Abstract

In industry, particle-laden fluids, such as particle-functionalized inks, are constructed by adding fine-scale particles to a liquid solution, in order to achieve desired overall properties in both liquid and (cured) solid states. However, oftentimes undesirable particulate agglomerations arise due to some form of mutual-attraction stemming from near-field forces, stray electrostatic charges, process ionization and mechanical adhesion. For proper operation of industrial processes involving particle-laden fluids, it is important to carefully breakup and disperse these agglomerations. One approach is to target high-frequency acoustical pressure-pulses to breakup such agglomerations. The objective of this paper is to develop a computational model and corresponding solution algorithm to enable rapid simulation of the effect of acoustical pulses on an agglomeration composed of a collection of discrete particles. Because of the complex agglomeration microstructure, containing gaps and interfaces, this type of system is extremely difficult to mesh and simulate using continuum-based methods, such as the finite difference time domain or the finite element method. Accordingly, a computationally-amenable discrete element/discrete ray model is developed which captures the primary physical events in this process, such as the reflection and absorption of acoustical energy, and the induced forces on the particulate microstructure. The approach utilizes a staggered, iterative solution scheme to calculate the power transfer from the acoustical pulse to the particles and the subsequent changes (breakup) of the pulse due to the particles. Three-dimensional examples are provided to illustrate the approach.

Similar content being viewed by others

Notes

Also, printed electronics, using processes such as high-resolution electrohydrodynamic-jet printing are also emerging as viable methods. For overviews, see Wei and Dong [62], who also develop specialized processes employing phase-change inks. Such processes are capable of producing micron-level footprints for high-resolution additive manufacturing.

Even if this wavelength to particle size ratio is not present, ray representation of p-waves is still often used, and can be considered as a way to approximately track the propagation of energy, however, without the ability to capture diffraction properly.

The product, \(||{\varvec{v}}^c_{j,\tau }-{\varvec{v}}^c_{i,\tau }||\Delta t\) has dimensions of length.

References

Afazov SM, Becker AA, Hyde TH (2012) Mathematical modeling and implementation of residual stress mapping from microscale to macroscale finite element models. J Manuf Sci Eng 134(2):021001-021001-11

Arbelaez D, Zohdi TI, Dornfeld D (2008) Modeling and simulation of material removal with particulate flow. Comput Mech 42:749–759

Arbelaez D, Zohdi TI, Dornfeld D (2009) On impinging near-field granular jets. Int J Numer Methods Eng 80(6):815–845

Aurich JC, Dornfeld DA (2010) In: JC Aurich, DA Dornfeld (eds) Proceedings of the CIRP international on burrs: analysis, control and removal. Springer, Berlin

Avci B, Wriggers P (2012) A DEM-FEM coupling approach for the direct numerical simulation of 3D particulate flows. J Appl Mech 79:010901-1–010901-7

Avila M, Gardner J, Reich-Weiser C, Tripathi Vijayaraghavan A, Dornfeld DA (2005) Strategies for burr minimization and cleanability in aerospace and automotive manufacturing. SAE Technical Paper 2005-01-3327. doi:10.4271/2005-01-3327

Avila M, Reich-Weiser C, Dornfeld DA, McMains S (2006) Design and manufacturing for cleanability in high performance cutting. CIRP 2nd international conference on high performance cutting, paper number 63. Vancouver

Bagherifard S, Giglio M, Giudici L, Guagliano M (2010) Experimental and numerical analysis of fatigue properties improvement in a titanium alloy by shot peening. In: Proceedings of the ASME. 49163, ASME 2010 10th biennial conference on engineering systems design and analysis, vol 2, pp 317–322

Bolintineanu DS, Grest GS, Lechman JB, Pierce F, Plimpton SJ, Schunk PR (2014) Particle dynamics modeling methods for colloid suspensions. Comput Part Mech 1(3):321–356

Borejko P, Chen CF, Pao YH (2011) Application of the method of generalized rays to acoustic waves in a liquid wedge over elastic bottom. J Comput Acoust 9(01):41–68

Boyer Timothy H (1988) The force on a magnetic dipole. Am J Phys 56(8):688–692. doi:10.1119/1.15501 Bibcode:1988AmJPh.56.688B

