousefi SR, Jasim LS (2022) Green synthesis of DyBa2Fe3O7. 988/DyFeO3 nanocomposites using almond extract with dual eco-friendly applications: photocatalytic and antibacterial activities. Int J Hydrog Energy 47(31):14319–14330

Norouzi N (2021) Assessment of technological path of hydrogen energy industry development: a review. Iran J Energy Environ 12(4):273–284

Teuku H, Alshami I, Goh J, Masdar MS, Loh KS (2021) Review on bipolar plates for low-temperature polymer electrolyte membrane water electrolyzer. Int J Energy Res 45(15):20583–20600

Yousefi SR, Masjedi-Arani M, Morassaei MS (2019) Hydrothermal synthesis of DyMn2O5/Ba3Mn2O8 nanocomposite as a potential hydrogen storage material. Int J Hydrog Energy 44(43):24005–24016

Martemianov S, Thomas A, Adiutantov N, Denisov E, Evdokimov Y (2020) Electrochemical noise analysis of a pem fuel cell stack under long-time operation: noise signature in the frequency domain. J solid state electrochem 24:3059–3071

Unnikrishnan A, Janardhanan VM, Rajalakshmi N, Dhathathreyan K (2018) Chlorine-contaminated anode and cathode pemfc-recovery perspective. J solid state electrochem 22:2107–2113

Verma A, Scott K (2010) Development of high-temperature PEMFC based on heteropolyacids and polybenzimidazole. J solid state electrochem 14:213–219

Wee J-H (2007) Applications of proton exchange membrane fuel cell systems. Renew Sust Energ Rev 11(8):1720–1738

Włodarczyk R (2022) Corrosion analysis of graphite sinter as bipolar plates in the low-temperature PEM fuel cell simulated environments. J solid state electrochem 26(1):39–47

Yousefi SR, Sobhani A, Salavati-Niasari M (2017) A new nanocomposite superionic system (CdHgI4/HgI2): synthesis, characterization and experimental investigation. Adv Powder Technol 28(4):1258–1262

Li M, Zeng C, Luo S, Shen J, Lin H, Cao C (2003) Electrochemical corrosion characteristics of type 316 stainless steel in simulated anode environment for PEMFC. Electrochim Acta 48(12):1735–1741

Li M, Luo S, Zeng C, Shen J, Lin H (2004) Corrosion behavior of TiN coated type 316 stainless steel in simulated PEMFC environments. Corros sci 46(6):1369–1380

Maizia R, Dib A, Thomas A, Martemianov S (2018) Statistical short-time analysis of electrochemical noise generated within a proton exchange membrane fuel cell. J solid state electrochem 22:1649–1660

Antunes RA, Oliveira MCL, Ett G, Ett V (2010) Corrosion of metal bipolar plates for PEM fuel cells: a review. Int J Hydrog Energy 35(8):3632–3647

Gao P, Xie Z, Ouyang C, Tao T, Wu X, Huang Q (2018) Electrochemical characteristics and interfacial contact resistance of Ni-P/TiN/PTFE coatings on Ti bipolar plates. J solid state electrochem 22:1971–1981

Ghosh A, Goswami P, Mahanta P, Verma A (2014) Effect of carbon fiber length and graphene on carbon-polymer composite bipolar plate for PEMFC. J solid state electrochem 18:3427–3436

Hermann A, Chaudhuri T, Spagnol P (2005) Bipolar plates for PEM fuel cells: a review. Int J Hydrog Energy 30(12):1297–1302

Wang H, Turner J (2010) Reviewing metallic PEMFC bipolar plates. Fuel cells 10(4):510–519

Yang Y, Guo L–J, Liu H (2010) Effect of fluoride ions on corrosion behavior of SS316L in simulated proton exchange membrane fuel cell (PEMFC) cathode environments. J Power Sources 195(17):5651–5659

Yang Y, Guo LJ, Liu H (2011) Corrosion characteristics of SS316L as bipolar plate material in PEMFC cathode environments with different acidities. Int J Hydrog Energy 36(2):1654–1663

Yang YM, Guo L, Liu H (2012) Factors affecting corrosion behavior of SS316L as bipolar plate material in PEMFC cathode environments. Int J Hydrog Energy 37(18):13822–13828

Yang Y, Ning X, Tang H, Guo L, Liu H (2014) Effects of potential on corrosion behavior of uncoated SS316L bipolar plate in simulated PEM fuel cell cathode environment. Fuel Cells 14(6):868–875

