Abstract

A green sustainable strategy for biosynthesis of ZnONPs and chitosan nanoparticles (ZnONPs: 20–25 nm and CSNPs: 70–90 nm) has been developed, their potential applications in multifunctional finishing of cotton and viscose fabrics to impart anti-crease, anti-UV and antibacterial functions using citric acid/Na-hypophosphite CA (15 g/L)/SHP (15 g/L), as CH2O-free ester-crosslinking system and the pad-dry-cure method. The obtained results signify that the extent of improvement in the imparted functional properties is governed by type of cellulosic substrate, kind and concentration of nano-additive as well as type of bio-functional additive, namely, L-ascorbic acid or vanillin (20 g/L each). Moreover, the best results show that using CSNPs (2.5 g/L)/ZnONPs (15 g/L), as an eco-friendly two component mixture, brought about an enhancement in both chemical and functional properties of treated substrates which can be ranked as follows: nitrogen content (N%): viscose (1.818) > cotton (1.592); metal content (%): viscose (1.35) > cotton (1.24); WRA°: cotton (196) > viscose (165); anti-UV (UPF): cotton (47) > viscose (40); anti-S. aureus (R%): viscose (97) > cotton (94) and anti-E. coli (R%): viscose (92) > cotton (89), keeping other parameters constant. Major characteristics of the so-prepared nanoparticles as well as developed cellulosic fabrics were analyzed by FTIR, TEM, SEM and EDX techniques, as well as %N and %Zn content analysis. Durability to wash was evaluated and fabrics modification/functionalization, mechanism was also proposed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Eco-friendly surface modification and multifunctionalization of cellulosic fabrics using various emerging and sustainable technologies [12, 15, 28, 57] as well as environmentally sound textile chemicals and auxiliaries are the most recent trends in textile finishing processes [16, 17, 28, 35] for imparting highly demanded, novel and outstanding functional properties such as antibacterial [2, 14, 44, 47], UV protection, self-cleaning [36, 46, 47, 49, 52], wrinkle recovery [9, 27, 38, 51], enhanced fragrance [17, 20, 25], etc., with high values added, taken into account the ever-growing consumer demands for high product and ecology quality, along with economical social concerns [48].

Chitosan (CS) and CS derivatives are currently used in textiles modification, coloration and/or functionalization for their cationic active sites, N+H2 groups, especially at acidic conditions [23, 42, 57, 62]. Antimicrobial activity of CS is attributed to the interaction between its positively charged active sites and the negatively charged sites on the microbial surface [30, 37, 43], which, in turn, results in disruption of the harmful microbial cells, changes in their metabolism and leads to cell death [37, 61].

On the other hand, ionic gelation method is widely used for obtaining CS nanocomposites via interaction of positively charged Na-tripolyphosphate (TPP) under appropriate conditions, thereby forming coacervates as a direct consequence of electrostatic interaction between the two aqueous phases along with ionic gelation via transition from liquid to gel phase [5]. The experimental results showed that the antibacterial activity against both Gram-positive and Gram-negative bacteria of CS-TPP NPs suspension was better than that of the CS solution [5].

Recently, various techniques of ZnONPs such as chemical reduction [29, 40], plant extract [1, 3, 45], fungus [55], electrochemical method [8], microwave [58] as well as in situ preparation [4] and their potential textile applications to impart multifunctional properties such as antibacterial, self-cleaning, flame retardant and UV protection, taking in consideration both the environmental concerns and the ever-growing consumer demands have been developed and successfully carried out [6, 7, 10, 39, 47, 50, 56]. ZnONPs have been widely utilized in textile functionalization due to its desirable physical and chemical properties, biocompatibility compared with other metal oxides and its low production cost. ZnONPs finished fabrics showed excellent antibacterial activity due to the ability of ZnONPs to destroy the growth of the microbe [41]. Moreover, ZnONPs exhibit significant activity even at neutral condition, in the absence of light as well as excellent stability under high temperature and UV. ZnONPs, as an n-type semiconductor, show photocatalytic activity which, in turn, distinguish ZnO with unique multifunctional properties [31, 32, 53, 59].

Additionally, a green biosynthesis/cost-effective routes for fabrication of metal (M) and metal-oxide (MO) nanoparticles (NPs) using Miswak-rich active phenolic constituents for promoting, reduction, formation and stabilization of the demanded MNPs or MONPs as well as their potential applications have been developed and implemented recently [33, 54]. It was observed that the antibacterial activity of the biosynthesized nanoparticles using an eco-friendly aqueous solution of Miswak root extract was better than that prepared by non-eco-friendly conventional chemical methods [54].

