Abstract

Objective

The purpose of this study was to perform an integrative review on laser texturing the inner surface of lithium disilicate-reinforced glass ceramic or zirconia to increase their bond strength to resin-matrix cements.

Materials and method

A bibliographic review was performed on PubMed using the following search terms: “zirconia” OR “lithium disilicate” AND “laser” AND “surface” OR “roughness” AND “bond strength” AND “luting agent” OR “resin cement.” Studies published in English language until March 15, 2023, were selected regarding the purpose of this study.

Results

A total of fifty-six studies were identified althoug thirteen studies were selected. The findings revealed that zirconia surfaces were significantly modified after laser irradiation resulting in macro-scale aligned retentive regions with depth values ranging from 50 to 120 µm. Average roughness values of laser-textured zirconia by Er,Cr:YSGG laser (~ 0.83 µm) were quite similar when compared to grit-blasted zirconia surfaces (~ 0.9 µm) although roughness increased up to 2.4 µm depending on the laser type and parameters. Lithium disilicate-reinforced glass ceramics textured with Er:YAG revealed an average roughness of around 3.5 µm while surfaces textured using Nd:YAG laser revealed an average roughness of 2.69 µm; that was quite similar to the roughness values recorded for etched surfaces (2.64 µm). The shear bond strength (SBS) values of zirconia surfaces textured on Nd:YVO4 laser irradiation were slightly higher (~ 33.5 MPa) than those recorded for grit-blasted zirconia surfaces (28 MPa). Laser-textured zirconia surfaces on CO2 laser revealed higher SBS values (18.1 ±0.8 MPa) than those (9.1 ± 0.56 MPa) recorded for untreated zirconia surfaces. On lithium disilicate-reinforced glass ceramics, higher SBS values to resin-matrix cements were recorded for specimens textured with a combination of fractional CO2 laser irradiation and HF acid etching (~ 22–24 MPa) when compared with grit-blasted specimens (12.2 MPa). Another study revealed SBS values at around 27.5 MPa for Er:YAG-textured lithium disilicate-reinforced glass ceramics to resin-matrix cements.

Conclusions

The laser irradiation at high power increases the roughness of the inner surface of lithium disilicate-reinforced glass ceramic or zirconia leading to an enhanced bond strength to resin-matrix cements. Thus, the laser type and irradiation parameters can be adjusted to enhance the macro- and micro-scale retention of zirconia and glass ceramic surfaces to resin-matrix cements.

Clinical relevance

Alternative methods for surface modification of lithium disilicate-reinforced glass ceramic and zirconia surfaces have been assessed to provide proper morphological aspects for enhanced adhesion to resin-matrix cements. An increase in the bond strength of glass ceramics or zirconia to resin-matrix cements can improve the long-term performance of cemented prosthetic structures in the oral cavity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nowadays, the use of polycrystalline ceramics and glass ceramics has been increasingly preferred by clinicians and patients considering esthetic outcomes [1, 2]. Lithium disilicate-reinforced glass ceramics and polycrystalline ceramics such as zirconia are the first choice for manufacturing veneer, crown, inlay, and onlay restorations over teeth or dental implant abutments [1, 2]. The surface modification of dentin or enamel is carried out by acid etching with 37% H3PO4 acid followed by conditioning with methacrylate-based adhesives for adhesion to glass ceramics or zirconia. Titanium abutment base can also be modified by grit blasting with alumina particles (Al2O3) followed by acid etching with (5–10%) HF acid and then conditioning with silane and methacrylate-based adhesives [1, 3] (1,9). In the same way, surfaces of lithium disilicate-reinforced glass ceramics can also be modified by acid etching with (5–10%) HF acid providing a standard rough surface for adhesion to adhesive systems and resin-matrix cements. Thus, the roughness of enamel, dentin, glass ceramics, and titanium surfaces can be increased by acid etching that increase the adhesion area for mechanical interlocking to adhesives and resin-matrix cements [1,2,3,4]. However, acid etching with HF or H3PO4 acids cannot alter surfaces of polycrystalline ceramics such as zirconia considering a highly chemical stability of the ceramic [5, 6]. Zirconia has well-reported enhanced mechanical properties although the surface modification using traditional methods for further adhesion to resin-matrix cements is a major disadvantage [2, 5,6,7,8,9]. Therefore, alternative surface modification methods must be studied to enhance the zirconia bonding to resin-matrix cements [6, 7, 10].

The long-term clinical success of ceramic-based restorations is strongly dependent on their retention to teeth or abutment substrates by using adhesive systems and resin-matrix cements [1, 2, 7]. Traditional methods of surface modification such as grit blasting and acid etching have limited capability to achieve optimum morphological aspects and roughness over zirconia for mechanical interlocking of adhesive systems and resin-matrix cements [8,9,10]. Also, grit blasting with Al2O3 or SiO2 particles shows limitations considering limited morphological aspects, contamination with remnant abrasive particles, and risks of cracks’ propagation [5]. The combination of different traditional surface modification techniques has been studied and associated with novel methods such as laser-assisted approaches [6, 7, 10].

