Abstract

Dielectric behaviour of BiFeO3 ceramics, obtained by hot-pressing of nanopowders produced by mechanochemical synthesis from Bi2O3 and Fe2O3 oxides (weight ratio 2:1), was studied in the temperature range 125–575 K. The ceramics was found to exhibit step-like dielectric response ε*(T) with high permittivity values, similar to the behaviour of materials with giant dielectric permittivity. Three overlapping relaxation processes contribute to the dielectric response: i) relaxation in the low-temperature range (220–420 K), characterized by activation energy of 0.4 eV, ii) relaxation in the temperature range 320–520 K with activation energy of 1.0 eV and iii) broad dielectric anomaly in the vicinity of 420 K, which disappears after 1 h annealing at 775 K. The low-temperature relaxation is ascribed to the carrier hopping process between Fe2+ and Fe3+ ions. The presence of mixed valence of the Fe ions was proved by X-ray photoelectron spectroscopy. Dielectric relaxation in the middle-temperature range is considered as a result of grain boundary effect and internal barrier layers related to Bi25FeO40 phase as verified by X-ray diffraction. The high-temperature dielectric anomaly we relate to short-range hopping of ordered oxygen vacancies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The interest in materials with high dielectric permittivity value is still increasing due to their wide applications in microelectronics industries. Among so called giant permittivity compounds with room temperature permittivity ε′ ~ 105 the most important are ACu3Ti4O12 [1, 2] and complex perovskites AFe1/2B 1/2 O3 [3]. It is widely proposed in the literature that the unusual dielectric behavior of the materials is related to the electrically inhomogeneous microstructure (grain-boundary structure) of the ceramics that enhances the dielectric permittivity by the barrier layer mechanism [4–10]. Malone and Subramanian point out to the contribution of electric conductivity originating from the multivalent Cu and Fe ions and oxygen vacancies [11]. It appears that the problem of electric conductivity in BiFeO3 (BFO), which is the most studied single phase room temperature magnetoelectric multiferroic, is of great importance because the temperature at which the antiferromagnetic ordering disappears (TN = 640 K) is significantly removed from the ferroelectric Curie temperature (TC = 1100 K) [12].

Recently the magnetoelectric multiferroics gain a great interest because the magnetoelectric (ME) coupling opens up an opportunity to design and develop advanced magnetoelectric RAMs, magnetic field sensors, spintronics elements etc. [13–18]. It has been shown however that the ME coupling is not the only way to induce high magnetodielectric response but the response may originate from various kinds of heterogeneity as grain boundary layers and superlattices [19]. Kamba et al. have shown that the magnetodielectric response of BFO ceramics in the temperature range 10–300 K is not originating from the ME effect (coupling of dielectric polarization and magnetization in the multiferroic) but is due to a combination of Maxwell-Wagner type polarization and the magnetoresistance [20]. They found that the relative changes in the dielectric permittivity under influence of magnetic field up to 9 T at the temperature above 250 and bellow 200 K, i. e., in the range where the Maxwell—Wagner mechanism does not contribute to the permittivity, are very low (~10−5).

It should however be noted that the dielectric response and electric conductivity of BFO ceramics are determined by the processing conditions [21–25], which are responsible not only for the oxygen deficiency and the presence of Fe2+ but also for the formation of various parasitic phases [26, 27]. BFO ceramics obtained by rapid liquid phase sintering [21, 22] as well as ceramics sintered from coprecipitation powder at 800°C and 850°C [23] are single-phased ceramics of a high electric resistivity with ferric Fe3+ ions. Low ac conductivity of BFO ceramics sintered from powders obtained in coprecipitation process was measured at low temperatures (at 25°C: ~2⋅10−5 Ω−1 m−1 and ~2⋅10−4 Ω−1 m−1 for 100 kHz and 2 MHz, respectively) with activation energy of 0.13 eV. At temperatures higher than ~350°C the conductivity increases rapidly with activation energy of 1.26 eV and its low-frequency values become higher than those for the high frequency [23]. Another dielectric behaviour with three relaxation processes have been reported for the ceramics sintered at 700°C during 4 h from pure precipitation-synthesized BFO powder [25]. The low-temperature relaxation with activation energy of 0.34 eV was attributed by the authors to the hopping conductivity of the localized charge carriers, the middle-temperature relaxation process of the activation energy 0.77 eV was related to the grain boundary effect, whereas the high-temperature relaxation with the highest activation energy (0.95 eV) to the defects and/or the conduction.

