Abstract

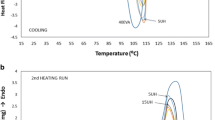

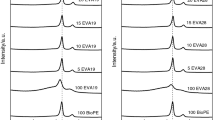

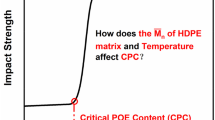

Propylene-ethylene random copolymer (PEC) elastomer was used to toughen high-density polyethylene (HDPE). The morphology, thermal behavior, rheological, and mechanical properties of HDPE/PEC blends were investigated. Scanning electron microscopy (SEM) results revealed that PEC-rich domains dispersed evenly in the HDPE matrix, and HDPE/PEC blends were immiscible. Rheological measurements indicated that the HDPE/PEC blends exhibited higher melt strength and viscosity than neat HDPE, which was beneficial to foaming and blow molding of HDPE. From the results of DSC, PEC elastomer inhibited the crystallization and reduced the degree of crystallinity of HDPE. It was noteworthy that the significant enhancement of the toughness of HDPE was obtained by adding PEC elastomer. The maximum elongation at break (684.6%) and impact strength (35.3 kJ m−2) were achieved for the HDPE/PEC blends, which increased by 110% and 240%, respectively, compared with neat HDPE. Therefore, PEC elastomer could be used as an effective impact modifier for HDPE.

Similar content being viewed by others

References

Hsuan YG, Zhang JY, Wong WK (2007) Evaluation of long term stress crack resistance of corrugated high density polyethylene pipes. Plast Rubber Compos 36:201–206

Feng J, Zhang R, Wu J, Yang W, Yang M, Feng J (2014) Largely enhanced molecular orientation and mechanical property of injection-molded high-density polyethylene parts via the synergistic effect of polyamide 6 in situ microfibrillar and intense shear flow. Colloid Polym Sci 292:3033–3044

Wang L, Yang B, Sun N, Zhang K, Feng J, Yang M (2012) Role of gas delay time on the hierarchical crystalline structure and mechanical property of HDPE molded by gas-assisted injection molding. Colloid Polym Sci 290:1133–1144

Jian Y, Ming L (2018) Enhanced mechanical properties of bamboo fiber/HDPE composites by grafting poly(amido amine) onto fiber surface. Compos Interface 25:1–11

Yan L, Yong Z, Zhang Y (2004) Morphology and mechanical properties of HDPE/SRP/elastomer composites: effect of elastomer polarity. Polym Test 23:83–90

Sae-Oui P, Sirisinha C, Sa-Nguanthammarong P, Thaptong P (2010) Properties and recyclability of thermoplastic elastomer prepared from natural rubber powder (NRP) and high density polyethylene (HDPE). Polym Test 29:346–351

Bing N, Qin Z, Qiang F, Gong Z, Shen K (2002) Super polyolefin blends achieved via dynamic packing injection molding: the morphology and mechanical properties of HDPE/EVA blends. Polymer 43:7367–7376

Ahn Y, Ahn JW, Han C (2017) Effects of polyolefin elastomer on physico-mechanical and thermal properties of HDPE/CaCO3/LDPE-g-MA/POE composites. Korean J Chem Eng 34:1531–1540

Lv Y, Peng C (2018) Chemically grafting carbon nanotubes onto carbon fibers for enhancing interfacial strength in carbon fiber/HDPE composites. Surf Interface Anal 50:552–557

Liu WX (2004) Processing and properties of MWNT/HDPE composites. Carbon 42:271–277

Cao D, Cao Y, Wu C (2009) Morphology and dynamic mechanical properties of high density polyethylene/petroleum resin/polyethylene–octylene elastomer blends. Polym Bull 63:57–67

Aligholizadeh E, Yazdani M, Sabouri H (2020) Modeling hyperviscoelastic behavior of elastomeric materials (HDPE/POE blend) at different dynamic biaxial and uniaxial tensile strain rates by a new dynamic tensile-loading mechanism. J Elastom Plast 52:285–303

Liu S, Wang K, Zhang Z, Ren Y, Chen L, Sun X, Liang W (2020) Effects of ethylene-octene copolymer (POE) on the brittle to ductile transition of high-density polyethylene/POE blends. Polym Eng Sci 60:2640–2652

Li Y, Zhang Y, Zhang Y (2010) Mechanical properties of high-density polyethylene/scrap rubber powder composites modified with ethylene–propylene–diene terpolymer, dicumyl peroxide, and silicone oil. J Appl Polym Sci 88:2020–2027

Mohamed MA, Shaltout NA, Miligy A (2011) The effect of gamma irradiation and particle size of CaCO3 on the properties of HDPE/EPDM blends. Arab J Chem 4:71–77

Stelescu DM, Airinei A, Homocianu M, Fifere N, Timpu D, Aflori M (2013) Structural characteristics of some high density polyethylene/EPDM blends. Polym Test 32:187–196

Chen Y, Zou H, Liang M, Cao Y (2014) Melting and crystallization behavior of partially miscible high density polyethylene/ethylene vinyl acetate copolymer (HDPE/EVA) blends. Thermochim Acta 586:1–8