The laser-assisted approaches already have many applications in oral pathology, endodontics, operative dentistry, and prosthodontics [5, 6, 10, 11]. The surface modification of implants and prosthetic structures by high intensity laser irradiation has gathered attention to improve roughness and wettability for adhesion to resin-matrix cements [7, 10, 12,13,14,15]. Currently, different morphological surface features (i.e., micro-grooves, cross-lines, pits, valleys, and peaks) can be produced on ceramics and glass ceramics by using different laser intensity, type, time, and frequency [7, 10, 12,13,14,15,16,17]. Previous studies have reported the surface modification of zirconia leading to an increased roughness after short (mili- to nano-seconds) or ultra-short (pico- to femtoseconds) periods of time (pulses) using different types of lasers such as Nd:YAG, Er:YAG, CO2, Er,Cr:YSGG, and Nd:YVO4 [7, 10, 12,13,14,15,16,17,18,19]. However, zirconia is susceptible to defects such as cracks depending on the mode and intensity of the laser irradiation. Minimal surrounding defects and contaminants have been reported after surface modification of zirconia by using ultra-short pulsed lasers such as pico- and femtosecond lasers [7, 10, 13]. Also, a minimal tetragonal-to-monoclinic phase transformation was detected in zirconia after irradiation with ultra-short laser pulses [19]. Thus, further studies are required to validate adequate parameters for surface modification of zirconia and glass ceramics by laser-assisted approaches to improve their bond strength to resin-matrix cements.

The main aim of the present study was to carry out an integrative review on laser texturing the inner surface of zirconia in comparison to lithium disilicate-reinforced glass ceramics used for enhanced bonding of veneer and crowns to resin-matrix cements. It was hypothesized that the laser irradiation at high power increases the roughness of the inner surface of zirconia or lithium disilicate-reinforced glass ceramics leading to an enhanced bond strength to resin-matrix cements.

Method

Information sources and search strategy

A bibliographic review was performed on PubMed (via National Library of Medicine) taking into account such database includes the major journals in the field of dentistry and biomaterials. The present method was performed in accordance with the search strategy applied in previous studies on integrative or systematic reviews [2, 6, 11, 20,21,22,23,24,25]. The following search terms were applied: “zirconia” OR “lithium disilicate” AND “laser” AND “surface” OR “roughness” AND “bond strength” AND “luting agent” OR “resin cement.” At first, combination of three or four key terms was used to find relevant studies.

Also, a hand search was performed on the reference lists of all primary sources and eligible studies of this integrative review for further relevant publications. The inclusion criteria encompassed articles published in the English language, from January 2012 until March 15, 2023, reporting the effects of the laser irradiation on the surface modification of lithium disilicate-reinforced glass ceramic or zirconia veneers and their adhesion to resin-matrix cements. The eligibility inclusion criteria used for article searches also involved: in vitro studies, meta-analyses, randomized controlled trials, animal assays, and prospective cohort studies. The exclusion criteria were the following: papers without abstract, case report with short follow-up period, and articles assessing only traditional methods of surface modification. Studies based on publication date were not restricted during the search process.

Study selection and data collection process

At first, studies were examined for relevance by title, and the abstracts were assessed for those studies which were not excluded at this step. Two of the authors (JCMS, ARE) individually analyzed the titles and abstracts of the retrieved potentially relevant articles meeting the inclusion criteria. The total of the studies was compiled for each combination of key terms, and therefore, the duplicates were removed using Mendeley citation manager. The second step comprised the evaluation of the abstracts following the eligibility criteria. Selected studies were independently read and analyzed concerning the purpose of this study. At last, the eligible articles received a study nomenclature label, combining first author names and year of publication. The following variables were collected for this review: authors’ names, journal, publication year, aims, materials, laser parameters, roughness, and adhesion. PICO question was adjusted to the issue where “P” was related to the patients or specimens while “I” referred to the methods of analyses while “C” was related to comparison of findings and “O” to the main outcomes. Data of the reports were harvested directly into a specific data collection form to avoid multiple data recording considering multiple reports within the same study (e.g., reports with different set-ups). This evaluation was individually carried out by two researchers, followed by a joint discussion to select the relevant studies.

Results

The search of articles on PubMed identified a total of 56 studies and duplicates were removed considering the initial combination of key terms, as seen in Fig. 1. A total of 22 studies was discarded considering that they did not meet the inclusion criteria. The remnant 10 studies were full read and selected. Three studies were added by hand search since they were considered as relevant regarding information on laser parameters, methods, and main outcomes.

Of the 13 selected studies, yttria-stabilized tetragonal zirconia polycrystals (Y-TZP) were assessed by 9 studies [8, 9, 26,27,28,29,30,31,32] although ceria-stabilized tetragonal zirconia polycrystals (Ce-TZP) were also assessed by one study [27]. The effects of laser irradiation on lithium disilicate-reinforced glass ceramic were investigated by four studies [33,34,35,36]. The following types of laser were assessed by the selected studies: Er,Cr:YSGG [9, 30], Er:YAG [33, 34, 36], Nd:YAG [34], CO2 [8,32,35,], and Nd:YVO4 [27]. The laser irradiation parameters varied among the studies as seen in Table 1. For instance, the power of the Er,Cr:YSGG laser irradiation ranged from 1 up to 6 W [9, 30] while Er:YAG laser was assessed at power intensity range between 4 and 10 W [33,34,35]. The power assessed for CO2 laser ranged from 3 up to 20 W [8, 32, 35] while the power of Nd:YAG laser was assessed at 2.5 W [34]. After laser irradiation, roughness values were recorded by four studies [26, 29, 32, 34] although the shear bond strength (SBS) of laser-textured zirconia to resin-matrix cements was recorded by each one of the selected studies.

The main findings of the selected studies can be drawn as follows:

-

The surfaces of the zirconia were significantly modified after laser irradiation with Yb-doped fiber or Nd:YVO4 laser resulting in aligned retentive regions with macro-scale depth values ranging from 50 up to 120 µm [27].

