Abstract

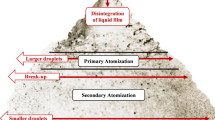

The aim of this work is to carry out an experimental investigation into the generation of airborne microparticles when millimetric droplets of aqueous solutions impact onto a liquid film. Impact experiments using 3.9 mm diameter droplets were carried out for Weber numbers between 159 and 808, with a fixed Ohnesorge number of 2 × 10−3 and film parameters S f (the ratio between the thickness of the liquid film h film and the diameter of the impacting droplet d i) between 0.3 and 1. Observed results show that the deposition/splashing threshold is independent of the parameter S f in agreement with the data in the literature. The aerosol measurement results demonstrate the production of solid particles from the evaporation of secondary microdroplets with diameters less than 30 μm formed when splash occurs. The median diameter of these microdroplets is around 20 μm, corresponding to a value of d 50/d i = 5 × 10−3. Taken together, the results show that the mass and the number of particles emitted increase as the Weber number increases. Moreover, at a Weber number of 808, the results show that the mass and number of particles emitted increases as the parameter S f decreases. In this case, the mean number of microdroplets emitted per impact is equal to 14 for S f = 1 and equal to 76 for S f = 0.3.

Similar content being viewed by others

Abbreviations

- cst:

-

constant

- Bo:

-

bond number (=ρ l g d i²/γ)

- Ca:

-

capillary number (=μ l v i/γ)

- Cu:

-

Cunningham correction factor

- d :

-

diameter

- d 50 :

-

median diameter

- d ae :

-

aerodynamic diameter

- d ev :

-

equivalent volume diameter

- d mod :

-

droplet secondary mode diameter

- C :

-

concentration

- C eq :

-

equilibrium concentration

- f :

-

impact frequency of droplets

- f* :

-

non-dimensional impact frequency (=f d i /v i)

- Fr :

-

Froude number (=v i²/d i g)

- F v :

-

volume fraction

- g :

-

acceleration of gravity

- H r :

-

relative humidity

- h film :

-

film thickness

- K :

-

transfer coefficient

- La :

-

Laplace number

- m :

-

mass

- N impact :

-

number of droplet emitted by impact

- Oh :

-

Ohnesorge number (=μ l/(d i γ ρ l )1/2)

- P :

-

pressure

- q :

-

flow rate of particles

- Q :

-

volumic flow rate

- Q a :

-

inlet volumic flow rate

- Q ext :

-

sampling volumic flow rate

- Re :

-

Reynolds number of droplet (=ρ l v i d i /μ l)

- Re p :

-

Reynolds number of particle (=ρ g v Sed d ae /μ g)

- R r :

-

air change rate

- R s :

-

roughness

- S r :

-

non-dimensional roughness (=R s/d i)

- S f :

-

non-dimensional film thickness (=h film/d i)

- S :

-

surface aera of ground vessel

- t :

-

time

- t r :

-

air change time

- t res :

-

residence time of particle

- T :

-

temperature

- T L :

-

deposition/splashing limit

- v :

-

velocity

- v Sed :

-

settling velocity

- V e :

-

vessel volume

- We :

-

Weber number (=ρ l v i² d i /γ)

- g:

-

gas

- i:

-

of the impacting droplet

- l:

-

liquid

- L:

-

limit

- s:

-

of the secondary droplet

- So:

-

solute (sodium fluorescein)

- ρ :

-

density

- μ :

-

dynamic viscosity

- γ :

-

surface tension

- σ :

-

standard deviation

References

Baron P, Willeke K (2001) Aerosol measurement—principles, techniques, and applications, 2nd edn. Wiley inter-science, New York

Cai YK (1989) Phenomena of a liquid drop falling to a liquid surface. Exp Fluids 7:388–394

Coghe A, Cossali GE, Marengo M (1995) A first study about single drop impingement on thin film liquid film in a low laplace number range. In: Proceedings PARTEC95, Nurnberg

Coghe A, Brunello G, Cossali GE, Marengo M (1999) Single drop splash on thin film: measurements of crown characteristics. In: ILASS Europe

Cossali GE, Coghe A, Marengo M, (1997) The impact of a single drop on a wetted solid surface. Exp Fluids 22:463–472

Cossali GE, Marengo M, Coghe A, Zhdanov S (2004) The role of time in single drop splash on thin film. Exp Fluids 36:888–900

Davidson MR (2002) Spreading of an inviscid drop impacting on liquid film. Chem Eng Sci 57:3639–3647