To date, there are few studies focused on the positive role of eco-friendly multifunctionalization of cellulosic substrates using, (i) citric acid/NaH2PO2 (CA/SHP) as zero-CH2O ester-crosslinking system along with biosynthesized ZnONPs using Miswak extracts as bio-reductant and ii) CA/SHP CSNPs alone and in combination with L-ascorbic or vanillin as green bioactive functional additives. Herein, we reported biosynthesis and characterization of ZnONPs and CSNPs along with their potential applications in functional finishing of cotton and viscose substrates using a pad-dry-cure process. The effect of finishing bath constituents on the imparted multifunctional properties such as anti-crease, UV protection and antibacterial activity against both Gram-positive (S. aureus) and Gram-negative (E. coli) bacteria was analyzed. Furthermore, the mode of interaction among the finishing bath constituents and the cellulosic substrates was suggested, and extent of fixation was investigated.

Materials and methods

Materials

Mill scoured and bleached cotton (140 g/m2) and viscose (130 g/m2) woven fabrics were used in this study. Miswak (Salvadora persica root) was purchased from the local market. Chitosan (CS, Mol. Wt. 2.4 × 104 Da and 89.2% deacetaylated), Na-tripolyphosphate monohydrate (TPP) and L-ascorbic acid are purchased from Sigma-Aldrich. Citric acid, glacial acetic acid, Na-hypophosphite monohydrate (SHP, NaH2PO2.H2O), vanillin, zinc acetate, (Zn(CH3COO)2) 0.2H2O and sodium hydroxide were of laboratory reagent grade.

Methods

Preparation of Miswak extract

Freshly obtained roots were cut into small pieces, then grounded. Subsequently, 10 g of the powder were immersed in 100 ml of distilled water and refluxed for 5 h. The obtained extract was filtered by using Whatman No. 1 filter paper, then stored in a refrigerator at 4 °C for biosynthesis of ZnONPs.

Biosynthesis of ZnONPs

ZnONPs were fabricated by adding of 4 ml of freshly prepared Miswak aqueous extract to 100 ml of Zn-acetate aqueous solution (0.225 M), stirred for 12 h, and pH was maintained at 12 by adding 0.02 M NaOH solution and mixing for 1 h, after which it was centrifuged at 6000 rpm for 30 min. The obtained precipitate was washed several times with bi-distilled water to get pH 7 dried at 90 °C for 8 h.

Preparation of CS/TPP NPs suspension

Preparation of CS/TPP NPs was carried out successfully according to the method given by Bangun et al. [5] with some modifications. Briefly, 3 g of CS were dissolved in 600 ml of 1% acetic acid and stirred continuously for 30 min. Subsequently, an aqueous solution of TPP (1.4 g/600 ml) was then slowly added and stirred for 2 h at room temperature and sonicated for 1 h.

Functional finishing of cellulosic fabrics

Cotton and viscose fabric samples were padded twice in various functional finishing formulations containing:

-

(i)

Citric acid (30 g/L), as ester-cross linker, and SHP (15 g/L), as a catalyst, CS-TPP NP (2.5 g/L), as a polycationic agent, and ZnONPs (0–15 g/L), as a multifunctional agent, or

-

(ii)

CA/SHP (30 g/L/15 g/L), CS-TPP NPs (2.5 g/L) and L-ascorbic acid (0–20 g/L) or vanillin (0–20 g/L), as environmentally sound functional additive, to give wet pick-up of 85%, followed by drying at 100 °C/3 min and curing at 150 °C/3 min, thoroughly washed to remove unfixed/non-reacted constituents and finally dried and conditioned before evaluation.

Testing and analysis

Fourier transform infrared (FTIR) spectroscopy

Fourier transform infrared (FTIR) spectroscopy was carried out using a Nicolet 380 spectrophotometer (Thermo Scientific), and the IR spectra were scanned 32 times over the wavenumber range of 4000–400 cm−1. The sample (0.002 g) was mixed with KBr to reach (0.2 g) to form around disk suitable for measurements.

Transmission electron microscopy (TEM)

TEM images of the samples were obtained using a JEOL (JEM-1400 TEM, Japan), with an accelerating voltage of 100 kV. The CSNPs and ZnONPs suspension sample was ultrasonically dispersed in deionized water. Then, a small droplet of the diluted CSNPs and ZnONPs suspension was deposited on a 300-mesh copper grid coated with holey carbon film.

Particle size analysis

The average size and size distribution of the CSNPs and ZnONPs were estimated by dynamic light scattering (DLS) using a Malvern Zetasizer Nano ZS (Malvern Instruments Ltd., UK) equipped with a He–Ne laser (0.4 m W; 633 nm) and a temperature-controlled cell holder. The mean intensity weighted diameter was recorded as the average of three measurements.

Scanning electron microscopy (SEM)

SEM images for surface morphology of the samples were taken using SEM Model Quanta 250 FEG (Field Emission Gun) attached with EDX Unit (Energy-Dispersive X-ray Analyses), with accelerating voltage 30 KV, magnification 14 × up to 1,000,000 and resolution for Gun.1n. The surfaces of all the samples were coated with a gold thin layer under vacuum before SEM studies.

Textile testing

The amount of metal content in the post-treated fabric samples was determined by a flame atomic absorption spectrophotometer (GBC-Avanta, Australia).

