Abstract

Purpose

The main aim of the present study was to carry out a scoping review on the differences in degree of conversion of monomers regarding several types resin cements, indirect restorative materials, and light-curing procedures used in dentistry.

Method

A bibliographic review was performed on PubMed using the following search items: “degree of conversion” OR “filler” AND “resin cement” OR “inorganic cement” AND “organic” OR “radiopacity” OR “refractive” OR “transmittance” OR “type” AND “resin composite.” The search involved articles published in English language within the last thirteen years. A research question has been formulated following the PICO approach as follow: “How different is the degree of conversion of monomers comparing several types of resin-matrix cements?”.

Results

Within the 15 selected studies, 8 studies reported a high degree of conversion (DC) of the organic matrix ranging from 70 up to 90% while 7 studies showed lower DC values. Dual-cured resin-matrix cements revealed the highest mean values of DC, flexural strength, and hardness when compared with light- and self-polymerized ones. DC mean values of resin-matrix cements light-cured through a ceramic veneer with 0.4 mm thickness were higher (~ 83%) than those recorded for resin-matrix cements light-cured through a thicker ceramic layer of 1.5 mm (~ 77%).

Conclusions

The highest percentage of degree of conversion of monomers was reported for dual-cured resin-matrix cements and therefore both chemical and light-induced pathways promoted an enhanced polymerization of the material. Similar degree of conversion of the same resin-matrix cement were recorded when the prosthetic structure showed a low thickness. On thick prosthetic structures, translucent materials are required to allow the light transmission achieving the resin-matrix cement.

Clinical relevance

The chemical composition of resin-matrix cements and the light-curing mode can affect the polymerization of the organic matrix. Thus, physical properties of the materials can vary leading to early clinical failures at restorative interfaces. Thus, the analysis of the polymerization pathways of resin-matrix cements is significantly beneficial for the clinical performance of the restorative interfaces.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In contemporary dental practice, resin-matrix cements are routinely used for bonding prosthetic structures such as prosthetic crowns, multi-unit prostheses, veneers, onlays, inlays, and fiber-reinforced posts [1,2,3,4]. However, clinical failures on resin-matrix cements have been reported considering the change of color, marginal leakage, microstructure, and fracture at interfaces [3, 5]. The cementation of indirect restorations over tooth tissues also depends on the surface modification of the inner surface of the indirect restorations by grit-blasting, chemical conditioning, and acid etching [6, 7]. Clinical issues have been associated with several factors including mainly the type of resin-matrix cement, type of prosthetic structures, prosthetic restoration to surrounding tissues, light-curing unit, and polymerization mode. Thus, an insufficient polymerization of the resin-matrix cement has become a major concern taking into account the required physical properties for long-term performance in the oral cavity [6,7,8,9].

Resin-matrix cements are mainly composed of an organic matrix embedding silanized inorganic fillers [2, 5]. The organic matrix of resin-matrix cements comprises a mixture of monomers such as bisphenol-A glycol dimethacrylate (Bis-GMA), urethane dimethacrylate (UDMA), and triethylene glycol dimethacrylate (TEGDMA) [5, 10,11,12,13]. Chemical agents (i.e., peroxides) and photoinitiators systems (i.e., camphorquinone combined with tertiary amine) are key compounds to initiating the cross-linking among chain of monomers leading to the polymerization [14]. Depending on the photoinitiatior, the cross-linking of monomers is stimulated by light irradiance with a wavelength ranging from 360 up to 500 nm [4]. However, monomers with a high molecular mass usually exhibit low mobility that contributes to a lower shrinkage although it increases the viscosity of the cement and decreases the degree of conversion (DC) of monomers [4, 15]. Low viscosity monomers such as TEGDMA have the purpose of decreasing the viscosity allowing the flowability of the resin-matrix cement [16]. The optical and mechanical properties of the resin-matrix cements are tailored from the reinforcement of the organic matrix with micro- and nano-scale inorganic fillers such as zirconia, zirconium silicate, barium glass, ytterbium fluoride, and/or amorphous silica [13, 17].

The percentage of DC usually represents the amount of polymerized double carbon bonds that were converted into single bonds in the carbon chain [10, 18]. The DC percentage of resin-matrix cements generally ranges from 52 up to 75% [19,20,21]. Both extrinsic and intrinsic material factors influence DC, namely the monomers nature, inorganic particles, and photoinitiators [10]. Thus, other extrinsic factors involving polymerization pathways can affect DC. In order to have a correct DC the distance between the light curing (LCU) unit and indirect restoration must be below 8 mm, the LCU must guarantee the correct irradiance and the time exposure must be sufficient for the polymerization reaction to correctly occur. Other parameters must also be ensured, namely, the resin cement thickness, the indirect restoration thickness, and the compatibility between the wavelength of LCU and photoinitiator system [22, 23].

Previous studies have reported a correlation between DC percentage and physical properties of the resin-matrix cement. Indeed, a high DC percentage is correlated with enhanced physical properties as reported by high mean values of flexural strength, elastic modulus, fracture toughness, and hardness [19,20,21]. Indeed, the hardness measurement is often used as an indirect method to measure the polymerization efficiency [24]. The increase of the monomers’ cross-linking over light-curing can be monitored by the elastic modulus and hardness acquired by micro- and nano-indentation assays [10, 25].

A low DC percentage is a result from failure on the polymerization of the resin-matrix cement leading to poor chemical and physical stability [20]. For instance, insufficient polymerization of the resin-matrix cement can promote the chemical reactivity of the material with the surrounding environment leading to changes in optical properties [11]. A low degree of conversion can promote detrimental effects to the physical properties of the materials, namely water sorption solubility, low strength and hardness [23]. Another issue that could lead to toxicity is the excessive amount of resin cement that can be trapped into surrounding tissues. Thick layers of resin cement debris that are not correctly polymerized can cause inflammatory reactions to the surrounding tissues including the dentin-pulp complex [26]. Additionally, the mechanical properties of the material are negatively affected and therefore the resin-matrix cement becomes susceptible to cracks and catastrophic fracture at the restorative interface.

The main aim of the present study was to carry out a scoping review on the differences in degree of conversion of monomers regarding several types of resin cements, indirect restorative materials, and light-curing procedures used in dentistry. It was hypothesized that the degree of conversion of monomers varies depending on the inorganic fillers, organic matrix of the resin cements, types of indirect restorative materials and polymerization pathways.