Engel OG (1967) Initial pressure, initial flow velocity and the time dependence of crater depth in fluid impact. J Appl Phys 38:3935–3940

Godish T (2001) Indoor environmental quality. Lewis Publishers, London

Gregory PH, Guthrie EJ, Bunce ME (1959) Experiments on splash dispersal of fungus spores. J Gen Microbiol 20:328–354

Gueyffier D (2000) Etude de l’impact de gouttes sur un film liquide mince: développement de la corolle et formation de projections. Ph.D. thesis, Université Pierre et Marie Curie

Hinds W (1999) Aerosol technology—properties, behavior, and measurement of airborne particles, 2nd edn. Wiley-Interscience, New York

Hobbs PV, Osheroff T (1967) Splashing of drops on shallow liquids. Science 158:1184–1186

Josserand C, Zaleski S (2003) Droplet splashing on a thin liquid film. Phys Fluids 15:1650–1657

Kersten B, Ohl CD, Prosperetti A (2003) Transient impact of a liquid column on a miscible liquid surface. Phys Fluids 15:821–824

Levin Z, Hobbs PV (1971) Splashing of water drops on solid and wetted surfaces: hydrodynamics and charge separation. Philos Trans R Soc Lond A 1200(269):555–585

Macklin WC, Metaxas GJ (1976) Splashing of drops on liquid layers. J Appl Phys 47:3963–3970

Manzello SL, Yang JC (2002) An experimental study of a water droplet impinging on a liquid surface. Exp Fluids 32:580–589

Mundo C, Sommerfeld M, Tropea C (1995) Droplet-wall collisions: experimental studies of the deformation and breakup process. Int J Multiphase Flow 2:151–173

Mundo C, Sommerfeld M, Tropea C (1998) On the modeling of liquid sprays impinging on surfaces. Atomization Sprays 8:625–652

Nikolopoulos N, Theodorakakos A, Bergeles G (2005), Normal impingement of a droplet onto a wall film: a numerical investigation. Int J Heat Fluid Flow 26:119–132

Oguz HN, Prosperetti A (1989) Surface tension effects in the contact of liquid surfaces. J Fluid Mech 203:149–171

Pumphrey HC, Elmore PA (1990) The entrainment of bubbles by drop impacts. J Fluid Mech 220:539–567

Range K, Feuillebois F (1998) Influence of surface roughness on liquid drop impact. J Colloid Interface Sci 203:16–30

Rein M (1993) Phenomena of liquid drop impact on solid and liquid surfaces. Fluid Dyn Res 12:61–93

Rein M (1996) The translational regime between coalescing and splashing drops. J Fluid Mech 306:145–165

Rieber M, Frohn A (1999) A numerical study on the mechanism of splashing. Int J Heat Fluid Flow 20:455–461

Rioboo R, Bauthier C, Conti J, Voué M, De Coninck J (2003) Experimental investigation of splash and crown formation during single drop impact on wetted surfaces. Exp Fluids 35:648–652

Samenfink W, Elsaber A, Dullenkopf K, Wittig S (1999) Droplet interaction with shear-driven liquid film: analysis of deposition and secondary droplet characteristics. Int J Heat Fluid Flow 20:462–469

Sehmel GA (1967) The density of uranine particles produced by a spinning disc aerosol generator. Am Ind Hyg Assoc J 28:491–492

Shin J, McMahon TA (1990) The tuning of a splash. Phys Fluids A 2:1312–1317

Sivakumar D, Tropea C (2002) Splashing impact of a spray onto a liquid film. Phys Fluids 14:L85–L88

Stow CD, Stainer RD (1977) The physical products of a splashing water drop. J Met Soc Jpn 55:518–531

Stow CD, Hadfield MG (1981) An experimental investigation of fluid flow resulting from the impact of a water drop with an unyielding dry surface. Proc R Soc Lond A 373:419–441

Thoroddsen ST, Takehara K (2000) The coalescence cascade of a drop. Phys Fluids 12:1265–1267

Vander Wal RL, Berger GM, Mozes SD (2006a) The combined influence of a rough surface and thin fluid film upon the splashing threshold and splash dynamics of a droplet impacting onto them. Exp Fluids 40:23–32

Vander Wal RL, Berger GM, Mozes SD (2006b) Droplets splashing upon films of the same fluid of various depths. Exp Fluids 40:33–52

