Abstract

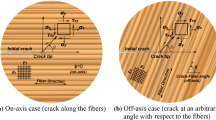

A new comprehensive criterion has been presented to assess the fracture response in cracked wood as natural orthotropic material based on the maximum strain energy release rate criterion (SER) under mixed-mode I/II loading. A general off-axis case is assumed for desired crack-fiber angle. The most important purpose of the proposed paper is to accurately predict the fracture behavior of orthotropic materials. In this article, two influencing factors on fracture assessment are discussed comprehensively. The first one is employing the accurate model of the orthotropic material named as reinforcement isotropic solid (RIS) model, and the second factor is considering the effects of the T-stress term. The SER concept is extended in combination with the reinforcement isotropic solid (RIS) model for orthotropic materials. Using RIS, a mapping between the stress fields in the isotropic and orthotropic materials is established. In this article, the reinforcement coefficients are extracted using a new method called "corresponding stresses" for the desired crack-fiber angles. These coefficients depend on the mechanical properties of the orthotropic material and crack-fiber angle. The results obtained from the curves of reinforcement coefficients indicate that as the crack-fiber angle increases, the reinforcement coefficients decrease drastically. The SER around the crack tip is extracted considering the normal and shear stress fields and the non-singular T-stress term. Using extracted results, it can be shown that the T-stress term has a serious role in predicting the crack behavior of orthotropic materials. It is practically impossible to calculate the fracture toughness of pure modes I and II when the crack is not along the fibers. Based on the proposed extended maximum strain energy release rate (EMSER) criterion, a new concept called equivalent fracture toughness (EFT) is introduced as a fracture property of orthotropic materials. To validate and evaluate the accuracy of the EMSER criterion, the fracture limit curves (FLCs) for different angles between crack and fibers are compared with available experimental data from the literature. Compared to other criteria, a prominent correlation is obtained between the theoretical results evaluated by the EMSER criterion and available test data.

Similar content being viewed by others

Abbreviations

- \(A_{i}\) :

-

Normal and shear stress field coefficients

- \(B\) :

-

Normalized T-stress term

- \(C_{i}\),\(D_{i}\) :

-

The factors in SER criterion

- \(C_{ij}\) :

-

Compliance coefficient in elastic materials

- \(E_{I}\),\(E_{II}\) :

-

Generalized elastic moduli

- \(E_{1}\),\(E_{2}\) :

-

Elastic module of matrix, fiber

- \(f_{ij}\),\(g_{ij}\) :

-

Angular functions of the stress state in the vicinity of the crack for orthotropic materials

- \(\hat{f}_{ij}\), \(\hat{g}_{ij}\) :

-

Angular functions of the stress state in the vicinity of the crack for orthotropic materials

- \(V_{f}\) :

-

The volume fraction of fibers

- \(G_{12}\) :

-

Shear module

- \(G_{c}\) :

-

Critical strain energy release rate

- \(G(\theta )\) :

-

Strain energy release rate

- \({\text{n}}\) :

-

Experimental factor

- \(K_{I}\),\(K_{II}\) :

-

Mode I and II stress intensity factors

- \(K_{IC}\),\(K_{IIC}\) :

-

Mode I and II fracture toughness

- \((K_{IC} )_{eq}\) :

-

Equivalent fracture toughness in mod I

- \({\text{P}}\),\({\text{Q}}\) :

-

The strengths along and across the fibers

- \(r_{c}\) :

-

The critical distance

- \(r\),\(\theta\) :

-

Polar distance from the crack tip, Polar angle

- \(T\) :

-

T-stress term

- \(\alpha_{i}\) :

-

Reinforcement coefficients

- \(\varphi\) :

-

Angle between loading and fibers

- \(\theta_{IC}\),\(\theta_{IIC}\) :

-

Crack initiation angle under pure mode I and II loading

- \(\nu_{12}\),\(v_{21}\) :

-

Poisson’s ratio of a composite in different directions

- \(\eta\), \(\xi\), \(\lambda\) :