-

The average roughness of laser-textured surfaces using Yb-doped fiber laser system was recorded at around 2.4 µm that was significantly higher when compared to the untreated zirconia surfaces (~ 0.2 µm). Nevertheless, the average roughness recorded for laser-textured surfaces using Er,Cr:YSGG (~ 0.83 µm) was quite similar to those recorded for grit-blasted zirconia surfaces (~ 0.9 µm) [26].

-

Surfaces of lithium disilicate-reinforced glass ceramics were also modified by laser irradiation although the etching with HF acid resulted in high mean values of roughness [34]. Lithium disilicate-reinforced glass ceramics textured by Er:YAG laser revealed an average roughness of around 3.5 µm while surfaces textured with Nd:YAG revealed an average roughness of 2.69 µm that was quite similar to the roughness values recorded for etched surfaces (2.64 µm) [34].

-

Laser-textured zirconia surfaces showed high values of shear bond strength (SBS) to resin-matrix cements [8, 27]. The SBS values of zirconia surfaces textured on Nd:YVO4 laser were slightly higher (~ 33.5 MPa) than those recorded for grit-blasted zirconia surfaces (28 MPa) [27]. Laser-textured zirconia surfaces on CO2 laser revealed the highest SBS values (18 ±0.8 MPa) while lowest values (9.1 ± 0.56 MPa) were recorded for untreated zirconia surfaces [8].

-

On lithium disilicate-reinforced glass ceramics, higher values of SBS to resin-matrix cements were recorded for specimens textured with a combination of fractional CO2 laser irradiation and HF acid etching (~ 22–24 MPa) when compared with grit-blasted specimens (12.2 MPa) [35]. Another study revealed SBS values at around 27.5 MPa for Er:YAG-textured lithium disilicate-reinforced glass ceramics to resin-matrix cements [33, 34]. Surfaces grit-blasted with Al2O3 particles showed the lowest mean bond strength to the resin composite (15.62 MPa) [33].

Discussion

This review reported relevant findings on laser-textured lithium disilicate-reinforced glass ceramic or zirconia surfaces and their adhesion to resin-matrix cements. Results showed an increased roughness of the glass ceramics and zirconia when compared to untreated surfaces. Thus, high values of roughness reveal an increase in the retentive area to silane agents, adhesive systems, and resin-matrix cements. Indeed, those findings validate the hypothesis of the present review. Nevertheless, different types of laser and irradiation parameters are reported in literature. A detailed discussion on laser parameters as well as on zirconia and glass ceramics and their adhesion to resin-matrix cements is given as follows.

Previous studies revealed the surface modification of zirconia and glass ceramics by using different laser types (Er,Cr:YSGG, Er:YAG, Nd:YAG, CO2, and Nd:YVO4) and irradiation parameters (Table 1). A previous study reported adhesive effects of Y-TZP textured by CO2 laser irradiation (wavelength of 10.6 mm) at a pulse repetition rate of 1000 Hz and pulse duration of 160 ms at an average power setting of 3 W and at 1 mm away from the surface [8]. Specimens were bonded to a resin-matrix cement and submitted to SBS testing. The highest shear bond strength (SBS) values (1. ±0.8 MPa) were recorded for laser-textured zirconia surfaces while the lowest values (9 ±0.5 MPa) were recorded for untreated zirconia (control group) surfaces [8].

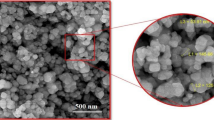

In another study, conical spots were shaped onto zirconia structures by CO2 laser texturing and compared to machined, grit-blasted, and polished zirconia surfaces [29]. The morphological aspects of the surfaces were inspected by scanning electron microscopy (SEM) while the zirconia phases were identified by X-ray diffraction (XRD). Surfaces were bonded to a resin-matrix cements and assessed by shear bond strength assays. The shear bond strength of grit-blasted or laser-textured zirconia to resin cement was 2.3 times higher than that for untreated zirconia. Surface modification by laser spotting improved the SBS to the resin cement. However, no significant difference was detected between grit-blasted and laser-textured surfaces [32].

In a previous study, a texturing on Y-TZP resin at different laser beam incidence angles (90, 75, 60, and 45 degree) was assessed using a femtosecond laser, and the SBS values of Y-TZP to resin cement (Rely X™, 3 M ESPE, USA) were measured [31]. The SBS values of each specimen was measured using a universal testing machine at crosshead speed of 1 mm/min. SEM images of the zirconia to resin cement interfaces showed the profile of the orifices shaped by the femtosecond laser. A higher contact area between Y-TZP and resin-matrix cement increased as function of the decrease in the laser beam incidence, as seen in Table 1. The results showed that the laser beam was applied to a surface at an angle of 45 degree which resulted in significantly higher SBS (~ 18 MPa) than that recorded for other groups: at 90 degree (~ 10. MPa), at 75 degree (~ 13 MPa), and at 60 degree (~ 15 MPa). Thus, findings revealed that the decrease of the angle between the ceramic surface and the laser beam resulted in an increase in the contact area of Y-TZP and resin-matrix cement leading to higher SBS values [31]. A femtosecond laser irradiation was also assessed on highly translucent zirconia or lithium disilicate-reinforced glass ceramics producing dot patterns with a line distance of 20 or 40 µm over the surfaces. Dot patterns were produced with peak fluence of 4 or 8 J/cm2 and irradiation number of 10 or 20 shots. Roughness parameters were measured by 3D confocal laser microscopy, and the microstructure was analyzed by SEM. The findings revealed similar morphological aspects for both glass ceramic and zirconia considering the surface modification parameters. The laser-textured surfaces with crossed-line patterns at a distance of 20 or 40 µm revealed a great potential for further studies [17].