Nitrogen content of fixed finished fabric was estimated as per a standard Kjeldahl method [60] using instrument model DNP-3000 (Raypa-SPAIN) using standard reference materials [60].

UPF was determined according to the Australian/New Zealand Standard (AS/NZS 4399-1996). Fabric can be rated as providing good, very good and excellent protection if their UPF values range 15–24, 25–39 and above 40, respectively.

The antimicrobial activity assessment against Gram-positive, Staphylococcus aureus (S. aureus) and Gram-negative, Escherichia coli (E. coli) bacteria was determined quantitatively according to AATCC 100 test method. The reduction of colonies was calculated using the following equation: R = 100 (B−A)/B, where R: % reduction, A: the number of bacterial colonies survived after contacting with treated sample and B: the number of colonies present in untreated control sample (blank).

Dry wrinkle recovery was determined according to AATCC Test Method 66-2008 using iron recovery apparatus type FF-07 (Metrimpex).

Results and discussion

Synthesis of CS-TPP, TEM morphology and DLS analysis

Incorporation of CS–NH2, acetic acid and Na-TPP in aqueous solution under appropriate conditions would be expected to enable the following interactions [5]. On the other hand, TEM and DLS analysis (Fig. 1a and b) of the fabricated CS-TPP NPs demonstrated that the obtained NPs have uniform, well disperse and capped structure with particle size in the range of 70–90 nm.

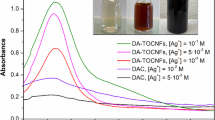

Green biosynthesis and characterization of ZnONPs using Miswak extract

The suggested mechanism of interaction among (Zn(CH3COO)2)0.2H2O, as a precursor and phenolic constituents of Miswak extract under appropriate pH and stirring conditions are given in Scheme 1. On the other hand, Fig. 2a and b shows the TEM image and DLS analysis of biosynthesized ZnONPs using the phenolic constituents of Miswak root extract to promote both the reduction process and stabilization of the fabricated ZnONPs under the given conditions. Both Fig. 2a and b demonstrate well-distributed NPs within a range of 20–25 nm.

FTIR spectra of (a) Miswak extract and produced ZnONPs are shown in Fig. 3. Figure 3a shows broadband corresponding to the –OH functional group and N–H stretch at 3545 cm−1. The band at 2919.17 cm−1 is attributed to C–C stretch of alkynes triple bond. Moreover, a strong peak at 1720.32 cm−1 is related to C=O stretching along with two bands at 1640.24 cm−1, 1413.24 cm−1 and 1124.34 cm−1 attributed to C–C, C–N and C–O stretching, respectively [5]. Additionally, the formation of NPs is a direct consequence of the presence of different reducing functional groups such as oxygen and nitrogen-containing groups, as shown in Fig. 3a, which facilitate reduction of metal to the nanosized scale.

Furthermore, FTIR spectrum of biosynthesized ZnONPs (Fig. 3b) also indicates that all the aforementioned peaks which correspond to Miswak extract constituents (Fig. 3a) are presented with a slight shift in a few peaks. Also, FTIR data of green fabricated ZnONPs confirm the presence of new bands near the region of 500 cm−1, which assigned to Zn–O stretching [11]. On the other hand, the peak detected around 500 cm−1 confirmed the presence of metal-oxide bond, Zn–O, which confirms the biosynthesis of ZnONPs using Miswak.

Multifunctionalization of cotton and viscose cellulosic fabrics using the bio-fabricated ZnONPs

Effect of inclusion of the biosynthesized ZnONPs (0–15 g/L) into the finishing formulation along CA/SHP (30/15 g/L) and CS-TPP (2.5 g/L) on the N%, Zn% content, WRA, UPF and antibacterial activity, expressed as (%R), of ester-crosslinked cellulosic substrates is presented in Table 1. The experimental results in Table 1 demonstrate that: (i) increasing ZnONPs concentration up to 15 g/L results in an increase in the %N, %Zn content, a reasonable increase in WRA, a significant improve in UV protection efficiency and a remarkable increase in the imparted antibacterial activity against the harmful S. aureus and E. coli bacteria, regardless of the treated substrate.

The increase in %N is a direct consequence of enhancing the extent of CS-TPP fixation onto/within the cellulose structure [23]. The increase in %Zn content is a direct consequence fixation of Zn+2 onto/within the ester-crosslinked structure via its –COOH groups [23] and –NH2 active sites of loaded CS-TPP NPs.

The reasonable improve in WRA of finished substrates reflects the positive role of ZnONPs in enhancing the extent of ester-crosslinking along with the positive role of NPs in minimizing the slipping of cellulosic chains, i.e., high anti-crease property [27].

The remarkable increase in UV protection functionality, expressed as UPF value, of ZnO immobilized onto/within the ester-crosslinked cellulose structure is attributed to its ability to block and shield the harmful UV-B radiation and hinder its transmittance through the modified cellulose structure to the textile consumer skin [19, 47].