Hence, it appears that a fundamental understanding of the correlations between the structure and the properties in BFO ceramics is still inadequate. To improve the understanding of the problem we report here the results of the dielectric response studies of hot-pressed ceramics obtained by hot-pressing of BFO nanopowders prepared by a mechanochemical synthesis (solid-solid reaction initiated by milling in high-energy ball mills). The parameters of the mechanochemical process, like milling time, shock frequency and the kinetic energy per hit, strongly affects the properties of the milling product, as well as the value of the dielectric permittivity [28]. We discover that the obtained ceramics exhibits a high dielectric permittivity. It has been established that three dielectric relaxation processes contribute to the dielectric response in the temperature range 125–575 K. X-ray diffraction (XRD) analysis reveal the presence of a trace of Bi25FeO40 and we understand that the parasitic phase plays an important role in the observed dielectric properties. The electrical inhomogeneity of the material enables us to justify the relatively giant value of dielectric permittivity using the well–known internal barrier layer capacitor model [4, 5, 8]. In addition, X-ray photoelectron spectroscopy (XPS) studies were performed in order to evaluate the contents of mixed valences Fe2+ and Fe3+ ions, since the perovskites containing polyvalent cations such as Fe, Mn and Cu are known to exhibit a prominent dielectric permittivity step due to electron transfer between both valence states [6, 11, 29].

2 Experimental

2.1 Sample preparation

Bismuth ferrite nanopowder was synthesized by high-energy mechanical activation of commercially available oxides Bi2O3 (99.8% purity) and Fe2O3 (99% purity) purchased from Aldrich. The starting oxides weighted in 2Bi2O3:Fe2O3 ratio were placed in 250 ml stainless steel vial and subjected to high-energy milling using 10 grinding balls of 20 mm diameter made of stainless steel too. The weight ratio of the balls to the powder was 30:1. The mechanochemical synthesis was performed in Fritsch Pulverisette 6 planetary ball mill during 7 h under normal pressure. The calculated parameters [30] of the high energy milling were the following: the kinetic energy per hit and the shock frequency were 300 mJ/hit and 100 Hz, respectively. The obtained nanopowder was hot-pressed at 1073 K under pressure of 200 MPa during 2 h using graphite die/ram tool in order to compact the ceramics. Typical dimensions of samples were ~8 mm diameter and ca. 1 mm thickness. Both sides of the samples subjected to dielectric measurements were coated with gold electrodes using Baltec SCD 050 sputter coater.

2.2 XRD studies

The structure of the synthesized BFO was controlled by X-ray powder diffraction studies using X’Pert-PANalytical diffractometer with CuΚα radiation. The data were collected at room temperature in 2–theta range from 10° to 60° after milling and after the hot–pressing process of the sample.

2.3 XPS measurements

XPS spectra of BFO ceramic sample were recorded using a PHI 5700/660 Physical Electronics Photoelectron Spectrometer with monochromatized Al Kα X-ray radiation (1,486.6 eV). The Fe 2p core level XPS spectra of BFO ceramic samples were collected with UHV (standard pressure of 8 × 10−11 mBar) VG Scienta spectrometer with SES 100 analyzer. Measurements were performed with Mg anode (1,254 eV) at room temperature. In addition, in order to refine the samples surfaces, ion beam etching was carried out preceding each measurement. In every case the binding energy was determined by reference to the C1s component at the energy of 285 eV.

2.4 Dielectric measurements

Dielectric response and ac conductivity of the BFO ceramic samples were studied using an Alpha-A High Performance Frequency Analyzer (Novocontrol GmbH) combined with Quatro Cryosystem for the temperature control. The sample was fixed between two additional external electrodes in the sample holder and placed into a cryostat. The measurement was performed in the temperature range from 125 K to 575 K on heating at a rate of 1 K/min. The frequency varied from 1 Hz to 1 MHz at the oscillation voltage of 1 V. The measured dielectric permittivity data were collected and evaluated by WinDETA impedance analysis software and a WinFit V 3.2. program.