-

Stress reduction coefficients

- \(\sigma_{x}^{Iso}\),\(\sigma_{xy}^{Iso}\) :

-

Stress state of isotropic material in normal and tangential direction

- \(\sigma_{ij}^{orth}\) :

-

Stress state of orthotropic material

References

Braun, M., Iváñez, I., Ariza, M.: A numerical study of progressive damage in unidirectional composite materials using a 2D lattice model. Eng. Fract. Mech. 249, 107767 (2021)

Braun, M., Ariza, M.: New lattice models for dynamic fracture problems of anisotropic materials. Compos. B Eng. 172, 760–768 (2019)

Braun, M., Ariza, M.: A progressive damage based lattice model for dynamic fracture of composite materials. Compos. Sci. Technol. 200, 108335 (2020)

Ayatollahi, M., Dehghany, M., Kaveh, Z.: Computation of V-notch shape factors in four-point bend specimen for fracture tests on brittle materials. Arch. Appl. Mech. 83(3), 345–356 (2013)

Kiss, B., Szekrényes, A.: Fracture and mode mixity analysis of shear deformable composite beams. Arch. Appl. Mech. 89(12), 2485–2506 (2019)

Sahlabadi, M., Soltani, N.: Experimental and numerical investigations of mixed-mode ductile fracture in high-density polyethylene. Arch. Appl. Mech. 88(6), 933–942 (2018)

Majidi, H., Ayatollahi, M., Torabi, A.: On the use of the extended finite element and incremental methods in brittle fracture assessment of key-hole notched polystyrene specimens under mixed mode I/II loading with negative mode I contributions. Arch. Appl. Mech. 88(4), 587–612 (2018)

Zhang, P., Han, S., Golewski, G. L., Wang, X.: Nanoparticle-reinforced building materials with applications in civil engineering, vol. 12, ed: SAGE Publications Sage UK: London, England, 2020, p. 1687814020965438

Golewski, G.L.: On the special construction and materials conditions reducing the negative impact of vibrations on concrete structures. Materials Today: Proceedings 45, 4344–4348 (2021)

Golewski, G.L., Szostak, B.: Strength and microstructure of composites with cement matrixes modified by fly ash and active seeds of CSH phase. Struct. Eng. Mech. 82(4), 543–556 (2022)

Fakoor, M., Khezri, M.S.: A micromechanical approach for mixed mode I/II failure assessment of cracked highly orthotropic materials such as wood. Theoret. Appl. Fract. Mech. 109, 102740 (2020)

Hou, C., Jin, X., Fan, X., Xu, R., Wang, Z.: A generalized maximum energy release rate criterion for mixed mode fracture analysis of brittle and quasi-brittle materials. Theoret. Appl. Fract. Mech. 100, 78–85 (2019)

Mirsayar, M., Joneidi, V., Petrescu, R., Petrescu, F., Berto, F.: Extended MTSN criterion for fracture analysis of soda lime glass. Eng. Fract. Mech. 178, 50–59 (2017)

Bernard, O., Rostand, M.P., Evelyne, T., Michel, G.: Experimental investigation of mixed mode fracture of tropical wood material. Procedia Struct. Integrity 13, 347–352 (2018)

Razavi, S.M.J., Neisiany, R.E., Ayatollahi, M., Ramakrishna, S., Khorasani, S.N., Berto, F.: Fracture assessment of polyacrylonitrile nanofiber-reinforced epoxy adhesive. Theoret. Appl. Fract. Mech. 97, 448–453 (2018)

Dönmez, A., Bažant, Z.P.: Size effect on branched sideways cracks in orthotropic fiber composites. Int. J. Fract. 222(1), 155–169 (2020)

Ghasemi-Ghalebahman, A., Akbardoost, J., Ghaffari, Y.: Evaluation of size effect on mixed-mode fracture behavior of epoxy/silica nanocomposites. J. Strain Anal. Eng. Design 52(4), 239–248 (2017)