The data in Table 1 also signify that incorporation of the biosynthesized ZnONPs up to 15 g/L along with CS-TPP NPs in the finishing formulation is accompanied by a remarkable increase in the imparted antibacterial activity against both the S. aureus and E. coli bacteria regardless of the used substrate. The higher the ZnONPs concentration, the more efficient the imparted antibacterial functionality is [34, 49].

Moreover, the remarkable enhancement in the imparted antibacterial activity by increasing ZnONPs concentration up to 15 g/L along with the presence of CS-TPP NPs as bioactive agent could be discussed in terms of: (i) the synergistic antibacterial effect of the loaded ZnONPs via destruction of bacterial cell integrity/liberation of Zn2+ ions/generation of reactive oxygen species (·OH,·O2−,·HO2 and H2O2) that capable to penetrate through the cell thereby inhibiting or killing the pathogenic microorganisms [23], (ii) the polycationic nature, –NH2 groups, of chitosan and its ability to inhibit the growth of harmful bacteria via: interaction with negatively charged moieties at its surface [37] and (iii) the phytochemical constituents of Miswak bark extract [18].

Additionally, the improvement in the imparted antibacterial activity against S. aureus bacterium is better than E. coli bacterium, as a direct consequence of variation in cell constitution and physiology as well as the metabolism [13, 22].

The data in Table 1 also demonstrate that the variation in the imparted functional properties, i.e., easy care, anti-UV and antibacterial functionalities, as well as both the %N and %Zn content are governed by type of the finished substrate and reflected the differences between the viscose and cotton substrates in: fabric weight, structure, amorphous/crystalline ratio, availability and accessibility of –OH active sites, location and extent of distribution of bio- and nano-active agents onto and/or within finished cellulose structure, as well as degree of fixation and immobilization of the used nano-active ingredients [21, 24].

Inclusion of CS-TPP NPs into ester-crosslinking formulation along with biosynthesized ZnONPs as functional nano-additive, followed by padding, drying and curing at appropriate fixation conditions would be expected to facilitate multifunctionalization of the viscose and cotton cellulosic substrates simultaneously in one step as shown in Scheme 2 [21, 23] as follows:

Multifunctionalization of cotton and viscose cellulosic fabrics using CSNPs along with L-ascorbic acid or vanillin additives

As far as the change in %N, WRA, UPF and antibacterial activity of treated cellulosic substrates as a function of type and concentration of function of type and concentration of functional additive, the data in Table 2 clearly demonstrate that inclusion of L-ascorbic or vanillin (0–20 g/L) additive along with CSNPs (2.5 g/L) and CA/SHP ester-crosslinking system (30/15 g/L) in the finishing formulation followed by padding and curing is accompanied by an increase in %N, WRA and UPF values as well as in the imparted antibacterial activity against both the S. aureus and E. coli pathogenic bacteria, irrespective of the treated substrate. The higher the functional additive concentration, the better are the imparted functionalities, i.e., fabric resiliency, anti-UV capability and antibacterial efficacy [26].

The enhancement in the imparted functional properties reflects the positive role of functional properties reflects the positive role of functional additive in: increasing the extent of CSNPs fixation, expressed as % N, enhancing the UV shielding and blocking capability, expressed as UPF value, along with supporting the imparted antibacterial activity to the treated substrates, expressed as % R, against the tested pathogens. On the other hand, the positive changes in the aforementioned properties are governed by type of functional additive and follows, the decreasing order: L-ascorbic acid < vanillin, as well as kind of cellulosic substrate as discussed earlier, keeping other parameters constant [20, 25, 26].

The imparted anti-UV and antibacterial effects of L-ascorbic could be discussed in terms of: the presence of antioxidant and flavonoids constituents, its ability to lower the pH, its anti-quorum sensing activity, its oxygen absorption characteristics thereby acting as a barrier for oxygen availability for tested microorganisms, as well as due to the significant synergistic antibacterial effects of CSNPs, L-ascorbic acid at low pH against the tested S. aureus and E. coli bacteria [26].

On the other hand, the significant improvement in antibacterial functionality against both S. aureus and E. coli harmful bacteria by fixation and immobilization of vanillin, as a safe and effective anti-UV and antibacterial agent onto/within the ester-crosslinked substrates most probably is due to its ability as phenolic aldehyde to damage and disrupt the bacterial cell which, in turn, adversely affects its growth and survival, along with its ability to absorb the harmful UV-B radiation [20].

The variation in the imparted antibacterial functionality is governed by chemical composition, molecular size, bioactive constituents, extent of loading and release, mode of action, as well as, the synergistic effect of the functional additives and other finishing bath constituents [20]. Moreover, simplified reaction Scheme 3 for fixation and immobilization of the functional additives onto and for within the ester-crosslinked cellulose structure during the thermofixation step could be suggested as follows [20].