3 Results and discussion

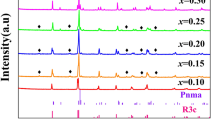

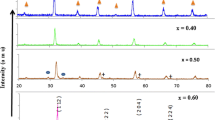

X-ray powder diffraction studies revealed the structure of the synthesized BFO as trigonal (R3c). The mean grain size calculated according to the Scherer formula [31], was 26 nm after milling and 64 nm after hot–pressing. Figure 1 shows the XRD patterns of BFO nanopowder after milling and that after hot–pressing. The spectrum observed for the nanopowder immediately after milling shows the presence of X-ray diffraction peak at 2Θ angle of about 27.2° considered as belonging to pure Bi. The trace of Bi disappears after hot-pressing at 1073 K due to both the high volatility of this element and formation of a parasitic phase. The spectrum recorded after the hot-pressing is characterized by a number of diffraction peaks at about 27.7°, 54.0° and 55.6° owing to the contribution of secondary Bi25FeO40 phase. The peak of relatively high intensity in the vicinity of 44.2° is coming from the iron sample holder. Moreover, a weak diffraction peak of unknown origin was observed at 46.7°. We assigned the positions of particular X-ray diffraction peaks to the components using ISCD 2010 data base of inorganic compounds.

As both the presence of a parasitic phase and the mixed valence of iron ions are very crucial to the dielectric properties of the ceramics, BFO was also characterized by XPS spectroscopy. Figure 2 shows XPS spectrum of the ceramics obtained from mechanically synthesized nanopowders by hot-pressing. One can observe that the characteristic core level spectra manifest themselves at the energies higher than ~20 eV and the valence band is separated from the Fermi level by energy gap of ~2.2 eV (see the inset). Fe 2p core level XPS spectrum of the BFO ceramics obtained from mechanochemically synthesized nanopowders is presented in Fig. 3. The line shape deconvolution of the Fe 2p 3/2 maximum (Gaussian-Lorentzian curve fitting) yields two peaks which can be ascribed to the presence of both Fe3+ and Fe2+ ions with binding energies of 709.4 eV and 707.8 eV, respectively [32]. The integrated intensities of the two contributions are comparable (that of the Fe2+ 2p 3/2 is of ~51% of the total Fe 2p 3/2 component, that of Fe3+ 2p 3/2 is of ~49% of the total Fe 2p 3/2 maximum) which implies ~50% of the iron ions occurring in the Fe2+ valence state. The composition of the BFO ceramics was calculated from the integrals of “Bi4f”, “Fe2p” and “O1s”, the three photoelectron profiles, with the following sensitivity correction factors: Bi—31 at.%, Fe—10.5 at.% and O—58.5 at.%. Thus determined composition differs considerably from the BiFeO3 stoichiometry and is due to the ratio of the oxides used for mechanochemical synthesis (2Bi2O3:Fe2O3). The Bi surplus is apparent in the hot-pressed ceramics as well as the admixture of bismuth-rich Bi25FeO40 phase observable in the XRD pattern.

Figure 4 shows temperature dependences of real ε′ and imaginary ε″ parts of dielectric permittivity of the hot-pressed BFO sample. Only below 150 K one can observe the intrinsic permittivity of ε′ ≈ 80. At higher temperatures the two parts of dielectric permittivity remarkably rise due to the contribution of three dielectric relaxation processes that occur in the temperature ranges: 220–370 K, 350–470 K and in the vicinity of 420 K. Following the nomenclature of Hunpratub et al. [25], we denote the three temperature ranges as the low–temperature dielectric relaxation (LTDR), middle–temperature dielectric relaxation (MTDR) and high–temperature dielectric relaxation (HTDR), respectively. A step-like decrease in the ε′ value between successive relaxation processes is characteristic of so—called giant dielectric constant materials as Ba(Fe1/2Nb1/2)O3, Sr(Fe1/2Nb1/2)O3 [33] and CaCu3Ti4O12 [34]. Both the low—and middle—temperature dielectric relaxations are characterized by a strong dispersion. On rising the frequency the maxima of dielectric absorption of both LTDR and HTDR shift towards higher temperatures, whereas the maximum related to the HTDR only weakly depends on the temperature.