A previous study also assessed the effects of thermal cycling on the SBS values of laser-textured zirconia surfaces to resin-matrix cements. Y-TZP was textured on Yb-doped laser irradiation at a pulse repetition rate of 60 Hz and pulse duration of 6.6 s and at an average power setting of 24 W [26]. Then, laser-textured surfaces were conditioned with a primer adhesive and bonded to a resin-matrix cement (Panavia V5™, Kuraray, Japan) [26]. Half of the specimens were submitted to thermal cycling, and then, the specimens were assessed by SBS testing. After thermal cycling, laser-textured Y-TZP surfaces to the resin-matrix cement were slightly higher (10 MPa, respectively) than those recorded for grit-blasted zirconia ones (2 MPa) [23]. There were no significant differences in SBS values when comparing laser-textured (12 MPa) and grit-blasted (14.5 MPa) surfaces without the effect of the thermal cycling [26]. Even though SBS values were not statistically different without thermal cycling, the adhesion of the laser-textured zirconia surfaces reached noticeable high adhesion to resin-matrix cements. In another study, zirconia surfaces were textured on Yb-doped pulsed fiber laser irradiation (wavelength of 1070 nm) with a maximum average output power of 20 W, a pulse duration of 100 ns, and a repetition rate in the range 20–100 kHz [28]. Surfaces were conditioned with a primer adhesive following by bonding to a flowable resin-matrix composite (Tetric Evo Flow™, Ivoclar Vivadent, Liechtenstein) and then assessed by SBS tests [28]. Laser-textured surfaces revealed higher fracture forces to resin-matrix cements (132.5 ±61.35 N) when compared with non-textured ones (105.7 ±56.1 N). However, the difference was not considered statistically significant (p = 0.2155).

In a previous selected study, Y-TZP or Ce-TZP surfaces were modified on Nd:YVO4 laser irradiation (wavelength of 1065 nm) at 70 kHz from 60 mm away to the surface [27]. Morphological aspects of surfaces showed aligned retentive regions with macro-scale depth values ranging from 50 to 120 µm [27]. The rough profile of the zirconia to the resin-matrix cement interface can be noticed in Fig. 2 while non-textured zirconia surfaces provide a smooth interface profile. Surfaces were conditioned with a primer adhesive (Clearfil Ceramic Primer Plus™, Kuraray, Japan) and bonded to resin-matrix cements (Gradia™, GC, Corp, Japan). Half of the specimens were submitted to thermal cycling, and then, all the specimens were mechanically tested by SBS tests. After thermal cycling, SBS values of laser-textured Y-TZP or Ce-TZP surfaces to the resin-matrix cement were slightly higher (33.5 and 24.5 MPa, respectively) than those recorded for grit-blasted zirconia ones (15.5 and 16.5 MPa, respectively) [27]. There were no significant differences in SBS values when comparing laser-textured Y-TZP or Ce-TZP (28.6 and 27.6 MPa, respectively) and grit-blasted surfaces (28.9 and 25.6 MPa, respectively) without the effect of the thermal cycling [27].

Adapted from Henriques et al. [7]

Schematics of the A CAD-CAM and B laser approaches for C crown and D implant abutment surfaces. SEM images of the interfaces of E non-textured and F laser-textured zirconia to a resin-matrix cement.

Yttria-stabilized tetragonal zirconia polycrystals (Y-TZP) are produced by introducing 2–5 mol% Y2O3 into ZrO2 formulations [37, 38] for stabilization of the tetragonal phase that results in Y-TZP with a significant increase in the following properties: elastic modulus at 230–270 GPa, fracture toughness of approximately 9–10 MPa.m1/2, flexural strength values at around 1200 MPa, and hardness at 1.1 GPa [39, 40]. Also, mechanical properties of zirconia are improved when the tetragonal phase is stabilized by the incorporation of small contents of oxides such as cerium oxide (ceria, CeO2), magnesium oxide (magnesia, MgO), and calcium oxide (calcia, CaO) [37, 38]. The abovementioned mechanical property values are significantly higher when compared with those recorded for glass ceramics. Additionally, oxide-stabilized zirconia has an inherent and remarkable pathway to inhibit the propagation of cracks when the material is submitted to high stresses (i.e., from surface modification method). High stresses result in a phase transformation from tetragonal to the monoclinic with an increase in the surrounding volume leading to compressive stresses over the crack. For instance, tetragonal-to-monoclinic phase conversion can take place under cyclic stresses from thermal fluctuations or mastication loading as well as can occur over the surface modification by grit blasting or laser texturing [37,38,39,40,41,42]. Nevertheless, Y-TZP is susceptible to the propagation of cracks depending on the pressure, medium, and surface modification parameters [41,42,43]. Thus, zirconia surface modification is still a contemporary challenge considering a balance among chemical stability, physical properties, and degradation behavior. It should be emphasized that the integrity of the zirconia or glass ceramic prosthetic structures can be readily compromised by improper treatment of inner surfaces for cementation and/or failures in the cementation procedures.