SEM and EDX analysis

Figure 4 demonstrates the changes in surface morphology and elemental composition of selected untreated cotton (a, b) and viscose (e, f) samples as well as treated cotton (c, d) and viscose (g, h) fabric samples using CA/SHP (30/15 g/L), CSNPs (2.5 g/L) and ZnONPs (15 g/L) finishing formulation. SEM of the selected fabrics samples clearly shows that ester-crosslinking of the cellulosic substrates in the presence of CSNPs and ZnONPs forms surface deposits as a direct consequence of loading the functional additives onto the ester-crosslinked cotton (Fig. 4c) and viscose (Fig. 4g) compared with the untreated ones (Fig. 4a and e), respectively. The change in surface morphology reflects the differences between cotton and viscose substrates in fabric surface, extent of modification as well as post-coating and deposition of the thermofixed ingredients onto the fabric during the thermofixation step.

Additionally, EDX spectra of multifunctionalized cotton (Fig. 4d) and viscose (Fig. 4h) demonstrated new peaks of N, P and Zn elements in their pattern confirming the fixation and immobilization of CSNPs, SHP and ZnONPs onto the ester-crosslinked substrates in comparison with the untreated ones (Fig. 4b and f), respectively. The extent of ester-crosslinking and simultaneous fixation of the used functional additives is determined by type of cellulose, kind of functional additive as well as degree of fixation and immobilization during the curing step.

Fixation and immobilization of ZnONPs onto the modified cellulose structure could be discussed in terms of the availability of both –NH2 groups and free –COOH groups in the crosslinked cellulose structure which can help in coordination and immobilization of ZnONPs [23].

Durability to wash

The washing durability of multifunctionalized cellulosic substrates was also evaluated, and the experimental results are given in Table 3. The data in Table 3 demonstrate that increasing the washing cycles up to 10 results in a reasonable decrease in both the chemical and functional properties of the developed fabrics. The extent of decrease in the aforementioned properties is governed by type of cellulosic substrate and functional additives. The reasonable decrease in the evaluated properties is a direct consequence of the partial removal of unreacted and non-fixed active ingredients and confirms the high degree of fixation of the finishing formulation constituents during the thermofixation step.

FTIR features of finished substrates

Figures 5 and 6 show the results of FTIR analysis of untreated and finished of some selected samples.

Untreated cotton (Fig. 5a) showed the following peaks: nearly 3339.42 cm−1, around 2897.32 cm−1 and 1600 cm−1 attributed to O–H stretching, C–H stretching and due to the adsorbed water molecule, respectively. While the IR spectra of finished cotton fabric sample with CA/SHP, CSNPs and ZnONPs (Fig. 5b) showed an additional peak at 1730 cm−1 corresponded to C=O stretching for ester linked cellulose with citric acid and a new peak at 500 cm−1 attributed to the bio-prepared ZnONPs.

Regarding finished cotton fabric samples with L-ascorbic acid and vanillin, respectively, Fig. 6b and c, the C=C stretching in the L-ascorbic and vanillin overlaps with the OH bending in untreated fabric samples at 1600.42 cm−1. Moreover, additional new peaks were observed at 1313.35 cm−1 and 1311.42 cm−1 for the C–O stretching bands in L-ascorbic and vanillin, respectively.

Conclusion

The main task of the present research work is to a develop a single-stage multifunctional treatment of cotton and viscose cellulosic substrates to impart anti-crease, UV blocking and antibacterial functions using environmentally sound and sustainable finishing formulations. Green synthesis of ZnONPs and CSNPs and their positive role in the development of multifunctionalized cotton and viscose fabrics using CA/SHP as ester-crosslinking system and pad-dry-cure thermofixation method are reported. Inclusion of ZnONPs (15 g/L) or a synergistic constitutions of CSNPs (2.5 g/L)/L-ascorbic acid (20 g/L) or CSNPs (2.5 g/L)/vanillin (20 g/L) in the ester-crosslinking formulations resulted in a remarkable improvement in the imparted anti-crease, UV protection and antibacterial efficacy of the finished fabrics, irrespective of the treated substrate.

The extent of improvement in the imparted functional properties is determined by the kind of cellulosic substrate as well as type of finishing formulation constituents. Moreover, FTIR, SEM and EDX analysis confirm surface modification and functionalization of the treated fabric samples. The results obtained further signify that increasing washing cycles up to 10 cycles resulted in a slight decrease in the imparted functional properties. Thus, it can be concluded that developing of durable multifunctionalized textile products using an eco-friendly, and facile single-step finishing regime greatly supports the possibility of a wide range of potential and practical applications.