Torabi, A., Campagnolo, A., Berto, F.: Experimental and theoretical investigation of brittle fracture in key-hole notches under mixed mode I/II loading. Acta Mech. 226(7), 2313–2322 (2015)

Wang, Y., Wang, K., Wang, B., Zheng, L., Zhang, C.: Fracture analysis of superconducting composites with a sandwich structure based on electromagnetic–thermal coupled model. Acta Mech. 230(12), 4435–4451 (2019)

Fakoor, M., Ghoreishi, S.M.N.: Verification of a micro-mechanical approach for the investigation of progressive damage in composite laminates. Acta Mech. 230(1), 225–241 (2019)

Abdollahzadeh Jamalabadi, M.Y., Zabari, N., Bratasz, Ł: Three-dimensional numerical and experimental study of fracture saturation in panel paintings. Wood Sci. Technol. 55, 1555–1576 (2021)

Wu, H., Zhao, G., Liang, W.: Investigation of cracking behavior and mechanism of sandstone specimens with a hole under compression. Int. J. Mech. Sci. 163, 105084 (2019)

Nasrnia, A., Haji Aboutalebi, F.: Experimental investigation and numerical simulations of U-notch specimens under mixed mode loading by the conventional and extended finite element methods,". Archiv. Appl. Mech. 88(9), 1461–1475 (2018)

Ayatollahi, M., Torabi, A., Bahrami, B.: Comprehensive notch shape factors for V-notched Brazilian disk specimens loaded under mixed mode I/II from pure opening mode to pure closing mode. Arch. Appl. Mech. 87(2), 299–313 (2017)

Anaraki, A.G., Fakoor, M.: A new mixed-mode fracture criterion for orthotropic materials, based on strength properties. J. Strain Anal. Eng. Design 46(1), 33–44 (2011)

Benveniste, Y., Aboudi, J.: Crack propagation in a laminated composite material modeled by a two-dimensional mixture theory. Acta Mech. 29(1), 213–227 (1978)

Mirsayar, M.: Maximum principal strain criterion for fracture in orthotropic composites under combined tensile/shear loading, Theor. Appl. Fract. Mech. p. 103291 (2022)

Gheibi, M., Shojaeefard, M., Googarchin, H.S.: Experimental and numerical analysis on the cohesive behavior of an automotive adhesive improved by MWCNT subjected to mode I and II loadings. Int. J. Mech. Sci. 153, 271–286 (2019)

De Moura, M., Chousal, J.: Cohesive and continuum damage models applied to fracture characterization of bonded joints. Int. J. Mech. Sci. 48(5), 493–503 (2006)

Huang, C.-C., Cheng, J.-H.: A new forming-limit criterion for fracture prediction in a powder forging application. Int. J. Mech. Sci. 47(7), 1123–1145 (2005)

Pant, M., Singh, I., Mishra, B.: A novel enrichment criterion for modeling kinked cracks using element free Galerkin method. Int. J. Mech. Sci. 68, 140–149 (2013)

Heo, S., Yang, W.: Mixed-mode stress intensity factors and critical angles of cracks in bolted joints by weight function method. Arch. Appl. Mech. 72(2), 96–106 (2002)

Ioakimidis, N.I.: Application of quantifier elimination to mixed-mode fracture criteria in crack problems. Arch. Appl. Mech. 87(10), 1567–1604 (2017)

Fakoor, M., Khansari, N.M.: General mixed mode I/II failure criterion for composite materials based on matrix fracture properties. Theoret. Appl. Fract. Mech. 96, 428–442 (2018)

Frühmann, K., Tschegg, E., Dai, C., Stanzl-Tschegg, S.: Fracture behaviour of laminated veneer lumber under Mode I and III loading. Wood Sci. Technol. 36(4), 319–334 (2002)

Vasic, S., Smith, I., Landis, E.: Finite element techniques and models for wood fracture mechanics. Wood Sci. Technol. 39(1), 3–17 (2005)

Kumar, S.S., Clement, H.A., Karthik, R.: Mixed mode fracture analysis of multiple cracks in flat and curved stiffened panels of aircraft fuselage structures. Arch. Appl. Mech. 87(11), 1815–1828 (2017)

