Abstract

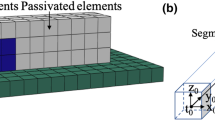

One key aspect of many additive manufacturing processes is the deposition of heated mixtures of particulate materials onto surfaces, which then bond and cool, leading to complex microstructures and possible residual stresses. The overall objective of this work is to construct a straightforward computational approach that researchers in the field can easily implement and use as a numerically-efficient simulation and design tool. Specifically because multifield coupling is present, a recursive, staggered, temporally-adaptive, finite difference time domain scheme is developed to resolve the internal microstructural thermal and mechanical fields, accounting for the simultaneous elasto-plasticity and damage. The time step adaptation allows the numerical scheme to iteratively resolve the changing physical fields by refining the time-steps during phases of the process when the system is undergoing large changes on a relatively small time-scale and can also enlarge the time-steps when the processes are relatively slow. The spatial discretization grids are uniform and dense. The deposited microstructure is embedded into spatial discretization. The regular grid allows one to generate a matrix-free iterative formulation which is amenable to rapid computation and minimal memory requirements, making it ideal for laptop computation. Numerical examples are provided to illustrate the approach. This formulation is useful for material scientists who seek ways to deposit such materials while simultaneously avoiding inadvertent excessive residual stresses.

Similar content being viewed by others

Notes

3D printing was pioneered by Hull [33] of the 3D-Systems Corporation in 1984.

In many processes, the mixture of particles are heated during deposition to enhance bonding or to decrease the viscosity of the flow through the dispenser. This is essentially a material similar to a functionalized ink or slurry, which may not necessarily involve selective laser processing afterwards.

For further details on these types of phenomenological (damage) formulations, the interested reader is referred to the seminal work of Kachanov [35].

Typically, the number of iterations needed to solve the coupled system, if an iterative scheme is used, increases with the time step size and the value of \(\phi \).

A closely related method, Electron Beam Melting, fully melts the material and produces dense solids that are void free.

For the class of problems under consideration, due to the linear dependency on \(\Delta t\), \(p \approx 1\).

Typically, \(K_d\) is chosen to be between five to ten iterations.

At the implementation level, since the exact solution is unknown, the following relative error term is used, \(\varpi ^{L+1,K} \mathop {=}\limits ^\mathrm{def}||\varvec{W}^{L+1,K}-\varvec{W}^{L+1,K-1}||\).

In order to streamline the notation, we drop the cumbersome \(\mathcal{O}(\Delta t)\)-type terms.

References

Avci B, Wriggers P (2012) A DEM-FEM coupling approach for the direct numerical simulation of 3D particulate flows. J Appl Mech 79:010901-1–010901-7

Akisanya AR, Cocks ACF, Fleck NA (1997) The yield behavior of metal powders. Int J Mech Sci 39:1315–1324

Ames WF (1977) Numerical methods for partial differential equations, 2nd edn. Academic Press, New York

Anand L, Gu C (2000) Granular materials: constitutive equations and shear localization. J Mech Phys Solids 48:1701–1733

Axelsson O (1994) Iterative solution methods. Cambridge University Press, Cambridge

Bianco M, Bilardi G, Pesavento F, Pucci G, Schrefler BA (2003) A frontal solver tuned for fully coupled non-linear hygro-thermo-mechanical problems. Int J Numer Methods Eng 57:18011818

Bolintineanu DS, Grest GS, Lechman JB, Pierce F, Plimpton SJ, Schunk PR (2014) Particle dynamics modeling methods for colloid suspensions. Comput Part Mech 1(3):321–356

Brown S, Abou-Chedid G (1994) Yield behavior of metal powder assemblages. J Mech Phys Solids 42:383–398

Campello EMB, Zohdi TI (2014) A computational framework for simulation of the delivery of substances into cells. Int J Numer Methods Biomed Eng 30(11):1132–1152

Campello EMB, Zohdi TI (2014) Design evaluation of a particle bombardment system to deliver substances into cells. Comput Mech Eng Sci 98(2):221–245

Cante J, Davalos C, Hernandez JA, Oliver J, Jonsen P, Gustafsson G, Haggblad HA (2014) PFEM-based modeling of industrial granular flows. Comput Part Mech 1(1):47–70

Carbonell JM, Onate E, Suarez B (2010) Modeling of ground excavation with the particle finite element method. J Eng Mech, ASCE 136:455–463

Deckard C (1986) Method and apparatus for producing parts by selective sintering US Patent 4,863,538

