Abstract

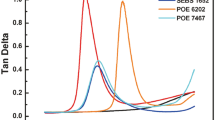

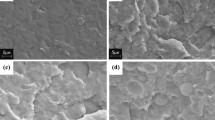

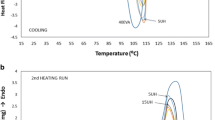

In this study, the brittle-ductile transition of poly(ethylene-co-octene) (POE) toughened high density polyethylene (HDPE) was studied in terms of HDPE molecular weight, elastomer content and temperature. The relation among HDPE molecular weight, critical elastomer content and temperature, the relation among critical interparticle distance (\({ID}_{c}\)), HDPE molecular weight and temperature at critical brittle-ductile transition point were given. From these relations, the high impact HDPE blends with the lowest elastomer content, i.e. with the lowest rigidity loss, could be obtained. The results show that the lowest modulus loss for high impact HDPE/POE blend reduces markedly with the increase of HDPE molecule weight.

Similar content being viewed by others

References

Hu C, Liao X, Qin Q-H, Wang G (2019) The fabrication and characterization of high density polyethylene composites reinforced by carbon nanotube coated carbon fibers. Compos A Appl Sci Manuf 121:149–156. https://doi.org/10.1016/j.compositesa.2019.03.027

Negawo TA, Polat Y, Kilic A (2021) Effect of compatibilizer and fiber loading on ensete fiber-reinforced HDPE green composites: Physical, mechanical, and morphological properties. Compos Sci Technol 213:108937. https://doi.org/10.1016/j.compscitech.2021.108937

Akgul Y, Ahlatci H, Turan ME, Simsir H, Erden MA, Sun Y, Kilic A (2020) Mechanical, tribological, and biological properties of carbon fiber/hydroxyapatite reinforced hybrid composites. Polym Compos 41:2426–2432. https://doi.org/10.1002/pc.25546

Ameen Khan M, Sailaja RRN (2018) Nanocomposites of HDPE/LDPE/Nylon 6 reinforced with MWCNT, Kenaf fiber, nano Mg(OH)2 and PEPA with enhanced mechanical, thermal, and flammability characteristics. Polym Compos 39:E1474–E1486. https://doi.org/10.1002/pc.24366

Chan JX, Wong JF, Hassan A, Mohamad Z, Othman N (2019) Mechanical properties of wollastonite reinforced thermoplastic composites: A review. Polym Compos 41:395–429. https://doi.org/10.1002/pc.25403

Arzhakova OV, Dolgova AA, Yarysheva AY, Nikishin II, Volynskii AL (2020) Mechanoresponsive Hard Elastic Materials Based on Semicrystalline Polymers: From Preparation to Applied Properties. ACS Appl Polym Mater 2:2338–2349. https://doi.org/10.1021/acsapm.0c00288

Candadai AA, Weibel JA, Marconnet AM (2019) Thermal Conductivity of Ultrahigh Molecular Weight Polyethylene: From Fibers to Fabrics. ACS Appl Polym Mater 2:437–447. https://doi.org/10.1021/acsapm.9b00900

Peng F, Jiang H, Woods A, Joo P, Amis EJ, Zacharia NS, Vogt BD (2019) 3D Printing with Core-Shell Filaments Containing High or Low Density Polyethylene Shells. ACS Appl Polym Mater 1:275–285. https://doi.org/10.1021/acsapm.8b00186

Sakakibara K, Moriki Y, Tsujii Y (2018) Preparation of High-Performance Polyethylene Composite Materials Reinforced with Cellulose Nanofiber: Simultaneous Nanofibrillation of Wood Pulp Fibers during Melt-Compounding Using Urea and Diblock Copolymer Dispersant. ACS Appl Polym Mater 1:178–187. https://doi.org/10.1021/acsapm.8b00071

Sun M, Zhu S, Zhang C, Olah A, Baer E, Schiraldi DA (2019) HDPE/EVOH Multilayered, High Barrier Films for Flexible Organic Photovoltaic Device Packaging. ACS Appl Polym Mater 1:259–266. https://doi.org/10.1021/acsapm.8b00181

