Abstract

A gold(III)-imprinted thiocyanato-functionalized silica network of type SBA-15 was prepared by co-condensation of tetraethoxysilane (TEOS) with thiocyanatopropyltriethoxysilane (TCTES) in the presence of Pluronic123 and Au(III) ions. Compared to the non-imprinted material, the imprint has a higher selectivity and adsorption capacity for Au(III). The maximum static adsorption capacity for Au(III) is 475 mg·g−1 for the ion-imprinted, and 62 mg·g−1 for the non-imprinted sorbent. The imprint was applied to the sorption of Au(III) from digested geological samples prior to its determination by graphite furnace atomic absorption spectrometry. Adsorption is fast and does not substantially prolong the analytical procedure. Under optimum conditions, the detection limit for Au(III) is 2 ng·g−1. The method was validated by analyzing certified reference materials, and results were in good agreement with certified values. The procedure was successfully applied to the separation and determination of gold in complex geological samples.

Schematic presentation of the preparation of ion-imprinted thiocyanato-functionalized mesoporous silica and its application for the preconcentration of gold from digested soils before its determination by slurry sampling graphite furnace atomic absorption spectrometry (GF AAS).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The numerous applications of gold, which is classified as a toxic element, necessitate the development of reliable and precise analytical procedures for its determination in various environmental samples [1].

Trace level determinations of gold are usually performed by using atomic absorption spectrometry (AAS) [2], inductively coupled plasma atomic emission spectrometry (ICP-OES) [3] and inductively coupled plasma mass spectrometry (ICP-MS) [4]. However, in many cases the presence of a complex sample matrix precludes obtaining reliable results by direct application of those spectrometric techniques. Extensive and difficult to eliminate interferences often necessitate separation/preconcentration of the analyte prior to its determination [5]. Among the separation techniques [6,7,8,9,10,11] used for preconcentration of gold solid phase extraction (SPE) seems to be especially attractive [12]. Various sorbents like nanotubes [13], activated carbon [14], Amberlite XAD resins [15], polyurethane foams [16], nanoclays [17] and silica gels [18] have been used for enrichment of Au(III) ions from different media.

Due to high selectivity towards the target ions, ion-imprinted polymers have gained popularity [19]. Synthesis of these materials is based on interactions between the imprinted ions and the functional monomers. Functional monomers agglomerate around the template creating a three-dimensional complex, which is joined with the polymeric matrix during the polymerization process. The cross-linking monomer or other matrix-making material is responsible for the spatial locking of the produced complex and the rigidity of the polymer, which determines the stability of the recognition sites. Subsequently the material is subjected to intense washing steps in order to remove the template. The selectivity of the polymeric material is related to the charge, coordination geometry, coordination number and size of the target ion [20]. Ion-imprinted polymers have various desireable properties such as: the high recognition, chemical and mechanical stability, ease and low cost of preparation as well as high adsorption selectivity towards specific analytes. However, these materials are characterized by low active surface, which confers low adsorption capacities towards specific metal ions [21].

To overcome this limitation the mesoporous organosilica matrix has been applied in this study to make new ion-imprinted materials. This concept is based upon ordered mesoporous silicas (like SBA-15), which have the desirable properties: high surface area (up to 1000 m2 g−1), large pore sizes and volumes (up to 30 nm, 1.3 cm3 g−1, respectively), good mechanical and chemical stability related to the thick pore walls (3.1–6.4 nm) and the homogeneity of pores [22]. Also the surface of the mesoporous silica can be easily modified. Since silica is a non-swelling material, unlike organic polymers, the recognition sites present on its surface are more stable, which results in higher selectivity towards target ions [23]. Ion-imprinted mesoporous organosilicas can be prepared using a sol-gel or grafting method. In the first case functional monomers co-condense with a silica precursor in the presence of imprinted ions, while in the latter mesoporous silica obtained in the presence of an ionic template is subjected to functionalization. The synthesis performed in the presence of the ionic template leads to the creation of recognition sites in the framework of the mesoporous silica sorbents [24].