Domas F (1997) Eigenschaft profile und Anwendungsübersicht von EPE und EPP. Technical report of the BASF Company

Donev A, Cisse I, Sachs D, Variano EA, Stillinger F, Connelly R, Torquato S, Chaikin P (2004a) Improving the density of jammed disordered packings using ellipsoids. Science 303:990–993

Donev A, Stillinger FH, Chaikin PM, Torquato S (2004b) Unusually dense crystal ellipsoid packings. Phys Rev Lett 92:255506

Donev A, Torquato S, Stillinger F (2005a) Neighbor list collision-driven molecular dynamics simulation for nonspherical hard particles-I. Algorithmic details. J Comput Phys 202:737

Donev A, Torquato S, Stillinger F (2005b) Neighbor list collision-driven molecular dynamics simulation for nonspherical hard particles-II. Application to ellipses and ellipsoids. J Comput Phys 202:765

Donev A, Torquato S, Stillinger FH (2005c) Pair correlation function characteristics of nearly jammed disordered and ordered hard-sphere packings. Phys Rev E 71:011105

Duran J (1997) Sands, powders and grains. An introduction to the physics of granular matter. Springer, New York

Dwivedi G, Wentz T, Sampath S, Nakamura T (2010) Assessing process and coating reliability through monitoring of process and design relevant coating properties. J Thermal Spray Technol 19:695–712

Fleck NA (1995) On the cold compaction of powders. J Mech Phys Solids 43:1409–1431

Fuller SB, Wilhelm EJ, Jacobson JM (2002) Ink-jet printed nanoparticle microelectromechanical systems. J Microelectromech Syst 11:54–60

Gamota D, Brazis P, Kalyanasundaram K, Zhang J (2004) Printed organic and molecular electronics. Kluwer Academic Publishers, New York

Gethin DT, Lewis RW, Ransing RS (2003) A discrete deformable element approach for the compaction of powder systems. Model Simul Mater Sci Eng 11(1):101–114

Ghosh S (2011) Micromechanical analysis and multi-scale modeling using the Voronoi cell finite element method. CRC Press/Taylor & Francis, Boca Raton

Ghosh S, Dimiduk D (2011) Computational methods for microstructure-property relations. Springer, New York

Gu C, Kim M, Anand L (2001) Constitutive equations for metal powders: application to powder forming processes. Int J Plast 17:147–209

Haruta M (2002) Catalysis of gold nanoparticles deposited on metal oxides. Cattech 6(3):102–115

Hashin Z, Shtrikman S (1962) On some variational principles in anisotropic and nonhomogeneous elasticity. J Mech Phys Solids 10:335–342

Hashin Z (1983) Analysis of composite materials: a survey. ASME J Appl Mech 50:481–505

Housholder R (1979) Molding process. US Patent 4,247,508

Hull C (1984) Apparatus for production of three-dimensional objects by stereolithography. US Patent 4,575,330

Jikov VV, Kozlov SM, Olenik OA (1994) Homogenization of differential operators and integral functionals. Springer, New York

Kachanov LM (1986) Introduction to continuum damage mechanics. Martinus Nijoff, Dordricht

Kachanov M (1993) Elastic solids with many cracks and related problems. Advance applied mechanics, vol 30. Academic Press, New York

Kachanov M, Tsukrov I, Shafiro B (1994) Effective moduli of solids with cavities of various shapes. Appl Mech Rev 47:S151–S174

Kachanov M, Sevostianov I (2005) On the quantitative characterization of microstructures and effective properties. Int J Solids Struct 42:309–336

Kansaal A, Torquato S, Stillinger F (2002) Diversity of order & densities in jammed hard-particle packings. Phys Rev E 66:041109

Martin P (2009) Handbook of deposition technologies for films and coatings, 3rd edn. Elsevier, Oxford

Martin P (2011) Introduction to surface engineering and functionally engineered materials. Scrivener and Elsevier, Hoboken

Labra C, Onate E (2009) High-density sphere packing for discrete element method simulations. Commun Numer Methods Eng 25(7):837–849

Leonardi A, Wittel FK, Mendoza M, Herrmann HJ (2014) Coupled DEM-LBM method for the free-surface simulation of heterogeneous suspensions. Comput Part Mech 1(1):3–13

Lewis RW, Gethin DT, Yang XSS, Rowe RC (2005) A combined finite-discrete element method for simulating pharmaceutical powder tableting. Int J Numer Methods Eng 62:853869