Lopez-Manchado MA, Yazdani-Pedram M, Retuert J, Quijada R (2003) Effect of monomethyl itaconate-grafted HDPE and EPR on the compatibility and properties of HDPE-EPR blends. J Appl Polym Sci 89:2239–2248. https://doi.org/10.1002/app.12454

Sarkhel G, Aswini B, Banerjee A (2010) High-Density Polyethylene-Ethylene Propylene Rubber-Based Thermoplastic Elastomer: A Mechanical Modeling, Thermal and Rheological Study. Polym-Plast Technol 49:1049–1054. https://doi.org/10.1080/03602559.2010.482087

Greco R, Mancarella C, Martuscelli E, Ragosta G, Yin J (1987) Polyolefin blends: 1. Effect of EPR composition on structure, morphology and mechanical properties of HDPE/EPR alloys. Polymer 28:1922–1928. https://doi.org/10.1016/0032-3861(87)90301-6

Bartczak Z, Argon AS, Cohen RE, Weinberg M (1999) Toughness mechanism in semi-crystalline polymer blends: I High-density polyethylene toughened with rubbers. Polymer 40:2331–2346. https://doi.org/10.1016/s0032-3861(98)00445-5

Zhou Y, Wang W, Dou R, Li L-P, Yin B, Yang M-B (2013) Effect of EPDM-g-MAH on the morphology and properties of PA6/EPDM/HDPE ternary blends. Polym Eng Sci 53:1845–1855. https://doi.org/10.1002/pen.23445

Na B, Zhang Q, Wang Y, Du R, Fu Q (2003) Three-dimensional phase morphologies in HDPE/EVA blends obtained via dynamic injection packing molding. Polymer 44:5737–5747. https://doi.org/10.1016/s0032-3861(03)00524-x

Na B, Zhang Q, Fu Q, Zhang G, Shen KZ (2002) Super polyolefin blends achieved via dynamic packing injection molding: the morphology and mechanical properties of HDPE/EVA blends. Polymer 43:7367–7376. https://doi.org/10.1016/s0032-3861(02)00637-7

Khonakdar HA, Jafari SH, Hässler R (2007) Glass-transition-temperature depression in chemically crosslinked low-density polyethylene and high-density polyethylene and their blends with ethylene vinyl acetate copolymer. J Appl Polym Sci 104:1654–1660. https://doi.org/10.1002/app.25790

Savini G, Oréfice RL (2017) Toughening high density polyethylene submitted to extreme ambient temperatures. J Polym Res. https://doi.org/10.1007/s10965-017-1243-2

Savini G, Oréfice RL (2021) Super ductility in HDPE/EVA blends triggered by synthetic amorphous nanotalc. J Polym Res. https://doi.org/10.1007/s10965-020-02389-7

Liu SC, Wang KJ, Zhang ZF, Ren YQ, Chen LL, Sun XJ, Liang WB (2020) Effects ofethylene-octene copolymer (POE)on the brittle to ductile transition of high-density polyethylene/POE blends. Polym Eng Sci 60:2640–2652. https://doi.org/10.1002/pen.25532

Murugan S, Munusamy Y, Muniandy M, Ismail H (2018) Development of HDPE-modified eggshell composite. Polym Compos 39:1630–1637. https://doi.org/10.1002/pc.24108

Ostafinska A, Vackova T, Slouf M (2018) Strong synergistic improvement of mechanical properties in HDPE/COC blends with fibrillar morphology. Polym Eng Sci 58:1955–1964. https://doi.org/10.1002/pen.24805

Vacková T, Slouf M, Nevoralová M, Kaprálková L (2012) HDPE/COC blends with fibrous morphology and their properties. Eur Polym J 48:2031–2039. https://doi.org/10.1016/j.eurpolymj.2012.09.005

Kakroodi AR, Bainier J, Rodrigue D (2012) Mechanical and Morphological Properties of Flax Fiber Reinforced High Density Polyethylene/Recycled Rubber Composites. Int Polym Proc 27:196–204. https://doi.org/10.3139/217.2473

Colom X, Carrillo F, Canavate J (2007) Composites reinforced with reused tyres: Surface oxidant treatment to improve the interfacial compatibility. Compos A 38:44–50. https://doi.org/10.1016/j.compositesa.2006.01.022