Cante J, Davalos C, Hernandez JA, Oliver J, Jonsen P, Gustafsson G, Haggblad HA (2014) PFEM-based modeling of industrial granular flows. Comput Part Mech 1(1):47–70

Carbonell JM, Onate E, Suarez B (2010) Modeling of ground excavation with the particle finite element method. J Eng Mech ASCE 136:455–463

Chen Z, Yang F, Meguid SA (2014) Realistic finite element simulations of arc-height development in shot-peened Almen strips. J Eng Mater Technol 136(4):041002-041002-7

Choi S, Park I, Hao Z, Holman HY, Pisano AP, Zohdi TI (2010) Ultra-fast self-assembly of micro-scale particles by open channel flow. Langmuir 26(7):4661–4667

Choi S, Stassi S, Pisano AP, Zohdi TI (2010) Coffee-ring effect-based three dimensional patterning of micro, nanoparticle assembly with a single droplet. Langmuir 26(14):11690–11698

Choi S, Jamshidi A, Seok TJ, Zohdi TI, Wu MC, Pisano AP (2012) Fast, high-throughput creation of size-tunable micro, nanoparticle clusters via evaporative self-assembly in picoliter-scale droplets of particle suspension. Langmuir 28(6):3102–3111

Ciampini D, Spelt JK, Papini M (2003) Simulation of interference effects in particle streams following impact with a flat surface. Part I. Theory and analysis. Wear 254:237–249

Ciampini D, Spelt JK, Papini M (2003) Simulation of interference effects in particle streams following impact with a flat surface. Part II. Parametric study and implications for erosion testing and blast cleaning. Wear 254:250–264

Cullity BD, Graham CD (2008) Introduction to magnetic materials (2 ed). Wiley-IEEE Press, p 103. ISBN 0-471-47741-9

Demko M, Choi S, Zohdi TI, Pisano AP (2012) High resolution patterning of nanoparticles by evaporative self-assembly enabled by in-situ creation and mechanical lift-off of a polymer template. Appl Phys Lett 99:253102-1–253102-3

Demko MT, Cheng JC, Pisano AP (2010) High-resolution direct patterning of gold nanoparticles by the microfluidic molding process. Langmuir, pp 412–417

Donev A, Cisse I, Sachs D, Variano EA, Stillinger F, Connelly R, Torquato S, Chaikin P (2004a) Improving the density of jammed disordered packings using ellipsoids. Science 303:990–993

Donev A, Stillinger FH, Chaikin PM, Torquato S (2004b) Unusually dense crystal ellipsoid packings. Phys Rev Lett 92:255506

Donev A, Torquato S, Stillinger F (2005a) Neighbor list collision-driven molecular dynamics simulation for nonspherical hard particles-I. Algorithmic details. J Comput Phys 202:737

Donev A, Torquato S, Stillinger F (2005b) Neighbor list collision-driven molecular dynamics simulation for nonspherical hard particles-II. Application to ellipses and ellipsoids. J Comput Phys 202:765

Donev A, Torquato S, Stillinger FH (2005c) Pair correlation function characteristics of nearly jammed disordered and ordered hard-sphere packings. Phys Rev E 71:011105

Duran J (1997) Sands, powders and grains. An introduction to the physics of granular matter. Springer, Berlin

Elbella A, Fadul F, Uddanda SH, Kasarla NR (2012) Influence of shot peening parameters on process effectiveness. In: Proceedings of the ASME. 45196, vol 3: design, materials and manufacturing, parts A, B, and C, pp 2015–2021

Feynman RP, Leighton RB, Sands M (2006) The Feynman Lectures on Physics 2. ISBN 0-8053-9045-6

Frenklach M, Carmer CS (1999) Molecular dynamics using combined quantum & empirical forces: application to surface reactions. Adv Class Traject Methods 4:27–63

Gomes-Ferreira C, Ciampini D, Papini M (2004) The effect of inter-particle collisions in erosive streams on the distribution of energy flux incident to a flat surface. Tribol Int 37:791–807

Ghobeity A, Spelt JK, Papini M (2008) Abrasive jet micro-machining of planar areas and transitional slopes. J Micromech Microeng 18:055014