Method

Search strategy

A bibliographic review was performed on PubMed (via National Library of Medicine) considering that includes the major journals in the field of dentistry and biomaterials. The present search of studies was carried out in accordance with previous integrative review articles [23, 26,27,28,29]. The following search terms were assessed: “degree of conversion” OR “filler” AND “resin cement” OR “inorganic cement” AND “organic” OR “radiopacity” OR “refractive” OR “transmittance” OR “type” AND “resin composite.” Combination of terms were assessed regarding the purpose of this study. Also, a hand-search was performed on the reference lists of all primary sources and eligible studies of this integrative review for additional relevant publications. The inclusion criteria encompassed articles published in the English language from January 2011 up to January 2024, focusing on the degree of conversion of the organic matrix of resin-matrix cements. The eligibility inclusion criteria used for article searches also involved in vitro studies; randomized controlled trials; animal assays; and prospective cohort studies. The exclusion criteria were the following: papers without abstract; case report with short follow-up period; reviews; pilot studies; studies on the effect of fillers through other composite materials applied in different biomedical or engineering fields. Studies based on publication date were not restricted during the search process. A research question has been formulated following the PICO (Population, Intervention, Comparison, and Outcome) approach as follow: “How different is the degree of conversion of monomers comparing several types of resin-matrix cements?” The following factors were taken into consideration: (i) Population: resin cements, human participants, animals, indirect restorative materials, polymerization mode; (ii) Intervention: mechanical assays, optical analyses, microscopy, chemical analyses, cementation procedures, light-curing mode, and equipment. (iii) Comparison: different resin cements, polymerization parameters, types of restorative materials. (iv) Outcomes: major findings related to the degree of conversion of different resin cements affected or not by the indirect restorative material.

Study selection and data collection process

The selection of studies was carried out in three steps. At first, studies were scanned for relevance by title, and abstracts of the non-excluded studies were evaluated. Two researchers (MS and JCMS) independently analyzed the titles and abstracts of potentially relevant retrieved articles that met the inclusion criteria. The total of articles was compiled for each key term combination and therefore duplicates were removed using the Mendeley Reference Manager (ed. Elsevier). The second step comprised the evaluation of the abstracts and non-excluded articles, following the eligibility criteria on the abstract review. Selected articles were individually read and analyzed concerning the purpose of this study. The study selection at that step also encompassed the exclusion criteria. At last, the eligible articles received a study nomenclature label, combining first author names and year of publication. The following variables were collected for this review: authors’ names, study design/purpose, resin-matrix cements (chemical composition), restoration type, light-curing procedure, degree of conversion (%), and main outcomes. Data of the studies were harvested directly into a specific data-collection form to preventing multiple data recording within the same study (e.g., reports with different set-ups). Such evaluation was individually carried out by two researchers, followed by a joint discussion to select the most relevant studies.

Results

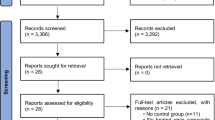

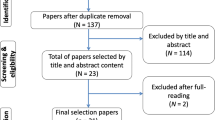

The initial search on PubMed database identified a total of 140 studies of which 38 duplicates were removed on the gradual combination of some terms (Fig. 1). The titles and abstracts of the 102 articles were read seeking concordance with the inclusion criteria of the present study. A total of 72 studies were excluded concerning they did not meet the inclusion criteria. The evaluation of titles and abstracts resulted in 30 potentially relevant studies, although 15 studies were excluded because they did not provide comprehensive data taking into account the purpose of this review study. Thus, 15 studies were included in this review (Fig. 1).

Within the 15 selected studies, 8 studies (53%) reported a high degree of conversion (DC) of the organic matrix ranging from 70 up to 90% [30,31,32,33,34,35,36,37] while 7 studies (46%) showed lower DC values [38,39,40,41,42,43,44]. Ten studies (66%) evaluated the DC by chemical analyses such as Fourier transform infrared spectroscopy (FTIR) [32, 33, 35, 37,38,39, 41,42,43,44] while 3 studies evaluated the DC using Raman spectroscopy [30, 31, 34], and another one performed near-infrared spectroscopy (NIRS) analyses [36]. Other 3 studies (20%) correlated flexural strength or hardness values with the DC [38, 39, 44]. Four studies (26%) evaluated the effects of resin-matrix composites thickness on the DC values. The commercially available resin-matrix cements assessed were: Panavia™ (Kuraray Noritake Dental Inc. Okayama, Japan); Mutli link™ (Ivoclar Vivadent, Schaan, Leichtenstein); Rely X™ (3M ESPE, Saint Paul, Minesotta, USA); Choice 2™ (Bisco, Inc. Schaumburg, IL, USA); Nexus 3™ (Kerr,Orange,USA), G-CEM LinkAce™ (GC Corp, Japan), and Enamel HFO™ (Micerium, Avegno, Italy) (Table 1). Most of resin-matrix composites revealed an organic matrix composed of Bis-GMA [30, 32, 33, 37, 44], UDMA [30,31,32, 35, 36, 39, 41,42,43], Bis-EMA [33], TEGDMA [30, 33,34,35,36, 39, 41,42,43], and camphorquinone (CQ)/tertiary amine photoinitiator system [35, 36, 40, 42]. The following micro- or nano-scale inorganic fillers were found in resin-matrix cements: amorphous silica, strontium glass, zirconium silicate, barium borosilicate glass, fluoro-aluminosilicate glass, sodium persulfate cupric acetate, and ytterbium fluoride (Table 1). The data recorded for resin-cement matrix, type of restoration, light curing parameters, degree of conversion and properties are given in Table 1.

The main findings are described as follow.

-

Selected studies revealed that some resin-matrix cements composed mainly of UDMA:HEMA 3:1 (36%) and TEGDMA (5%) reached the highest degree of conversion (DC) after 24 h [36]. The highest DC mean values acquired by FTIR analyses were recorded at 92 and 95% for Variolink™ and Enamel HFO™ [32, 36] followed by DC mean values ranging between 77 and 80% for two experimental flowable resin composites and a dual cure self-adhesive composite cement-G-CEM LinkAce™ [30, 31]. The lowest DC mean values were recorded at 10 and 38% by FTIR [41, 43, 44] and ranging from 30 up to 40% by NIRS [40];

-

The auto-polymerizing pathway itself was not enough to ensure high hardness mean values of resin-matrix cements. Dual-cured resin-matrix cements showed higher hardness mean values (10.7) when compared with light-cured cements (1.25) [44]. Resin-matrix cements containing spherical-shape particles showed higher flexural strength (120–129 MPa), flexural modulus (12–15 GPa), and hardness (101–117 HV) mean values than those recorded for resin-matrix cements with irregular-shape particles [39]. The addition of hybrid nano-scale fibers filled with Nb2O5 and Nb2O5/SiO2 into the U200™ self-adhesive resin-matrix cement showed higher values of flexural strength at 66 MPa when compared with the control groups, 42.3 MPa and 40 MPa [38];

-

DC mean values of resin-matrix cements light-cured through a ceramic veneer with 0.4 mm thickness was higher (83%) than those recorded for resin-matrix cements light-cured through a thicker ceramic layer of 1.5 mm (77.8%) [30]. Light attenuation and DC were significantly influenced by increasing thickness of the indirect restoration up to 5 mm and type of overlying material [31, 35]. Also, an adequate DC percentage was recorded at 61 and 54.6% for light-curing and dual-curing resin cements after polymerization underneath lithium disilicate-reinforced glass ceramics with thickness at 0.6 and 1.5 mm [42].