George J (2000) Dynamically vulcanised thermoplastic elastomer blends of polyethylene and nitrile rubber. Polymer 41:1507–1517. https://doi.org/10.1016/s0032-3861(99)00302-x

Liao CZ, Bao SP, Tjong SC (2011) Microstructure and Fracture Behavior of Maleated High-Density Polyethylene/Silicon Carbide Nanocomposites Toughened with Poly(styrene-ethylene-butylene-styrene) Triblock Copolymer. Adv Polym Tech 30:322–333. https://doi.org/10.1002/adv.20228

Attari M, Arefazar A, Bakhshandeh G (2015) Mechanical and thermal properties of toughened PA6/HDPE/SEBS-g-MA/Clay nanocomposite. Polym Eng Sci 55:29–33. https://doi.org/10.1002/pen.23866

Grala M, Bartczak Z (2015) Morphology and mechanical properties of high density polyethylene-POSS hybrid nanocomposites obtained by reactive blending. Polym Eng Sci 55:2058–2072. https://doi.org/10.1002/pen.24048

Ahmad I, Ismail R, Abdullah I (2011) Effects of PBO fiber and clay on the mechanical, morphological, and dynamic mechanical properties of NR/HDPE blends. Polym Eng Sci 51:419–425. https://doi.org/10.1002/pen.21847

Yin S, Tuladhar R, Shi F, Shanks RA, Combe M, Collister T (2015) Mechanical reprocessing of polyolefin waste: A review. Polym Eng Sci 55:2899–2909. https://doi.org/10.1002/pen.24182

Wang J, Zhang X, Jiang L, Qiao J (2019) Advances in toughened polymer materials by structured rubber particles. Prog Polym Sci. https://doi.org/10.1016/j.progpolymsci.2019.101160

Pechurai W, Nakason C, Sahakaro K (2008) Thermoplastic natural rubber based on oil extended NR and HDPE blends: Blend compatibilizer, phase inversion composition and mechanical properties. Polym Testing 27:621–631. https://doi.org/10.1016/j.polymertesting.2008.04.001

Deveci S, Kaliappan SK, Fawaz J, Gadgoli U, Das B (2018) Sensitivity of post yield axial deformation properties of high-density ethylene/α-olefin copolymers in relation to molecular structure and slow crack growth resistance. Polym Testing 72:285–297. https://doi.org/10.1016/j.polymertesting.2018.10.032

Kazanci M, Cohn D, Marom G, Migliaresi C, Pegoretti A (2002) Fatigue characterization of polyethylene fiber reinforced polyolefin biomedical composites. Compos A Appl Sci Manuf 33:453–458. https://doi.org/10.1016/s1359-835x(02)00002-7

Clemons C (2010) Elastomer modified polypropylene–polyethylene blends as matrices for wood flour–plastic composites. Compos A Appl Sci Manuf 41:1559–1569. https://doi.org/10.1016/j.compositesa.2010.07.002

Ou RX, Zhao H, Sui SJ, Song YM, Wang QW (2010) Reinforcing effects of Kevlar fiber on the mechanical properties of wood-flour/high-density-polyethylene composites. Compos A Appl Sci Manuf 41:1272–1278. https://doi.org/10.1016/j.compositesa.2010.05.011

Lei Y, Wu QL, Zhang QG (2009) Morphology and properties of microfibrillar composites based on recycled poly (ethylene terephthalate) and high density polyethylene. Compos A Appl Sci Manuf 40:904–912. https://doi.org/10.1016/j.compositesa.2009.04.017

Bai H, Wang Y, Song B, Huang T, Han L (2009) Effects of nucleating agents on microstructure and fracture toughness of poly(propylene)/ethylene-propylene-diene terpolymer blends. J Polym Sci Part B: Polym Phys 47:46–59. https://doi.org/10.1002/polb.21612

Xu Z, Jie S, Li B-G (2014) Well-defined PE-b-PDMS diblock copolymers via the combination of thiol-ene click and esterification reactions: Facile synthesis and compatibilization for HDPE/silicone oil blends. J Polym Sci Part A: Polym Chem 52:3205–3212. https://doi.org/10.1002/pola.27381