The current study investigated the adsorption of gold ions on the Au(III)-imprinted thiocyanato-functionalized SBA-15 followed by slurry sampling GF AAS determination. The impact of basic parameters on the adsorption capacity of gold ions onto Au(III)-imprinted modified SBA-15 such as contact time, pH of the sample and presence of chosen co-existing ions was investigated. The optimized conditions were then applied for Au(III) enrichment from solutions of digested geological samples before Au determination by slurry sampling GF AAS. Certified reference materials were used to verify and validate the procedure.

Experimental

Reagents and materials

The following compounds were used: tetraethoxysilane (TEOS, 99%, ABCR, Karlsruhe, Germany, www.abcr.de), thiocyanatopropyltriethoxysilane (TCTES, 95%, Sigma-Aldrich, Poznan, Poland, www.sigmaaldrich.com), Pluronic P123 (P123, Sigma-Aldrich, Poznan, Poland, www.sigmaaldrich.com), hydrochloric acid (Merck, Darmstadt, Germany, www.merckgroup.com), hydrofluoric acid, nitric acid (Merck, Darmstadt, Germany, www.merckgroup.com), standard solutions of Pt(IV) (1000 mg L−1, Merck, Darmstadt, Germany, www.merckgroup.com), Au(III) (1000 mg L−1, Merck, Darmstadt, Germany, www.merckgroup.com), Pd(II) (1000 mg L−1, Merck, Darmstadt, Germany, www.merckgroup.com) and Ru(III) (1000 mg L−1, Merck, Darmstadt, Germany, www.merckgroup.com), gold chloride (99%, Sigma-Aldrich, Poznan, Poland, www.sigmaaldrich.com), ethanol (EtOH, 99.8%, POCH, Gliwice, Poland, http://www.poch.com.pl), sodium hydroxide (Merck, Darmstadt, Germany, www.merckgroup.com), sodium chloride (Acros Organics, Geel, Belgium, www.acros.com), potassium nitrate (POCH, Gliwice, Poland, http://www.poch.com.pl), thiourea (99%, Sigma-Aldrich, Poznan, Poland, www.sigmaaldrich.com). Throughout all analytical work, Milli-Q water was used (Millipore, Darmstadt, Germany, http://www.merckmillipore.com).

The certified reference materials Ma–2b (CANMET, Ottawa, Ontario, www.nrcan.gc.ca), SARM–7 (IAEA, Vienna, www.iaea.org), SRM 886 (NIST, Gaithersburg, Maryland, www.nist.gov) and WPR–1 (CANMET, Ottawa, Ontario, www.nrcan.gc.ca) were used to verify and validate the procedure. Samples of copper shale (POLK I and POLK II) and magmatic rocks (PIG I, PIG II, PIG III and PIG IV) were obtained from the Central Laboratory of the Polish Geological Institute (www.pgi.gov.pl).

Instruments

Nitrogen adsorption/desorption isotherms were measured at −196 °C using an ASAP-2405 N analyzer (Micromeritics Corp., Norcross, Georgia, USA, www.micromeritics.com). Powder X-ray diffraction (XRD) patterns were recorded using a Empyrean (Panalytical, Almelo, Netherlands, www.malvernpanalytical.com) diffractometer (CuKα radiation) with 0.02° size step and 10 s time step covering the range of 0.5 < 5.0° at room temperature. X-ray photoelectron spectroscopy (XPS) spectra were collected using a Multi-Chamber Analytical System (Prevac, Rogów, Poland, www.prevac.pl) with monochromated Kα Al radiation (1486.6 eV) (Gammadata, Scienta, Uppsala, Sweden, www.scienta.se) and an X-ray power of 450 W. The binding energy scale was referenced against C1s = 284.7 eV line. The vacuum in the analysis chamber was better than 1.5 ∙ 10−7 Pa.