Lewis RW, Schrefler BA, Simoni L (1992) Coupling versus uncoupling in soil consolidation. Int J Numer Anal Methods Geomech 15:533–548

Lewis RW, Schrefler BA (1998) The finite element method in the static and dynamic deformation and consolidation of porous media, 2nd edn. Wiley press, New York

Liu Y, Nakamura T, Dwivedi G, Valarezo A, Sampath S (2008) Anelastic behavior of plasma sprayed zirconia coatings. J Am Ceram Soc 91:4036–4043

Liu Y, Nakamura T, Srinivasan V, Vaidya A, Gouldstone A, Sampath S (2007) Nonlinear elastic properties of plasma sprayed zirconia coatings and associated relationships to processing conditions. Acta Mater 55:4667–4678

Maxwell JC (1867) On the dynamical theory of gases. Philos Trans Soc Lond 157:49

Maxwell JC (1873) A treatise on electricity and magnetism, 3rd edn. Clarendon Press, Oxford

Mura T (1993) Micromechanics of defects in solids, 2nd edn. Kluwer Academic Publishers, Dordrecht

Nakamura T, Liu Y (2007) Determination of nonlinear properties of thermal sprayed ceramic coatings via inverse analysis. Int J Solids Struct 44:1990–2009

Nakamura T, Qian G, Berndt CC (2000) Effects of pores on mechanical properties of plasma sprayed ceramic coatings. J Am Ceram Soc 83:578–584

Nakanishi H, Bishop KJM, Kowalczyk B, Nitzan A, Weiss EA, Tretiakov KV, Apodaca MM, Klajn R, Stoddart JF, Grzybowski BA (2009) Photoconductance and inverse photoconductance in thin films of functionalized metal nanoparticles. Nature 460:371–375

Nemat-Nasser S, Hori M (1999) Micromechanics: overall properties of heterogeneous solids, 2nd edn. Elsevier, Amsterdam

Onate E, Idelsohn SR, Celigueta MA, Rossi R (2008) Advances in the particle finite element method for the analysis of fluid-multibody interaction and bed erosion in free surface flows. Comput Methods Appl Mech Eng 197(19–20):1777–1800

Onate E, Celigueta MA, Idelsohn SR, Salazar F, Surez B (2011) Possibilities of the particle finite element method for fluid-soil-structure interaction problems. Comput Mech 48:307–318

Pöschel T, Schwager T (2004) Computational granular dynamics. Springer, New York

Qian G, Nakamura T, Berndt CC (1998) Effects of thermal gradient and residual stresses on thermal barrier coating fracture. Mech Mater 27:91–110

Ransing RS, Lewis RW, Gethin DT (2004) Using a deformable discrete-element technique to model the compaction behaviour of mixed ductile and brittle particulate systems. Philos Trans R Soc Ser A 362(1822):1867–1884

Rayleigh JW (1892) On the influence of obstacles arranged in rectangular order upon properties of a medium. Philos Mag 32:481–491

Rojek J, Labra C, Su O, Onate E (2012) Comparative study of different discrete element models and evaluation of equivalent micromechanical parameters. Int J Solids Struct 49:1497–1517. doi:10.1016/j.ijsolstr.2012.02.032

Rojek J (2014) Discrete element thermomechanical modelling of rock cutting with valuation of tool wear. Comput Part Mech 1(1):71–84

Onate E, Celigueta MA, Latorre S, Casas G, Rossi R, Rojek J (2014) Lagrangian analysis of multiscale particulate flows with the particle finite element method. Comput Part Mech 1(1):85–102

Schrefler BA (1985) A partitioned solution procedure for geothermal reservoir analysis. Commun Appl Numer Methods 1:53–56

Sevostianov I, Gorbatikh L, Kachanov M (2001) Recovery of information of porous/microcracked materials from the effective elastic/conductive properties. Mater Sci Eng A 318:1–14

Sevostianov I, Kachanov M (2008) Connections between elastic and conductive properties of heterogeneous materials. Adv Appl Mech 42:69–253

Sevostianov I, Kachanov M (2000) Modeling of the anisotropic elastic properties of plasma-sprayed coatings in relation to their microstructure. Acta Mater 48(6):1361–1370

Sevostianov I, Kachanov M (2001) Thermal conductivity of plasma sprayed coatings in relation to their microstructure. J Therm Spray Technol 9(4):478–482