To understand the physical nature of LTDR and MTDR, the experimental results of dielectric spectrum measurement were fitted to the Cole—Cole equation superposed to the conductivity term [35]:

where: k denotes the number of relaxation processes, Δ—difference between the permittivity value at the lowest at highest frequency of the dispersion step, ε ∞ —the permittivity value at the highest frequency, ε 0 —the dielectric constant of free space, α—degree of the distribution of relaxation times τ, σ 0 —the specific dc conductivity, N—exponent of the frequency dependence of ε″. Figure 5 shows the frequency dependences of ε″ at four temperatures in the range of LTDR and MTDR processes. The experimental data (the squares) are in a good agreement with the best fits to the Cole—Cole equation, represented by the continuous lines drawn over the points. The dashed line is related to the conductivity term \( {\left( {\frac{{{\sigma_0}}}{{{\varepsilon_0}\omega }}} \right)^N} \) in the Eq. 1. The other continuous lines refer to the contributions of separated relaxation processes. It is clearly seen from the fitting results that both LTDR and MTDR are of the Debye-type. The values of α were obtained to be 0.74–0.79 for the LTDR and 0.83–0.95 for the MTDR. Based on the fitting results, it can be verified that the relaxation times of both LTDR and MTDR obey the Arrhenius law:

where τ 0 denotes the preexponential factor, E a is the activation energy required for relaxation process, and k B is the Boltzmann constant. Figure 6 shows the relaxation times of the both processes plotted as a function of reciprocal temperature. The activation energy E a values calculated from Eq. 2 are: 0.39 and 0.98 eV for the LTDR and MTDR, respectively. The relatively small energy of the low-temperature relaxation is characteristic of the process originated from the ordering of Fe2+ and Fe3+ in the arrangement of polar symmetry [36]. Two-site polaron hopping process of the charge transfer between Fe2+ and Fe3+ leads to the hopping conduction of the localized charge carrier inside the grain. The obtained E a value (0.4 eV) compares well with 0.325 eV for BiFeO3 ceramics prepared from pure precipitation-synthesized powder [25], 0.21 eV for YFeO3 [29] and 0.29 eV for LuFe2O4 [36]. The mutual feature of the LTDR in these ceramics leads us to suppose that the LTDR process in BFO ceramics obtained from mechanochemically synthesized nanopowders is related to mixed valence of the iron ions. This mixed-valence ferrous/ferric structure was confirmed in the XPS experiments (Fig. 3). The ordering of the cations with mixed valence can produce polar clusters that grow in size with decreasing temperature but do not freeze, hence the thermally activated dielectric relaxation process is possible. The larger the number of dipoles the larger the magnitude of the dielectric permittivity ε′ step. For instance, the ratio of Fe2+:Fe3+ in Sr(Fe1/2Nb1/2)O3 amounts to 1:1, which yields 103 dielectric permittivity step [33], whilst the relatively small fraction of Fe2+:Fe3+ in YFeO3, namely 1:4 is the reason for the permittivity step of the order of just ten [29]. The BFO ceramics prepared from mechanochemically obtained powders, with almost the same contents of Fe2+ and Fe3+ cations shows the dielectric permittivity ε′ step of about 103.

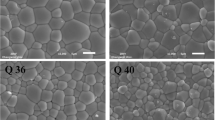

The behavior of MTDR seems very similar to that reported for so-called giant dielectric constant materials and is closely related to the microstructure, in particular, to the grain boundary, grain sizes and defect structure [21–27]. Shao et al. reported the relationship between the microstructures and activation energies of the MTDR of CaCu3Ti4O12 ceramics [37] and an enhancement of the relaxation due to presence of parasitic phase [38]. Sinclair et al. demonstrated that CaCu3Ti4O12 ceramics is electrically inhomogeneous and consists of semiconducting grains with insulating grain boundaries and related the giant dielectric phenomenon to a grain boundary (internal) barrier layer capacitor [39, 40]. The grain boundary effect was also observed in the ceramics obtained from pure precipitation-synthesized BiFeO3 powder: the samples synthesized at 973 K were characterized by a pronounced grain and grain boundary configuration and exhibited strong MTDR with activation energy of 0.69 eV [25]. In the case of our BFO ceramics obtained from mechanochemically synthesized nanopowders, the MTDR can be attributed to the combined effect of the grain boundary and the presence of secondary Bi25FeO40 phase acting as an additional internal barrier layer making the heterogeneity more complex. The secondary phase can be considered as a semiconducting one due to its energy gap of 1.78 eV [41]. The activation energy of 1.0 eV is slightly higher compared to that of BFO obtained from pure precipitation-synthesized powder, probably due to the increase in the heterogeneity. Although the authors suspect that the MTDR can be attributed to the combined effect originating from the grain boundaries and the secondary Bi25FeO40 phase, the electron microscopy investigations should be undertaken to confirm this assumption. The microscopic grain boundary studies will be the subject of our future study.