Chen Y, Zou H, Liang M (2014) Thermal, rheological, morphological and mechanical properties of high density polyethylene/ethylene vinyl acetate copolymer (HDPE/EVA) blends. Polym Sci Ser A 56:465–471

Wang D, Li F, Xu X, Zhong L, Guan C, Gao Y, Jiang W, Liang H (2022) Brittle ductile transition of POE toughened HDPE and its lowest rigidity loss: effect of HDPE molecular weight. J Polym Res 29:38

Sonnier R, Leroy E, Clerc L, Bergeret A, Lopez-Cuesta J-M, Bretelle A-S, Ienny P (2008) Compatibilizing thermoplastic/ground tyre rubber powder blends: efficiency and limits. Polym Test 27:901–907

John B, Varughese KT, Oommen Z, Pötschke P, Thomas S (2003) Dynamic mechanical behavior of high-density polyethylene/ethylene vinyl acetate copolymer blends: the effects of the blend ratio, reactive compatibilization, and dynamic vulcanization. J Appl Polym Sci 87:2083–2099

Nittaa KH, Shinb YW, Hashiguchib H, Tanimotoc S, Terano M (2005) Morphology and mechanical properties in the binary blends of isotactic polypropylene and novel propylene-co-olefin random copolymers with isotactic propylene sequence 1. Ethylene–propylene copolymers. Polymer 46:965–975

Chen J, Cao Y, Li H (2010) The effect of propylene–ethylene copolymers with different comonomer content on melting and crystallization behavior of polypropylene. J Appl Polym Sci 116:1172–1183

Li Y, Cheng H, Yu Y, Han C, Chen G, Zhu Y (2021) Performance of thermal conductive high density polyethylene composite. Chinese J Appl Chem 38:954–960

Khonakdar H, Jafari S, Yavari A, Asadinezhad A, Wagenknecht U (2005) Rheology, morphology and estimation of interfacial tension of LDPE/EVA and HDPE/EVA blends. Polym Bull 54:75–84

Jafari SH, Hesabi MN, Khonakdar HA, Asl-Rahimi M (2011) Correlation of rheology and morphology and estimation of interfacial tension of immiscible COC/EVA blends. J Polym Res 18:821–831

Souza AMC, Demarquette NR (2002) Influence of composition on the linear viscoelastic behavior and morphology of PP/HDPE blends. Polymer 43:1313–1321

Utracki LA, Wilkie CA (2014) Polymer blends handbook. Crystallization, micro-and nano-structure, and melting behavior of polymer blends, 2nd edn. Springer, New York, pp 365–446

Bartczak Z, Argon AS, Cohen RE, Weinberg M (1999) Toughness mechanism in semi-crystalline polymer blends: I. High-density polyethylene toughened with rubbers. Polymer 40:2331–2346

Kajiyama T, Tanaka K, Takahara A (1997) Surface molecular motion of the monodisperse polystyrene films. Macromolecules 30:280–285

Winkler RG, Matsuda T, Yoon DY (1993) Stochastic dynamics simulations of polymethylene melts confined between solid surfaces. J Chem Phys 98:729

Mazidi MM, Edalat A, Berahman R, Hosseini FS (2018) Highly-toughened polylactide-(PLA-) based ternary blends with significantly enhanced glass transition and melt strength: tailoring the interfacial interactions, phase morphology, and performance. Macromolecules 51:4298–4314

Lin Y, Zhang K, Dong Z, Dong L, Li Y (2007) Study of hydrogen-bonded blend of polylactide with biodegradable hyperbranched poly(ester amide). Macromolecules 40:6257–6267

Zhang K, Ran X, Wang X, Han C, Han L, Wen X, Zhuang Y, Dong L (2011) Improvement in toughness and crystallization of poly(L-lactic acid) by melt blending with poly(epichlorohydrin-co-ethylene oxide). Polym Eng Sci 51:2370–2380

Sun S, Xu X, Yang H, Zhang H (2005) Toughening of poly(butylene terephthalate) with epoxy-functionalized acrylonitrile-butadiene-styrene. Polymer 46:7632–7643

Wu G, Zhang J, Shi H, Zhang H (2004) The influence of core-shell structured modifiers on the toughness of poly (vinyl chloride). Eur Polym J 40:2451–2456

Chang S, Xie T, Yang G (2006) Morphology and mechanical properties of high-impact polystyrene/elastomer/magnesium hydroxide composites. J Appl Polym Sci 28:5184–5190

Acknowledgements

The authors gratefully acknowledge the financial support from Key Laboratory for Comprehensive Energy Saving of Cold Regions Architecture of Ministry of Education, Jilin Jianzhu University in Jilin Province.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y., Li, D., Cheng, H. et al. Morphology, rheological, thermal, and mechanical properties of high-density polyethylene toughened by propylene-ethylene random copolymers. Colloid Polym Sci 301, 117–126 (2023). https://doi.org/10.1007/s00396-022-05049-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-022-05049-y