Sevostianov I, Kachanov M (2001) Plasma-sprayed ceramic coatings: anisotropic elastic and conductive properties in relation to the microstructure; cross-property correlations, with I. Sevostianov. Mater Sci Eng-A 297:235–243

Tatzel H (1996) Grundlagen der Verarbeitungstechnik von EPP-Bewährte und neue Verfahren. Technical report of the BASF Company

Torquato S (2001) Random heterogeneous materials: microstructure and macroscopic properties. Springer, New York

Turska E, Schrefler BA (1994) On consistency, stability and convergence of staggered solution procedures. Rend Mat Acc Lincei, Rome, S. 9, 5:265–271

Wang X, Schrefler BA (1998) A multifrontal parallel algorithm for coupled thermo-hydro-mechanical analysis of deforming porous media. Int J Numer Methods Eng 43:1069–1083

Widom B (1966) Random sequential addition of hard spheres to a volume. J Chem Phys 44:3888–3894

Young DM (1950) Iterative methods for solving partial difference equations of elliptic type. Doctoral thesis. Harvard University

Zienkiewicz OC (1984) Coupled problems & their numerical solution. In: Lewis RW, Bettes P, Hinton E (eds) Numerical methods in coupled systems. Wiley, Chichester, pp 35–38

Zienkiewicz OC, Paul DK, Chan AHC (1988) Unconditionally stable staggered solution procedure for soil-pore fluid interaction problems. Int J Numer Methods Eng 26:1039–1055

Zohdi TI (2002) An adaptive-recursive staggering strategy for simulating multifield coupled processes in microheterogeneous solids. Int J Numer Methods Eng 53:1511–1532

Zohdi TI (2003) On the compaction of cohesive hyperelastic granules at finite strains. Proc R Soc 454(2034):1395–1401

Zohdi TI (2003) Genetic design of solids possessing a random-particulate microstructure. Philos Trans R Soc 361(1806):1021–1043

Zohdi TI (2004) Modeling and simulation of a class of coupled thermo-chemo-mechanical processes in multiphase solids. Comput Methods Appl Mech Eng 193(6–8):679–699

Zohdi TI (2006) Computation of the coupled thermo-optical scattering properties of random particulate systems. Comput Methods Appl Mech Eng 195:5813–5830

Zohdi TI, Wriggers P (2008) Introduction to computational micromechanics. Springer, New York Second Reprinting

Zohdi TI (2010) Simulation of coupled microscale multiphysical-fields in particulate-doped dielectrics with staggered adaptive FDTD. Comput Methods Appl Mech Eng 199:79–101

Zohdi TI (2012) Dynamics of charged particulate systems. Modeling, theory and computation. Springer, New York

Zohdi TI (2012) Electromagnetic properties of multiphase dielectrics. A primer on modeling, theory and computation. Springer, New York

Zohdi TI (2013a) Numerical simulation of charged particulate cluster-droplet impact on electrified surfaces. J Comput Phys 233:509–526

Zohdi TI (2013b) Rapid simulation of laser processing of discrete particulate materials. Arch Comput Methods Eng. doi:10.1007/s11831-013-9092-6 pp 1–17

Zohdi TI (2014) A direct particle-based computational framework for electrically-enhanced thermo-mechanical sintering of powdered materials. Math Mech Solids. doi:10.1007/s11831-013-9092-6 pp 1–21

Zohdi T (2014) Embedded electromagnetically sensitive particle motion in functionalized fluids. Comput Part Mech 1(1):27–45

Zohdi TI (2014) Additive particle deposition and selective laser processing-a computational manufacturing framework. Comput Mech 54:171–191

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Spatial finite difference stencils

The following standard approximations are used:

-

1.

For the first derivative of a primal variable u at \((x_1,x_2,x_3)\):

$$\begin{aligned} \frac{\partial u}{\partial x_1}\approx \frac{u(x_1+\Delta x_1,x_2,x_3)-u(x_1-\Delta x_1,x_2,x_3)}{2\Delta x_1} \end{aligned}$$(7.1) -

2.