In order to study the physical nature of HTDR, we measured the frequency dependence of ac conductivity (σ ac ) in the temperature range from 400 K to 570 K at 10 K steps and we compared the dielectric spectra for the hot-pressed sample and the sample annealed in the air at 775 K for 1 h. Figure 7 shows the frequency dependence of σ ac at several temperatures. The σ ac indicates a dispersion which shifts towards higher frequencies with increasing the temperature. At low frequencies, the conductivity σ ac saturates to a constant value i.e. the dc conductivity σ dc . The resulting σ dc is plotted as the function of reciprocal temperature in Fig. 8. In the plot one can see, it properly obeys the Arrhenius law:

where σ 0 is the pre-exponential term. The calculated value of activation energy E a = 1.1 eV is very near to 1.08 eV obtained for YFeO3 in the high temperature range (469–579 K) [29] and 0.99–1.12 eV for (Sr1−1.5xBix)TiO3 (0.0133 ≤ x ≤ 0.133), also at higher temperatures (550–680 K) [42]. The values of activation energy are typical for doubly ionized oxygen vacancies \( V_0^{{\prime \prime }} \). It was reported by Waser et al. [43] that the oxygen vacancies in Bi doped SrTiO3 can move due to the thermal activation. The mobility of oxygen vacancy at 513 K can attain 7·10−9 cm2/(Vs) and the activation energy of oxygen vacancy is 1.093 eV. Moreover, Paladino [44] did prove that the activation energy for the diffusion of the doubly—ionized oxygen vacancies in SrTiO3 crystal is 0.98 eV. Based on these results, we suggest that, the HTDR process is related to the oxygen vacancies \( V_0^{{\prime \prime }} \) commonly present in perovskite structures. A short-range hopping of the oxygen vacancies resembles the dipolar reorientation and results in a dielectric relaxation peak, whereas long-range motion of double-ionized oxygen vacancies leads to the dc conductivity. One should also presume that other point defects may contribute into HTDR.

The influence of annealing at 775 K in air on the real ε′ and imaginary ε″ parts of dielectric permittivity is shown in Fig. 9. The temperature of the annealing was chosen based on our previous DSC measurement results which revealed the exothermic oxygen sorption process in the vicinity of 775 K, similarly like in other perovskite-type oxides [45]. Moreover, the chosen temperature is low enough to prevent the volatilization of Bi. The annealing was performed for the samples with evaporated gold electrodes as well as without them. The dielectric measurement results allow us to state that the electrodes do not change the composition of the annealed samples. It appears that the LTDR behavior is almost unaffected by the annealing process, though a small temperature range extension of the permittivity step of the MTDR is observed. The annealing process was found however, to smear out the HTDR: the two ε′ and ε″ maxima disappear. Considering that the dielectric permittivity ε′ steps of both LTDR and MTDR rise after annealing due to suppression the HTDR peaks, we can argue that the dielectric steps in the dielectric spectrum of the BFO ceramics result from a competition balance of the relaxation processes. The dielectric permittivity ε′ steps of both LTDR and MTDR lengthen after annealing. The above results are quite similar to those reported earlier in Ba(Fe1/2Nb1/2)O3 [46] Ba(Fe1/2Ta1/2)O3 [33] and YFeO3 [29].