Vander Wal RL, Berger GM, Mozes SD (2006c) The splash/non-splash boundary upon a dry surface and thin fluid film. Exp Fluids 40:53–59

Walzel P (1980) Zerteilgrenze beim Tropfenaufprall. Chem Ing Tech 52:338–339

Wang AB, Chen CC (2000) Splashing impact of a single drop onto very thin liquid films. Phys Fluids 12:2155–2158

Worthington AM (1908) A study of splashes. Longmans, Green, London

Wu ZN (2003) Prediction of the size distribution of secondary ejected droplets by crown of droplets impinging on a solid wall. Prob Eng Mech 18:241–249

Yarin AL, Weiss DA (1995) Impact of drops on solid surfaces: selfsimilar capillary waves, and splashing as a new type of kinematics discontinuity. J Fluid Mech 283:141–173

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1 Calculation of the particle emission rate

The purpose of this model is to define the relationship between the mass and granulometry of the sampled aerosol and the actual emission of microdroplets during the impact. The model should take full account of evaporation and settling of these particles during the sampling process. It is based on equations describing the evolution of the concentration of particles emitted in a ventilated closed vessel with filtered air. A first equation describes the evolution of the concentration during the growth phase with a constant particles emission rate. The second equation describes the evolution of the concentration during the decay phase when the emission of particles has ceased.

If the initial concentration (t = 0) is equal to zero and the particle emission rate is q(d ae), the evolution of the concentration within a ventilated closed vessel with a filtered air inlet flow rate equal to the extraction flow rate of Q ext, is obtained by solving a classic equation which relates the rate of the particle concentration (Baron and Willeke 2001):

where d ae is the aerodynamic diameter of the particles, v Sed (d ae) is the settling velocity and q(d ae) is the particle emission rate. Q ext is the extraction rate in volume per unit time. S is the settling surface area, in this case the area of the base of the closed vessel (0.6536 m2). V e is the volume of the closed vessel (0.562 m3). Equation 9 is valid if it can be assumed that the concentration within the well mixed ventilated closed vessel is homogeneous at all times.

In the Stokes regime, the settling velocity of a particle for a particle Reynolds number (Re p) less than 0.1 may be expressed as follows (Hinds 1999):

where ρ 0 is the reference density of 1,000 kg m−3, μ g is the dynamic viscosity of air (1.81 × 10−5 Pa s at T = 293 K and P = 101.3 kPa), g is the acceleration due to gravity and Cu(d ae) is the Cunningham correction factor at the said diameter. The correction factor Cu(d ae) is given by the following (Baron and Willeke 2001):

where P is the pressure in kPa and d ae the aerodynamic diameter in μm.

The particle Reynolds number Re p is defined as:

where ρ g is the density of the carrier gas.

Equation 10 may be used with Reynolds numbers less than one if an error of 10% in the settling velocity can be tolerated. In practice, a Reynolds number of 0.1 corresponds to the spherical particle settling with a aerodynamic diameter of 37 μm in still air; a Reynolds number of one corresponds to the settling of a reference density spherical particle with a diameter of 80 μm.

If the emission of particles ceases at time t 1, i.e. q(d ae) = 0, the decrease in concentration at t ≥ t 1 is given by the following equation:

The mean concentration within the closed vessel between time t = 0 and t 2 where t 2 > t 1 is given by the following equation:

Combining Eqs. 9, 13 and 14, it is possible to express the particle emission rate as a function of the mean concentration between t = 0 and t 2 as follows:

The next step is to express the rate of emission of microdroplets of diameter d s as a function of the aerodynamic diameter d ae of the dry residues. This may be achieved using the volume equivalent diameter of the dry residues. The relationship between the equivalent volume diameter and the aerodynamic diameter of a particle is given by the expression (Baron and Willeke 2001):

where d ev is the equivalent volume diameter, ρ 0 is the reference density of 1,000 kg m−3 and ρ So the density of the particle. In these experiments, the solid particles are composed of sodium fluorescein which has a density of 1,500 kg m−3. χ is the dynamic shape factor of the particles and may be equal to one as the solid particles formed by the evaporation of a droplet of sodium fluorescein solution may be assumed to be spherical (Sehmel 1967).

The volume equivalent diameter of the dry residue resulting from the evaporation of a droplet with a diameter d s may also be expressed as:

where \( F_{{v_{{{\text{so}}}} }} \) is the volume fraction of the non-volatile impurities in solution. In these experiments, this fraction is equivalent to the concentration of sodium fluorescein in solution.