Discussion

The present integrative review reported the main findings of relevant previous studies, taking into account the degree of conversion (DC) of several resin-matrix cements used in dentistry. A large variation of DC values was recorded for commercially available resin-matrix cements and therefore physical properties were also affected. The variation of DC values was dependent on the inorganic fillers, organic matrix content, restorative materials, and polymerization mode. Thus, the findings of the selected studies validate the hypothesis of the present review. A detailed discussion of the main factors that affects the polymerization of resin-matrix cements is provided as follows.

Resin-matrix cements in dentistry

Resin-matrix cements are widely used for luting of indirect restorations including onlays, inlays, crowns, and intraradicular posts (Fig. 2) [47, 48]. The resin-matrix composites possess the following properties which are important for cementing ceramic veneers: low solubility, translucency, flowability, and elasticity [23, 24, 49]. The chemical composition of resin-matrix cements involves the presence of Bis-GMA, TEGDMA, Bis-EMA and UDMA embedding silanized inorganic fillers such as colloidal silica, ytterbium, or barium glass as seen in Fig. 2E and F. The chemical composition of the resin-matrix cements also varies in the presence or not of photoinitiator compounds [27, 29, 33, 50]. For light-activated curing, photoinitiator compounds such as camphorquinone coupled to a tertiary amine in the organic matrix are stimulated by the light irradiance at a wavelength ranging from 420 up to 490 nm [51,52,53,54]. Other photoinitiators can be associated with the camphorquinone or used separately such as 1-type is trimethylbenzoyl-diphenylphosphine oxide (TPO), benzoyl peroxide (BPO), phenanthrenequinone (PQ), benzophenone (BP), and 1-phenyl-1,2 propanodione (PPD), type I photoinitiators. However, previous studies have revealed changes in degree of conversion, polymerization shrinkage, color stability, and mechanical properties of resin-matrix composites containing novel photoinitiators [20, 55]. The type I photoinitiators have promoted properties optical properties when compared to CQ, although differences in chemical composition, thickness, shade, and opacity of indirect restorative materials can cause polymerization issues in deeper restorative areas [56,57,58]. A recent article [59] investigated the relationship between the ceramic veneers thickness, photoinitiators, and polymerization of resin-matrix cements, and conclude the light irradiance was attenuated under different thickness, mostly in violet spectrum, and consequently affecting the mechanical properties of resin-matrix cements.

Currently, resin-matrix cements involve a dual polymerization pathway under light-induced and chemical activation that are complementary [22, 43, 57]. The formulation of dual-cured resin cements includes a catalyst paste (chemical initiator) and a base paste (light-cured resin cement and tertiary amine) [2, 8, 20]. Traditional dual-cured resin-matrix cements requires a previous application of an adhesive system coating the tooth substrate. Self-adhesive resin cements can contain functional monomers for chemical bonding such as 10-methacryloyloxydecyl dihydrogen phosphate (10- MDP), 4-methacryloxyethyl trimellitate anhydride (4-META), or phosphoric esters (Table 1). Self-adhesive resin-matrix cements have acidic monomers to partially demineralize the smear layer structure [28, 29, 41]. Dual-cured resin-matrix cements reveal advantages over chemically-cured resin cements considering a high degree of conversion (DC) of monomers, gradual shrinkage stresses, and feasible working time for chair-side procedures [23, 26, 29, 41, 43, 60]. However, light-cured resin-matrix cements are indicated beneath thin veneers since the light transmission is required for their polymerization pathway [23, 24, 26, 28, 31].

Thus, the organic matrix of resin-matrix cements is reinforced by inorganic fillers, with a weight content ranging from 36 to 87% [60,61,62,63,64]. Those inorganic particles revealed irregular- or rounded-shape morphological aspects and size at micro-scale (0.1 up to 10 µm) and nano-scale (20–60 nm) depending on the manufacturing [65,66,67]. A high filler content provides a high strength of the resin-matrix cement that enhances the mechanical properties of the interface [23, 24, 29]. However, the content and type of fillers content and optical properties also affect light transmittance under polymerization. A high content of inorganic fillers can negatively affect the light transmittance under light curing although it also depends on the size and chemical composition of the inorganic fillers [38, 41, 68]. The refractive indexes of the organic matrix and the inorganic fillers should be balanced to allow the light transmittance through the resin-matrix cements [63, 69].

A high content of nano- and micro-scale inorganic particles results in a low organic matrix volume under polymerization. The size and the content of inorganic fillers highly enhanced the strength and elastic modulus in resin-matrix composites [20, 24, 38, 39]. Thus, the particle size distribution into resin-matrix cements plays a key role on the performance of the materials. Variations in particle size influences tensile bond strength, shear bond strength, and marginal fitting to dentin [20, 24, 29, 38, 39, 51]. The organic content of resin-matrix cements is susceptible to the absorption of water and fluids that also depends on the DC of monomers [24, 29]. The DC of monomers is influenced by the content, type and size of the inorganic fillers [24, 29, 51, 53]. Fillers’s content directly affects monomers conversion, due to the attenuation of light that is enhanced at higher filler content concerning light scattering [17, 24]. However, light transmission is affected by both fillers size and fillers amount. Higher filler amount tends to reduce light transmission due to the increased light refraction at the interfaces between filler particles and resin matrix although the type of inorganic particles also influences the light behavior [17, 24, 29]. Thus, filler particles with high refractive indexes, such zirconia (e.g.) allow higher light transmission values, which is critical for light-curing materials such as dual-cured resin-matrix cements [24, 29, 32, 51].

Degree of conversion of monomers in the resin-matrix cement

Adequate polymerization is fundamental to gathering physicochemical properties of the resin-matrix cements leading to an optimal stability of color and chemical composition [70]. Degree of conversion (DC) of monomers refers to the conversion of monomeric carbon–carbon double bonds into polymeric carbon–carbon single bonds [8, 71,72,73,74,75,76]. The DC provides a significant status of the mechanical performance of resin-matrix materials since an adequate polymerization results in enhanced physical properties [8, 9, 22, 24, 77,78,79,80].

Several methods have been used to assess the DC, such as FTIR spectroscopy as shown in the selected studies given in Table 1 and illustrated in Fig. 3. FTIR spectroscopy has been used widely as an appropriate and reliable method. FTIR spectrometer detects C = C stretching vibrations and therefore such method has been used directly before and after polymerization of resin-matrix materials [33, 35, 41, 82,83,84]. There are multiple techniques that quantify DC of monomers that include mid-and-near infrared spectroscopy and Raman spectroscopy, Table 1 [30, 31, 34, 85]. FTIR is the most common analytical method to determine DC, the mid-IR spectrum (∼ 4000–400 cm−1 that corresponds to 2500–25,000 nm) contains several fundamental absorbance bands associated with the carbon–carbon double bond in methacrylate monomers [85,86,87]. The near-infrared spectroscopy is also used for DC assessment, at a spectrum ranging 4000 up to 12,500 cm−1 (2500–800 nm), providing a direct measurement of the methacrylate groups and other reactive groups. Raman spectroscopy, like FTIR allows the measurement of reactive groups concentration during and following polymerization, although the measurement involves light scattering rather than light absorption. Also, Raman spectroscopy is usually applied to measure DC polymerization quality in adhesive layers [85].