For the derivative of a flux at \((x_1,x_2,x_3)\), with an arbitrary material coefficient a:

$$\begin{aligned}&\frac{\partial }{\partial x_1} \left( a\frac{\partial u}{\partial x_1}\right) \nonumber \\&\quad \approx \frac{\left( a\frac{\partial u}{\partial x_1}\right) |_{x_1+\frac{\Delta x_1}{2},x_2,x_3} -\left( a\frac{\partial u}{\partial x_1}\right) |_{x_1-\frac{\Delta x_1}{2},x_2,x_3}}{\Delta x_1}\nonumber \\&\quad =\frac{1}{\Delta x_1}\left[ a(x_1 +\frac{\Delta x_1}{2},x_2,x_3)\right. \nonumber \\&\qquad \left. \times \left( \frac{u(x_1+\Delta x_1,x_2,x_3)-u(x_1,x_2,x_3)}{\Delta x_1}\right) \right] \nonumber \\&\qquad -\,\frac{1}{\Delta x_1}\left[ a(x_1-\frac{\Delta x_1}{2},x_2,x_3) \right. \nonumber \\&\qquad \left. \times \left( \frac{u(x_1,x_2,x_3)-u(x_1-\Delta x_1,x_2,x_3)}{\Delta x_1}\right) \right] ,\nonumber \\ \end{aligned}$$(7.2)where we have used

$$\begin{aligned} a(x_1+\frac{\Delta x_1}{2},x_2,x_3)\approx & {} \frac{1}{2}\left( a(x_1+\Delta x_1,x_2,x_3)\right. \nonumber \\&\left. +\,a(x_1,x_2,x_3)\right) \end{aligned}$$(7.3)and

$$\begin{aligned} a(x_1-\frac{\Delta x_1}{2},x_2,x_3)\approx & {} \frac{1}{2}\left( a(x_1,x_2,x_3)\right. \nonumber \\&\left. +\,a(x_1-\Delta x_1,x_2,x_3)\right) \end{aligned}$$(7.4) -

3.

For the cross-derivative of a flux at \((x_1,x_2)\):

$$\begin{aligned}&\frac{\partial }{\partial x_2} \left( a\frac{\partial u}{\partial x_1}\right) \approx \frac{\partial }{\partial x_2} \left( a(x_1,x_2,x_3)\right. \nonumber \\&\quad \left. \times \left( \frac{u(x_1+\Delta x_1,x_2,x_3)-u(x_1-\Delta x_1,x_2,x_3)}{2\Delta x_1}\right) \right) \nonumber \\&\quad \approx \frac{1}{4\Delta x_1\Delta x_2}( a(x_1,x_2+\Delta x_2,x_3)\left[ u(x_1+\Delta x_1,x_2\right. \nonumber \\&\left. \qquad +\Delta x_2,x_3)-u(x_1-\Delta x_1,x_2+\Delta x_2,x_3)\right] \nonumber \\&\qquad - a(x_1,x_2-\Delta x_2,x_3)\left[ u(x_1+\Delta x_1,x_2-\Delta x_2,x_3)\right. \nonumber \\&\qquad \left. -u(x_1-\Delta x_1,x_2-\Delta x_2,x_3)\right] ), \end{aligned}$$(7.5)

Remark

To illustrate second-order accuracy, consider a Taylor series expansion for an arbitrary function u

and

Subtracting the two expressions yields

Appendix 2: temporally-adaptive iterative methods

Implicit time-stepping methods, with time step size adaptivity, built on approaches found in Zohdi [79, 82, 85, 88] and [90] were used throughout the analysis in the body of the work. In order to introduce basic concepts, we consider a first order differential equation for a field \(\varvec{W}\):

which, after being discretized using a trapezoidal “\(\phi \)-method” (\(0\le \phi \le 1\))

Generally, for systems of equations of this form, a straightforward iterative scheme can be written as

where \(\mathcal{R}\) is a remainder term that does not depend on the solution, i.e. \(\mathcal{R} \ne \mathcal{R}(\varvec{W}^{L+1})\), and \(K=1, 2, 3, \ldots \) is the index of iteration within time step \(L+1\). The convergence of such a scheme is dependent on the behavior of \(\mathcal{G}\). Namely, a sufficient condition for convergence is that \(\mathcal{G}\) is a contraction mapping for all \(\varvec{W}^{L+1,K}\), \(K=1, 2, 3\ldots \) In order to investigate this further, we define the iteration error as

A necessary restriction for convergence is iterative self consistency, i.e. the “exact” (discretized) solution must be represented by the scheme