Ghobeity A, Krajac T, Burzynski T, Papini M, Spelt JK (2008) Surface evolution models in abrasive jet micromachining. Wear 264:185–198

Haile JM (1992) Molecular dynamics simulations: elementary methods. Wiley, New York

Hase WL (1999) Molecular dynamics of clusters, surfaces, liquids, & interfaces. Advances in classical trajectory methods, vol 4. JAI Press, Greenwich

Garg S, Dornfeld D, Berger K (2010) Formulation of the chip cleanability mechanics from fluid transport. In: Aurich JC, Dornfeld DA (eds) Burrs analysis, control and removal. Springer, Berlin, pp 229–236

Jackson JD (1998) Classical electrodynamics, 3rd edn. Wiley, New York

Kansaal A, Torquato S, Stillinger F (2002) Diversity of order and densities in jammed hard-particle packings. Phys Rev E 66:041109

Johnson K (1985) Contact mechanics. Cambridge University Press, Cambridge

Luo L, Dornfeld DA (2001) Material removal mechanism in chemical mechanical polishing: theory and modeling. IEEE Trans Semicond Manuf 14(2):112–133

Luo L, Dornfeld DA (2003) Effects of abrasive size distribution in chemical-mechanical planarization: modeling and verification. IEEE Trans Semicond Manuf 16:469–476

Luo L, Dornfeld DA (2003) Material removal regions in chemical mechanical planarization for sub-micron integration for sub-micron integrated circuit fabrication: coupling effects of slurry chemicals, abrasive size distribution, and wafer-pad contact area. IEEE Trans Semicond Manuf 16:45–56

Luo L, Dornfeld DA (2004) Integrated modeling of chemical mechanical planarization of sub-micron IC fabrication. Springer, Berlin

Labra C, Onate E (2009) High-density sphere packing for discrete element method simulations. Commun Numer Methods Eng 25(7):837–849

Leonardi A, Wittel FK, Mendoza M, Herrmann HJ (2014) Coupled DEM-LBM method for the free-surface simulation of heterogeneous suspensions. Comput Part Mech 1(1):3–13

Markauskasa D, Maknickas A, Kacianauskas R (2015) Simulation of acoustic particle agglomeration in poly-dispersed aerosols. Proced Eng 102:1218–1225

Martin P (2009) Handbook of deposition technologies for films and coatings, 3rd edn. Elsevier, Oxford

Martin P (2011) Introduction to surface engineering and functionally engineered materials. Scrivener and Elsevier. J Vac Sci Technol A2(2):500

Moelwyn-Hughes EA (1961) Physical chemistry. Pergamon, London

Onate E, Idelsohn SR, Celigueta MA, Rossi R (2008) Advances in the particle finite element method for the analysis of fluid-multibody interaction and bed erosion in free surface flows. Comput Methods Appl Mech Eng 197(19–20):1777–1800

Onate E, Celigueta MA, Idelsohn SR, Salazar F, Surez B (2011) Possibilities of the particle finite element method for fluid-soil-structure interaction problems. Comput Mech 48:307–318

Onate E, Celigueta MA, Latorre S, Casas G, Rossi R, Rojek J (2014) Lagrangian analysis of multiscale particulate flows with the particle finite element method. Comput Part Mech 1(1):85–102

Rapaport DC (1995) The art of molecular dynamics simulation. Cambridge University Press, Cambridge

Rojek J, Labra C, Su O, Onate E (2012) Comparative study of different discrete element models and evaluation of equivalent micromechanical parameters. Int J Solids Struct 49:1497–1517. doi:10.1016/j.ijsolstr.2012.02.032

Rojek J (2014) Discrete element thermomechanical modelling of rock cutting with valuation of tool wear. Comput Part Mech 1(1):71–84

Schlick T (2000) Molecular modeling & simulation. An interdisciplinary guide. Springer, New York

Stillinger FH, Weber TA (1985) Computer simulation of local order in condensed phases of silicon. Phys Rev B 31:5262–5271

Tersoff J (1988) Empirical interatomic potential for carbon, with applications to amorphous carbon. Phys Rev Lett 61:2879–2882