Lithium disilicate-reinforced glass ceramic contains approximately 65% volume fraction of lithium disilicate crystals, 34% volume fraction of residual glass, and 1% volume fraction of porosity after heat treatment [44]. The glass matrix is derived from a multi-component system, formulated from SiO2-Li2O-K2O-ZnO-Al2O3-La2O3-P2O5 glass system [44, 46]. Lithium disilicate glass ceramics have shown elastic modulus of around 60–105 GPa, fracture toughness at 2–3 MPa.m1/2, bend strength values around 320 ± 30 MPa, and hardness at 5.5 ± 0.3 GPa [44,45,46,47]. Such properties are adequate for their application on anterior teeth region although depending on the patient conditions. Thus, low mean values of strength and fracture toughness of the glass ceramics can induce mechanical failures over the surface modification method as well as under cyclic loading in the oral cavity.

In a previous study, lithium disilicate-reinforced glass ceramics were textured on CO2 laser irradiation (wavelength of 10.6 µm) at two different irradiation intensities (10W and 28 J or 20 W and 28 J) at a pulse repetition rate of 200 Hz and pulse duration of 1.7 ms or 0.58 ms [35]. Surfaces were conditioned with a silane compound (Silane Bond Enhancer™, Pulpdent Corp., USA) followed by bonding to a resin-matrix cement (Clearfill SA Luting™, Kuraray, Japan), and then, the specimens were submitted to SBS tests [35]. The highest SBS values to resin-matrix cement were recorded for specimens textured with a combination of fractional CO2 laser irradiation and HF acid etching (22.4 and 24.3 MPa, respectively). Grit-blasted specimens exhibited the lowest shear bond strength (12.2 MPa) to resin-matrix cements [35]. Considering the glass matrix of lithium disilicate-reinforced glass ceramics, roughness can be increased by etching with 5–10% HF for further adhesion to resin-matrix cements. Additionally, a combination with laser texturing approach becomes beneficial for increasing the retentive area leading to a high bonding to the resin-matrix cement.

Another previous study reported the influence of grit blasting, acid etching, and laser irradiation on the shear bond strength of lithium disilicate-reinforced glass ceramic (IPS Empress 2™, Ivovlar Vivadent, Liechcheinstein) and a feldspar-based porcelain (VITA VM 9™, VITA Zahnfabrik, Germany) to a resin-matrix cement (Panavia 2.0, Kuraray, Japan) [36]. Each of the two ceramic groups was further divided into five groups regarding the surface treatment method and parameters. The laser-textured surfaces were irradiated with Er:YAG laser at 1 mm distance, 500 mJ energy, 100 μs pulse length, 20 Hz, and 10 W power. After bonding to the resin-matrix cement, specimens were stored in water for 24 h and then assessed by SBS test using a universal testing machine at a crosshead speed of 0.5 mm/min. Statistical analyses indicated that the SBS was significantly affected by the surface modification methods (p < 0.05), although there was significant correlation between the ceramic systems. Grit-blasted plus laser-textured surfaces showed the highest mean SBS values for both ceramics groups. Atomic force microscopy images revealed a rough morphological aspect for grit-blasted surfaces [36].

In another study, lithium disilicate-reinforced glass ceramic was also modified by Er:YAG (200 mJ, pulse repletion at 10 pps) or Nd:YAG (120 mJ, pulse repletion at 15 pps) pulsed laser irradiation [34]. Groups of specimens were etched with HF, and all of the surfaces were conditioned with silane coating (Monobond Plus™, Ivoclar Vivadent, Liechtenstein) and then bonded to a dual-cure resin-matrix cement (Variolink II™, Ivoclar Vivadent, Liechtenstein). Lithium disilicate-reinforced glass ceramics textured by Er:YAG laser revealed an average roughness of around 3.5 µm while surfaces textured by Nd:YAG laser revealed an average roughness of 2.69 µm that was quite similar to the roughness values recorded for etched surfaces (2.64 µm) [31]. Er:YAG-textured surfaces revealed the highest SBS values to resin-matrix cements (27.5 MPa). Thus, lithium disilicate-reinforced glass ceramics etched with HF acid or laser-textured resulted in surfaces with roughness values higher than those recorded for untreated surfaces [34].

Nowadays, ceramics and glass ceramics are used to synthesize metal free (e.g., zirconia or zirconia-to-porcelain systems) and metal ceramic (e.g., feldspar-based ceramic fused on metallic materials) for implant- or teeth-supported prostheses (Fig. 2). On teeth, crowns or multi-unit prostheses are retained by using resin-matrix cements. Screw or cement-retained crowns consist of two ways of retaining the implant abutment prosthetic [1, 48, 49]. Thus, ceramics and glass ceramics have shown optical properties to significantly improve esthetic appearances, although higher failure rates are associated with fractures, crack propagation, and poor cement and/or bonded retention [1, 50,51,52]. Thus, the brittle mechanical behavior of glass ceramics and zirconia remains a concern regarding catastrophic fracture or abrupt stress distribution across the structural materials and interfaces. High concentration of stresses at prosthetic structural materials can increase the risks of brittle fractures at the zirconia or glass ceramics to adhesive and resin-matrix interfaces [1, 7, 41,42,43,44]. Then, surface modification of ceramics using traditional physical methods and laser-texturing approaches can be optimized regarding novel approaches to avoid clinical failures.