Measurements of gold concentrations in the liquid phase of the studied adsorption systems, depending on the gold concentration, were carried out using a Varian (Mulgrave, Victoria, Australia, www.agilent.com) SpectrAA atomic absorption spectrometer equipped with air/acetylene flame or Varian (Mulgrave, Victoria, Australia, www.agilent.com) SpectrAA 800 atomic absorption spectrometer equipped with a GTA 100 graphite furnace and Zeeman background correction. The temperature program used for determination of gold in liquids and slurries was: drying: 120 °C for 35 s, pyrolysis: 1000 °C for 10 s, atomization: 2600 °C for 5 s.

Synthesis of adsorbent

Ion-imprinted materials were synthesized via a sol-gel process by a one-pot route synthesis. In the model synthesis, 2 g of P123 was dissolved in 72 mL of 1.6 mol L−1 HCl under vigorous stirring at 40 °C. After 8 h of stirring 0.15 g of gold chloride was added. After dissolution of the solid 18 mmol (19 mmol) of TEOS was added dropwise, followed by 2 mmol (1 mmol) of TCTES. The resulting mixture was stirred for 24 h at 40 °C and aged at 100 °C for next 48 h. The solids were filtered. Finally, the solid material was purified from Pluronic123 by triple extraction with acidified ethanol (99.8%) at 78 °C, whereas the template Au(III) ions were removed from the material using 0.5 mol L−1 thiourea in 5% HCl, until Au was not detected in the leaching solution. The process was monitored by GF AAS. The control sorbents were similarly synthesized but in absence of gold chloride. The ion-imprinted materials were labeled Au(III)/S1(TEOS:TCTES 18:2) and Au(III)/S2 (TEOS:TCTES 19:1), whereas non-imprinted materials were labeled S1 (TEOS:TCTES 18:2) and S2 (TEOS:TCTES 19:1).

Adsorption and selectivity measurement

In every adsorption experiment, 50 mg of adsorbent and 50 mL of Au(III) solution were stirred at 25 ± 0.5 °C. After the adsorption equilibrium had been attained, the solution was separated from the sorbent by centrifugation and gold was determined by F AAS.

The adsorption of Au(III) onto studied materials a (mg g−1), was calculated as follows:

where ci is the initial Au(III) concentration (mg L−1), c is the equilibrium Au(III) concentration (mg L−1), V is the volume of the solution (L) and m is the mass of the adsorbent (g).

The selectivity of Au(III) adsorption in the presence of Pd(II), Pt(IV) and Ru(III) ions was tested for Au(III)/S1 and S1 sorbents using the same concentrations of Au(III) and competitive ions. The distribution coefficients of Pd(II), Pt(IV), Ru(III) and Au(III) ions can be determined as follows:

where ci is the initial concentration (mg L−1), c is the equilibrium concentration (mg L−1), V is the volume of the solution (L) and m is the mass of the adsorbent (g).

The selectivity coefficient for the sorption Au(III) in the presence of competition ions is given as:

where X represents Pd(II), Ru(III), Pt(IV). Selectivity coefficient represents Au(III) adsorption selectivity when there are other metal ions present in aqueous solution. A larger k suggest a higher selectivity for the Au(III) ions. A relative selectivity coefficient can be defined as:

A higher relative selectivity coefficient indicates stronger adsorption affinity and better selectivity of imprinted adsorbents for the Au(III) ions compared to non-imprinted material.

Determination of gold

For the determination of gold in geological samples (POLK I, POLK II, PIG I, PIG II, PIG III, PIG IV) and certified reference materials, 0.1 g of a given dried sample was weighed, placed into Teflon vessel and treated with 10 mL of aqua regia. Samples were digested in the microwave system (Mars 5, CEM Corp, Matthews, North Carolina, USA, http://cem.com) at 190 °C and 1.24 MPa. The digested samples were made up to 50 mL with Milli-Q water and transferred to 100 mL beakers and evaporated almost to dryness. Subsequently 2 mL of 30% HCl were added and samples were again evaporated, with this step repeated several times to convert gold to chloride complexes. The blanks were prepared in the same way. The samples were then made up to 50 mL with Milli-Q water and pH was adjusted to 2 by addition of sodium hydroxide. The solutions were shaken with 0.02 g of the Au(III)/S1 for 3 h. The Au-loaded sorbent was separated from the solution by filtration and dried at 105 °C to constant weight. The slurries for GF AAS analysis were prepared by mixing of 0.01 g of dried Au-loaded Au(III)/S1 with 0.1 mL of 40% HF in Eppendorf vessels and after 15 min with 0.9 mL of 5% HCl. Since the complete dissolution of sorbent was achieved the contents of Eppendorf vessels were not homogenized before GF AAS analysis.