Torquato S (2002) Random heterogeneous materials: microstructure & macroscopic properties. Springer, New York

Virovlyanskii AL (1995) Interrelation between ray and mode field representations in an acoustic waveguide. Radiophys Quant Electron 38:76

Wei C, Dong J (2014) Development and modeling of melt electrohydrodynamic-jet printing of phase-change Inks for high-resolution additive manufacturing. J Manuf Sci Eng 136:061010. doi:10.1115/1.4028483 Paper No: MANU-14-1179

Wellmann C, Lillie C, Wriggers P (2008) A contact detection algorithm for superellipsoids based on the common-normal concept. Eng Comput 25:432–442

Wellmann C, Lillie C, Wriggers P (2008) Homogenization of granular material modelled by a three-dimensional discrete element method. Comput Geotech 35:394–405

Wellmann C, Lillie C, Wriggers P (2008) Comparison of the macroscopic behavior of granular materials modeled by different constitutive equations on the microscale. Finite Elem Anal Des 44:259–271

Wellmann C, Wriggers P (2011) In: Onate E, Owen DRJ (eds) Homogenization of granular material modeled by a 3D DEM, particle-based methods: fundamentals and applications, pp. 211–231

Wellmann C, Wriggers P (2012) A two-scale model of granular materials. Comput Methods Appl Mech Eng 205–208:46–58

Widom B (1966) Random sequential addition of hard spheres to a volume. J Chem Phys 44:3888–3894

Wriggers P (2002) Computational contact mechanics. Wiley, New York

Wriggers P (2008) Nonlinear finite element analysis. Springer, Berlin

Zohdi TI (2002) An adaptive-recursive staggering strategy for simulating multifield coupled processes in microheterogeneous solids. Int J Numer Methods Eng 53:1511–1532

Zohdi TI (2003) On the compaction of cohesive hyperelastic granules at finite strains. Proc R Soc 454(2034):1395–1401

Zohdi TI (2007) P-wave induced energy and damage distribution in agglomerated granules. Model Simul Mater Sci Eng 15:S435–S448

Zohdi TI (2007) Computation of strongly coupled multifield interaction in particle-fluid systems. Comput Methods Appl Mech Eng 196:3927–3950

Zohdi TI, Wriggers P (2008) Introduction to computational micromechanics. Second Reprinting. Springer, Berlin

Zohdi TI (2014) Embedded electromagnetically sensitive particle motion in functionalized fluids. Comput Part Mech 1:27–45

Zohdi TI (2012) Estimation of electrical-heating load-shares for sintering of powder mixtures. Proc R Soc 468:2174–2190

Zohdi TI (2012) Dynamics of charged particulate systems. Modeling, theory and computation. Springer, Berlin

Zohdi TI (2013) Numerical simulation of charged particulate cluster-droplet impact on electrified surfaces. J Comput Phys 233:509–526

Zohdi TI (2014) A direct particle-based computational framework for electrically-enhanced thermo-mechanical sintering of powdered materials. Math Mech Solids, pp 1–21. doi:10.1007/s11831-013-9092-6

Zohdi TI (2014) Additive particle deposition and selective laser processing-a computational manufacturing framework. Comput Mech 54:171–191

Zohdi TI (2015) On the thermal response of a laser-irradiated powder particle in additive manufacturing. CIRP J Manuf Sci Technol. doi:10.1016/j.cirpj.2015.05.001

Zohdi TI (2015) Modeling and simulation of the post-impact trajectories of particles in oblique precision shot-peening. Comput Part Mech. doi:10.1007/s40571-015-0048-5

Zohdi TI (2006) On the optical thickness of disordered particulate media. Mech Mater 38:969–981

Zohdi TI, Kuypers FA (2006) Modeling and rapid simulation of multiple red blood cell light scattering. Proc R Soc Interface 3(11):823–831

Zohdi TI (2006) Computation of the coupled thermo-optical scattering properties of random particulate systems. Comput Methods Appl Mech Eng 195:5813–5830

Zohdi TI (2012) Modeling and simulation of the optical response rod-functionalized reflective surfaces. Comput Mech 50(2):257–268