Wang H, Turner JA (2004) Ferritic stainless steels as bipolar plate material for polymer electrolyte membrane fuel cells. J Power Sources 128(2):193–200

Feng K, Wu G, Li Z, Cai X, Chu PK (2011) Corrosion behavior of SS316L in simulated and accelerated PEMFC environments. Int J Hydrog Energy 36(20):13032–13042

Mani SP, Rajendran N (2017) Corrosion and interfacial contact resistance behavior of electrochemically nitrided 316L SS bipolar plates for proton exchange membrane fuel cells. Energy 133:1050–1062

Papadias DD, Ahluwalia RK, Thomson JK, Meyer HM, Brady MP, Wang H (2015) Degradation of SS316L bipolar plates in simulated fuel cell environment: corrosion rate, barrier film formation kinetics and contact resistance. J Power Sources 273:1237–1249

Wang Y, Northwood DO (2007) Effects of O2 and H2 on the corrosion of SS316L metallic bipolar plate materials in simulated anode and cathode environments of PEM fuel cells. Electrochim Acta 52(24):6793–6798

Meyers JP, Darling RM (2006) Model of carbon corrosion in PEM fuel cells. J Electrochem Soc 153(8):A1432–A1442

Reiser CA, Bregoli L (2005) A reverse-current decay mechanism for fuel cells. Electrochem Solid-State Lett 8(6):A273–A276

Tang H, Qi Z, Ramani M, Elter JF (2006) PEM fuel cell cathode carbon corrosion due to the formation of air/fuel boundary at the anode. J Power Sources 158(2):1306–1312

Ren P, Pei P, Chen D, Zhang L, Li Y, Song X (2022) Corrosion of metallic bipolar plates accelerated by operating conditions in a simulated PEM fuel cell cathode environment. Renew Energy 194:1277–1287

Ren P, Pei P, Li Y, Wu Z, Chen D, Huang S (2020) Degradation mechanisms of proton exchange membrane fuel cell under typical automotive operating conditions. Prog Energy Combust Sci 80:100859

Chen H, Zhao X, Zhang T, Pei P (2019) The reactant starvation of the proton exchange membrane fuel cells for vehicular applications: a review. Energy Convers Manag 182:282–298

Zhang T, Wang P, Chen H, Pei P (2018) A review of automotive proton exchange membrane fuel cell degradation under start-stop operating condition. Appl Energy 223:249–262

Keller P, Strehblow HH (2004) XPS investigations of electrochemically formed passive layers on Fe/Cr-alloys in 0.5 M H2SO4. Corros Sci 46(8):1939–1952

Wegrelius L, Falkenberg F, Olefjord I (1999) Passivation of stainless steels in hydrochloric acid. J Electrochem Soc 146:1397–1406

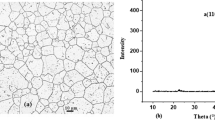

Lee SH, Kim JH, Lee YY, Wee DM (2010) Effects of low-temperature nitridation on the electrical conductivity and corrosion resistance of 446M stainless steel as bipolar plates for proton exchange membrane fuel cell. Int J Hydrog Energy 35(2):725–730

Leng Y, Ming P, Yang D, Zhang C (2020) Stainless steel bipolar plates for proton exchange membrane fuel cells: materials, flow channel design and forming processes. J Power Sources 451:227783

Inzelt G, Lewenstam A, Scholz F (2013) Handbook of reference electrodes Springer 541:105–118

Davies D, Adcock P, Turpin M, Rowen S (2000) Stainless steel as a bipolar plate material for solid polymer fuel cells. J Power Sources 86(1–2):237–242

Wang H, Sweikart MA, Turner JA (2003) Stainless steel as bipolar plate material for polymer electrolyte membrane fuel cells. J Power Sources 115(2):243–251

Turan C, Cora ÖN, Koç M (2011) Effect of manufacturing processes on contact resistance characteristics of metallic bipolar plates in PEM fuel cells. Int J Hydrog Energy 36(19):12370–12380

Song G (2005) Transpassivation of Fe–Cr–Ni stainless steels. Corros Sci 47(8):1953–1987

Zhu M, Zhang Q, Yuan Y, Guo S, Pan J (2020) Passivation behavior of 2507 super duplex stainless steel in simulated concrete pore solution. J Mater Eng Perform 29(5):3141–3151