Golewski, G.L.: An extensive investigations on fracture parameters of concretes based on quaternary binders (QBC) by means of the DIC technique. Constr. Build. Mater. 351, 128823 (2022)

Golewski, G.: Comparative measurements of fracture toughgness combined with visual analysis of cracks propagation using the DIC technique of concretes based on cement matrix with a highly diversified composition. Theoret. Appl. Fract. Mech. 121, 103553 (2022)

Golewski, G.L.: Fracture Performance of Cementitious Composites Based on Quaternary Blended Cements. Materials 15(17), 6023 (2022)

Sistaninia, M., Sistaninia, M.: Theoretical and experimental investigations on the mode II fracture toughness of brittle materials. Int. J. Mech. Sci. 98, 1–13 (2015)

Saeedi, M., Morovvati, M., Alizadeh-Vaghasloo, Y.: Experimental and numerical study of mode-I and mixed-mode fracture of ductile U-notched functionally graded materials. Int. J. Mech. Sci. 144, 324–340 (2018)

Rodríguez-González, J., May-Pat, A., Avilés, F.: A beam specimen to measure the face/core fracture toughness of sandwich materials under a tearing loading mode. Int. J. Mech. Sci. 79, 84–94 (2014)

Gorji, M.B., Furmanski, J., Mohr, D.: From macro-to micro-experiments: Specimen-size independent identification of plasticity and fracture properties. Int. J. Mech. Sci. 199, 106389 (2021)

Zhang, P., Pereira, M.P., Abeyrathna, B., Rolfe, B.F., Wilkosz, D.E., Weiss, M.: Improving the shear test to determine shear fracture limits for thin stainless steel sheet by shape optimisation. Int. J. Mech. Sci. 164, 105116 (2019)

Shahani, A., Nejadi, M.: Investigation on the mechanical properties and fracture toughness of graphite. Fatigue Fract. Eng. Mater. Struct. 38(10), 1209–1218 (2015)

Shahani, A.R., Baghaee, M., Shooshtar, H.: An improvement to the single specimen test method for fracture characterization of elastomer materials using DENT specimen. Polym. Testing 87, 106435 (2020)

Aliha, M., Ghoreishi, S., Imani, D., Fotoohi, Y., Berto, F.: Mechanical and fracture properties of aluminium cylinders manufactured by orbital friction stir welding. Fatigue Fract. Eng. Mater. Struct. 43(7), 1514–1528 (2020)

Pour, P.H., Aliha, M., Keymanesh, M.: Evaluating mode I fracture resistance in asphalt mixtures using edge notched disc bend ENDB specimen with different geometrical and environmental conditions. Eng. Fract. Mech. 190, 245–258 (2018)

Golewski, G.L.: Evaluation of fracture processes under shear with the use of DIC technique in fly ash concrete and accurate measurement of crack path lengths with the use of a new crack tip tracking method. Measurement 181, 109632 (2021)

Golewski, G.L.: Validation of the favorable quantity of fly ash in concrete and analysis of crack propagation and its length–Using the crack tip tracking (CTT) method–In the fracture toughness examinations under Mode II, through digital image correlation. Constr. Build. Mater. 296, 122362 (2021)

Van der Put, T.: A new fracture mechanics theory for orthotropic materials like wood. Eng. Fract. Mech. 74(5), 771–781 (2007)

Khaji, Z., Fakoor, M.: Strain energy release rate in combination with reinforcement isotropic solid model (SERIS): a new Mixed-mode I/II Criterion to investigate fracture behavior of orthotropic materials," Theor. Appl. Fracture Mech. p. 102962, (2021)

Wu, E.: Application of fracture mechanics to anisotropic plates (1967)

Hunt, D., Croager, W.: Mode II fracture toughness of wood measured by a mixed-mode test method. J. Mater. Sci. Lett. 1(2), 77–79 (1982)