Results

Choice of materials

The synthesis of Au(III) ion-imprinted thiocyanato-functionalized silicas of SBA-15 type was undertaken because the designed material was expected to have high specific surface area, high hydrothermal stability, easily accessible adsorption sites and exhibit high selectivity and adsorption capacity for Au(III) ions. The advantage of the Au(III) ion-imprinted thiocyanato-functionalized silicas synthesized in the presence of P123 micelles are the wide, cylindrical, hexagonally ordered mesopores ensuring the effective diffusion of the adsorbate and homogenously distributed Au(III) shape-matched adsorption centers. Due to the presence of the silica skeleton, the materials do not swell, which means that the adsorption centers are more stable than in the case of polymer sorbents. The important aspect influencing the synthesis of ion-imprinted SBA-15 is the simplicity of the preparation described in the “Synthesis of adsorbent” section. In the reaction mixture Pluronic 123 triblock copolymer forms a hexagonal micellar template on which surface co-condensation of TEOS and TCTES in the presence if AuCl3 occurs. SBA-15 material with pores filled with P123 and –SCN groups bonded with gold is obtained. To remove P123 and gold templates, acidified ethanol and thiourea are used, respectively.

Characterization

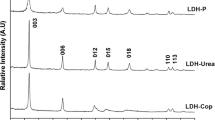

The porosity and the degree of order of the materials were monitored by measurements of nitrogen adsorption/ desorption isotherms and XRD analysis (See Electronic Supporting Material (ESM)).

As presented in Table 1, the values of SBET for S1 and S2 are equal to 683 and 668 m2 g−1, respectively. Although the increase of the amount of TCTES in the reaction mixture used for synthesis does not cause a decrease of the active surface, it leads to the diminution of the pore volumes and their diameter.

The addition of AuCl3 to the reaction mixture results in a collapsed porous structure. However, the SBET of Au(III)/S1 and Au(III)/S2 is still high and equal to 290 and 389 m2 g−1, respectively.

Based on the XRD patterns (See ESM) for pristine SBA-15 and thiocyanato-functionalized materials S1 and S2 it can be concluded that the increase of the molar ratio of TCTES results in deterioration of the ordering of the material. Moreover, the addition of Au(III) ions leads to further deterioration of the degree of order, that is reflected in the absence of the peak chcaracteristic for hexagonall P6mm symmetry on the Au(III)/S1 pattern.

Adsorption conditions optimisation

In order to ensure the highest adsorption of Au(III) ions from digested geological samples onto synthesized materials the pH value of the solution and contact time were optimized (ESM). In short, the following experimental conditions were found to give the best adsorption results:

-

a).

pH value

The adsorption of Au(III) onto Au(III)/S1 and Au(III)/S2 is very high in the pH range 0.5 to 4.2. In the case of S1 adsorption is also high in the pH range between 2.0 and 4.2, whereas for S2 highest adsorption values are obtained in the pH range between 3.0 and 4.2. For further adsorption experiments with application of S1, Au(III)/S1 and Au(III)/S2 the selected pH was 2.0 and for S2 pH selected was 3.0.

-

b).

contact time

For sorbents S2 and Au(III)/S2 10 h are required to reach adsorption equilibrium. In the case of Au(III)/S1 and S1 the times needed for reaching equilibrium are about 3 and 20 h, respectively.