High energy density (20 J/cm2) derived from both increased light curing time and low irradiance from the LCU results in a faster release of free radicals and, consequently, a higher DC of the resin-matrix cements [22, 88]. Previous findings reported that an increase in light exposure time associated with low irradiance improved DC and the polymerization depth due to the delay in the formation of rigid grid bonds between polymer chains [42]. DC percentage in the organic matrix depends on the light curing unit (LCU) irradiance, light wavelength, light exposure time, light transmission, and light absorption by the photoinitiator [8, 24, 35, 51,52,53,54]. Several studies have reported that DC values should be higher than 55% on occlusal restorations [33, 35, 41, 42, 54, 68, 89]. DC is also dependent on the filler volume, fraction, particle size, shape and the refractive index [24]. Inorganic fillers that have refractive index close to monomers of the organic matrix, allow better light transmittance, which in turn influences the DC of resin cements [24, 29, 88]. It is also worth to mention that the type of monomers within the composition of resin matrix cement, beyond the refractive index compatibility, must demonstrate the right viscosity that favors the monomers mobility and also the final degree of conversion [8, 50]. Bis-GMA is known as monomer with increased viscosity and then diluent monomers (e.g., TEGDMA) are added to the Bis-GMA organic matrix formulations to decrease the viscosity and improve monomers cross-link. However Bis-GMA is still used in resin cements formulations due to adequate overall mechanical properties. UDMA is a monomer with more flexibility and crosslinking capacity and it can be incorporated with Bis-GMA in organic matrix formulations [14, 90]. The DC of resin cements with Bis-GMA in their composition is dependent on the amount of TEGDMA, that improves the degree of conversion because of its mobility and reactivity [87]. Polymerization of resin-based materials depends on chemical composition and refractive indexes of both inorganic and organic components [23, 29, 91].

Regarding the translucency, it has been reported that the higher the opacity and saturation of the resin-matrix cement decreases the light transmission leading to poor physicochemical properties [31, 43, 53, 92]. Thus, use of higher opacity ceramics is required in clinical cases to mimic the optical properties of the surrounding teeth although the light curing time should be extended to provide a required amount of energy for polymerization [3, 13, 22,23,24, 70]. The evaluation of the DC by keeping light curing unit at a 6-mm distance from the top surface of the specimen is clinically relevant because it simulates what happen to DC in difficult-to-access posterior restorations [88].

The light irradiance under light curing arriving at the luting agent is also affected by the indirect restoration [31, 34, 43, 54, 92]. The thickness and translucency of the ceramic restoration affect the light transmittance towards the resin-matrix cement [13, 34, 35, 37, 40, 42, 44, 92]. The amount of light irradiating through the zirconia or glass–ceramic prosthetic structures depends on the translucency, microstructure, chemical composition, irradiation energy, thickness, porosity, and manufacturing technique [55, 93, 94]. Glass–ceramic materials such as lithium disilicate-reinforced glass ceramics are translucent although a thick structure decreases the light transmittance towards the resin-matrix cement [3, 23, 24]. Considering the zirconia structures, fully stabilized zirconia is more translucent than partially stabilized zirconia. Indeed, the translucency of the prosthetic structures are mainly affected by their thickness and by the resin-matrix cement itself since a high translucency is achieved within thin zirconia or glass–ceramic veneers associated with resin-matrix cement [3, 23, 31]. It has been reported viable methods for cementing higher translucent glass ceramics up to 2-mm thick using a combination of high light irradiance and exposure time on the light-curing procedure [24, 29, 70].

In fact, the DC percentage of monomers varies regarding the type of resin-matrix cements and the mode of polymerization. There are many variables involved in the evaluation of DC for resin-matrix materials related to the prosthetic materials and resin-matrix cement itself. The limitations of this review study are resultant from the low number of studies comparing similar parameters such the chemical composition and microstructure of the resin-matrix cement and mode of polymerization. The light-curing unit (LCU) does not work at the same light irradiance comparing different in vitro studies and therefore the LCU should be cautiously monitored prior to the polymerization procedure. Clinicians should also be aware on the development of novel resin-matrix cement taking into account the type of photoinitiators and inorganic fillers. Then, the polymerization parameters (light irradiance, wavelength, and exposure time) can be optimized to achieve a high DC percentage of the organic matrix. Further studies should be carried out concerning the type and content of the organic matrix and inorganic fillers.

Conclusions

Within the limitations of the selected studies, the main conclusions can be drawn as follow:

-

Most of resin-matrix composites revealed an organic matrix composed of Bis-GMA, UDMA, Bis-EMA, and TEGDMA. The main photoinitiator system comprised camphorquinone (CQ) and tertiary amine while the chemical composition, size, and content of inorganic fillers varied comparing the resin-matrix cements. Thus, the refractive indexes of the organic matrix and the inorganic fillers should be balanced to allow a high light transmittance through the resin-matrix cements and providing the required energy for the degree of conversion of monomers.

-

Most studies have reported a high degree of conversion (DC) of the organic matrix ranging from 70 up to 90%. Dual-curing resin-matrix cements showed the highest percentage of DC although a longer light exposure time is required for achieving an enhanced degree of conversion of monomers of the resin-matrix cement under prosthetic structures. A high degree of conversion of monomers resulted in enhanced physical properties of the resin-matrix cements. Dual-cured resin-matrix cements showed higher hardness mean values when compared with light-cured cements, showing that polymerization mode influences their mechanical properties.

-

The thickness and microstructure of zirconia or glass–ceramic prosthetic structures play a key role on the light transmission towards the resin-matrix cement, and therefore directly influence DC percentage. Similar DC values for the same resin-matrix cement were recorded when the prosthetic structure showed a thickness below 1.5 mm. On thick prosthetic structures, translucent materials are required to allow the light transmission achieving the resin-matrix cement and guarantee high DC values. Thus, the equipment and procedures of light-curing must be carefully monitored by the clinician concerning the prosthetic structures and resin-matrix cements for optimal clinical outcomes.

Data availability

No datasets were generated or analysed during the current study.