Enforcing this restriction, a sufficient condition for convergence is the existence of a contraction mapping

where, if \(0\le \eta ^{L+1,K}<1\) for each iteration K, then \(\varpi ^{L+1,K}\rightarrow 0\) for any arbitrary starting value \(\varvec{W}^{L+1,K=0}\), as \(K \rightarrow \infty \). This type of contraction condition is sufficient, but not necessary, for convergence. Inserting these approximations into \(\dot{\varvec{W}}=\varvec{\Lambda }(\varvec{W})\) leads to

whose contraction constant is scaled by \(\eta \propto \phi \Delta t\). Therefore, if convergence is slow within a time step, the time step size, which is adjustable, can be reduced by an appropriate amount to increase the rate of convergence. Decreasing the time step size improves the convergence, however, we want to simultaneously maximize the time-step sizes to decrease overall computing time, while still meeting an error tolerance on the numerical solution’s accuracy. In order to achieve this goal, we follow an approach found in Zohdi [79, 82, 85, 88] and [90] originally developed for continuum thermo-chemical multifield problems in which one first approximates

(S is a constant) and secondly one assumes the error within an iteration to behave according to

\(K=1, 2,\ldots \), where \(\varpi ^{L+1,0}\) is the initial norm of the iterative error and S is intrinsic to the system.Footnote 6 Our goal is to meet an error tolerance in exactly a preset number of iterations. To this end, one writes

where \(C_{tol}\) is a (coupling) tolerance and where \(K_{d}\) is the number of desired iterations.Footnote 7 If the error tolerance is not met in the desired number of iterations, the contraction constant \(\eta ^{L+1,K}\) is too large. Accordingly, one can solve for a new smaller step size, under the assumption that S is constant,

The assumption that S is constant is not critical, since the time steps are to be recursively refined and unrefined throughout the simulation. Clearly, the expression in Eq. 8.12 can also be used for time step enlargement, if convergence is met in less than \(K_d\) iterations.Footnote 8

Appendix 3: Second-order temporal discretization

Discretization of temporally second-order equations can be illustrated by considering

Expanding the field \(\varvec{V}\) in a Taylor series about \(t+\phi \Delta t\) we obtain

and

Subtracting the two expressions yields

where \(\hat{\mathcal{O}}(\Delta t)=\mathcal{O}((\Delta t)^2)\), when \(\phi =\frac{1}{2}\). Thus, inserting this into the governing equation yields

Note that adding a weighted sum of Eqs. 9.2 and 9.3 yields

which will be useful shortly. Now expanding the field \(\varvec{U}\) in a Taylor series about \(t+\phi \Delta t\) we obtain

and

Subtracting the two expressions yields

Inserting Eq. 9.6 yields

and thus using Eq. 9.5 yields

The term \(\varvec{\Psi }(\varvec{U}(t+\phi \Delta t))\) can be handled in two main ways:

-

\(\varvec{\Psi }(t+\phi \Delta t)\approx \varvec{\Psi }(\phi \varvec{U}(t+\Delta t)+(1-\phi )\varvec{U}(t))\) or

-

\(\varvec{\Psi }(t+\phi \Delta t)\approx \phi \varvec{\Psi }(\varvec{U}(t+\Delta t))+(1-\phi )\varvec{\Psi }(\varvec{U}(t))\).

The differences are quite minute between either of the above, thus, for brevity, we choose the latter. In summary, we have the following:

We note that

-

When \(\phi =1\), then this is the (implicit) Backward Euler scheme, which is very stable (very dissipative) and \(\mathcal{O}((\Delta t)^2)\) locally in time,

-

When \(\phi =0\), then this is the (explicit) Forward Euler scheme, which is conditionally stable and \(\mathcal{O}((\Delta t)^2)\) locally in time,

-

When \(\phi =0.5\), then this is the (implicit) “Midpoint” scheme, which is stable and \(\hat{\mathcal{O}}((\Delta t)^2)=\mathcal{O}((\Delta t)^3)\) locally in time.

In summary, we have for the velocityFootnote 9

and for the position

or more explicitly

In iterative (recursion) form

Remark

Applying this scheme to the balance of linear momentum continuum formulation, under infinitesimal deformations, \(\nabla _x \cdot {\varvec{\sigma }}+\varvec{f}=\rho \frac{\partial ^2 \varvec{u}}{\partial t^2}\) we use \(\varvec{\Psi }(\varvec{u}(t))=\frac{\nabla _x\cdot {\varvec{\sigma }}+\varvec{f}}{\rho }\), and must apply the (iterative) process introduced earlier to all nodes in the system.

Rights and permissions

About this article

Cite this article

Zohdi, T.I. Modeling and simulation of cooling-induced residual stresses in heated particulate mixture depositions in additive manufacturing. Comput Mech 56, 613–630 (2015). https://doi.org/10.1007/s00466-015-1191-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-015-1191-9