Adsorption capacity

The adsorptions isotherms of Au(III) from aqueous solutions onto studied thiocyanato-functionalized materials are shown in Fig. 1. The adsorption capacities are directly proportional to the amount of TCTES used for sorbent synthesis. Thus the number of the adsorption sites is most likely correlated with the concentration of -SCN groups on the sorbent surface. However, their accessibility for Au(III) ions is probably limited and for this reason the key factor affecting the sorption ability and capacity of sorbent is the presence of Au(III) ion-imprinted sites, which eliminate the steric hindrance and allow for efficient binding of Au(III) with the sorbent surface. The maximum static adsorption capacity of the imprinted materials is above 7 times higher than that for non-imprinted sorbents. The highest adsorption of 475 mg g−1 was obtained for Au(III)/S1 sorbent; this value significantly exceeds adsorption capacities reported in the literature and summarized in Table 3. Based on its highest adsorption capacity, Au(III)/S1 material was chosen for subsequent analytical applications.

Effect of interfering ions

Due to the common use of aqua regia for digestion of analysed solid samples the influence of nitrates and chlorides on the adsorption of Au(III) was also investigated for Au(III)/S1 and S1 materials. It was found that the presence of chlorides and nitrates does not hinder Au(III) adsorption from solutions obtained after acidic digestion of environmental solid samples. Detailed information concenrning the effect of the above-mentioned anions on the Au(III) adsorption is presented in the ESM.

Desorption studies

The desorption of Au using different concentrations of hydrochloric acid, nitric acid and thiourea was performed by applying the batch method. The Au desorption efficiency from Au(III)/S1 material was 18% for 10 mol L−1 HCl, 33% for 14 mol L−1 HNO3 and 70% for 1 mol L−1 thiourea.

Due to incomplete desorption of Au the slurry sampling graphite furnace atomic absorption spectrometry was proposed for determination of gold in real samples after its enrichment onto Au(III)/S1. Detailed information concenrning the desorption studies is presented in the ESM.

XPS studies

In this work XPS was used to investigate the mechanism of the Au(III) ions adsorption onto the thiocyanato-functionalized SBA-15 and their chemical transformations on its surface. In Fig. 2a XPS spectrum for Au-loaded Au(III)/S1 material is presented. In addition to peaks characteristic for thiocyanato-functionalized silica also peaks assigned to gold are very distinctive. The deconvolution of Au 4f region (Fig. 2b) allows distinguishing the three doublets for Au 4f 7/2 and Au 4f 5/2 transitions at 84.3 and 88.0 eV (first doublet), 85.4 and 89.1 eV (second) and 86.4 and 90.1 eV (third). These correspond to metallic Au, Au(I) and Au(III), respectively. The predominant form was metallic gold, whereas Au(I) and Au(III) was only about 8% of the total Au. Based on the Au 4f region spectrum of Au-loaded Au(III)/S1, it can be concluded that the adsorption of Au(III) is associated with its reduction to Au(0). While comparing the S 2p regions of S1 (Fig. 2c), Au(III)/S1 (Fig. 2d) and Au-loaded Au(III)/S1 (Fig. 2e), it can be seen that for S1 material only sulphur in –C-S-CN groups is present (S 2p 3/2 and S 2p ½ at 163.9 and 165.1 eV, respectively). For two other materials also S bonded with Au (S 2p 3/2 and S 2p ½ at 162.3 and 163.4 eV, respectively) and sulphates (S 2p 3/2 and S 2p ½ at 168.2 and 169.4 eV, respectively) appears wherein the ratio of S2−:S0:S6+ is 12:76:12 for Au(III)/S1 and 26:56:18 for Au-loaded Au(III)/S1. Thus adsorption of Au(III) results in disproportionation of sulphur. Nitrogen irrespective of the type of sorbent is present as amine, imine and quaternary N which is reflected as three peaks in N 1 s region of XPS spectrum. The N 1 s region for Au-loaded Au(III)/S1 is presented in Fig. 2f.

Selectivity experiment

To measure the selectivity of the Au(III)/S1 competitive ion adsorption studies were performed using the double mixture solutions of Au(III)/Pt(IV), Au(III)/Pd(II) and Au(III)/Ru(III). The Pt(IV), Pd(II) and Ru(III) ions were chosen due to their similar ionic properties and ionic radii. The distribution coefficients, selectivity coefficients and relative selectivity coefficients are summarized in Table 2.