References

Gracis S, Thompson V, Ferencz J, Silva N, Bonfante E (2015) A new classification system for all-ceramic and ceramic-like restorative materials. Int J Prosthodont 28:227–35. https://doi.org/10.11607/IJP.4244

Maletin A, Ristic I, Veljovic T, Ramic B, Puskar T, Jeremic-Knezevic M et al (2022) Influence of dimethacrylate monomer on the polymerization efficacy of resin-based dental cements: FTIR analysis. Polymers (Basel) 14. https://doi.org/10.3390/POLYM14020247

Turp V, Turkoglu P, Sen D (2018) Influence of monolithic lithium disilicate and zirconia thickness on polymerization efficiency of dual-cure resin cements. J Esthet Restor Dent 30:360–368. https://doi.org/10.1111/jerd.12390

Felicitas M, Marcel R, Anja L, Marc R, Patrick K, Henning G et al (2021) Impact of polymerization and storage on the degree of conversion and mechanical properties of veneering resin composites. Dent Mater J 40:487–497. https://doi.org/10.4012/dmj.2019-394

Da STM, Sales ALLS, Pucci CR, Borges AB, Torres CRG (2017) The combined effect of food-simulating solutions, brushing and staining on color stability of composite resins. Acta Biomater Odontol Scand 3:1. https://doi.org/10.1080/23337931.2016.1276838

Raszewski Z, Brząkalski D, Derpeński Ł, Jałbrzykowski M, Przekop RE (2022) Aspects and Principles of material connections in restorative dentistry—a comprehensive review. Materials 15. https://doi.org/10.3390/ma15207131

Nilsson E, Alaeddin S, Karlsson S, Milleding P, Wennerberg A (2000) Factors affecting the shear bond strength of bonded composite inlays. Int J Prosthodont 13:52–58

Al-Zain AO, Eckert GJ, Lukic H, Megremis SJ, Platt JA (2018) Degree of conversion and cross-link density within a resin-matrix composite. J Biomed Mater Res B Appl Biomater 106:1496–1504. https://doi.org/10.1002/JBM.B.33960

Durner J, Obermaier J, Draenert M, Ilie N (2012) Correlation of the degree of conversion with the amount of elutable substances in nano-hybrid dental composites. Dent Mater 28:1146–1153. https://doi.org/10.1016/J.DENTAL.2012.08.006

Xu T, Li X, Wang H, Zheng G, Yu G, Wang H et al (2020) Polymerization shrinkage kinetics and degree of conversion of resin composites. J Oral Sci 62:275–280. https://doi.org/10.2334/josnusd.19-0157

Lopes-Rocha L, Mendes JM, Garcez J, Sá AG, Pinho T, Souza JCM et al (2021) The effect of different dietary and therapeutic solutions on the color stability of resin-matrix composites used in dentistry: an in vitro study. Materials 14. https://doi.org/10.3390/MA14216267

Porojan L, Vasiliu RD, Bîrdeanu MI, Porojan SD (2021) Surface characterisation of dental resin composites related to conditioning and finishing. Polymers (Basel) 13. https://doi.org/10.3390/POLYM13234236

Butler S, Santos GC, Santos MJC (2021) Do high translucency zirconia shades contribute to the degree of conversion of dual-cure resin cements? Quintessence Int 53:8–14. https://doi.org/10.3290/j.qi.b1901343

Pratap B, Gupta RK, Bhardwaj B, Nag M (2019) Resin based restorative dental materials: characteristics and future perspectives. Jpn Dent Sci Rev 55:126. https://doi.org/10.1016/J.JDSR.2019.09.004

dos Santos RL, Sampaio GAM, de Carvalho FG, Pithon MM, Guênes GMT, Alves PM (2014) Influence of degree of conversion on the biocompatibility of different composites in vivo. J Adhes Dent 16. https://doi.org/10.3290/J.JAD.A29704

Favarão J, de Oliveira DCRS, Rocha MG, Zanini MM, Abuna GF, Mendonça MJ et al (2019) Solvent degradation and polymerization shrinkage reduction of resin composites using isobornyl methacrylate. Braz Dent J 30:272–278. https://doi.org/10.1590/0103-6440201802525

Balbinot E do CA, Pereira MFCC, Skupien JA, Balbinot CEA, da Rocha G, Vieira S (2019) Analysis of transmittance and degree of conversion of composite resins. Microsc Res Tech 82:1953–61. https://doi.org/10.1002/JEMT.23364

Alshamrani AA, Raju R, Ellakwa A (2022) Effect of printing layer thickness and postprinting conditions on the flexural strength and hardness of a 3d-printed resin. Biomed Res Int 2022. https://doi.org/10.1155/2022/8353137

Sirovica S, Solheim JH, Skoda MWA, Hirschmugl CJ, Mattson EC, Aboualizadeh E et al (2020) Origin of micro-scale heterogeneity in polymerisation of photo-activated resin composites. Nat Commun 11:1849. https://doi.org/10.1038/s41467-020-15669-z

Kim M, Suh BI, Shin D, Kim KM (2016) Comparison of the physical and mechanical properties of resin matrix with two photoinitiator systems in dental adhesives. Polymers (Basel) 8. https://doi.org/10.3390/POLYM8070250

He J, Garoushi S, Vallittu PK, Lassila L (2018) Effect of low-shrinkage monomers on the physicochemical properties of experimental composite resin. Acta Biomater Odontol Scand 4:30. https://doi.org/10.1080/23337931.2018.1444488

Price RBT (2017) Light curing in dentistry. Dent Clin North Am 61:751–778. https://doi.org/10.1016/j.cden.2017.06.008

Tafur-Zelada CM, Carvalho O, Silva FS, Henriques B, Özcan M, Souza JCM (2021) The influence of zirconia veneer thickness on the degree of conversion of resin-matrix cements: an integrative review. Clin Oral Investig 25:3395–3408. https://doi.org/10.1007/s00784-021-03904-w

Fidalgo-Pereira R, Catarino SO, Carvalho Ó, Veiga N, Torres O, Braem A et al (2024) Light transmittance through resin-matrix composite onlays adhered to resin-matrix cements or flowable composites. J Mech Behav Biomed Mater 151:106353. https://doi.org/10.1016/j.jmbbm.2023.106353

Kowalska A, Sokolowski J, Bociong K (2021) The photoinitiators used in resin based dental composite-a review and future perspectives. Polymers (Basel) 13. https://doi.org/10.3390/polym13030470

Martinez-Gonzalez M, Fidalgo-Pereira RC, Torres O, Silva F, Henriques B, Özcan M et al (2022) Toxicity of resin-matrix cements in contact with fibroblast or mesenchymal cells. Odontology. https://doi.org/10.1007/s10266-022-00758-w

Lopes-Rocha L, Ribeiro-Gonçalves L, Henriques B, Özcan M, Tiritan ME, Souza JCM (2021) An integrative review on the toxicity of Bisphenol A (BPA) released from resin composites used in dentistry. J Biomed Mater Res B Appl Biomater. https://doi.org/10.1002/jbm.b.34843