Zohdi TI (2013) Rapid simulation of laser processing of discrete particulate materials. Arch Comput Methods Eng 20:309–325

Zohdi TI (2015) A computational modelling framework for high-frequency particulate obscurant cloud performance. Int J Eng Sci 89:75–85

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Basics of acoustics

In our approach, we model the individual particles as being rigid, and the material surrounding the particles as being isotropic and having a relatively low shear modulus, in the zero limit becoming an acoustical medium. Generally, for an isotropic material, one has the classical relationship between the components of infinitesimal strain (\({\varvec{\epsilon }}\)) to the Cauchy stress (\({\varvec{\sigma }}\))

where \({\mathbb {E}}\) is the elasticity tensor and where \({\varvec{\epsilon }}^{\prime }\) is the strain deviator. The corresponding strain energy density is

We focus on the dilatational deformation in the low-shear modulus matrix surrounding the particles. This naturally leads to an idealized “acoustical” material approximation, \(\mu \approx 0\). Hence, Eq. 41 collapses to \({\varvec{\sigma }}=-p \mathbf{1}\), where the pressure is \(p=-3\, \kappa \,\frac{\mathrm{tr} {{\varvec{\epsilon }}}}{3} \mathbf{1}\) and with a corresponding strain energy of \({W=\frac{1}{2}\frac{p^2}{\kappa }}\). By inserting the simplified expression of the stress \({\varvec{\sigma }}=-p\mathbf{1}\) into the equation of equilibrium, we obtain

where \({\varvec{u}}\) is the displacement. By taking the divergence of both sides, and recognizing that \(\nabla \cdot {\varvec{u}}=-\frac{p}{\kappa }\), we obtain

If we assume a harmonic solution, we obtain

and

We insert these relations into Eq. 44, and obtain an expression for the magnitude of the wave number vector

Equation 43 (balance of linear momentum) implies

Now we integrate once, which is equivalent to dividing by \(-j\omega \), and obtain the velocity

and do so again for the displacement

Thus, we have

The reflection of a plane harmonic pressure wave at an interface is given by enforcing continuity of the (acoustical) pressure and disturbance velocity at that location; this yields the ratio between the incident and reflected pressures. We use a local coordinate system (Fig. 3), and require that the number of waves per unit length in the \(x-\mathrm{direction}\) must be the same for the incident, reflected and refracted (transmitted) waves,

From the pressure balance at the interface, we have

where \(P_i\) is the incident pressure ray, \(P_r\) is the reflected pressure ray, and \(P_t\) is the transmitted pressure ray. This forces a time-invariant relation to hold at all parts on the boundary, because the arguments of the exponential must be the same. This leads to (\(k_i=k_r\))

and

The continuity of the displacement, and hence the velocity

leads to, after use of Eq. 51,

We solve for the ratio of the reflected and incident pressures to obtain

where \(\hat{A}\mathop {=}\limits ^\mathrm{def}\frac{A_t}{A_i}=\frac{\rho _tc_t}{\rho _ic_i}\), where \(\rho _t\) is the medium which the ray encounters (transmitted), \(c_t\) is corresponding sound speed in that medium, \(A_t\) is the corresponding acoustical impedance, \(\rho _i\) is the medium in which the ray was traveling (incident), \(c_i\) is corresponding sound speed in that medium \(A_i\) is the corresponding acoustical impedance. The relationship (the law of refraction) between the incident and transmitted angles is \(c_tsin\theta _t=c_isin\theta _i\). Thus, we may write the Fresnel relation

where \(\tilde{c}\mathop {=}\limits ^\mathrm{def}\frac{c_i}{c_t}\). The reflectance for the (acoustical) energy \(\mathcal{R}=r^2\) is

For the cases where \(sin \theta _t=\frac{sin \theta _i}{\tilde{c}}>1\), one may rewrite the reflection relation as

where \(j=\sqrt{-1}\). The reflectance is \(\mathcal{R} \mathop {=}\limits ^\mathrm{def}r \bar{r}=1\), where \(\bar{r}\) is the complex conjugate. Thus, for angles above the critical angle \(\theta _i \ge \theta ^*_i\), all of the energy is reflected. We note that when \(A_t=A_i\) and \(c_i=c_t\), then there is no reflection. Also, when \(A_t>>A_i\) or when \(A_t<<A_i\), then \(r\rightarrow 1\).