The emission rate of microdroplets q(d s ) is obtained from Eqs. 15, 16 and 17. Finally, the number of microdroplets of diameter d s emitted per impact is given by:

where f is the impact frequency.

In this approach, it is assumed that the microdroplets evaporate quickly and that any settling of the microdroplets is negligible compared with that of the dry residue. This assumption has been verified by comparing the time required for the evaporation of the microdroplets with the characteristic residence time of the particles in the ventilated closed vessel.

Table 4 shows the evaporation times calculated for droplets with a range of diameters in air at 20°C and with a relative humidity H r of 50%. These calculations have been performed for an aqueous solution of sodium fluorescein with a concentration of 10 g l−1.

Table 4 also shows the volume equivalent diameter and the aerodynamic diameter of the dry residues calculated using Eqs. 16 and 17. The characteristic residence time of the droplets and the dry residues within the ventilated closed vessel have also been calculated.

The characteristic residence time for the air in the ventilated closed vessel is given by:

In these experiments, this characteristic time also known as the air change time t r was measured by means of a gas tracer as 232 s (Appendix 2).

For particles with an aerodynamic diameter greater than 1 μm, their characteristic residence time in suspension in the ventilated closed vessel is calculated as follows, taking account of settling:

Table 4 shows that the evaporation time for droplets with a diameter below 40 μm is always very much less than the characteristic residence time of the droplet. Among phenomena affecting the evolution of the droplets in the ventilated closed vessel, the evaporation of the droplets is therefore faster than the sampling or settling. This result also shows that the particles sampled by the measurement instruments are dry residues.

However, a comparison between the characteristic air change time and the dry residue residence time shows a difference of greater than 5% for a dry residue aerodynamic diameter greater than 2.3 μm. This difference is due to settling of the particles and is taken into account in the calculation of the microdroplet emission rate.

The uncertainty in the number of microdroplets emitted per impact \( {\left( {\sigma _{{N^{{{\text{impact}}}} (d_{{\text{s}}} )}} } \right)} \) is calculated using a classical error propagation method:

where N impact(d s) is a function of a number of variables (x j) and standard deviations (σ xj), particularly the mean concentration of particles sampled during an experiment, the sampling rate (with a relative uncertainty of 2.1%), the volume of the vessel (with a relative uncertainty of 2.1%), and the surface area subject to deposition by settling (with a relative uncertainty of 1.8%).

In order to minimise the uncertainty relating to the mean concentration, C mean(d ae) is calculated from measurements of the mass of sodium fluorescein collected on the HEPA filter (m filter) and the normalised volume fraction F v (d ev) of the size distribution of the dry residues as measured by the APS. The expression used is as follows:

where V p is the volume sampled by the high-flow rate sampler between t = 0 and t 2.

This calculation of the mean concentration results in a lower uncertainty than would a simple calculation based on the concentration measured directly by the APS. This is because of the high uncertainty in the APS sampling rate, 1.0 ± 0.2 l min−1, i.e. 20%, compared with that of the high-flow rate sampler with flow rate of only 2%.

Of all the parameters, F v has the highest uncertainty as it is calculated by applying Poisson’s law to low counts (the uncertainty for a count of N particles is equal to \( {\sqrt N }. \) For example, the relative uncertainty in F v , calculated from the number of particles counted by the APS during the experiment in which the greatest number of particles were produced, and therefore having the lowest relative uncertainty, was 22%. Given that this relative uncertainty is considerably higher than those related to the sampled volume and others, only the uncertainty relating to F v is taken into account when calculating the uncertainty relating to N impact(d s).

Appendix 2 Experiment used to validate the transfer model

The equations used to describe the evolution of the particle concentration in the ventilated closed vessel are validated in two following sections. The first relates to the assumption of a homogeneous concentration within the ventilated closed vessel at all times, and the second relates to the method used to account for settling of the dry residues.

The assumption that the concentration is homogeneous throughout the ventilated closed vessel was validated by an experiment measuring evolution in the concentration of a tracer gas, sulphur hexafluoride (SF6) within the ventilated closed vessel. These experiments were also used to determine the characteristic air change time within the ventilated closed vessel. Experiments using a particulate tracer (a polydispersed aerosol of glass spheres) were used to validate the correction for settling during sampling. These experiments provided an overall characterisation of the representivity of the aerosol samples taken at various points away from the emission source.