Even though a limited number of studies in literature, the selected studies reveal noteworthy data on laser-textured lithium disilicate-reinforced glass ceramic or zirconia surfaces and their adhesion to resin-matrix cements. In fact, several laser protocols have been assessed to enhance the retentive morphological aspects and increase the roughness for adhesion of ceramics and glass ceramics to resin-matrix cements. Indeed, the variability of laser types and irradiation parameters brings a broad data on the efficiency of the laser-assisted methods for surface modification of zirconia and glass ceramics. Also, further studies are performed to validate the effects of different laser parameters, restorative materials, and types of resin-matrix cements. Laser-assisted methods have been increasingly gathering attention in the technological field although most of laser apparatus are still quite expensive for clinical or laboratory application.

Conclusions

Within the limitations of the selected studies, the main outcomes can be drawn as follows:

-

On lithium disilicate-reinforced glass ceramics, higher shear bond strength values to resin-matrix cements were recorded for specimens textured with a combination of fractional CO2 laser irradiation and HF acid etching when compared with grit-blasted specimens. In fact, the association of traditional surface modification methods and laser-texturing provide beneficial effects for adhesion of glass-ceramics to resin-matrix cements.

-

Laser-textured zirconia surfaces on CO2 or Nd:YVO4 laser revealed higher shear bond strength to resin-matrix cements than those recorded for untreated zirconia surfaces. Thus, laser texturing approaches can become an alternative method for the modification of zirconia surfaces.

-

The laser irradiation at high power increases the roughness of the inner surface of lithium disilicate-reinforced glass ceramic or zirconia veneers and crowns leading to an enhanced bond strength to resin-matrix cements. Thus, the laser type and irradiation parameters can be adjusted to enhance the macro- and micro-scale retention of zirconia and glass ceramics surfaces. Further studies should consider other parameters related to the power output, frequency, and mode as well as the fluence of the laser irradiation to establish a standard guidelines for laser-texturing.

Data availability

Data will be available upon reasonable request.

References

Vahey BR, Sordi MB, Stanley K, Magini RS, Novaes de Oliveira AP, Fredel MC et al (2018) Mechanical integrity of cement- and screw-retained zirconium-lithium silicate glass-ceramic crowns to Morse taper implants. J Prosthet Dent. 120(5):721–31

Tafur-Zelada CM, Carvalho O, Silva FS, Henriques B, Özcan M, Souza JCM. The influence of zirconia veneer thickness on the degree of conversion of resin-matrix cements: an integrative review. Clin Oral Investig. 2021

Souza JCM, Sordi MB, Kanazawa M, Ravindran S, Henriques B, Silva FS, et al. Nano-scale modification of titanium implant surfaces to enhance osseointegration. Vol. 94, Acta Biomaterialia. Acta Materialia Inc; 2019. p. 112–31.

Magalhães T, Fidalgo-Pereira R, Torres O, Carvalho Ó, Silva FS, Henriques B, Özcan M, Souza JCM (2023) Microscopic Inspection of the adhesive interface of composite onlays after cementation on low loading: an in vitro study. J Functional Biomaterials 14(3):148. https://doi.org/10.3390/jfb14030148

Schünemann FH, Galárraga-Vinueza ME, Magini R, Fredel M, Silva F, Souza JCM et al (2019) Zirconia surface modifications for implant dentistry. Mater Sci Eng C, Mater Bio Applic 98:1294–305. Available from: http://www.sciencedirect.com/science/article/pii/S0928493118320009

Cunha W, Carvalho O, Henriques B, Silva FS, Özcan M, Souza JCM (2022) Surface modification of zirconia dental implants by laser texturing. Lasers Med Sci 37(1):77–93

Henriques B, Hammes N, Souza JCM, Özcan M, Mesquita-Guimarães J, Silva FS et al (2020) Influence of ns-Nd:YAG laser surface treatment on the tensile bond strength of zirconia to resin-matrix cements. Ceram Int 46(17):27822–27831. Available from: https://www.sciencedirect.com/science/article/pii/S0272884220322987

Murthy V, Manoharan Balaji, Livingstone D (2014) Effect of four surface treatment methods on the shear bond strength of resin cement to zirconia ceramics- a comparative in vitro study. J Clin Diagn Res 9:65–8

Turker N, Özarslan MM, Buyukkaplan US, Başar EK (2020) Effect of different surface treatments applied to short zirconia and titanium abutments. Int J Oral Maxillofac Implants 35(5):948–954

Han J, Zhang F, Van Meerbeek B, Vleugels J, Braem A, Castagne S (2021) Laser surface texturing of zirconia-based ceramics for dental applications: A review. Mater Sci Eng C 123:112034. https://www.sciencedirect.com/science/article/pii/S0928493121001739

Souza JCM, Fernandes V, Correia A, Miller P, Carvalho O, Silva F, Özcan M, Henriques B (2022) Surface modification of glass fiber-reinforced composite posts to enhance their bond strength to resin-matrix cements: an integrative review. Clin Oral Investig 26(1):95–107. https://doi.org/10.1007/s00784-021-04221-y

Kasraei S, Rezaei-Soufi L, Heidari B, Vafaee F (2014) Bond strength of resin cement to CO2 and Er:YAG laser-treated zirconia ceramic. Restor Dent Endod 39(4):296–302

Bitencourt SB, Ferreira LC, Mazza LC, Dos Santos DM, Pesqueira AA, Theodoro LH (2021) Effect of laser irradiation on bond strength between zirconia and resin cement or veneer ceramic: a systematic review and meta-analysis. J Indian Prosthodont Soc 21(2):125–137

Abu Ruja M, De Souza GM, Finer Y (2019) Ultrashort-pulse laser as a surface treatment for bonding between zirconia and resin cement. Dent Mater 35(11):1545–1556