The distribution coefficients and selectivity coefficients in ion-imprinted sorbent revealed a significant increase for Au(III) adsorption on Au(III)/S1. Additionally, relative selectivity coefficients were greater than 16, which indicates that Au(III)/S1 possess very high selectivity towards Au(III) ions.

Analytical features and application

The calibration plots for gold were obtained using a blank and 5 calibration solutions in the range 5–100 μg L−1. The comparison of calibration plot slopes for modified SBA-15 slurries and aqueous solutions confirmed that it was acceptable to use aqueous standards solution for quantitative determination of gold.

The detection limits for gold determination (LOD) (calculated as the average of signals for seven blank samples plus 3 times the standard deviation of the signals) in solution obtained after digestion of samples was 0.01 μg L−1 which corresponds to 2 ng g−1 in conversion to solid. The characteristic mass (amount providing a signal of 0.0044 s) calculated from the integrated absorbance was 13.8 pg. For a comparison, some previously reported procedures for the determination of gold are summarized in Table 3. As shown, Au(III)/S1 material is characterized by the highest sorption capacity.

The Au(III)TCTES/S1 has been utilized for enrichment and determination of Au in geological samples in view of the great selectivity and sorption capacity for Au(III) ions. The procedure was validated by the application of certified reference materials (Ma-2b, SRM-886, WPR-1, UMT-1 and SARM-7). Additionally, this procedure was applied for determination and preconcentration of gold in magmatic rocks and copper shale samples. The analytical data are shown in Table 4. The precision of gold determination in the geological samples by the presented method can be regarded as acceptable. Moreover, the close agreement of the determined content of Au in reference materials by this method with values reported in the certificates confirms the accuracy of the the method.

The method is fairly simple for routine applications and the only limitation found is the time-consuming removal of Au(III) template. However, after a prolonged process of template removal, the obtained material is characterised by high selectivity and extremely high adsorption affinity against Au(III) ions.

Conclusion

A new selective and sensitive method for determination of trace levels of gold was developed. Au(III)-imprinted thiocyanato-functionalized SBA-15 was used as an adsorbent for gold enrichment from digested geological samples before its determination by slurry sampling GF AAS technique. This new gold ions imprinted material was prepared by a one-pot route synthesis by co-condensation of TEOS with TCTES in the presence of Pluronic123 surfactant and gold ions. The Au(III)/S1 exhibited higher adsorption capacity and selectivity for Au(III) ions in comparison with the control adsorbent prepared in the similar process but without Au(III) ions. The presence of ion-imprinted adsorption sites caused an increase of the rate of Au(III) adsorption and shortened the time needed to reach adsorption equilibrium compared to the control adsorbent. The ion-imprinted material exhibited an extremely high (475 mg g−1) adsorption capacity towards Au(III) ions. The adsorption of Au(III) onto ion-imprinted thiocyanato-functionalized SBA-15 was mainly the result of the reduction of Au(III) ions to metallic gold. The application of 10 mol L−1 HCl and 14 mol L−1 HNO3 or thiourea solutions does not cause the complete desorption of gold adsorbed onto studied ion-imprinted organosilica material. Thus slurry sampling GF AAS technique was used for gold determination after its preconcentration onto Au(III)-imprinted thiocyanato-functionalized SBA-15. The method was successfully applied to the analysis of trace gold in geological samples of various matrices. The precision and accuracy of the method were satisfactory for the intended use.

References

Chaves JDS, Damasceno JL, Paula MC, de Oliveira PF, Azevedo GC, Matos RC, Lourenço MC, Tavares DC, Silva H, Fontes AP, de Almeida MV (2015) Synthesis, characterization, cytotoxic and antitubercular activities of new gold(I) and gold(III) complexes containing ligands derived from carbohydrates. BioMetals 28:845–860

Moghaddam FH, Taher MA, Behzadi M, Naghizadeh M (2015) Modified carbon nanotubes as a sorbent for solid-phase extraction of gold and its determination by graphite furnace atomic absorption spectrometry. Microchim Acta 182:2123–2129

