Abstract

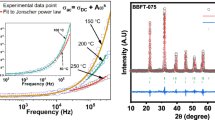

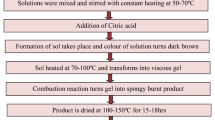

A series of La and Ti co-doped bismuth ferrite ceramics have been synthesized using the modified sol–gel approach and their crystal structures were verified using X-ray diffraction. Complex impedance analysis has been used to examine the conduction mechanisms and microscopic dielectric relaxations in all of these materials. To examine the behaviour of the dielectric constant's dispersion, the modified Debye's function has been utilized. The dielectric characteristics of each sample have been described using the brick-layer model. In order to understand the conduction mechanism, relaxation period and activation energies, Arrhenius equation and Jonscher's power law were used. The dc conductivity (σDc) decreases significantly by increasing the co-doping percentage of La and Ti which indicates that the dielectric properties of the BFO is improved by the co-doping. The Jonscher's power law fitting parameters indicate that the correlated barrier hopping (CBH) conduction model is followed in all the co-doped samples. Moreover, Electric modulus spectroscopy and the observed values of activation energies suggests the localized and long-range relaxation processes, which are basically non-Debye type relaxation processes. The minimum value of dielectric loss factor was obtained for 10% of La and Ti co-doping. The observed trend in values of activation energies also suggests that the best dielectric properties are obtained for the 10% of La and Ti co-doping in BFO and it retain high dielectric constant up to higher temperature.

Similar content being viewed by others

Data availability

Data will be made available on the reasonable request.

References

J.F. Scott, J. Mater. Chem. (2012). https://doi.org/10.1039/c2jm16137k

N.A. Hill, J. Phys. Chem. B (2000). https://doi.org/10.1002/chin.200049237

R. Ramesh, N.A. Spaldin, Nat. Mater. (2007). https://doi.org/10.1038/nmat1805

G. Catalan, J.F. Scott, Adv. Mater. (2009). https://doi.org/10.1002/adma.200802849

S.W. Cheong, M. Mostovoy, Nat. Mater. (2007). https://doi.org/10.1038/nmat1804

W. Eerenstein, N.D. Mathur, J.F. Scott, Nature (2006). https://doi.org/10.1002/chin.200644216

D.H. Wang, W.C. Goh, M. Ning, C.K. Ong, Appl. Phys. Lett. (2006). https://doi.org/10.1063/1.2208266

L.W. Martin, R. Ramesh, Acta Mater. (2012). https://doi.org/10.1016/j.actamat.2011.12.024

R. Ramesh, Nature (2009). https://doi.org/10.1038/4611218a

J. Wang, J.B. Neaton, H. Zheng, Science (2003). https://doi.org/10.1002/chin.200324015

A. Singh, V. Pandey, R.K. Kotnala, D. Pandey, Phys. Rev. Lett. (2008). https://doi.org/10.1103/physrevlett.101.247602

I. Dzyaloshinsky, J. Phys. Chem. Solids (1958). https://doi.org/10.1016/0022-3697(58)90076-3

A. Palewicz, R. Przeniosolo, I. Sonsnowska, A.W. Hewat, Acta Cryst. B (2007). https://doi.org/10.1107/s0108768107023956

A. Palewicz, I. Sonsnowska, R. Przeniosolo, A.W. Hewat, Acta Cryst. Phys. Pol. A (2010). https://doi.org/10.12693/aphyspola.117.296

S. Ghosh, S. Dasgupta, A. Sen, H.S. Maiti, J. Am. Ceram. Soc. (2005). https://doi.org/10.1111/j.1551-2916.2005.00306.x

C.H. Yang, D. Kan, I. Takeuchi, V. Nagarajan, Phys. Chem. Chem. Phys. (2012). https://doi.org/10.1039/c2cp43082g

R.D. Shannon, Acta Crystallgr. A (1976). https://doi.org/10.1107/s0567739476001551

S.M. Selbach, T. Tybell, M.A. Einarsurd, T. Grande, Chem. Mater. (2007). https://doi.org/10.1021/cm071827w

R. Haumont, J. Kreisel, P. Bouvier, Phase Transition (2006). https://doi.org/10.1080/01411590601067342

A.V. Zalesskii, A.A. Frolov, T.A. Khimich, A.A. Bush, Phys. Solid State (2003). https://doi.org/10.1134/1.1537425

V.R. Palkar, D.C. Kundaliya, S.K. Malik, S. Bhattacharya, Phys. Rev. B (2004). https://doi.org/10.1103/PhysRevB.69.212102

Q. Xu, H. Zai, D. Wu, Y.K. Tanga, M.X. Xu, J. Alloys Compd. (2009). https://doi.org/10.1016/j.jallcom.2009.05.129

S. Ghosh, S. Dasgupta, A. Sen, H.S. Maiti, Mater. Res. Bull. (2005). https://doi.org/10.1016/j.materresbull.2005.07.017

J.K. Kim, S.S. Kim, W.J. Kim, Mater. Lett. (2005). https://doi.org/10.1016/j.matlet.2005.07.050