Fernandes V, Silva AS, Carvalho O, Henriques B, Silva FS, Özcan M et al (2021) The resin-matrix cement layer thickness resultant from the intracanal fitting of teeth root canal posts: an integrative review. Clin Oral Investig. https://doi.org/10.1007/s00784-021-04070-9

Fidalgo-Pereira R, Torres O, Carvalho Ó, Silva FS, Catarino SO, Özcan M et al (2023) A scoping review on the polymerization of resin-matrix cements used in restorative dentistry. Materials 16:1560

Tomaselli L de O, Oliveira DCRS de, Favarão J, Silva AF da, Pires-de-Souza F de CP, Geraldeli S et al (2019) Influence of pre-heating regular resin composites and flowable composites on luting ceramic veneers with different thicknesses. Braz Dent J 30:459–66. https://doi.org/10.1590/0103-6440201902513

Lise DP, Van Ende A, De Munck J, Yoshihara K, Nagaoka N, Cardoso Vieira LC et al (2018) Light irradiance through novel CAD-CAM block materials and degree of conversion of composite cements. Dent Mater 34:296–305. https://doi.org/10.1016/j.dental.2017.11.008

de Kuijper MCFM, Ong Y, Gerritsen T, Cune MS, Gresnigt MMM (2021) Influence of the ceramic translucency on the relative degree of conversion of a direct composite and dual-curing resin cement through lithium disilicate onlays and endocrowns. J Mech Behav Biomed Mater 122:104662. https://doi.org/10.1016/j.jmbbm.2021.104662

de Mendonça LM, Ramalho IS, Lima LASN, Pires LA, Pegoraro TA, Pegoraro LF (2019) Influence of the composition and shades of ceramics on light transmission and degree of conversion of dual-cured resin cements. J Appl Oral Sci 27:e20180351. https://doi.org/10.1590/1678-7757-2018-0351

Hardy CMF, Bebelman S, Leloup G, Hadis MA, Palin WM, Leprince JG (2018) Investigating the limits of resin-based luting composite photopolymerization through various thicknesses of indirect restorative materials. Dent Mater 34:1278–1288. https://doi.org/10.1016/j.dental.2018.05.009

Castellanos M, Delgado AJ, Sinhoreti MAC, de Oliveira DCRS, Abdulhameed N, Geraldeli S et al (2019) Effect of thickness of ceramic veneers on color stability and bond strength of resin luting cements containing alternative photoinitiators. J Adhes Dent 21:67–76. https://doi.org/10.3290/j.jad.a41997

Albuquerque PPAC, Duarte MF de B, Moreno MBP, Schneider LFJ, Moraes RR, Cesar PF et al (2019) Physicochemical properties and microshear bond strength of experimental self-adhesive resin cements to dentin or yttria-stabilized tetragonal zirconia polycrystal. J Adhes Dent 21:133–41. https://doi.org/10.3290/j.jad.a42363

Hoorizad Ganjkar M, Heshmat H, Hassan AR (2017) Evaluation of the effect of porcelain laminate thickness on degree of conversion of light cure and dual cure resin cements using FTIR. J Dent (Shiraz) 18:30–36

Velo MMAC, Nascimento TRL, Scotti CK, Bombonatti JFS, Furuse AY, Silva VD et al (2019) Improved mechanical performance of self-adhesive resin cement filled with hybrid nanofibers-embedded with niobium pentoxide. Dent Mater 35:e272–e285. https://doi.org/10.1016/j.dental.2019.08.102

Barbon FJ, Moraes RR, Isolan CP, Spazzin AO, Boscato N (2019) Influence of inorganic filler content of resin luting agents and use of adhesive on the performance of bonded ceramic. J Prosthet Dent 122:566.e1-566.e11. https://doi.org/10.1016/j.prosdent.2019.09.013

Franken P, Rodrigues SB, Collares FM, Samuel SMW, Leitune VCB (2019) Influence of N-(2-hydroxyethyl)acrylamide addition in light- and dual-cured resin cements. J Dent 90:103208. https://doi.org/10.1016/j.jdent.2019.103208

de Almeida CM, Meereis CTW, Leal FB, Ogliari AO, Piva E, Ogliari FA (2018) Evaluation of long-term bond strength and selected properties of self-adhesive resin cements. Braz Oral Res 32:e15. https://doi.org/10.1590/1807-3107bor-2018.vol32.0015

Scotti N, Comba A, Cadenaro M, Fontanive L, Breschi L, Monaco C et al (2016) Effect of lithium disilicate veneers of different thickness on the degree of conversion and microhardness of a light-curing and a dual-curing cement. Int J Prosthodont 29:384–8. https://doi.org/10.11607/ijp.4811

Kim M-J, Kim K-H, Kim Y-K, Kwon T-Y (2013) Degree of conversion of two dual-cured resin cements light-irradiated through zirconia ceramic disks. J Adv Prosthodont 5:464–470. https://doi.org/10.4047/jap.2013.5.4.464

Cho S-H, Lopez A, Berzins DW, Prasad S, Ahn KW (2015) Effect of different thicknesses of pressable ceramic veneers on polymerization of light-cured and dual-cured resin cements. J Contemp Dent Pract 16:347–352. https://doi.org/10.5005/jp-journals-10024-1688

Mihali SG, Lolos D, Popa G, Tudor A, Bratu DC (2022) Retrospective long-term clinical outcome of feldspathic ceramic veneers. Materials 15. https://doi.org/10.3390/ma15062150

Gaile M, Papia E, Zalite V, Locs J, Soboleva U (2022) Resin cement residue removal techniques: in vitro analysis of marginal defects and discoloration intensity using micro-CT and stereomicroscopy. Dent J (Basel) 10. https://doi.org/10.3390/dj10040055

Jacob S, Zubair S, Thomas M, Jathanna V, Shenoy R (2021) Effect of surface treatment on the dislocation resistance of prefabricated esthetic fiber posts bonded with self-adhesive resin cement: a systematic review and meta-analysis. J Conserv Dent 24:113. https://doi.org/10.4103/JCD.JCD_656_20

Vasiliu S, Racovita S, Gugoasa IA, Lungan MA, Popa M, Desbrieres J (2021) The benefits of smart nanoparticles in dental applications. Int J Mol Sci 22:1–24. https://doi.org/10.3390/IJMS22052585

Henriques B, Fabris D, Tuyama E, Mesquita-Guimarães J, Silva FS, Souza JCM et al (2019) Shear bond strength of PEEK and PEEK-30GF cemented to zirconia or titanium substrates. J Adhesion Sci Technol 33:1090–101. https://doi.org/10.1080/01694243.2019.1565289

Ferracane JL, Stansbury JW, Burke FJ (2011) Self-adhesive resin cements - chemistry, properties and clinical considerations. J Oral Rehabil 38:295–314. https://doi.org/10.1111/j.1365-2842.2010.02148.x