4 Conclusions

BFO ceramic with addition of Bi25FeO40 secondary phase was obtained from nanopowders produced by high energy ball milling of Bi3O3 and Fe2O3 oxides of the weight ratio 2:1. The obtained BFO ceramics can be considered as a material of high dielectric permittivity that is very promising from the application point of view. Three dielectric relaxation processes in the low—(LTDR) middle—(MTDR) and high (HTDR) temperature range were found to contribute to the dielectric response. The LTDR, characterized by the activation energy of 0.4 eV, is related to hopping of electronic charge carriers, which are produced to compensate the changes in the oxidation state of iron ions. This argument is supported by the mixed-valence Fe2+/Fe3+ structure evidenced in the Fe 2p 3/2 core level XPS spectra. The MTDR, with activation energy of 1.0 eV, is considered as originating from a contribution of grain boundaries and the secondary Bi25FeO40 phase acting as an internal barrier layers. The HTDR, which can be suppressed by thermal annealing, may be related to short-range hopping of the ordered oxygen vacancies. Long-range transport of double-ionized oxygen vacancies results in dc conductivity, which reaches 10−6 S/cm and 8.5⋅10−5 S/cm at 480 K and 570 K, respectively and is characterized by an activation energy of 1.1 eV. As the dielectric permittivity steps are results of the competing balance of the three relaxation processes, it seems to be very probable that dielectric response may be tailored to the application requirements by optimizing the parameters of the mechanochemical synthesis and thermal treatment.

References

A.P. Ramirez, M.A. Subramanian, M. Gardela, G. Blumberg, D. Li, T. Vogt, S.M. Shapiro, Giant dielectric constant response in a copper-titanate. Solid State Commun. 115, 217–220 (2000)

M.A. Subramanian, D. Li, N. Duan, B.A. Reisner, A.W. Sleight, High dielectric constant in ACu3Ti4O12 and ACu3Ti3FeO12 phases. J. Solid State Chem. 151, 323–325 (2000)

I.P. Raevski, S.A. Prosandeev, A.S. Bogatin, M.A. Malitskaya, L. Jastrabik, High dielectric permittivity in AFe1/2B 1/2 O3 nonferroelectric perovskite ceramics (A = Ba, Sr, Ca;B = Nb, Ta, Sb). J. Appl. Phys. 93, 4130–4136 (2003)

M.H. Cohen, J.B. Neato, L. He, D. Vanderbilt, Extrinsic models for the dielectric response of CaCu3Ti4O12. J. Appl. Phys. 94, 3299–3306 (2003)

G. Cao, L. Feng, C. Wang, Grain-boundary and subgrain-boundary effects on the dielectric properties of CaCu3Ti4O12 ceramics. J. Phys. D Appl. Phys. 40, 2899–2905 (2007)

C. Wang, H.J. Zhang, P.M. He, G.H. Cao, Ti-rich and Cu-poor grain-boundary layers of CaCu3Ti4O12 detected by x-ray photoelectron spectroscopy. Appl. Phys. Lett. 91, 052910-1-3 (2007)

C.C. Wang, L.W. Zhang, Anomalous thermal hysteresis in dielectric permittivity of CaCu3Ti4O12. Appl. Phys. Lett. 92, 132903-1-3 (2008)

P. Fiorenza, R. Lo Nigro, C. Bongiorno, V. Raineri, M.C. Ferarrelli, D.C. Sinclair , A.R. West, Localized electrical characterization of the giant permittivity effect in CaCu3Ti4O12 ceramics. Appl. Phys. Lett. 92, 182907-1-3 (2008)

D. Fu, H. Taniguchi, T. Taniyama, M. Itoh, S. Koshihara, Origin of giant dielectric response in nonferroelectric CaCu3Ti4O12: inhomogeneous conduction nature probed by atomic force microscopy. Chem. Mater. 20, 1694–1698 (2008)

S.Y. Chung, Comment on “Origin of giant dielectric response in nonferroelectric CaCu3Ti4O12: inhomogeneous conduction nature probed by atomic force microscopy”. Chem. Mater. 20, 6284–6285 (2008)

M. Maglione, M.A. Subramanian, Dielectric and polarization experiments in high loss dielectrics: a word of caution. Appl. Phys. Lett. 93, 032902-1-3 (2008)