References

Ahmad W, Kalra D (2020) Green synthesis, characterization and anti microbial activities of ZnO nanoparticles using Euphorbia hirta leaf extract. J King Saud Univ—Sci 32:2358–2364. https://doi.org/10.1016/j.jksus.2020.03.014

Akalin GO, OztunaTaner O, Taner T (2022) The preparation, characterization and antibacterial properties of chitosan/pectin silver nanoparticle films. Polym Bull 79:3495–3512. https://doi.org/10.1007/s00289-021-03667-0

Akintelu SA, Folorunso AS (2020) A review on green synthesis of zinc oxide nanoparticles using plant extracts and its biomedical applications. BioNanoScience 10:848–863. https://doi.org/10.1007/s12668-020-00774-6

Arputharaj A, Nadanathangam V, Shukla SR (2017) A simple and efficient protocol to develop durable multifunctional property to cellulosic materials using in situ generated nano-ZnO. Cellulose 24:3399–3410. https://doi.org/10.1007/s10570-017-1335-5

Bangun H, Tandiono S, Arianto A (2018) Preparation and evaluation of chitosan-tripolyphosphate nanoparticles suspension as an antibacterial agent. J Appl Pharm Sci 8:147–156

Becenen N, Altun Ö (2016) Applications of TiO2, ZnO and Ag nanomaterials to denim fabric. J Nanosci Nanotechnol 16:5359–5363

Boticas I, Dias D, Ferreira D, Magalhães P, Silva R, Fangueiro R (2019) Superhydrophobic cotton fabrics based on ZnO nanoparticles functionalization SN. Appl Sci 1:1376. https://doi.org/10.1007/s42452-019-1423-2

Chandrappa KG, Venkatesha TV (2012) electrochemical synthesis and photocatalytic property of zinc oxide nanoparticles. Nano-Micro Lett 4:14–24. https://doi.org/10.1007/bf03353686

Dehabadi VA, Buschmann H-J, Gutmann JS (2013) Durable press finishing of cotton fabrics: an overview. Text Res J 83:1974–1995. https://doi.org/10.1177/0040517513483857

Eid BM, El-Sayed GM, Ibrahim HM, Habib NH (2019) Durable antibacterial functionality of cotton/polyester blended fabrics using antibiotic/MONPs composite. Fibers and Polym 20:2297–2309

Fakhari S, Jamzad M, KabiriFard H (2019) Green synthesis of zinc oxide nanoparticles: a comparison. Green Chem Lett Rev 12:19–24

Fouda MMG, Fahmy HM (2011) Multifunctional finish and cotton cellulose fabric. Carbohyd Polym 86:625–629. https://doi.org/10.1016/j.carbpol.2011.04.086

Gouda M, Ibrahim NA (2008) New approach for improving antibacterial functions of cotton fabric. J Ind Text 37:327–339. https://doi.org/10.1177/1528083707081595

Gulati R, Sharma S, Sharma RK (2022) Antimicrobial textile: recent developments and functional perspective. Polym Bull 79:5747–5771. https://doi.org/10.1007/s00289-021-03826-3

Gulrajani ML, Deepti G (2011) Emerging techniques for functional finishing of textiles. Indian J Fibre Text Res 36:388–397

Gulrajani ML, Gupta D (2011) Emerging techniques for functional finishing of textiles. Indian J Fibre Text Res 36:388–397

Haji A (2020) Functional finishing of textiles with β-cyclodextrin. In: Shabbir M, Ahmed S, Sheikh JN (eds) Frontiers of textile materials. Scrivener Publishing Wiley, Beverly, USA, pp 87–116. https://doi.org/10.1002/9781119620396.ch4

Halawany HS (2012) A review on miswak (Salvadora persica) and its effect on various aspects of oral health. Saudi Dent J 24:63–69

Ibrahim N, El-Zairy E, Emara S, Khalil H (2022b) Environmentally sound approach for developing antibacterial/anticrease cellulosic fabrics. Egypt J Chem 65(9):737–748. https://doi.org/10.21608/ejchem.2022.119128.5358

Ibrahim NA, Abd El-Ghany NA, Eid BM, Mabrouk EM (2018) Green options for imparting antibacterial functionality to cotton fabrics. Int J Biol Macromol 111:526–533. https://doi.org/10.1016/j.ijbiomac.2018.01.013

Ibrahim NA, Abo-Shosha MH, Gaffar MA, Elshafei AM, Abdel-Fatah OM (2006) Antibacterial properties of ester—cross-linked cellulose-containing fabrics post-treated with metal salts. Polym-Plast Technol Eng 45:719–727. https://doi.org/10.1080/03602550600611198

Ibrahim NA, Aly AA, Gouda M (2008) Enhancing the antibacterial properties of cotton fabric. J Ind Text 37:203–212. https://doi.org/10.1177/1528083707078127

Ibrahim NA, Eid BM, Abd El-Aziz E, Abou Elmaaty TM, Ramadan SM (2017) Loading of chitosan–nano metal oxide hybrids onto cotton/polyester fabrics to impart permanent and effective multifunctions. Int J Biol Macromol 105:769–776

Ibrahim NA, Eid BM, Abdel Aziz MS, Hamdy SM, Abd Allah SE (2018) Green surface modification and nano-multifunctionalization of denim fabric. Cellulose 25:6207–6220. https://doi.org/10.1007/s10570-018-1985-y