Yang Y, Ning X, Tang H, Guo L, Liu H (2014) Effects of passive films on corrosion resistance of uncoated SS316L bipolar plates for proton exchange membrane fuel cell application. Appl Surf Sci 320:274–280

Oguzie EE, Li J, Liu Y, Chen D, Li Y, Yang K (2011) The effect of Cu addition on the electrochemical corrosion and passivation behavior of stainless steels. Electrochim Acta 55(17):5028–5035

Luo H, Su H, Dong C, Xiao K, Li X (2015) Electrochemical and passivation behavior investigation of ferritic stainless steel in alkaline environment. Constr Build Mater 96:502–507

Betova I, Bojinov M, Laitinen T, Mäkelä K, Pohjanne P, Saario T (2002) The transpassive dissolution mechanism of highly alloyed stainless steels: I. Experimental results and modelling procedure. Corros Sci 44(12):2675–2697

Vielstich W, Lamm A, Gasteiger H (2003) Handbook of fuel cells. Fundamentals, technology, applications 273

Wang H, Teeter G, Turner J (2008) Investigation of a duplex stainless steel as polymer electrolyte membrane fuel cell bipolar plate material. J Electrochem Soc 152(3):B99–B104

Wang H, Turner JA (2008) Anodic behavior of high nitrogen-bearing steels in PEMFC environments. J Power Sources 180(2):791–796

Xuan J, Liu Y, Xu L, Bai S, Xin Y, Wang L (2022) Investigation of acidity on corrosion behavior and surface properties of SS304 in simulated PEMFC cathode environments. Int J Hydrog Energy 47:22938–22951

Li X, Zhou P, Ogle K, Proch S, Paliwal M, Jansson A (2020) Transient stainless-steel dissolution and its consequences on ex-situ bipolar plate testing procedures. Int J Hydrog Energy 45(1):984–995

Olsson CO, Landolt D (2001) Film growth during anodic polarization in the passive region on 304 stainless steels with Cr, Mo, or W additions studied with EQCM and XPS. J Electrochem Soc 148(11):B438–B449

Kirchheim R, Heine B, Hofmann S, Hofsäss H (1990) Compositional changes of passive films due to different transport rates and preferential dissolution. Corros Sci 31:573–588

Chen M, Ding JC, Kwon S-H, Wang Q, Zhang S (2022) Corrosion resistance and conductivity of NbN-coated 316L stainless steel bipolar plates for proton exchange membrane fuel cells. Corros Sci 196:110042

Liu C, Wu J (2007) Influence of pH on the passivation behavior of 254SMO stainless steel in 3.5% NaCl solution. Corros Sci 49(5):2198–2209

Olefjord I, Elfstrom BO (1982) The composition of the surface during passivation of stainless steels. Corrosion 38(1):46–52

Olefjord I, Brox B, Jelvestam U (1985) Surface composition of stainless steels during anodic dissolution and passivation studied by ESCA. J Electrochem Soc 132(12):2854–2861

Luo H, Dong C, Xiao K, Li X (2016) The passive behaviour of ferritic stainless steel containing alloyed tin in acidic media. RSC adv 6(12):9940–9949

Shibata T (2009) Critical factors for controlling the stability of the passive film on stainless steels. ECS Trans 16(52):331–343

Guo P, Lin X, Macdonald DD, Ter-Ovanessian B, Liu J, Song G (2022) Unveiling the transpassive film failure of 3D printing transition alloys. Corros Sci 204:110412

Olsson CO, Landolt D (2003) Passive films on stainless steels—chemistry, structure and growth. Electrochim Acta 48(9):1093–1104

Kumagai M, Myung S-T, Ichikawa T, Yashiro H (2010) Applicability of extra low interstitials ferritic stainless steels for bipolar plates of proton exchange membrane fuel cells. J Power Sources 195(21):7181–7186

Kong D, Ni X, Dong C, Zhang L, Man C, Yao J (2018) Heat treatment effect on the microstructure and corrosion behavior of 316L stainless steel fabricated by selective laser melting for proton exchange membrane fuel cells. Electrochim Acta 276:293–303

Ma J, Zhang B, Fu Y, Hu X, Cao X, Pan Z (2022) Effect of cold deformation on corrosion behavior of selective laser melted 316L stainless steel bipolar plates in a simulated environment for proton exchange membrane fuel cells. Corros Sci 201:110257

Olefjord I, CR C (1991) Surface composition of stainless steel during active dissolution and passivation. ISIJ Int 31(2):134–141