Zhang G, Tian M (2015) A rapid and practical strategy for the determination of platinum, palladium, ruthenium, rhodium, iridium and gold in large amounts of ultrabasic rock by inductively coupled plasma optical emission spectrometry combined with ultrasound extraction. Opt Spectrosc 118:513–518

Turkin AA, Chizhov AS, Seregina IF, Filatova DG, Karpov YA (2015) Determination of gold and antimony in advanced materials based on tin dioxide using inductively coupled plasma mass spectrometry. Inorg Mater 51:1420–1422

Xue D, Wang H, Liu Y, Shen P (2015) Multicolumn solid phase extraction with hybrid adsorbent and rapid determination of Au, Pd and Pt in geological samples by GF-AAS. Miner Eng 81:149–151

Mowafy EA, Mohamed D (2016) Extraction and separation of gold(III) from hydrochloric acid solutions using long chain structurally tailored monoamides. Sep Purif Technol 167:146–153

Sacmaci S, Kartal S, Kalkan G (2015) Determination of gold in various environment samples by flame atomic absorption spectrometry using dispersive liquid–liquid microextraction sampling. Croat Chem Acta 88:113–119

Zhou X, Wang P, Zhao Y, Ju S, Liu M (2015) Cloud point extraction using Tergitol TMN-6 of gold (III) in real samples by flame atomic absorption spectrometry determination. J Chem Soc Pak 37:680–686

Xie RF, Hu QF, Yang GY, Chen J, Han YS, Zhao YH, Li Z (2016) Solid-phase extraction gold from alkaline cyanide solution with quaternary ammonium surfactant. Rare Metals 35:282–288

Takada K, Ashino T, Itagaki T, Morimoto Y, Wagatsuma K, Abiko K (2002) Determination of trace element quantities in ultra high-purity iron by spectrochemical analysis after chemical separation. Mater Trans 43:105–110

Afzali D, Daliri Z, Taher MA (2014) Flame atomic absorption spectrometry determination of trace amount of gold after separation and preconcentration onto ion-exchange polyethylenimine coated on Al2O3. Arab J Chem 7:770–774

Ebrahimzadeh H, Moazzen E, Amini MM, Sadeghi O (2013) Novel ion-imprinted polymer coated on nanoporous silica as a highly selective sorbent for the extraction of ultratrace quantities of gold ions from mine stone samples. Microchim Acta 180:445–451

Duran A, Tuzen M, Soylak M (2015) Separation and enrichment of gold in water. Geological and environmental samples by solid phase extraction on multiwalled carbon nanotubes prior to its determination by flame atomic absorption spectrometry. J AOAC Int 98:1733–1738

Soylak M, Elci L, Dogan M (2000) A sorbent extraction procedure for the preconcentration of gold, silver and palladium on an activated carbon column. Anal Lett 33:513–525

Senturk HB, Gundogdu A, Bulut VN, Duran C, Soylak M, Elci L, Tufekci M (2007) Separation and enrichment of gold(III) from environmental samples prior to its flame atomic absorption spectrometric determination. J Hazard Mater 149:317–323

Xue D, Wang H, Liu Y, Shen P, Sun J (2016) Cytosine-functionalized polyurethane foam and its use as a sorbent for the determination of gold in geological samples. Anal Methods 8:29–39

Afzali D, Mostafavi A, Mirzaei M (2010) Preconcentration of gold ions from water samples by modified organo-nanoclay sorbent prior to flame atomic absorption spectrometry determination. J Hazard Mater 181:957–961

Bozkurt SS, Merdivan M (2009) Solid phase extraction of gold(III) on silica gel modified with benzoylthiourea prior to its determination by flame atomic absorption spectrometry. Environ Monit Assess 158:15–21

Fu J, Chen L, Li J, Zhang Z (2015) Current status and challenges of ion imprinting. J Mater Chem A 3:13598–13627

Fan HT, Fan X, Li J, Guo M, Zhang D, Yan F, Sun T (2012) Selective removal of arsenic(V) from aqueous solution using a surface-ion-imprinted amine-functionalized silica gel sorbent. Ind Eng Chem Res 51:5216–5223