Mall, S., Murphy, J.F., Shottafer, J.E.: Criterion for mixed mode fracture in wood. J. Eng. Mech. 109(3), 680–690 (1983)

Erdogan, F., Sih, G.: On the crack extension in plates under plane loading and transverse shear. J. Basic Eng. 85(4), 519–525 (1963)

Carloni, C., Nobile, L.: Maximum circumferential stress criterion applied to orthotropic materials. Fatigue Fract. Eng. Mater. Struct. 28(9), 825–833 (2005)

Fakoor, M., Rafiee, R., Zare, S.: Equivalent reinforcement isotropic model for fracture investigation of orthotropic materials. Steel Compos. Struct. 30(1), 1–12 (2019)

Romanowicz, M., Seweryn, A.: Verification of a non-local stress criterion for mixed mode fracture in wood. Eng. Fract. Mech. 75(10), 3141–3160 (2008)

Romanowicz, M.: A non-local stress fracture criterion accounting for the anisotropy of the fracture toughness. Eng. Fract. Mech. 214, 544–557 (2019)

Sih, G.C.: Strain-energy-density factor applied to mixed mode crack problems. Int. J. Fract. 10(3), 305–321 (1974)

Zhang, S., Jang, B., Valaire, B., Suhling, J.: A new criterion for composite material mixed mode fracture analysis. Eng. Fract. Mech. 34(3), 749–769 (1989)

Zhiming, Y., Ayari, M.: Prediction of crack propagation in anisotropic solids. Eng. Fract. Mech. 49(6), 797–808 (1994)

Farid, H.M., Fakoor, M.: Mixed mode I/II fracture criterion for arbitrary cracks in orthotropic materials considering T-stress effects. Theoret. Appl. Fract. Mech. 99, 147–160 (2019)

Farid, H.M., Fakoor, M.: Mixed mode I/II fracture criterion to anticipate behavior of the orthotropic materials. Steel Compos. Struct. 34(5), 671–679 (2020)

Daneshjoo, Z., Shokrieh, M., Fakoor, M., Alderliesten, R.: A new mixed mode I/II failure criterion for laminated composites considering fracture process zone. Theoret. Appl. Fract. Mech. 98, 48–58 (2018)

Jernkvist, L.O.: Fracture of wood under mixed mode loading: I. Derivation of fracture criteria. Eng. Fract. Mech. 68(5), 549–563 (2001)

Hussain, M., Pu, S., Underwood, J.: Strain energy release rate for a crack under combined mode I and mode II, In: Fracture analysis: Proceedings of the 1973 national symposium on fracture mechanics, part II, 1974: ASTM International

Khaji, Z., Fakoor, M.: A Semi-theoretical criterion based on the combination of strain energy release rate and strain energy density concepts (STSERSED): Establishment of a new approach to predict the fracture behavior of orthotropic materials. Theor. Appl. Fract. Mech. p. 103290 (2022)

Khaji, Z., Fakoor, M.: Strain energy release rate in combination with reinforcement isotropic solid model (SERIS): a new mixed-mode I/II criterion to investigate fracture behavior of orthotropic materials. Theoret. Appl. Fract. Mech. 113, 102962 (2021)

Fakoor, M.: Augmented strain energy release rate (ASER): A novel approach for investigation of mixed-mode I/II fracture of composite materials. Eng. Fract. Mech. 179, 177–189 (2017)

Mindess, S., Bentur, A.: Crack propagation in notched wood specimens with different grain orientations. Wood Sci. Technol. 20(2), 145–155 (1986)

Tu, J., Zhao, D., Zhao, J., Zhao, Q.: Experimental study on crack initiation and propagation of wood with LT-type crack using digital image correlation (DIC) technique and acoustic emission (AE). Wood Sci. Technol. 55(6), 1577–1591 (2021)

Budiansky, B., O’connell, R.J.: Elastic moduli of a cracked solid. Int. J. Solids Struct. 12(2), 81–97 (1976)

Nemat-Nasser, S., Hori, M.: Elastic solids with microdefects, In: Micromechanics and Inhomogeneity: Springer, pp. 297–320 (1990)