2.1 Characterisation of the air change time using a tracer gas

In these experiments, the closed vessel was ventilated with a flow rate of clean air (Q a) and a small flow rate of tracer gas q g (q g « Q a). The tracer gas was injected at the bottom of the vessel at a position representative of the point at which the microdroplets would be emitted during impact by a drip of droplets. The concentration of the tracer gas was measured at sampling points using infra-red spectrometers (BINOS) with a detection limit below 1 ppm.

Assuming that the concentration is homogeneous at all times, the evolution of the tracer gas concentration during injection is given by the equation (Godish 2001):

and where V e is the volume of the closed vessel and Q ext the flow rate of the extracted air. C eq = q g/Q ext is the concentration reached at equilibrium.

When the injection of tracer gas is stopped, the concentration decreases according to the equation (Godish 2001):

Figure 9 shows the evolution of the SF6 concentration measured in the vessel at the same point as the high flow rate sampler with an extraction flow rate of 145 l min−1. Figure 9 also shows the decay phase of the concentration on a logarithmic scale. The results clearly show that the decay phase follows an exponential curve in accordance with Eq. 24, validating the assumption of a homogeneous concentration within the ventilated closed vessel that was used to establish this equation. Using the results to adjust the equation provides an experimental determination of the characteristic air change time t r and the air change rate R r (R r = 1/t r).

Table 5 gives the results obtained in the six tracer gas experiments, together with the theoretical values of the air change time and air change rate.

The mean value of the air change rate R r determined experimentally was 15.5 ± 0.7 h−1. This result is in very close agreement with the theoretical value of 15.5 h−1. Similarly, the theoretical value of the characteristic air change time t r of 232 s is very close to the experimental value of 233 ± 10 s.

2.2 Characterisation of the transfer by means of a particulate tracer

The particulate tracer experiments were performed using a polydispersed aerosol of glass spheres with a dynamic shape factor χ = 1 and density ρ = 2.5 g cm−3. These experiments were used to characterise the representativeness of the aerosol samples taken at the point of measurement (filter and APS) relative to the point of emission by determining the transfer coefficients for particles with aerodynamic diameters of 0.6–20 μm. The use of a polydispersed aerosol enabled the whole range of interest (aerodynamic diameters of the dry residues between 0.6 and 20 μm) to be covered in a single experiment.

The transfer coefficient K(d ae) is used to relate the flow rate of particles at the source to their concentration at equilibrium in the vessel. It is given by:

where C eq(d ae) is the concentration at equilibrium at a given point within the ventilated vessel and q(d ae) is the flow rate at the source.

The equilibrium concentration (C eq) reached at time t » t r is given using the Eq. 9:

Combining Eqs. 25 and 26 gives the following expression for the transfer coefficient K(d ae):

In these experiments, the polydispersed aerosol was produced by continually dispersing the glass spheres powder using a PALAS RGB-1000 generator. The aerosol injected into the ventilated closed vessel was first electrically neutralised by eight americium 241 sources in order to avoid the losses of particles due to electrostatic effects. The sources were fixed in a tube through which the aerosol was passed in order to create a homogeneous bipolar ionisation zone by the emission of alpha radiation. The measurement system is shown in Fig. 10. The rate of particle injection was measured using the APS using a tube to connect the point of injection to the sampling point directly.

Figure 11 shows the theoretical transfer coefficients, calculated from equation 27 in the homogeneous air change case, together with the experimental gas and particulate transfer coefficients for a ventilation flow rate of Q ext = 145 l min−1.

Overall, the experimental results agreed well with the theoretical calculations taking into account losses due to settling. Given the experimental measurements and the theoretical values of K(d ae), and taking into account of the uncertainties, it is reasonable to assume that particles with aerodynamic diameters less than 5 μm behave very much like a gas in our ventilated closed vessel for a air change rate of 15.5 h−1. However, as the aerodynamic diameter rises above 5 μm, the behaviour increasingly deviates from that of a gas. The particulate transfer coefficient falls as the aerodynamic diameter of the particles increases. This behaviour is explained by the fact that the settling increases in line with the diameter of the particles.

These particulate tracer experiments validate the use of the particle transfer model taking into account losses through settling as a method of calculating the flow rate of the aerosol emitted from measurements of the concentration.

Rights and permissions

About this article

Cite this article

Motzkus, C., Géhin, E. & Gensdarmes, F. Study of airborne particles produced by normal impact of millimetric droplets onto a liquid film. Exp Fluids 45, 797–812 (2008). https://doi.org/10.1007/s00348-008-0500-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00348-008-0500-x