Remark

If one considers for a moment an incoming pressure wave (ray), which is incident on an interface between two general elastic media (\(\mu \ne 0\)), reflected shear waves must be generated in order to satisfy continuity of the traction,  This is due to the fact that

This is due to the fact that

For an idealized acoustical medium, \(\mu =0\), no shear waves need to be generated to satisfy Eq. 63.

Appendix 2: Contact area parameter and alternative models

1.1 Contact area parameter

Following Zohdi [80], and referring to Fig. 11, one can solve for an approximation of the common contact radius \(a_{ij}\) (and the contact area, \(A^c_{ij}=\pi a_{ij}^2\)) by solving the following three equations,

and

and

where \(R_i\) is the radius of particle i, \(R_j\) is the radius of particle j, \(L_i\) is the distance from the center of particle i and the common contact interpenetration line and \(L_j\) is the distance from the center of particle j and the common contact interpenetration line, where the extent of interpenetration is

The above equations yield an expression \(a_{ij}\), which yields an expression for the contact area parameter

where

An approximation of the contact area parameter for two particles in contact (see Zohdi [80])

1.2 Alternative models

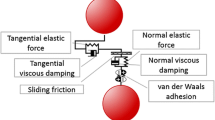

One could easily construct more elaborate relations connecting the relative proximity of the particles and other metrics to the contact force, \({\varvec{\Psi }}^{con,n}_{ij}\propto \mathcal{F}({\varvec{r}}_i, {\varvec{r}}_j, {\varvec{n}}_{ij},R_i,R_j,\ldots )\), building on, for example, Hertzian contact models. This poses no difficulty in the direct numerical method developed. For the remainder of the analysis, we shall use the deformation metric in Eq. 14. For detailed treatments, see Wellman et al. [63–67] and Avci and Wriggers [5]. We note that with the appropriate definition of parameters, one can recover Hertz, Bradley, Johnson–Kendell–Roberts, Derjaguin–Muller–Toporov contact models. For example, Hertzian contact is widely used, with the assumptions being

-

frictionless, continuous, surfaces,

-

each of contacting bodies are elastic half-spaces, whereby the contact area dimensions are smaller radii of the bodies and,

-

the bodies remain elastic (infinitesimal strains),

results in the following contact force:

which has the general form of \({\varvec{\Psi }}^{con,n}=K^*_{ij}\delta ^p_{ij}\), where

-

\(R^*=\left( \frac{1}{R_i}+\frac{1}{R_j}\right) ^{-1}\) and

-

\(E^*=\left( \frac{1-\nu _i^2}{E_i}+\frac{1-\nu _j^2}{E_j}\right) ^{-1}\),

where E is the Young’s modulus and \(\nu \) is the Poisson ratio, The contact area with such a model has already been incorporated in the relation above, and is equal to \(A^c_{ij}=\pi a^2\) where \(a=\sqrt{R^*\delta _{ij}}\). For more details, we refer the reader to Johnson [40]. It is obvious that for a deeper understanding of the deformation within a particle, it must be treated as a deformable continuum, which would require a highly-resolved spatial discretization, for example using the Finite Element Method for the contacting bodies. This requires a large computational effort. For the state of the art in finite element methods and contact mechanics, see the books of Wriggers [69, 70]. For work specifically focusing on the continuum mechanics of particles, see Zohdi and Wriggers [75].

Appendix 3: Iterative solution method

The set of equations represented by Eq. 34 can be solved recursively. Equation 34 can be solved recursively by recasting the relation as

which is of the form

where \(K=1, 2, 3,\ldots \) is the index of iteration within time step \(L+1\) and

-

\({\varvec{\Psi }}^{tot,L+1,K-1}_i \mathop {=}\limits ^\mathrm{def}{\varvec{\Psi }}^{tot,L+1,K-1}_i\left( {\varvec{r}}^{L+1,K-1}_1, {\varvec{r}}^{L+1,K-1}_2\ldots {\varvec{r}}^{L+1,K-1}_N\right) \),