R. Mazumder, D. Chakravarty, D. Bhattacharya, A. Sen, Mater. Res. Bull. (2009). https://doi.org/10.1016/j.materresbull.2008.07.017

S. Rani, M. Shekhar, P. Kumar, S. Prasad, Appl. Phys. A (2022). https://doi.org/10.1007/s00339-022-06171-y

X.Z. Chen, Z.C. Qiu, J.P. Zhou, G. Zhu, X.B. Bian, P. Liu, Mater. Chem. Phys. (2011). https://doi.org/10.1016/j.matchemphys.2011.01.027

Z.X. Cheng, A.H. Li, X.L. Wang, S.X. Dou, K. Ozawa, H. Kimura, S.J. Zhang, T.R. Shrout, J. Appl. Phys. (2008). https://doi.org/10.1063/1.2839325

Y. Dua, Z.X. Chenga, M. Shahbazia, E.W. Collingsb, S.X. Doua, X.L. Wanga, J. Alloys Compd. (2010). https://doi.org/10.1016/j.jallcom.2009.10.124

M. Kumar, K.L. Yadav, J. Appl. Phys. (2006). https://doi.org/10.1063/1.2349491

C.C. Lee, J.M. Wu, Solid-State Lett. (2007). https://doi.org/10.1149/1.2745123

J. Wu, J. Wang, J. Am. Ceram. Soc. (2010). https://doi.org/10.1111/j.1551-2916.2010.03816.x

Y.F. Cui, Y.G. Zhao, L.B. Luo, J.J. Yang, H. Chang, M.H. Zhu, T.L. Ren, D. Xie, Appl. Phys. Lett. (2010). https://doi.org/10.1063/1.3524225

Reetu, A. Agarwal, S. Sanghi, Ashima, N. Ahlawat, J. Phys. D Appl. Phys. (2012). https://doi.org/10.1088/0022-3727/45/16/165001

P. Kumar, M. Kar, J. Alloys Compd. (2014). https://doi.org/10.1016/j.jallcom.2013.09.107

G.H. Jaffari, A. Samad, A.M. Iqbal, S. Hussain, A. Mumtaz, M.S. Awan, S.I. Shah, J. Alloys Compds (2015). https://doi.org/10.1016/j.jallcom.2015.05.065

A.B.A. Hammad, H.S. Magar, A.M. Mansour, R.Y.A. Hassan, A.M.E. Nahrawy, Sci. Rep. (2023). https://doi.org/10.1038/s41598-023-36076-6

A.L. Patterson, Phys. Rev. (1939). https://doi.org/10.1103/PhysRev.56.978

A.K. Zak, W.A. Majid, M.E. Abrishami, R. Yousefi, Solid State Sci. (2011). https://doi.org/10.1016/j.solidstatesciences.2010.11.024

Y. Shahmoradi, D. Souri, M. Khorshidi, Ceram. Int. (2019). https://doi.org/10.1016/j.ceramint.2018.12.133

M. Abushad, W. Khan, S. Naseem, S. Husain, M. Naseem, A. Ansari, Ceram. Int. (2019). https://doi.org/10.1007/s42452-020-03669-z

S. Irfan, L. Li, A.S. Saleemi, C.W. Nan, J. Mater. Chem. (2017). https://doi.org/10.1039/C7TA01847A

G. Dhir, P. Uniyal, N.K. Verma, Physica B B (2018). https://doi.org/10.1016/j.physb.2017.12.004

A.M. El Nahrawy, A.M. Bakr, B.A. Hemdan, A.B. Abou Hammad, Int. J. Environ. Sci. Technol. (2020). https://doi.org/10.1007/s13762-020-02786-x

C.C. Qiu, Y.Y. Zhang, X.S. Lv, Y.G. Yang, L. Wei, H.J. Yu, J. Mater. Sci. Mater. Electron. (2020). https://doi.org/10.1007/s10854-020-03195-z

G. Datt, A.C. Abhyankar, J. Appl. Phys. (2017). https://doi.org/10.1063/1.4990275

Y.D. Kolekar, L.J. Sanchez, C.V. Ramana, J. Appl. Phys. (2014). https://doi.org/10.1063/1.4870232

M. Gowrishankar, D.R. Babu, P. Saravanan, Mater. Lett. (2016). https://doi.org/10.1016/j.matlet.2016.02.044

M.A. Dar, K. Majid, K.M. Batoo, R.K. Kotnala, J. Alloys Compd. (2015). https://doi.org/10.1016/j.jallcom.2015.01.190

M.H. Dhaou, S. Hcini, A. Mallah, M.L. Bouazizi, A. Jemni, Appl. Phys. (2017). https://doi.org/10.1007/s00339-016-0652-0