Leśniewska B, Godlewska-Żyłkiewicz B, Wilczewska AZ (2012) Separation and preconcentration of trace amounts of Cr(III) ions on ion imprinted polymer for atomic absorption determinations in surface water and sewage samples. Microchem J 105:88–93

Liu Y, Liu Z, Dai J, Gao J, Xie J, Yan Y (2011) Selective adsorption of Co (II) by mesoporous silica SBA-15-supported surface ion imprinted polymer: kinetics, isotherms and thermodynamics studies. Chin J Chem 29:387–398

Buhani, Narsito, Nuryono, Kunarti ES (2010) Production of metal ion imprinted polymer from mercapto–silica through sol–gel process as selective adsorbent of cadmium. Desalination 251:83–89

Lofgreen JE, Moudrakovski IL, Ozin GA (2011) Molecularly imprinted mesoporous organosilica. ACS Nano 5:2277–2287

Bayat M, Beyki MH, Shemirani F (2015) One-step and biogenic synthesis of magnetic Fe3O4–Fir sawdust composite: application for selective preconcentration and determination of gold ions. J Ind Eng Chem 21:912–919

Sabermahani F, Taher MA, Bahrami H (2012) Separation and preconcentration of trace amounts of gold from water samples prior to determination by flame atomic absorption spectrometry. Arab J Chem 9:1700–1705

Awuala MR, Ismael M (2014) Efficient gold(III) detection, separation and recovery from urban mining waste using a facial conjugate adsorbent. Sensors Actuators B Chem 196:457–466

Chen S, Guo X, Zhang Y, Lu D (2014) Preconcentration of trace gold and silver on titanium dioxide nanotubes and their determination by inductively coupled plasma mass spectrometry. Anal Methods 6:3668–3673

Ye J, Liu S, Tian M, Li W, Hu B, Zhou W, Jia Q (2014) Preparation and characterization of magnetic nanoparticles for the on-line determination of gold, palladium and platinum in mine samples based on flow injection micro-column preconcentration coupled with graphite furnace atomic absorption spectrometry. Talanta 118:231–237

Beyki MH, Shirkhodaie M, Shemirani F (2016) Polyol route synthesis of a Fe3O4@CuS nanohybrid for fast preconcentration of gold ions. Anal Methods 8:1351–1358

Ebrahimzadeh H, Moazzen E, Amini MM, Sadeghi O (2013) Novel ion-imprinted polymer coated multiwalled carbon nanotubes as a high selective sorbent for determination of gold ions in environmental samples. Chem Eng J 215-216:315–321

Moazzen E, Ebrahimzadeh H, Amini MM, Sadeghi O (2013) A high selective ion-imprinted polymer grafted on a novel nanoporous material for efficient gold extraction. J Sep Sci 36:1826–1833

Jalilian N, Ebrahimzadeh H, Asgharinezhad AA, Molaei K (2017) Extraction and determination of trace amounts of gold(III), palladium(II), platinum(II) and silver(I) with the aid of a magnetic nanosorbent made from Fe3O4-decorated and silica-coated graphene oxide modified with a polypyrrole-polythiophene copolymer. Microchim Acta 184:2191–2200

Acknowledgements

The authors are grateful to Professor Dr. Joseph H. Rule from Old Dominion University (Norfolk. VA) USA and his wife Dr. Anna M. Rule for their help with the English preparation of the manuscript.

The research was carried out with the equipment purchased through the financial support of the European Regional Development Fund in the framework of the Polish Innovation Economy Operational Program (contract no. POIG.02.01.00-06-024/09 Center of Functional Nanomaterials).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author(s) declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 288 kb)

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Dobrzyńska, J., Dąbrowska, M., Olchowski, R. et al. An ion-imprinted thiocyanato-functionalized mesoporous silica for preconcentration of gold(III) prior to its quantitation by slurry sampling graphite furnace AAS. Microchim Acta 185, 564 (2018). https://doi.org/10.1007/s00604-018-3106-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00604-018-3106-x