-

\({\varvec{\Psi }}^{tot,L}_i \mathop {=}\limits ^\mathrm{def}{\varvec{\Psi }}^{tot,L}_i\left( {\varvec{r}}^L_1, {\varvec{r}}^L_2\ldots {\varvec{r}}^L_N\right) \),

-

\(\mathcal{G}({\varvec{r}}_i^{L+1,K-1})=\frac{(\phi \Delta t)^2}{m_i}{\varvec{\Psi }}^{tot,L+1,K-1}_i\) and

-

\(\mathcal{L}_i={\varvec{r}}^L_i+{\varvec{v}}^L_i\Delta t+\frac{\phi (\Delta t)^2}{m_i}(1-\phi ){\varvec{\Psi }}^{tot,L}_i\).

The term \(\mathcal{L}_i\) is a remainder term that does not depend on the solution. The convergence of such a scheme is dependent on the behavior of \(\mathcal{G}\). Namely, a sufficient condition for convergence is that \(\mathcal{G}\) is a contraction mapping for all \({\varvec{r}}_i^{L+1,K}\), \(K=1, 2, 3\ldots \) In order to investigate this further, we define the iteration error as

A necessary restriction for convergence is iterative self consistency, i.e. the “exact” (discretized) solution must be represented by the scheme, \({\varvec{r}}^{L+1}_i=\mathcal{G}({\varvec{r}}^{L+1}_i)+\mathcal{L}_i\). Enforcing this restriction, a sufficient condition for convergence is the existence of a contraction mapping

where, if \(0\le \eta ^{L+1,K}<1\) for each iteration K, then \(\varpi ^{L+1,K}_i\rightarrow \mathbf{0}\) for any arbitrary starting value \({\varvec{r}}^{L+1,K\,=\,0}_i\), as \(K \rightarrow \infty \), which is a contraction condition that is sufficient, but not necessary, for convergence. The convergence of Eq. 71 is scaled by \({\eta \propto \frac{(\phi \Delta t)^2}{m_i}}\). Therefore, we see that the contraction constant of \(\mathcal{G}\) is:

-

directly dependent on the magnitude of the interaction forces (\(||{\varvec{\Psi }}||\)),

-

inversely proportional to the masses \(m_i\) and

-

directly proportional to \((\Delta t)^2\).

Thus, decreasing the time step size improves the convergence. In order to maximize the time-step sizes (to decrease overall computing time) and still meet an error tolerance on the numerical solution’s accuracy, we build on an approach originally developed for continuum thermo-chemical multifield problems (Zohdi [71]), where one assumes: (1) \(\eta ^{L+1,K} \approx S(\Delta t)^p\), (S is a constant) and (2) the error within an iteration behaves according to \((S (\Delta t)^p)^K\varpi ^{L+1,0}=\varpi ^{L+1,K}\), \(K=1, 2,\ldots \), where \(\varpi ^{L+1,0}={\varvec{r}}^{L+1,K=1}-{\varvec{r}}^L\) is the initial norm of the iterative (relative) error and S is intrinsic to the system. For example, for second-order problems, due to the quadratic dependency on \(\Delta t\), \(p \approx 2\). The objective is to meet an error tolerance in exactly a preset (the analyst sets this) number of iterations. To this end, one writes \((S (\Delta t_\mathrm{tol})^p)^{K_{d}}\varpi ^{L+1,0}=TOL\), where TOL is a tolerance and where \(K_{d}\) is the number of desired iterations. If the error tolerance is not met in the desired number of iterations, the contraction constant \(\eta ^{L+1,K}\) is too large. Accordingly, one can solve for a new smaller step size, under the assumption that S is constant,

The assumption that S is constant is not critical, since the time steps are to be recursively refined and unrefined throughout the simulation. Clearly, the expression in Eq. 75 can also be used for time step enlargement, if convergence is met in less than \(K_d\) iterations (typically chosen to be between five to ten iterations).

Rights and permissions

About this article

Cite this article

Zohdi, T.I. A discrete element and ray framework for rapid simulation of acoustical dispersion of microscale particulate agglomerations. Comput Mech 57, 465–482 (2016). https://doi.org/10.1007/s00466-015-1250-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-015-1250-2