Xu H, Wang L, Sun D, Yu H (2015) The passive oxide films growth on 316L stainless steel in borate buffer solution measured by real-time spectroscopic ellipsometry. Appl Surf Sci 351:367–373

Kocijan A, Donik Č, Jenko M (2007) Electrochemical and XPS studies of the passive film formed on stainless steels in borate buffer and chloride solutions. Corros Sci 49(5):2083–2098

Koumya Y, Idouhli R, Khadiri ME, Aityoub A, Benzakour J, Abouelfida A (2020) Semiconducting behavior and kinetics of passive film growth on AISI 321 stainless steel in sulfuric acid. Corros Rev 38(1):87–98

Milošev I, Strehblow HH (2000) The behavior of stainless steels in physiological solution containing complexing agent studied by X‐ray photoelectron spectroscopy. J Biomed MaterRes 52(2):404–412

Haupt S, Strehblow HH (1989) Combined electrochemical and surface analytical investigations of the formation of passive layers. Corros Sci 29(2–3):163–182

Castle J, Qiu J (1990) The application of ICP-MS and XPS to studies of ion selectivity during passivation of stainless steels. J Electrochem Soc 137(7):2031–2038

Hamm D, Ogle K, Olsson C-O, Weber S, Landolt D (2002) Passivation of Fe–Cr alloys studied with ICP-AES and EQCM. Corros Sci 44(7):1443–1456

Allen P, Hampson N, Bignold G (1981) The effect of the potential on the dissolution of magnetite. Surf Technol 12(2):199–204

Luo H, Su H, Dong C, Xiao K, Li X (2016) Influence of pH on the passivation behaviour of 904L stainless steel bipolar plates for proton exchange membrane fuel cells. JAlloys Compd 686:216–226

Lynch B, Neupane S, Wiame F, Seyeux A, Maurice V, Marcus P (2021) An XPS and ToF-SIMS study of the passive film formed on a model FeCrNiMo stainless steel surface in aqueous media after thermal pre-oxidation at ultra-low oxygen pressure. Appl Surf Sci 554:149435

Dobbelaar J, De Wit J (1990) Impedance measurements and analysis of the corrosion of chromium. J Electrochem Soc 137(7):2038–2046

Padhy N, Paul R, Mudali UK, Raj B (2011) Morphological and compositional analysis of passive film on austenitic stainless steel in nitric acid medium. Appl Surf Sci 257(11):5088–5097

Luo H, Dong C, Xiao K, Li X (2011) Characterization of passive film on 2205 duplex stainless steel in sodium thiosulphate solution. Appl Surf Sci 258(1):631–639

Maurice V, Yang W, Marcus P (1998) X-ray photoelectron spectroscopy and scanning tunneling microscopy study of passive films formed on (100) Fe-18Cr-13Ni single-crystal surfaces. J Electrochem Soc 145(3):909–920

Bojinov M, Betova I, Fabricius G, Laitinen T, Saario T (1999) The stability of the passive state of iron–chromium alloys in sulphuric acid solution. Corros Sci 41(8):1557–1584

Tanaka S, Hara N, Sugimoto K (1995) Corrosion characteristics of Fe2O3 Cr2O3 artificial passivation films under potentiostatic control. Mater Sci Eng A 198(1–2):63–69

Zhang Z, Ter–Ovanessian B, Marcelin S, Galipaud J (2021) Normand B. Role of alloying elements in passive and transpassive behavior of Ni–Cr-based alloys in borate buffer solution. J Electrochem Soc 168(8):081503

Ku R, Winterbottom WL (1985) Electrical conductivity in sputter-deposited chromium oxide coatings. Thin Solid Films 127(3–4):241–256

Brooks A, Clayton C, Doss K, Lu Y (1986) On the role of Cr in the passivity of stainless steel. J Electrochem Soc 133(12):2459–2464

Fredriksson W, Malmgren S, Gustafsson T, Gorgoi M, Edström K (2012) Full depth profile of passive films on 316L stainless steel based on high resolution HAXPES in combination with ARXPS. Appl Surf Sci 258(15):5790–5797

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tan, Z., Xu, R., Bi, H. et al. Effects of potential on corrosion behavior and contact resistance of 446 stainless steel in simulated proton exchange membrane fuel cell cathode environment. J Solid State Electrochem 27, 1993–2003 (2023). https://doi.org/10.1007/s10008-023-05469-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-023-05469-y