Anaraki, A.G., Fakoor, M.: Mixed mode fracture criterion for wood based on a reinforcement microcrack damage model. Mater. Sci. Eng., A 527(27–28), 7184–7191 (2010)

Anaraki, A.G., Fakoor, M.: General mixed mode I/II fracture criterion for wood considering T-stress effects. Mater. Des. 31(9), 4461–4469 (2010)

Fakoor, M., Ghoreishi, S.M.N.: Failure criterion for mixed mode fracture of cracked wood specimens. World Acad. Sci, Eng. Technol. Int. J. Mech. Aerospace, Ind. Mech. Manufact. Eng. 11(7), 1364–1370 (2017)

Larsson, S.-G., Carlsson, A.J.: Influence of non-singular stress terms and specimen geometry on small-scale yielding at crack tips in elastic-plastic materials. J. Mech. Phys. Solids 21(4), 263–277 (1973)

Zare, S., Hossein, A., Rafiee, R.: Extension of maximum tensile stress criterion to mixed mode fracture of orthotropic materials considering T-stress. Modares Mech. Eng. 17, 292–300 (2017)

Fakoor, M., Farid, H.M.: Mixed-mode I/II fracture criterion for crack initiation assessment of composite materials. Acta Mech. 230(1), 281–301 (2019)

Fakoor, M., Shahsavar, S.: The effect of T-stress on mixed mode I/II fracture of composite materials: reinforcement isotropic solid model in combination with maximum shear stress theory. Int. J. Solids and Struct., p. 111145 (2021)

Yosibash, Z.: Failure criteria for brittle elastic materials," In: Singularities in Elliptic Boundary Value Problems and Elasticity and Their Connection with Failure Initiation: Springer, pp. 185–220 (2012)

Fakoor, M., Shokrollahi, M.S.: A new macro-mechanical approach for investigation of damage zone effects on mixed mode I/II fracture of orthotropic materials. Acta Mechs. 229(8), 3537–3556 (2018)

Bouledroua, O., Meliani, M. H., Pluvinage, G.: A review of T-stress calculation methods in fracture mechanics computation Nature & Technol., no. 15, p. 20 (2016)

Leevers, P., Radon, J.: Inherent stress biaxiality in various fracture specimen geometries. Int. J. Fract. 19(4), 311–325 (1982)

Manafi Farid, H., Fakoor, M.: Matrix reinforcement coefficients models for fracture investigation of orthotropic materials. Modares Mech Eng 19, 2811–2822 (2019)

Fakoor, M., Rafiee, R.: Transition angle, a novel concept for predicting the failure mode in orthotropic materials. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 227(10), 2157–2164 (2013)

Jernkvist, L.O.: Fracture of wood under mixed mode loading: II. Experimental investigation of Picea abies. Eng. Fract. Mech. 68(5), 565–576 (2001)

Aliha, M., Mousavi, S., Bahmani, A., Linul, E., Marsavina, L.: Crack initiation angles and propagation paths in polyurethane foams under mixed modes I/II and I/III loading. Theoret. Appl. Fract. Mech. 101, 152–161 (2019)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A

Appendix A

\(F_{ij} (\theta )\) and \(g_{ij} (\theta )\) coefficients in Eqs. (11)-(13) are as follows:

In addition, \(\hat{f}_{ij} (\theta )\) and \(\hat{g}_{ij} (\theta )\) coefficients in Eqs. (8)-(10) are expressed as follows:

\(\mu_{2}\) and \(\mu_{1}\) coefficients are the roots of the following equation:

\(S_{ij}\) coefficients are the components of the compliance matrix as follows:

\(\nu_{1}\) and \(\nu_{2}\) coefficients are defined as follows:

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khaji, Z., Fakoor, M. Fracture study of wood considering the effect of T-stress term based on matrix reinforcement coefficients model. Arch Appl Mech 93, 1963–1983 (2023). https://doi.org/10.1007/s00419-023-02366-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-023-02366-8