Jiang W, Yu DH, An LJ, Jiang BZ (2004) Brittle-ductile transition of polypropylene/ethyllene-propylene-diene monomer blends induced by size, temperature, and time. J Polym Sci Part B: Polym Phys 42:1433–1440. https://doi.org/10.1002/polb.20023

Wu S (1985) Phase structure and adhesion in polymer blends: A criterion for rubber toughening. Polymer 26:1855–1863. https://doi.org/10.1016/0032-3861(85)90015-1

Contino M, Andena L, Rink M, Marra G, Resta S (2018) Time-temperature equivalence in environmental stress cracking of high-density polyethylene. Eng Fract Mech 203:32–43. https://doi.org/10.1016/j.engfracmech.2018.04.034

Yuan Q, Jiang W, Zhang HX, Yin JH, An LJ, Li RKY (2001) Brittle-ductile transition in high-density polyethylene/glass-bead blends: Effects of interparticle distance and temperature. J Polym Sci Part B: Polym Phys 39:1855–1859. https://doi.org/10.1002/polb.1160

Jiang W, Tjong SC, Li RKY (2000) Brittle-tough transition in PP/EPDM blends: effects of interparticle distance and tensile deformation speed. Polymer 41:3479–3482. https://doi.org/10.1016/s0032-3861(99)00747-8

Liu Y, Hu Y, Liu T, Ding JL, Zhong WH (2015) Mechanical behavior of high density polyethylene and its carbon nanocomposites under quasi-static and dynamic compressive and tensile loadings. Polym Testing 41:106–116. https://doi.org/10.1016/j.polymertesting.2014.11.003

Ren Y, Sun X, Chen L, Li Y, Sun M, Duan X, Liang W (2021) Structures and impact strength variation of chemically crosslinked high-density polyethylene: effect of crosslinking density. RSC Adv 11:6791–6797. https://doi.org/10.1039/d0ra10365a

Saifullah A, Thomas B, Cripps R, Tabeshfar K, Wang L, Muryn C (2018) Fracture toughness of rotationally molded polyethylene and polypropylene. Polym Eng Sci 58:63–73. https://doi.org/10.1002/pen.24531

Jia E, Zhao S, Shangguan Y, Zheng Q (2019) Toughening mechanism of polypropylene bends with polymer particles in core-shell structure: Equivalent rubber content effect related to core-shell interfacial strength. Polymer. https://doi.org/10.1016/j.polymer.2019.121602

Han S, Zhang T, Guo Y, Li C, Wu H, Guo S (2019) Brittle-ductile transition behavior of the polypropylene/ultra-high molecular weight polyethylene/olefin block copolymers ternary blends: Dispersion and interface design. Polymer. https://doi.org/10.1016/j.polymer.2019.121819

Wu S (1983) Impact fracture mechanisms in polymer blends: Rubber-toughened nylon. J Polym Sci: Polym Phys Edi 21:699–716. https://doi.org/10.1002/pol.1983.180210503

Li FS, Gao YB, Zhang CY, Jin J, Ji XL, Zhang Y, Zhang XQ, Jiang W (2020) Design of high impact thermal plastic polymer composites with balanced toughness and rigidity: Effect of matrix polymer molecular weight. Polymer. https://doi.org/10.1016/j.polymer.2020.122957

Li FS, Gao YB, Jiang W (2019) Design of high impact thermal plastic polymer composites with balanced toughness and rigidity: Toughening with one phase modifier. Polymer 170:101–106. https://doi.org/10.1016/j.polymer.2019.03.004

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (21875242, U21A2088) and R&D Foundation of Liaoyang Municipal Government.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• The relation among HDPE molecular weight, critical elastomer content and temperature, the relation among critical interparticle distance (IDc), HDPE molecular weight and temperature at critical brittle-ductile transition point were given.

• The higher number average molecular weight, the higher temperature, and the larger IDc is.

• The lowest modulus loss for high impact HDPE/POE blend reduces markedly with the increase of HDPE molecule weight.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, D., Li, F., Xu, X. et al. Brittle ductile transition of POE toughened HDPE and its lowest rigidity loss: effect of HDPE molecular weight. J Polym Res 29, 38 (2022). https://doi.org/10.1007/s10965-021-02882-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02882-7