Paranhos MPG, Burnett LHJ, Magne P (2011) Effect Of Nd:YAG laser and CO2 laser treatment on the resin bond strength to zirconia ceramic. Quintessence Int 42(1):79–89

Gomes AL, Ramos JC, Santos-del Riego S, Montero J, Albaladejo A (2015) Thermocycling effect on microshear bond strength to zirconia ceramic using Er:YAG and tribochemical silica coating as surface conditioning. Lasers Med Sci 30(2):787–795

Inokoshi M, Yoshihara K, Kakehata M, Yashiro H, Nagaoka N, Tonprason W, Xu K, Minakuchi S (2022) Preliminary study on the optimization of femtosecond laser treatment on the surface morphology of lithium disilicate glass-ceramics and highly translucent zirconia ceramics. Materials 15(10):3614

Tzanakakis E-GC, Beketova A, Papadopoulou L, Kontonasaki E, Tzoutzas IG (2021) Novel femto laser patterning of high translucent zirconia as an alternative to conventional particle abrasion. Dentistry J 9(2):20

Tzanakakis EC, Kontonasaki E, Andrikopoulos K, Voyatzis G, Tzoutzas I (2020) Surface characterization of monolithic zirconia submitted to different surface treatments applying optical interferometry and Raman spectrometry. Dent Mater J 39(1):111–117

Rodrigues YL, Mathew MT, Mercuri LG, da Silva JSP, Henriques B, Souza JCM. Biomechanical simulation of temporomandibular joint replacement (TMJR) devices: a scoping review of the finite element method. International Journal of Oral and Maxillofacial Surgery Churchill Livingstone 2018 p. 1032–42.

Noronha Oliveira M, Schunemann WVH, Mathew MT, Henriques B, Magini RS, Teughels W, et al. 2018 Can degradation products released from dental implants affect peri-implant tissues?. J Periodontal Res.53(1).

Fidalgo-Pereira R, Carpio D, Torres O, Carvalho O, Silva F, Henriques B, Özcan M, Souza JCM (2022) The influence of inorganic fillers on the light transmission through resin-matrix composites during the light-curing procedure: an integrative review. Clin Oral Invest 26(9):5575–5594. https://doi.org/10.1007/s00784-022-04589-5

Souza JCM, Pinho SS, Braz MP, Silva FS, Henriques B (2021) Carbon fiber-reinforced PEEK in implant dentistry: a scoping review on the finite element method. Comput Methods Biomech Biomed Engin 24(12):1355–1367. https://doi.org/10.1080/10255842.2021.1888939

Lopes-Rocha L, Ribeiro-Gonçalves L, Henriques B, Özcan M, Tiritan ME, Souza JCM (2021) An integrative review on the toxicity of bisphenol A (BPA) released from resin composites used in dentistry. J Biomed Mater Res B Appl Biomater 109(11):1942–1952. https://doi.org/10.1002/jbm.b.34843

Fernandes V, Silva AS, Carvalho O, Henriques B, Silva FS, Özcan M, Souza JCM (2021) The resin-matrix cement layer thickness resultant from the intracanal fitting of teeth root canal posts: an integrative review. Clin Oral Investig 25(10):5595–5612. https://doi.org/10.1007/s00784-021-04070-9

Toyoda K, Taniguchi Y, Nakamura K, Isshi K, Kakura K, Ikeda H et al (2022) Effects of ytterbium laser surface treatment on the bonding of two resin cements to zirconia. Dent Mater J 41(1):45–53

Iwaguro S, Shimoe S, Takenaka H, Wakabayashi Y, Peng T-Y, Kaku M (2022) Effects of dimensions of laser-milled grid-like microslits on shear bond strength between porcelain or indirect composite resin and zirconia. J Prosthodont Res 66(1):151–160

Fornaini C, Poli F, Merigo E, Lutey A, Cucinotta A, Chevalier M et al (2021) Nanosecond pulsed fiber laser irradiation for enhanced zirconia crown adhesion: morphological, chemical, thermal and mechanical analysis. J Photochem Photobiol B 219:112189

Kirmali O, Kustarci A, Kapdan A, Er K (2015) Efficacy of surface roughness and bond strength of Y-TZP zirconia after various pre-treatments. Photomed Laser Surg 33(1):15–21

Ahrari F, Boruziniat A, Alirezaei M (2016) Surface treatment with a fractional CO2 laser enhances shear bond strength of resin cement to zirconia. Laser Ther 25(1):19–26

Akpinar YZ, Kepceoglu A, Yavuz T, Aslan MA, Demirtag Z, Kılıc HS, Usumez A (2015) Effect of femtosecond laser beam angle on bond strength of zirconia-resin cement. Lasers Med Sci 30(8):2123–2128. https://doi.org/10.1007/s10103-015-1762-1

Uno M, Ishigami H (2023) The enhanced shear bond strength of resin cement to zirconia with ordered conical spots through the CO2 laser process. Dent Mater J 42(1):105–111. https://doi.org/10.4012/dmj.2022-070

Ergun-Kunt G, Sasany R, Koca MF, Özcan M. Comparison of silane heat treatment by laser and various surface treatments on microtensile bond strength of composite resin/lithium disilicate. Mater (Basel, Switzerland). 2021 14(24).