G. Catalan, J.F. Scott, Physics and applications of bismuth ferrite. Adv. Mater. 21, 2463–2485 (2009)

Ch Binek, B. Doudin, Magnetoelectronics with magnetoelectrics. J. Phys. Condens. Matter. 17, L39–L44 (2005)

M. Bibes, A. Barthélémy, Toward a magnetoelectric memory. Nat Mater. 7, 425–426 (2008)

Y.-H. Chu, L.W. Martin, M.B. Holcomb, M. Gajek, S.-J. Han, Q. He, N. Balke, C.-H. Yang, D. Lee, W. Hu, Q. Zhan, P.-L. Yang, A. Fraile-Rodríguez, A. Scholl, S.X. Wang, R. Ramesh, Electric-field control of local ferromagnetism using a magnetoelectric multiferroic. Nat Mater. 7, 478–482 (2008)

C-M Lin, W. Shih, I.Y. Chang, P-C Juan, J.Y. Lee, Metal-ferroelectric (BiFeO3)-insulator (Y2O3)-semiconductor capacitors and field effect transistors for nonvolatile memory applications. Appl. Phys. Lett. 94, 142905-1-3 (2009)

Z. Xing, J. Zhai, J. Li, D. Viehland, Investigation of external noise and its rejection in magnetoelectric sensor design. J. Appl. Phys. 106, 024512-1-7 (2009)

P. Rovillain, R. de Sousa, Y. Gallais, A. Sacuto, M.A. Méasson, D. Colson, A. Forget, M. Bibes, A. Barthélémy, M. Cazayous, Electric-field control of spin waves at room temperature in multiferroic BiFeO3. Nat Mater. 9, 975–979 (2010)

G. Catalan, Magnetocapacitance without magnetoelectric coupling. Appl. Phys. Lett. 88, 102902-1-3 (2006)

S. Kamba, D. Nuzhnyy, M. Savinov, J. Šebek, J. Prokleška, R. Daumont, J. Kreisel, Infrared and terahertz studies of polar phonons and magnetodielectric effect in multiferroic BiFeO3 ceramics. Phys. Rev., B 75, 024403-1-7 (2007)

Y.P. Wang, L. Zhou, M.F. Zhang, X.Y. Chen, J.-M. Liu, Z.G. Liu, Room-temperature saturated ferroelectric polarization in BiFeO3 ceramics synthesized by rapid liquid phase sintering. Appl. Phys. Lett. 84, 1731–1733 (2004)

A.K. Pradhan, K. Zhang, D. Hunter, J.B. Dadson, G.B. Loutts, P. Bhattacharya, R. Katiyar, J. Zhang, D.J. Sellmyer, U.N. Roy, Y. Cui, A. Burger, Magnetic and electrical properties of single-phase multiferroic BiFeO3. J. Appl. Phys. 97, 093903-1-4 (2005)

J-C Chen, J-M Wu, Dielectric properties and ac conductivities of dense single-phased BiFeO3 ceramics. Appl. Phys. Lett. 91, 182903-1-3 (2007)

S.V. Selbach, T. Tybel, M.-A. Einarsrud, T. Grande, The ferroic phase transitions of BiFeO3. Adv. Mater. 20, 3692–3696 (2008)

S. Hunpratub, P. Thongbai, T. Yamwong, R. Yimnirun, S. Maensiri, Dielectric relaxations and dielectric response in multiferroic BiFeO3 ceramics. Appl. Phys. Lett. 94, 062904-1-3 (2009)

M. Valant, A.-K. Axelsson, N. Alford, Peculiarities of a solid-state synthesis of multiferroic polycrystalline BiFeO3. Chem. Mater. 19, 5431–5436 (2007)

Y.U. Jian, C.J. Hao, Progress and prospect for high temperature single-phased magnetic ferroelectrics. Chin. Sci. Bull. 53, 2097–2112 (2008)

L.B. Kong, T.S. Zhang, J. Ma, F. Boey, Progress in synthesis of ferroelectric ceramic materials via high-energy mechanochemical technique. Progress Mater. Sci. 53, 207–322 (2008)

Y. Ma, X.M. Chen, Y.Q. Lin, Relaxorlike dielectric behavior and weak ferromagnetism in YFeO3 ceramics. J. Appl. Phys. 103, 124111-1-5 (2008)