Ibrahim NA, Eid BM, El-Zairy E, Barakat S (2022c) Environmentally sound approach for fabrication of antibacterial/anti-UV/anti-crease and fragrant denim fabrics. Egypt J Chem 65:377–389

Ibrahim NA, Eid BM, El-Zairy EM, Emam E, Barakat S (2019) Environmentally sound approach for imparting antibacterial and UV-protection functionalities to linen cellulose using ascorbic acid. Int J Biol Macromol 135:88–96. https://doi.org/10.1016/j.ijbiomac.2019.05.113

Ibrahim NA, Eid BM, Emam E-AM (2022d) An eco-friendly facile approach for imparting multifunctional protection properties to cellulose/wool blends. Polym Bull. https://doi.org/10.1007/s00289-021-04072-3

Ibrahim NA, Eid BM, Sharaf SM (2019) Functional finishes for cotton-based textiles: current situation and future trends. In: Shabbir M (ed) Textiles and clothing. John Wiley & Sons, Inc. and Scrivener Publishing LLC USA, Beverly, pp 131–190. https://doi.org/10.1002/9781119526599.ch7

Ibrahim NA, Nada AA, Eid BM, Al-Moghazy M, Hassabo AG, Abou-Zeid NY (2018) Nano-structured metal oxides: synthesis, characterization and application for multifunctional cotton fabric. Adv Nat Sci: Nanosci Nanotechnol 9:035014

Janjic S, Kostic M, Vucinic V, Dimitrijevic S, Popovic K, Ristic M, Skundric P (2009) Biologically active fibers based on chitosan-coated lyocell fibers. Carbohyd Polym 78:240–246. https://doi.org/10.1016/j.carbpol.2009.03.033

Javed A, Wiener J, Saskova J, Müllerová J (2022) Zinc oxide nanoparticles (ZnO NPs) and N-methylol dimethyl phosphonopropion amide (MDPA) system for flame retardant cotton fabrics. Polymers 14:3414

Karim-nejad MM, Nazari A, Davodi-roknabadi A (2015) Efficient flame retardant of mercerized cotton through cross-linking with citric acid and ZnO nanoparticles optimized by RSM models. J Text Inst 106:1115–1126

Khan M et al (2017) Miswak mediated green synthesized palladium nanoparticles as effective catalysts for the Suzuki coupling reactions in aqueous media. J Saudi Chem Soc 21:450–457

Khorasani MT, Joorabloo A, Moghaddam A, Shamsi H, MansooriMoghadam Z (2018) Incorporation of ZnO nanoparticles into heparinised polyvinyl alcohol/chitosan hydrogels for wound dressing application. Int J Biol Macromol 114:1203–1215. https://doi.org/10.1016/j.ijbiomac.2018.04.010

Kim YK (2010) Nanotechnology-based advanced coatings and functional finishes for textiles. In: Smith WC (ed) Smart textile coatings and laminates. Woodhead Publishing, Cambridge, pp 251–263. https://doi.org/10.1533/9781845697785.2.251

Kim YK (2015) Ultraviolet protection finishes for textiles. In: Paul R (ed) Functional finishes for textiles. Woodhead Publishing, Cambridge, pp 463–485. https://doi.org/10.1533/9780857098450.2.463

Kong M, Chen XG, Xing K, Park HJ (2010) Antimicrobial properties of chitosan and mode of action: a state of the art review. Int J Food Microbiol 144:51–63. https://doi.org/10.1016/j.ijfoodmicro.2010.09.012

Lam Y-L, Kan C-W, Yuen C-WM (2012) Developments in functional finishing of cotton fibres – wrinkle-resistant, flame-retardant and antimicrobial treatments. Text Prog 44:175–249. https://doi.org/10.1080/00405167.2012.735517

Lam YL, Kan CW, Yuen CWM (2011) Effect of zinc oxide on flame retardant finishing of plasma pre-treated cotton fabric. Cellulose 18:151–165. https://doi.org/10.1007/s10570-010-9466-y

Mehrotra N, Venkatraman U, Chaitra V, Kaviyarasi NS, Pradeep N (2020) Synthesis of zinc coneflower-porous starch composite for textile finishing SN. Appl Sci 2:455. https://doi.org/10.1007/s42452-020-2229-y

Mendes CR et al (2022) Antibacterial action and target mechanisms of zinc oxide nanoparticles against bacterial pathogens. Sci Rep 12:2658. https://doi.org/10.1038/s41598-022-06657-y

Muxika A, Etxabide A, Uranga J, Guerrero P, De La Caba K (2017) Chitosan as a bioactive polymer: processing, properties and applications. Int J Biol Macromol 105:1358–1368

Muzzarelli RAA, Mehtedi M, Mattioli-Belmonte M (2014) Emerging biomedical applications of nano-chitins and nano-chitosans obtained via advanced eco-friendly technologies from marine resources. Mar Drugs. https://doi.org/10.3390/md12115468