Leitune VCB, Collares FM, Trommer RM, Andrioli DG, Bergmann CP, Samuel SMW (2013) The addition of nanostructured hydroxyapatite to an experimental adhesive resin. J Dent 41:321–327. https://doi.org/10.1016/j.jdent.2013.01.001

Madruga FC, Ogliari FA, Ramos TS, Bueno M, Moraes RR (2013) Calcium hydroxide, pH-neutralization and formulation of model self-adhesive resin cements. Dent Mater 29:413–418. https://doi.org/10.1016/j.dental.2013.01.004

de Figueiredo EZ, de Souza Balbinot G, Castelo Branco Leitune V, Mezzomo Collares F (2021) Niobium silicate as a filler for an experimental photopolymerizable luting agent. J Prosthodont Res 65:25–30. https://doi.org/10.2186/jpr.JPOR_2019_420

Hadis M, Leprince JG, Shortall AC, Devaux J, Leloup G, Palin WM (2011) High irradiance curing and anomalies of exposure reciprocity law in resin-based materials. J Dent 39:549–557. https://doi.org/10.1016/j.jdent.2011.05.007

Novais VR, Raposo LHA, de Miranda RR, Lopes C de CA, Simamoto Júnior PC, Soares CJ (2017) Degree of conversion and bond strength of resin-cements to feldspathic ceramic using different curing modes. J Appl Oral Sci 25:61. https://doi.org/10.1590/1678-77572016-0221

de Oliveira D, Rocha MG, Correa IC, Correr AB, Ferracane JL, Sinhoreti MAC (2016) The effect of combining photoinitiator systems on the color and curing profile of resin-based composites. Dent Mater 32:1209–1217. https://doi.org/10.1016/j.dental.2016.06.010

Rueggeberg FA (2011) State-of-the-art: dental photocuring—a review. Dent Mater 27:39–52. https://doi.org/10.1016/j.dental.2010.10.021

Harlow JE, Rueggeberg FA, Labrie D, Sullivan B, Price RB (2016) Transmission of violet and blue light through conventional (layered) and bulk cured resin-based composites. J Dent 53:44–50. https://doi.org/10.1016/j.jdent.2016.06.007

Favarão J, Oliveira D, Zanini MM, Rocha MG, Correr-Sobrinho L, Sinhoreti M (2021) Effect of curing-light attenuation on color stability and physical and chemical properties of resin cements containing different photoinitiators. J Mech Behav Biomed Mater 113:104110. https://doi.org/10.1016/j.jmbbm.2020.104110

Liu C, Liu H, Qian Y-T, Zhu S, Zhao S-Q (2014) The influence of four dual-cure resin cements and surface treatment selection to bond strength of fiber post. Int J Oral Sci 6:56–60. https://doi.org/10.1038/ijos.2013.83

Ilie N, Hilton TJ, Heintze SD, Hickel R, Watts DC, Silikas N, Stansbury JW, Cadenaro M, Ferracane JL (2017) Academy of Dental Materials guidance-resin composites: part I-mechanical properties. Dent Mater 33(8):880–894. https://doi.org/10.1016/j.dental.2017.04.013

Cekic-Nagas I, Ergun G (2011) Effect of different light curing methods on mechanical and physical properties of resin-cements polymerized through ceramic discs. J Appl Oral Sci 19:403. https://doi.org/10.1590/S1678-77572011005000017

Bacchi A, Caldas RA, Cesar PF, Pfeifer CS (2019) Optical properties and colorimetric evaluation of resin cements formulated with thio-urethane oligomers. J Esthet Restor Dent 31:153. https://doi.org/10.1111/JERD.12437

Souza JCM, Bentes AC, Reis K, Gavinha S, Buciumeanu M, Henriques B, Silva FS, Gomes JR (2016) Abrasive and sliding wear of resin composites for dental restorations. Tribol Int 102:154–160. https://doi.org/10.1016/j.triboint.2016.05.035

Re D, Augusti G, Amato M, Riva G, Augusti D (2021) Esthetic rehabilitation of anterior teeth with laminates composite veneers. Case Rep Dent 12:1–9. https://doi.org/10.1155/2014/849273

García-Engra G, Fernandez-Estevan L, Casas-Terrón J, Fons-Font A, Castelo-Baz P, Agustín-Panadero R et al (2020) Fracture resistance of new metal-free materials used for cad-cam fabrication of partial posterior restorations. Medicina (B Aires) 56. https://doi.org/10.3390/MEDICINA56030132

Venturini AB, Prochnow C, Pereira GKR, Segala RD, Kleverlaan CJ, Valandro LF (2019) Fatigue performance of adhesively cemented glass-, hybrid- and resin-ceramic materials for CAD/CAM monolithic restorations. Dent Mater 35:534–542. https://doi.org/10.1016/J.DENTAL.2019.01.013

de Andrade KMG, Palialol AR, Lancellotti AC, Aguiar FHB, Watts DC, Gonçalves LS et al (2016) Effect of diphenyliodonium hexafluorphosphate on resin cements containing different concentrations of ethyl 4-(dimethylamino)benzoate and 2-(dimethylamino)ethyl methacrylate as co-initiators. Dent Mater 32:749–755. https://doi.org/10.1016/j.dental.2016.03.014

Faria-E-Silva AL, Pfeifer CS (2017) Impact of thio-urethane additive and filler type on light-transmission and depth of polymerization of dental composites. Dent Mater 33:1274–1285. https://doi.org/10.1016/j.dental.2017.07.020

Liporoni PCS, Ponce ACR, de Freitas MR, Zanatta RF, Pereira MCS, Catelan A (2020) Influence of thickness and translucency of lithium disilicate ceramic on degree of conversion of resinous materials. J Clin Exp Dent 12:e745. https://doi.org/10.4317/JCED.56921

Galvão MR, Caldas SGFR, Bagnato VS, Rastelli ANS, Andrade MF (2013) Evaluation of degree of conversion and hardness of dental composites photo-activated with different light guide tips - PubMed. Eur J Dent 7:86–93

Prasanna N, Pallavi Reddy Y, Kavitha S, Lakshmi NL (2007) Degree of conversion and residual stress of preheated and room-temperature composites. Indian J Dent Res 18:173–176. https://doi.org/10.4103/0970-9290.35827

Par M, Spanovic N, Tauböck TT, Attin T, Tarle Z (2019) Degree of conversion of experimental resin composites containing bioactive glass 45S5: the effect of post-cure heating. Sci Rep 9. https://doi.org/10.1038/S41598-019-54035-Y

Sarosi C, Moldovan M, Soanca A, Roman A, Gherman T, Trifoi A et al (2021) Effects of monomer composition of urethane methacrylate based resins on the C=C degree of conversion, residual monomer content and mechanical properties. Polymers (Basel) 13. https://doi.org/10.3390/POLYM13244415