Feitosa FA, Tribst JPM, Araújo RM, Pucci CR (2021) Surface etching and silane heating using Er:YAG and Nd:YAG lasers in dental ceramic luted to human dentin. Int J Appl Ceram Technol 18(5):1408–1416

Ahrari F, Boruziniat A, Mohammadipour HS, Alirezaei M (2017) The effect of surface treatment with a fractional carbon dioxide laser on shear bond strength of resin cement to a lithium disilicate-based ceramic. Dent Res J (Isfahan) 14(3):195–202. https://doi.org/10.4103/1735-3327.208762

Yavuz T, Dilber E, Kara HB, Tuncdemir AR, Ozturk AN (2013) Effects of different surface treatments on shear bond strength in two different ceramic systems. Lasers Med Sci 28(5):1233–1239. https://doi.org/10.1007/s10103-012-1201-5

Garvie RC, Hannink RH, Pascoe RT. Ceramic steel? Nature [Internet]. 1975;258(5537):703–4. Available from: https://doi.org/10.1038/258703a0

Zhang Y, Lawn BR (2018) Novel zirconia materials in dentistry. J Dent Res 97(2):140–147

Pozzobon JL, Pereira GKR, Wandscher VF, Dorneles LS, Valandro LF (2017) Mechanical behavior of yttria-stabilized tetragonal zirconia polycrystalline ceramic after different zirconia surface treatments. Mater Sci Eng C Mater Biol Appl 77:828–835

Guazzato M, Albakry M, Ringer SP, Swain MV (2004) Strength, fracture toughness and microstructure of a selection of all-ceramic materials Part II Zirconia-based dental ceramics. Dent Mater 20(5):449–56. https://doi.org/10.1016/j.dental.2003.05.002

Zhang Y (2012) Overview: damage resistance of graded ceramic restorative materials. J Eur Ceram Soc 32(11):2623–2632

Kohorst P, Borchers L, Strempel J, Stiesch M, Hassel T, Bach F-W et al (2012) Low-temperature degradation of different zirconia ceramics for dental applications. Acta Biomater 8(3):1213–1220. Available from: https://www.sciencedirect.com/science/article/pii/S1742706111005034

Sanon C, Chevalier J, Douillard T, Kohal RJ, Coelho PG, Hjerppe J et al (2013) Low temperature degradation and reliability of one-piece ceramic oral implants with a porous surface. Dent Mater 29(4):389–397

Guazzato M, Albakry M, Ringer SP, Swain MV (2010) Strength, fracture toughness and microstructure of a selection of all-ceramic materials Part I Pressable and alumina glass-infiltrated ceramics. Dent Mater 20(2004):441–8

Zhang Z, Guo J, Sun Y, Tian B, Zheng X, Zhou M et al (2018) Effects of crystal refining on wear behaviors and mechanical properties of lithium disilicate glass-ceramics. J Mech Behav Biomed Mater 81:52–60

Lien W, Roberts HW, Platt JA, Vandewalle KS, Hill TJ, Chu TMG (2015) Microstructural evolution and physical behavior of a lithium disilicate glass-ceramic. Dent Mater 31(8):928–940

Lawson NC, Bansal R, Burgess JO (2016) Wear, strength, modulus and hardness of CAD/CAM restorative materials. Dent Mater 32(11):e275–e283

Prado AM, Pereira J, Silva FS, Henriques B, Nascimento RM, Benfatti CAM et al (2017) Wear of Morse taper and external hexagon implant joints after abutment removal. J Mater Sci Mater Med 28(5):65. Available from: http://link.springer.com/10.1007/s10856-017-5879-6

Pereira J, Morsch CS, Henriques B, Nascimento RM, Benfatti CA, Silva FS et al (2016) Removal torque and biofilm accumulation at two dental implant-abutment joints after fatigue. Int J Oral Maxillofac Implants 31(4):813–819

Denry I, Kelly JR (2008) State of the art of zirconia for dental applications. Dent Mater 24(3):299–307

Yazigi C, Schneider H, Chaar MS, Ruger C, Haak R, Kern M (2018) Effects of artificial aging and progression of cracks on thin occlusal veneers using SD-OCT. J Mech Behav Biomed Mater 88:231–237

Souza MT, Peñarrieta-Juanito GM, Henriques B, Silva FS, Novaes de Oliveira AP, Souza JCM (2018) Lithium-zirconium silicate glass-ceramics for restorative dentistry: Physicochemical analysis and biological response in contact with human osteoblast. Materialia 2:37–45. Available from: http://www.sciencedirect.com/science/article/pii/S2589152918300620

Funding

Open access funding provided by University of Zurich. This work was also supported by the Portuguese Foundation for Science and Technology (FCT) in the subject of the following projects: SFRH/BPD/123769/ 2016, UIDB/04436/2020, UIDP/04436/2020, and Project LaserMULTICER POCI-01–0145-FEDER-031035. Also, a financial support was provided by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), Brazil, regarding the following project: CAPES-PRINT/88881.310728/2018-01.

Author information

Authors and Affiliations

Contributions

Conceptualization: J.C.M.S. and B.H.; methodology: J.C.M.S. and B.H.; investigation: A.R.-E., O.C., and J.C.M.S.; writing—original draft preparation: J.C.M.S., A.R.-E., and O.C.; writing—review and editing: J.C.M.S., B.H., F.S., and M.O.; supervision: F.S., M.O., and J.C.M.S. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Souza, J.C.M., Raffaele-Esposito, A., Carvalho, O. et al. Surface modification of zirconia or lithium disilicate-reinforced glass ceramic by laser texturing to increase the adhesion of prosthetic surfaces to resin cements: an integrative review. Clin Oral Invest 27, 3331–3345 (2023). https://doi.org/10.1007/s00784-023-05016-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-023-05016-z