Nawab R, Iqbal A, Niazi F, Iqbal G, Khurshid A, Saleem A, Munis MFH (2022) Review featuring the use of inorganic nano-structured material for anti-microbial properties in textile. Polym Bull. https://doi.org/10.1007/s00289-022-04418-5

Nilavukkarasi M, Vijayakumar S, Prathipkumar S (2020) Capparis zeylanica mediated bio-synthesized ZnO nanoparticles as antimicrobial, photocatalytic and anti-cancer applications. Mater Sci Energy Technol 3:335–343. https://doi.org/10.1016/j.mset.2019.12.004

Pakdel E, Daoud WA (2013) Self-cleaning cotton functionalized with TiO2/SiO2: focus on the role of silica. J Colloid Interface Sci 401:1–7. https://doi.org/10.1016/j.jcis.2013.03.016

Pandimurugan R, Thambidurai S (2017) UV protection and antibacterial properties of seaweed capped ZnO nanoparticles coated cotton fabrics. Int J Biol Macromol 105:788–795. https://doi.org/10.1016/j.ijbiomac.2017.07.097

Paul R (2015) Functional finishes for textiles: an overview. In: Paul R (ed) Functional finishes for textiles. Woodhead Publishing, Cambridge, pp 1–14. https://doi.org/10.1533/9780857098450.1

Prasad V, Arputharaj A, Bharimalla AK, Patil PG, Vigneshwaran N (2016) Durable multifunctional finishing of cotton fabrics by in situ synthesis of nano-ZnO. Appl Surf Sci 390:936–940. https://doi.org/10.1016/j.apsusc.2016.08.155

Raza Z, Anwar F, Ahmad S, Aslam M (2016) Fabrication of ZnO incorporated chitosan nanocomposites for enhanced functional properties of cellulosic fabric. Mater Res Express 3:115001

Roy Choudhury AK (2017a) Easy-care finishing. In: Roy Choudhury AK (ed) Principles of textile finishing. Woodhead Publishing, Cambridge, pp 245–284. https://doi.org/10.1016/B978-0-08-100646-7.00009-6

Roy Choudhury AK (2017b) Finishes for protection against microbial, insect and UV radiation. In: Roy Choudhury AK (ed) Principles of textile finishing. Woodhead Publishing, Cambridge, pp 319–382. https://doi.org/10.1016/B978-0-08-100646-7.00011-4

Saleemi S et al (2020) Surface functionalization of cotton and PC fabrics using SiO2 and ZnO nanoparticles for durable flame retardant properties. Coatings 10:124

Shaik MR et al (2016) “Miswak” based green synthesis of silver nanoparticles: evaluation and comparison of their microbicidal activities with the chemical synthesis. Molecules 21:1478

Sharma JL, Dhayal V, Sharma RK (2021) White-rot fungus mediated green synthesis of zinc oxide nanoparticles and their impregnation on cellulose to develop environmental friendly antimicrobial fibers. 3 Biotech 11:269. https://doi.org/10.1007/s13205-021-02840-6

Shehabeldine AM, Hashem AH, Wassel AR, Hasanin M (2022) Antimicrobial and antiviral activities of durable cotton fabrics treated with nanocomposite based on zinc oxide nanoparticles acyclovir, nanochitosan, and clove oil. Appl Biochem Biotechnol 194:783–800. https://doi.org/10.1007/s12010-021-03649-y

Sheikh J, Bramhecha I (2018) Multifunctional modification of linen fabric using chitosan-based formulations. Int J Biol Macromol 118:896–902. https://doi.org/10.1016/j.ijbiomac.2018.06.150

Suresh P, Vijaya JJ, Kennedy LJ (2015) Synergy effect in the photocatalytic degradation of textile dyeing waste water by using microwave combustion synthesized zinc oxide supported activated carbon reaction kinetics. Mech Catal 114:767–780. https://doi.org/10.1007/s11144-014-0799-7

Verbič A, Gorjanc M, Simončič B (2019) Zinc oxide for functional textile coatings: recent advances. Coatings 9:550

Vogel AI (1975) Elementary practical inorganic chemistry, 2nd edn. Longman, London

Wang X, Du Y, Fan L, Liu H, Hu Y (2005) Chitosan- metal complexes as antimicrobial agent: synthesis, characterization and structure-activity study. Polym Bull 55:105–113. https://doi.org/10.1007/s00289-005-0414-1

Youssef AM, Abdel-Aziz MS, El-Sayed SM (2014) Chitosan nanocomposite films based on Ag-NP and Au-NP biosynthesis by Bacillus Subtilis as packaging materials. Int J Biol Macromol 69:185–191. https://doi.org/10.1016/j.ijbiomac.2014.05.047

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have declared that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ibrahim, N.A., Ameen, H.A. & Eid, B.M. Green synthesized chitosan and ZnO nanoparticles for sustainable use in multifunctionalization of cellulosic fabrics. Polym. Bull. 81, 3621–3640 (2024). https://doi.org/10.1007/s00289-023-04887-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04887-2