M. Abdellaoui, E. Gaffet, The physics of mechanical alloying in a planetary ball mill: mathematical treatment. Acta Metall. Mater. 43, 1087–1098 (1995)

R. Jenkins, R.L. Snyder, Introduction to X-ray Powder Diffractometry. (John Wiley & Sons Inc., 1996)

J. Chastain, R.C. King Jr. (eds.), Handbook of X–ray Photoelectron Spectroscopy (Physical Electronics Inc., Minnesota, 1992)

Y.Y. Liu, X.M. Chen, X.Q. Liu, L. Li, Giant dielectric response and relaxor behaviors induced by charge and defect ordering in Sr(Fe1/2Nb1/2)O3 ceramics. Appl. Phys. Lett. 90, 192905-1-3 (2007)

L. Ni, X.M. Chen, Dielectric relaxations and formation mechanism of giant dielectric constant step in CaCu3Ti4O12 ceramics. Appl. Phys. Lett. 91, 122905-1-3 (2007)

A.K. Jonscher, Dielectric relaxation in solids (Chelsea Dielectrics Press Ltd, London, 1983)

N. Ikeda, H. Ohsumi, K. Ohwada, K. Ishii, T. Inami, K. Kakurai, Y. Murakami, K. Yoshii, S. Mori, Y. Horibe, H. Kito, Ferroelectricity from iron valence ordering in the charge-frustrated system LuFe2O4. Nature 436, 1136–1138 (2005)

S.F. Shao, J.L. Zhang, P. Zheng, W.L. Zhong, C.L. Wang, Microstructure and electrical properties of CaCu3Ti4O12 ceramics. J. Appl. Phys. 99, 084106-1-11 (2006)

S.F. Shao, J.L. Zhang, P. Zheng, C.L. Wang, J.C. Li, M.L. Zhao, High permittivity and low dielectric loss in ceramics with the nominal compositions of CaCu3−x La2x/3Ti4O12. Appl. Phys. Lett. 91, 042905-1-3 (2007)

D.C. Sinclair, T.B. Adams, F.D. Morrison, A.R. West, CaCu3Ti4O12: One-step internal barrier layer capacitor. Appl. Phys. Lett. 80, 2153–2155 (2002)

T.B. Adams, D.C. Sinclair, A.R. West, Giant barrier layer capacitance effects in CaCu3Ti4O12 ceramics. Adv. Mater. 14, 1321–1323 (2002)

G.-Q. Tan, Y.-Q. Zheng, H.-Y. Miao, A. Xia, H.-J. Ren, Controllable microwave hydrothermal synthesis of bismuth ferrites and photocatalytic characterization. J. Am. Ceram. Soc. 94, 1–10 (2011)

C. Ang, Z. Yu, L.E. Cross, Oxygen-vacancy-related low-frequency dielectric relaxation and electrical conduction in Bi:SrTiO3. Phys. Rev. B 62, 228–236 (2000)

R. Waser, T. Baiatu, K.H. Hrdtl, Dc Electrical Degradation of Perovskite–Type Titanates: I, Ceramics. J. Am. Ceram. Soc. 73, 1645–1653 (1990)

A.E. Paladino, Oxydation Kinetics of Single Crystal SrTiO3. J. Am. Ceram. Soc. 48, 476–478 (1965)

Z.H. Yang, Y.S. Lin, Synergetic thermal effects for oxygen sorption and order-disorder transition on perovskite-type oxides. Solid State Ionics 176, 89–96 (2005)

Z. Wang, X.M. Chen, L. Ni, YY Liu, X.Q. Liu, Dielectric relaxations in Ba(Fe1/2 Ta1/2)O3 giant dielectric constant ceramics. Appl. Phys. Lett. 90, 102905-1-3 (2007)

Acknowledgement

The work was supported by the funds from European Concerted Research Action designated as COST Action MP0904: Single- and multiphase ferroics and multiferroics with restricted geometries (SIMUFER).

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Markiewicz, E., Hilczer, B., Błaszyk, M. et al. Dielectric properties of BiFeO3 ceramics obtained from mechanochemically synthesized nanopowders. J Electroceram 27, 154–161 (2011). https://doi.org/10.1007/s10832-011-9660-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10832-011-9660-9