Z.Z. Lazarevic, C. Jovalekic, D.L. Sekulic, A. Milutinovic, S. Balos, M. Slankamenac, N.Z. Romcevic, Mat. Res. Bull. (2013). https://doi.org/10.1016/j.materresbull.2013.07.012

N. Sivakumar, A. Narayanasamy, C.N. Chinnasamy, B. Jeyadevan, J. Phys. Condens. MatterCondens. Matter (2007). https://doi.org/10.1088/0953-8984/19/38/386201

A.B. Abou Hammad, A.G. Darwish, A.M. El Nahrawy, Appl. Phys. A (2020). https://doi.org/10.1007/s00339-020-03679-z

C. Behera, P.R. Das, R.N.P. Choudhary, J. Electron. Mater. (2014). https://doi.org/10.1007/s11664-014-3216-0

D.K. Pradhan, P. Misra, S.V. Puli, S. Sahoo, J. Appl. Phys. (2014). https://doi.org/10.1063/1.4885420

R. Nongjai, S. Khan, K. Asokan, H. Ahmed, I. Khan, J. Appl. Phys. (2012). https://doi.org/10.1063/1.4759436

A.U. Rahman, M.A. Rafiq, S. Karim, K. Maaz, M. Siddique, M.M. Hasan, J. Phys. D Appl. Phys. (2011). https://doi.org/10.1088/0022-3727/44/16/165404

E. Markiewicz, B. Hilczer, M. Błaszyk, J. Electroceram.Electroceram. (2011). https://doi.org/10.1007/s10832-011-9660-9

A.B. Abou Hammad, A.M. Mansour, A.M. El Nahrawy, Phys. Scr. (2021). https://doi.org/10.1088/1402-4896/ac25a6

A.M. El Nahrawy, A.I. Ali, A.M. Mansour, A.B. Abou Hammad, B.A. Hemdan, S. Kamel, Carbohydr. Polym.. Polym. (2022). https://doi.org/10.1016/j.carbpol.2022.119656

K.S.A. Kumar, R.N. Bhowmik, Mater. Res. Exp. (2017). https://doi.org/10.1088/2053-1591/aa9d4a

Z.Z. Lazarevi, Jovaleki, A. Milutinovi, D. Sekuli, V.N. Ivanovski, A. Renik, B. Ceki, N.Z. Romevi, J. Appl. Phys. Appl. Phys. (2012). https://doi.org/10.1109/isaf.2012.6297730

K. Vasundhara, S.N. Achary, S.K. Deshpande, P.D. Babu, S.S. Meena, J. Appl. Phys. (2013). https://doi.org/10.1063/1.4804946

W. Chen, W. Zhu, O.K. Tan, X.F. Chen, J. Appl. Phys. (2010). https://doi.org/10.1063/1.3457217

K. Rajulu, V. Ch, B. Tilak, K.S. Rao, Appl. Phys. (2012). https://doi.org/10.1007/s00339-011-6631-6

A.I. Ali, B.A. Hemdan, A.M. Mansour, A.B. Abou Hammad, S. Kamel, A.M. El Nahrawy, Cellulose (2023). https://doi.org/10.1007/s10570-023-05416-0

Y. Zhou, X. Huang, L. Jiang, Y. Hou, H. Lin, Z. Cheng, D. Sun, J. Mater. Sci. Mater. Electron. (2022). https://doi.org/10.1007/s10854-022-09251-0

S. Sharma, K. Shamim, A. Ranjan, R. Rai, P. Kumari, S. Sinha, Ceram. Int. (2015). https://doi.org/10.1016/j.ceramint.2015.02.102

M. Zulqarnain, S.S. Ali, U. Hira, J.F. Feng, M.I. Khan, M. Rizwan, K. Javed, D.G. Farid, M.S. Hasan, J. Alloys Compd. (2022). https://doi.org/10.1016/j.jallcom.2021.162431

R. Schmidt, S. Pandey, P. Fiorenza, D.C. Sinclair, RSC Adv. (2013). https://doi.org/10.1039/c3ra41319e

A.B. AbouHammad, A.M. Bakr, M.S. Abdel-Aziz, A.M. El Nahrawy, J. Mater. Sci. Mater. Electron. (2020). https://doi.org/10.1007/s10854-020-03323-9

Acknowledgements

The authors acknowledge IIT Patna and Mahatma Gandhi Central University, Bihar for extending experimental facilities.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study, conception and design. Material preparation, data collection, analysis and manuscript writing were performed by Mukesh Shekhar, Amod Kumar and Sonu Rani. Supervision and review were done by Lawrence Kumar and Pawan Kumar. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interest to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shekhar, M., Kumar, A., Rani, S. et al. A study on temperature dependent dielectric relaxation behaviour and conduction mechanism of La and Ti co-doped bismuth ferrite. Appl. Phys. A 130, 237 (2024). https://doi.org/10.1007/s00339-024-07383-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-024-07383-0