Tsuzuki FM, de Castro-Hoshino LV, Lopes LCP, Sato F, Baesso ML, Terada RSS (2020) Evaluation of the influence of light-curing units on the degree of conversion in depth of a bulk-fill resin. J Clin Exp Dent 12:e1117–e1123. https://doi.org/10.4317/JCED.57288

Lopes C de CA, Rodrigues RB, Silva ALFE, Simamoto Júnior PC, Soares CJ, Novais VR (2015) Degree of conversion and mechanical properties of resin cements cured through different all-ceramic systems. Braz Dent J 26:484–9. https://doi.org/10.1590/0103-6440201300180

Par M, Attin T, Tarle Z, Tauböck TT (2020) A new customized bioactive glass filler to functionalize resin composites: acid-neutralizing capability, degree of conversion, and apatite precipitation. J Clin Med 9. https://doi.org/10.3390/JCM9041173

Lempel E, Czibulya Z, Kunsági-Máté S, Szalma J, Sümegi B, Böddi K (2014) Quantification of conversion degree and monomer elution from dental composite using hplc and micro-raman spectroscopy. Chromatographia 77:17. 2014;77:1137–44. https://doi.org/10.1007/S10337-014-2647-3

Alshali RZ, Silikas N, Satterthwaite JD (2013) Degree of conversion of bulk-fill compared to conventional resin-composites at two time intervals. Dent Mater 29. https://doi.org/10.1016/J.DENTAL.2013.05.011

Bin Nooh AN, Nahedh H Al, Alrefeai M, Alkhudhairy F (2021) The effect of irradiance on the degree of conversion and volumetric polymerization shrinkage of different bulk-fill resin-based composites: an in vitro study. Eur J Dent 15:312. https://doi.org/10.1055/S-0040-1721236

Serino G, Comba A, Baldi A, Carossa M, Baldissara P, Bignardi C, Audenino A, Torres CGR, Scotti N (2022) Could light-curing time, post-space region and cyclic fatigue affect the nanomechanical behavior of a dual-curing cement for fiber post luting? J Mech Behav Biomed Mater 125:104886. https://doi.org/10.1016/j.jmbbm.2021.104886

Al-Hamdan RS, Almutairi B, Kattan HF, Alsuwailem NA, Farooq I, Vohra F et al (2020) Influence of hydroxyapatite nanospheres in dentin adhesive on the dentin bond integrity and degree of conversion: a scanning electron microscopy (SEM), raman, fourier transform-infrared (FTIR), and microtensile study. Polymers (Basel) 12:1–15. https://doi.org/10.3390/POLYM12122948

Robertson L, Phaneuf M, Haimeur A, Pesun I, França R (2016) Degree of conversion and oxygen-inhibited layer effect of three dental adhesives. Dent J (Basel) 4. https://doi.org/10.3390/DJ4040037

Ozturk B, Cobanoglu N, Cetin Dr. AR, Gunduz B (2013) Conversion degrees of resin composites using different light sources. Eur J Dent 7:102

Ferracane JL, Hilton TJ, Stansbury JW, Watts DC, Silikas N, Ilie N et al (2017) Academy of dental materials guidance-resin composites: Part II-technique sensitivity (handling, polymerization, dimensional changes). Dent Mater 33:1171–1191. https://doi.org/10.1016/j.dental.2017.08.188

Aldhafyan M, Silikas N, Watts DC (2022) Influence of curing modes on conversion and shrinkage of dual-cure resin-cements. Dent Mater 38:194–203. https://doi.org/10.1016/j.dental.2021.12.004

Maletin A, Ristic I, Veljovic T, Ramic B, Puskar T, Jeremic-Knezevic M et al (2022) Influence of dimethacrylate monomer on the polymerization efficacy of resin-based dental cements—FTIR analysis. Polymers (Basel) 14. https://doi.org/10.3390/polym14020247

Jain L, Mehta D, Meena N, Gupta R (2018) Influence of light energy density, composite type, composite thickness, and postcuring phase on degree of conversion of bulk-fill composites. Contemp Clin Dent 9:S147. https://doi.org/10.4103/CCD.CCD_169_18

Carvalho EM, Ferreira PVC, Gutiérrez MF, Sampaio RF, Carvalho CN, de Menezes AS et al (2021) Development and characterization of self-etching adhesives doped with 45S5 and niobophosphate bioactive glasses: physicochemical, mechanical, bioactivity and interface properties. Dent Mater 37:1030–1045. https://doi.org/10.1016/j.dental.2021.03.004

Fugolin AP, Costa AR, Kono E, Quirk E, Ferracane JL, Pfeifer CS (2020) Influence of the organic matrix composition on the polymerization behavior and bulk properties of resin composites containing thiourethane-functionalized fillers. Eur Polym J 130. https://doi.org/10.1016/j.eurpolymj.2020.109664

Fujita K, Nishiyama N, Nemoto K, Okada T, Ikemi T (2005) Effect of base monomer’s refractive index on curing depth and polymerization conversion of photo-cured resin composites. Dent Mater J 24:403–408. https://doi.org/10.4012/dmj.24.403

Czasch P, Ilie N (2013) In vitro comparison of mechanical properties and degree of cure of a self-adhesive and four novel flowable composites. J Adhes Dent 15:229–236. https://doi.org/10.3290/j.jad.a29530

Runnacles P, Correr GM, Filho FB, Gonzaga CC, Furuse AY (2014) Degree of conversion of a resin cement light-cured through ceramic veneers of different thicknesses and types. Braz Dent J 25:38–42. https://doi.org/10.1590/0103-6440201302200

Perdigão J, Araujo E, Ramos RQ, Gomes G, Pizzolotto L (2021) Adhesive dentistry: Current concepts and clinical considerations. J Esthet Restor Dent 33:51–68. https://doi.org/10.1111/JERD.12692

Acknowledgements

The authors acknowledge the financial support provided by FCT-Portugal [UID/EEA/04436/2013, SFRH/BPD/123769/ 2016, and Project LaserMULTICER [POCI-01-0145-FEDER-031035].

Funding

Open access funding provided by FCT|FCCN (b-on). This work was supported by FCT-Portugal [UID/EEA/04436/2013, SFRH/BPD/123769/ 2016, and Project LaserMULTICER [POCI-01–0145-FEDER-031035].

Author information

Authors and Affiliations

Contributions

Conceptualization, J.C.M.S. and B.H..; methodology, J.C.M.S. and M.S.; Investigation, M.S., and R.F.P.; Writing—original draft preparation, J.C.M.S., M.S. and R.F.P.; writing—review and editing, J.C.M.S., B.H. and M.O..; Supervision, O.C., M.O. and J.C.M.S. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Santos, M., Fidalgo-Pereira, R., Torres, O. et al. The impact of inorganic fillers, organic content, and polymerization mode on the degree of conversion of monomers in resin-matrix cements for restorative dentistry: a scoping review. Clin Oral Invest 28, 454 (2024). https://doi.org/10.1007/s00784-024-05829-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00784-024-05829-6